Necessity has proved to be the mother of invention for Malvern, Worcestershire based Malvern Scaffolding Ltd. (Malvern).

Malvern’s tender was based on the assumption that the scaffold would be tied through the window openings. However, Wates’ project manager wanted to install windows while the scaffold was still at full height for roofing.

Malvern contacted ADI Supply Ltd. (ADI), a specialist in a wide variety of scaffold fixings, which agreed to work with Malvern in finding a solution. Striving to avoid drilling, Malvern with ADI attempted a brickie installed slide lock tie, which was rejected by Wates because of cold bridging concerns, and a tang type tie, the first of which fixed to the inner blockwork and the tang to the outer brickwork; both failed the pull test.

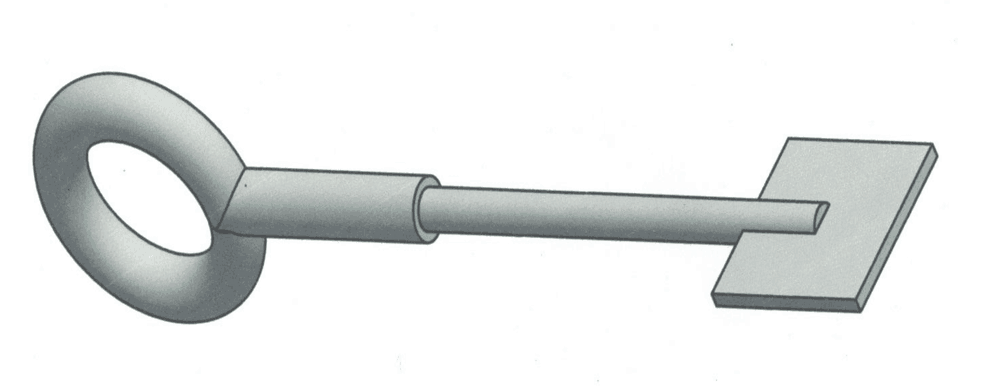

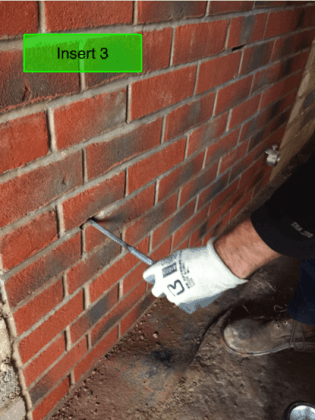

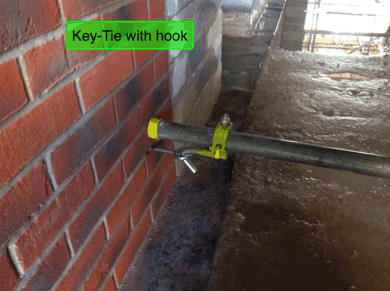

Developing the tang concept further Malvern and ADI came up with what was to become the, “Malvern Key-Tie.” The tie is essentially a hook fitting welded on to a bar with a plate welded at the end. The brickie prepares a putlog type joint, the tie plate is inserted behind the external brickwork and then turned to lock it off, then it’s a case of attaching the scaffold to the hook. Removal is the opposite process.

“The new ties are really quick to install through the slot the brickies leave behind,” said Jon Stone, Malvern’s commercial director. “There’s no drilling needed, no messing around in window openings. Just insert – lock – secure.

The scaffold is secured as in TG20 & TG4 using a hook fitting, but without the risk of damaging the front of the bricks, or having to relocate the ties once the windows need fitting. You can simply “fit and forget” and then retrieve them as the scaffold is stripped.”

