The Safe Scaffold Bolt Fitting..

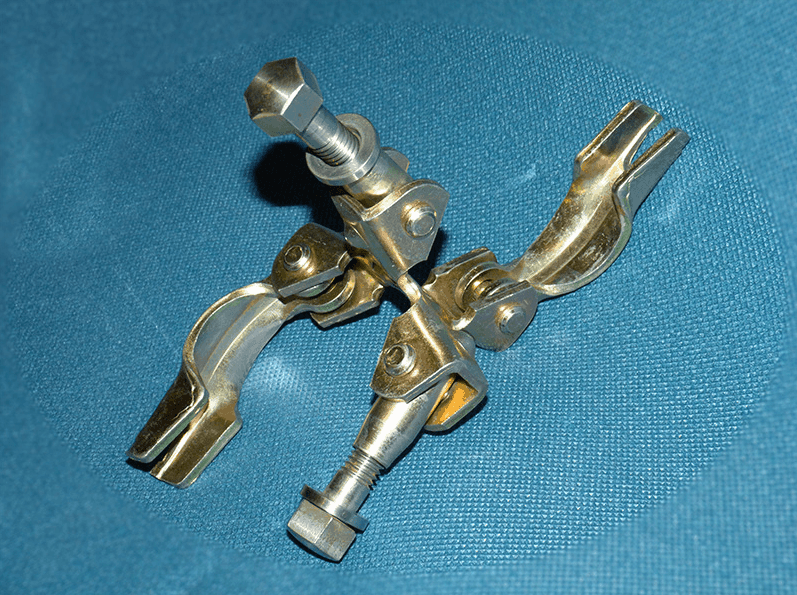

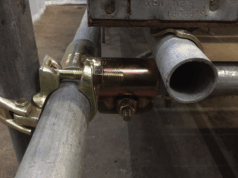

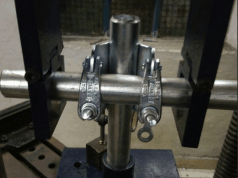

I present to you this new innovative fitting from Presco The Safe Scaffold Bolt Fitting. This new product is said to be an effective and safe method for eliminating protruding bolt threads. Ideal for use in narrow walkways, in cramped access areas and around doorways.

We wanted to find out more about this new product, so we contacted the creator Lee Lipinski who exclusively told ScaffMag the story behind this innovative new product.

So Lee can you tell our readers how you come up with the idea for The Safe Scaffold Bolt Fitting ?

In the beginning..

I came up with the idea for the Safe Scaffold Bolt Fitting whilst working on a Power Station as an Electrician in Hull, I was forever catching my high-visibility vest and overalls on protruding scaffolding bolts when working at height.

This became very annoying and potentially dangerous as the platforms we were working on were very narrow once the electrical containment was in place. This obviously meant that everybody had to walk side on for long periods of time which in turn, put us very close to the hand rails a lot of the time. The final straw for me was when a colleague snagged his safety harness upon a protruding bolt when leaning through the hand rails. For the safety conscious reader, he was clipped on to a higher tube via his harness. Unfortunately as he was now caught on a scaffold fitting bolt this meant he could not come back through until I came down from my platform and unhooked him.

Thankfully he was not holding heavy materials at the time as he would have had to let it go since I could not get to him quickly. So, after returning from Hull I started to research the myriad of scaffold fittings on the market. This involved, as you can imagine hours and hours of internet searching. Boredom doesn’t come close.

The Design Stage..

After said time I was happy that there were no other versions of what I had in mind on the market and hired a search company to verify this before applying for a patent. More hours tinkering in my garage with hand grinders, bits of tube and the odd M10 bolt, I finally came upon in my opinion the most effective way to remove the hazard of the protruding bolt in a traditional pressed steel scaffold fitting. Then I remembered a buddy from school who was in the designing world who had the software and know-how to bring my ideas to life and so I dropped him a Facebook message. He soon replied and our working relationship began.

He drew up the first set of drawings so they were readable by engineers. We went through at least 7 major modifications before the final design was settled on and then contacted a metalworking specialist. Within a week, I had my first prototype to try (it did not fit) but I had a Datum to work from and soon ironed out the bumps.

Of course during this time I was aware of plagiarism should the idea take off and so was given advice from a Design and patent company to ensure anyone I spoke to at least signed a NDA (Non-Disclosure Agreement). This of course gave me the peace of mind when discussing the product.

[quote type=”center”] After four hours of selling myself, I came out with my only prototype professionally tested on a UKAS test rig and passing with flying colours. [/quote]

My next step was to contact a Company that manufactured scaffold fittings in the UK so I could monitor the progress if they were interested. Turns out there is no such thing due to the price of British labour compared to other countries labour rates. This said, the company I’m currently working through, Presco Components Ltd are British based but manufacture in China.

So a three hour drive to Birmingham from Plymouth to meet at 8am was under way. After four hours of selling myself, I came out with my only prototype professionally tested on a UKAS test rig and passing with flying colours. The next step was to have China make prototype that would fit in Presco’s current range of fittings. A lot of modifications had to be made but we are finally there.

What the Safe Scaffold Bolt fits..

The basic version was designed for pressed steel fittings. This model will fit the following:

1. Standard Doubles

2. Swivels

3. Stair Tread Coupler

4. Girder Coupler

5. Access Gates

Note: Only Pressed Steel couplers available at present.

With slight adjustment to my bolt design it will fit the pressed steel Putlog coupler and the Board retainer. With cooperation from scaffold designers and manufactures I am able to tweak the design to fit Forged clamps.

I have shown many scaffold workers, and have tried to listen to what they would like and try to please their wishes. For example, The first major hurdle was to prevent the bolt coming out the end of the collar nut whilst being transported and the bolt vibrating out the end. Not noticing a bolt is missing after climbing four lifts with heavy gear can get very tedious I imagine.

The second problem in design was to make sure the strength was not compromised due to the shape and tolerances I had to work from. The bonus advantages from the nut being inside a long collar nut was the protection from the elements and protection from paints and other particulates that generally gather on the threaded bar. Of course the maintenance issues and the smooth operation of the bolts inside the collar nut are easily lubricated every time the bolt is wound back in and out.

Prices are initially not as cost effective as I hoped due to the manufacturing processes required being new to the factories.

All in all, I hope that this will become a familiar product on all sites around the world. (I can dream).

For more information please visit: www.ssbproducts.co.uk

Thanks Lee for taking time to tell us your story about The Safe Scaffold Bolt Fitting.

We would like to read your comments on this, do you think this is a good product and idea ? let us know in the comments below.

Lee lipinski

Hi,

how about when the fitting becomes streatched, as they do, will the bolt not go to the bottom of the long collar nut and give a false reading of tightness.

I can see all fitting being done like this i can see how it works and is so much better than the old fittings

These are the best bolt fittings i’ve ever used. Since purchasing these products i have had to employ more staff because i am so busy now, as these bolts are safer than the old style bolts so i get much more work.

THANK YOU LEE LIPINSKI for designing this great product i just wish i thought of it.

Thank you Krisyian. Can you post a pic of the other type please?

they look alright the last firm i worked at used them vantheil doubles which are even better i think

shame he had to go to china to have the prototype made!

gud idea mate hope it takes off

Looks like a good design..

There’s a good chance these could take off! Wish I had thought of it.

looks great! looking forward to using one! (lloyd)

I think this is a great idea,from an offshore point of view this fitting would come into its own, given the protection from the elements component, so yes without hesitation I would endorse this fitting as long as the bolt has a retainer fitted and remains captive in the collar nut……well done looks neat mate!