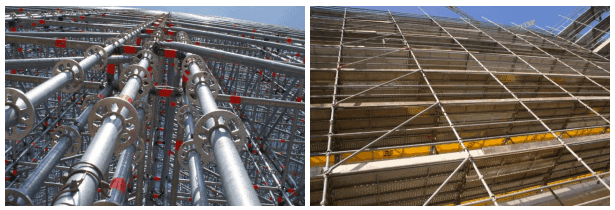

Safety concerns affecting the Canadian scaffolding industry have been identified in a recent comprehensive study into the practise of mixing modular system scaffolding components. The article published by the Scaffold Industry Association of Canada (SIAC) outlines the risks of mixing Original Equipment Manufacturers (OEM) components.

Meanwhile, here in the UK the CISRS (Construction Industry Scaffolders Record Scheme) are making major changes to its SSPTS (Systems Scaffold Product Training Scheme). In a recent NASC/CISRS newsletter to its members CISRS reported that it will be splitting its SSPTS courses into just two “Generic Training” groups.

ScaffMag interviewed a current industry source for views on this subject: –

“This is a well written article from across the pond, that highlights many of the same issues and problems we are currently facing within the UK scaffolding and access industry. The NASC has simply chosen to ignore historically and more recent OEM complaints and requests for clear guidance on product mixing, surrounding concerns at the antics of many “copyist” product manufacturers operating in the UK.

There are clear cases of blatant marketing propaganda campaigns being executed, by some of these copy product manufacturers and even product hire/sales organisations, are now exploiting this same situation. They claim their respective modular system products are compatible with and fully “approved” to allow the mixing of their products, with those of OEM’s in the UK.

These statements are of course blatantly misleading and deliberately created to take advantage of the current industry confusion and lack of a clear statement from the industry decision makers. The blanket statement issued from sources such as the NASC, CISRS, HSE & MCG members is simply: – “Refer to the manufacturers guidance!” The guidance from OEM’s such as Haki, Layher & Peri is very clear: – “Our original manufactured products MUST NOT be mixed with other similar “copy” products!” It seems this particular piece of manufacturers guidance is not worthy of due notice or enforcement, within the UK scaffolding and access industry at present!?

This situation has been further exacerbated most recently by ASITO (Access and Scaffolding Industry Training Organisation) who are backing the CISRS in its latest decision to re-categorise system scaffolding product training.

No longer is it necessary to undertake SSPTS training on a product by product basis. “Generic Training” is the new terminology adopted for these training courses, which enables a scaffolder to undertake a 2-day course in for example, Plettac and can then be deemed competent to install other rosette type systems such as: – Layher Allround/Peri-Up/Ringscaff/Metalusa/AT-PAC etc.

However, the rationale behind this decision is critically flawed, demonstrating a distinct lack of understanding and appreciation of OEM product differences & modular system configuration in general within the UK industry.

There can be no argument or difference of opinion regarding the facts that the rosette type modular product ranges are all very different from each other, in both design, load bearing capacity and the respective variables that exist amongst the OEM’s products & component ranges, regarding structural configuration versatility and abilities.

Therefore specific training must be undertaken on a “product by product” basis as it is NOW and NOT on a “Generic Training” type basis for these type systems.

Similarly only one training course will now be required to achieve competency for the installation of modular systems such as Cuplock/Tradlock/Genlock etc.

On balance, there are only two manufacturers that produce the modular “cup type” products range which is then individually labelled and marketed as: – Cuplok/Tradlok/Genlok. In essence, there are no technical differences between the aforementioned individually labelled products from an installation viewpoint, but obviously respective standards and deviations may exist between the two manufacturers.

Therefore from a product training perspective, the rationale applied of only one product training course being required, to achieve competency for the installation & dismantling of this type product is understandable in this case.

It will be interesting how ASITO/CISRS intend to categorise the Kwikstage and Haki products, which are neither “cup” nor “rosette” type modular systems?

The various product copyist and hire/sales outlets operating within our industry will no doubt seize upon this “mixed” message being delivered by those aforementioned organisations. That marketing message will be the mixing of product training lends support and advocates the mixing of different OEM products here in the UK.

As the use of modular system scaffolding products in the UK is very much on the rise, it would seem prudent for the industry decision makers to address these problems now, rather than later. This is certainly a case of the proverbial ticking bomb regarding accident(s) just waiting to happen!”

Read : The article published by the Scaffold Industry Association of Canada (SIAC) which outlines the risks of mixing Original Equipment Manufacturers (OEM) components.