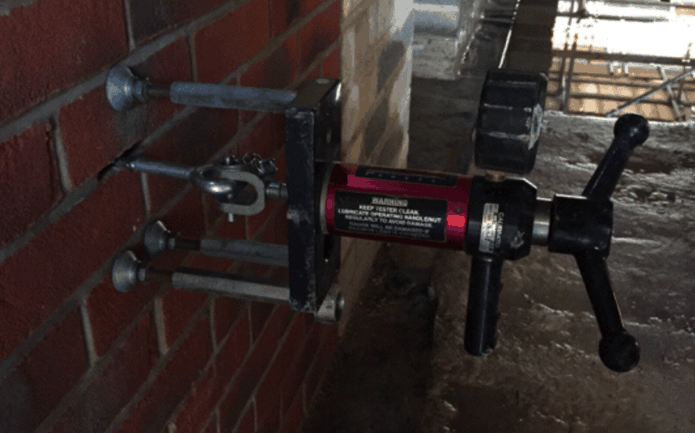

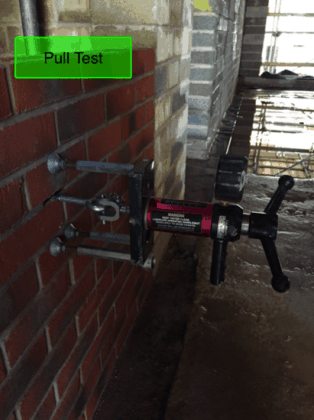

Bearing in mind that compliance for most progressive masonry jobs requires a tie of around 2.5kN Malvern say that the Malvern Key-Tie was tested in-situ to 9kN and pull tested to destruction at 12.5kN. This was sufficient said Malvern to rate the Malvern Key-Tie for standard duty at 6.1kN thus covering the majority of applications.

Stone said the current version of the tie works within the around 40mm space cavity between the outside skin and the insulation, which give the Malvern Key-Tie the space to turn. However, Stone also said that Malvern has used the Malvern Key-Tie where the insulation board takes up almost all of the cavity and the tie has performed well too. “It (the tie) doesn’t penetrate the insulation board,” said Stone.

There is a bit of an education process prior to using the Malvern Key-Tie explained Stone but once the brickies understand what they have to do in order for the tie to work, “brickies have been great,” he said.

We asked if Malvern had experienced any significant labour saving through using the Malvern Key-Tie and while Stone said that the company had not performed any time and motion study yet he said that the company estimated that on a 100m perimeter building that four or five hours could be saved using the Malvern Key-Tie compared to drilling and about half of that with using window ties.

“The contractor is so much happier with the end product,” said Stone. He said that the tie has also performed well on existing buildings too but the ability to use the tie is strongly dependant on the type of cavity that is present.

“We have entered the Malvern Key-tie as a new innovation in the NASC New Product Awards. We know we are up against some stiff competition but most of the other contenders are either system based or only used in special circumstances, whereas the new Malvern Key-tie can be used in numerous situations and will be of use to every scaffold firm in the country.

It is not just new builds either, most modern buildings have a cavity where the Malvern Key-tie can be used,” said Stone.

Lewis Young my ones still better

You’s two are of ya nuts it just won’t work cos asking a brickie to leave a bit of muck out 17 bricks along 4 courses up just ain’t gonna happen so instead we will be chiselling muck out after the walls built!! I think I’d prefer the drill thankyou very much

Mike Povey Malvern scaffold U0001f648

All good to do the pull test with a device that is also pushing the immediate surrounding bricks.. what about when your next tie is 4m away and nothing is pushing the wall, only pulling it.. down comes your scaffold and it takes a whole wall with it

Charlie Houston so if it’s not a new build it’s not worth a wank U0001f602

Brickies have to leave a slot out for it to be put in

No drill required?! How they getting that muck out then?! Did I miss that bit?

Richie Smith another good shout

Never have buy drills again

have to get Tim and terry to buy them first lol

No holes. Just fill the muck after adaptation. Good shout I rekon.

Good shout may have to bring it up in next meeting

Gary Smith. This is us I rekon. Good luck with them brickies getting the height right.

Only test on how good the tie is, an expensive bit of kit handle with care lol

Looks expensive. How many times can you throw it in a bin before it breaks.

“The brickies have been great” famous last words.