Visitors to the 2013 Bauma showcase had the opportunity to find out more about Harsco Infrastructure, which was one of the major exhibitors at this year’s event. On its 1,200 m² stand Harsco displayed a comprehensive range of products – including premium formwork and scaffolding systems, safety equipment and product support services – which reflected the company’s position as a leading single-source supplier with a presence in 32 countries, plus an extended international network of dealers and distributors

The products on the Harsco stand reflected the company’s innovative and on-going approach to serving its customers in the formwork and scaffolding sectors. They included Harsco Platinum 100 – a crane-operated wall formwork system that offers users significant additional quality combined with lower labor and life-cycle costs. The Harsco Platinum 100 elements have a high degree of shape retention and are designed for pressure ratings of 100 kN/m². They allow rapid shuttering and high-speed pouring at heights of up to 3.60 m without the need for extensions, and allow the overall system to use up to 30 per cent fewer ties than conventional wall formwork systems.

Harsco also displayed two special Topmax corner floor table elements which extend the versatility of the highly successful Topmax steel-frame floor table system. The new Topmax corner floor table elements simplify the task of erecting and stripping floor tables adjacent to columns in building corners. They have the same continuous edge profile as the standard floor tables, but come with a diagonal right or left side at a 45° angle. This makes it especially easy to shutter around corner columns.

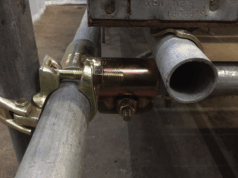

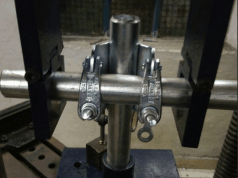

For the scaffold sector, Harsco also unveiled various products which simplify refurbishment work such as the installation of exterior insulation finishing systems (EIFS). A new telescopic board that integrates with the classic Bosta 70 scaffold system enables the gap between the scaffold and facade to be closed with ease, but without the mandatory inner edge protection that can hamper the work. A further innovation is a system-independent tie bridge suitable for all facade scaffold systems. Specially developed for facade insulation work, it solves tying problems where conventional ring screws are not sufficiently load-bearing for the large distance between the scaffold and facade. It provides a rigid link between the tightened ring screws and creates a load-bearing connection between the scaffold retainer and the tie.

The Harsco stand also offered information on the wide range of services which the company provides, including consultancy, project development, site logistics, professional cleaning and repair, form lining replacement, training and formwork services.