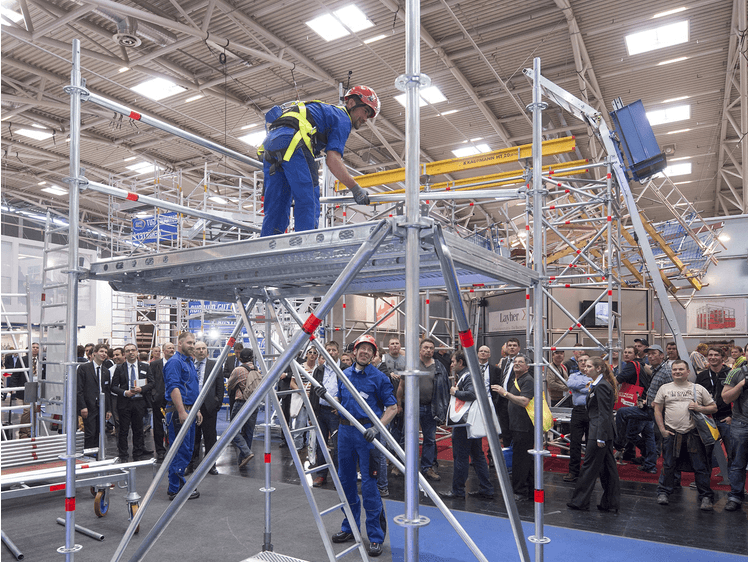

KHL.com has reported that Layher has debuted a new, lighter scaffolding solution – Allround Lightweight. Shown for the first time at Bauma 2013 in Munich, the Allround Lightweight modular scaffolding system features lighter components, increased load-bearing capacity and an AUtoLock function for wedge-head connectors.

According to Layher, Allround Lightweight can be assembled 10 percent faster than competitive scaffold systems and transport is 12 percent more efficient.

“Since assembly, dismantling and transport still account for 80 percent of the costs for scaffolding construction, three factors are critically important: design, functionality and component weight,” said Layher’s marketing director Franz Greisinger. “The focus is on making scaffolding construction easier, safer, and above all more economical. Studies have clearly shown that a significant reduction in assembly and dismantling time can be achieved by cutting back on component weight.”

To get Allround Lightweight as light as possible, Layher used high-tensile steel that allowed the company to make components with thinner walls. The wall thickness of the new ALlround standards LW has been reduced from 3.2mm to 2.8 mm.

“Depending on the length of the components, scaffolding erectors have up to 14 percent less weight to handle when transporting components by truck to the construction site and in scaffolding assembly itself,” the company said. “The wall thickness has been reduced in Allround O-ledgers LW as well, saving up to 1.6 kg while increasing bending stress capacity by 24 percent.”

To make transportation more efficient, Layher lowered the structural height of the product which reduces storage volumes. With the additional reduction in weight, scaffolders have faster loading and unloading time.

“With its 12 percent higher transport efficiency, Allround Lightweight requires fewer trips, which reduces transport costs for medium-size and large projects,” the company said. “In this way it is also friendlier to the environment.”

Also new is the AutoLock function that creates a positive connection between ledger and rosette. To bring the self-locking wedge into position, the fitter gives the ledger a quick turn and tips it forward. Then they place the wedge-head above the rosette of the Allround standard. When the wedge makes contact with the standard, it is automatically activated and falls into the recess provided for it. A hammer blow then creates a force transmitting connection. This saves one operation for each ledger connection and allows ledgers to be fitted from a secure position.

Lastly, the new U-ledgers LW are one-fourth lighter because the high-tensile steel makes V-reinforcement unnecessary, the company said. The structural height of the ledgers has been reduced by 4.5 cm. The new reinforced Allround U-ledgers LW have 10 cm more clearance than the previous U-bridging ledgers without compromising on load-bearing capacity.

Story Via: KHL.com