Written By Rhymer Rigby

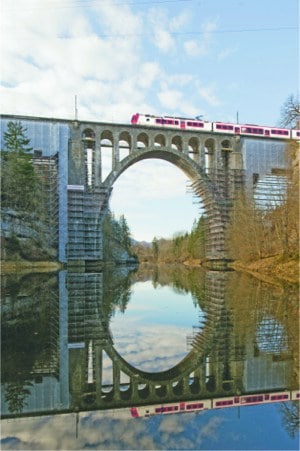

How do you scaffold a railway viaduct running across an Alpine valley or a pointy-steepled, centuries-old church on a peninsula which is surrounded on three sides by a lake? What about a 100 metre high concave-shaped dam or a new building on a steep mountainside? And how do you ensure that all these scaffolds can deal with tons of snow and ice? These are all questions that Switzerland’s largest scaffolding company routinely has to deal with.

In its home country, Roth Gerüste is well-known for its innovative, technically daring feats of scaffolding. And Roth Gerüste is the market leader in a country where scaffolding is taken very seriously indeed. “Here it is considered a craft in its own right and standards are extremely high” explains Giorgio Laurenti, chairman of Roth and Keystone Constructions AG, the Swiss family office and private equity group which owns a majority share of the company.

This is not just Swiss pride speaking. To illustrate the Swiss difference, Laurenti produces two pictures. One is of a scaffolded building in central London; the other is a scaffolded building in Switzerland. There’s nothing wrong with the former – it looks entirely normal – but the Swiss scaffolding is something else. Even from a distance and to my untrained eye, it’s sleek, high-tech and elegant.

The reason they look so different is, while UK scaffolders tend to use steel poles with bolted joints and wooden boards to walk on, at Roth Gerüste, it’s all mechanical joints, and high-tech, low-weight aluminium platforms. “It’s a modular system and it’s very efficient and light,” says Mr Laurenti. “It can go up and down very quickly.”

It has proven a sound business. In the words of Javad Marandi, the Swiss-based financier who is also an investor in Roth Gerüste: “It is a highly efficient company, well managed, and the market leader in an industry that has high barriers to entry. The company’s reputation within Switzerland has been built over many years.”

And this is in the context of the general investment climate in Switzerland. “Switzerland is a mature, low-risk market for investors, and attractive for investing in high-quality firms with steady growth potential.”

The high regard the Swiss hold scaffolding in is rooted in the landscape and climate. Sixty percent of Switzerland is mountainous and the weather is often severe in the winter. “This means that scaffolding has to be like engineering,” explains Mr Laurenti.

The scaffolders also ensure that they are logistically aligned with the contractors. “The efficiency of the construction site is highly dependent on the delivery timing of the scaffolding. So we have to be on site, on time and they really have to rely on us.” If the scaffolders are not there, everything is late, and costs rise. Roth Gerüste, Mr Laurenti says, is utterly committed to both reliability and Switzerland’s world-beating safety standards, both of which minimise delays. Indeed, well-designed scaffolding speeds up the construction process.

Indeed, it is a mistake to see scaffolding as static. “From the outside people see scaffolding go up as the building goes up and go down when it’s finished. But it’s a living, breathing thing that is often altered every day. Whenever you want to execute or change something, you have to ask the scaffolding guy to come on service and react quickly.” This is one of the reasons the company has 17 sites in a country half the size of Scotland. “We have to be reachable on site within 20-30 minutes.”

Because the company is so committed to reliability and quality, it has a strong emphasis on training. “Our staff come in fairly young and get trained and then they escalate in position, often doing different jobs until they become site managers,” says Mr Laurenti. Employees will sometimes go to other scaffolding companies, but retention is generally very high. “We give prizes for over five years, ten years, fifteen years. Some of the senior managers have been with us for twenty years.”

Roth Gerüste is also pushing the bounds of what can be scaffolded. The company has its own engineering division and development team which uses computer modelling to design ways to scaffold once impossible structures. Much of this is down to the demands of clients – as architecture changes and becomes more daring, scaffolding has to change with it. “We are working on scaffolding which is suspended from a building’s roof,” says Mr Laurenti. “You build the scaffold based on this suspension and it never touches the ground.”

Perhaps surprisingly, for all this, the company has no plans to take Swiss quality scaffolding out of Switzerland. Indeed, Mr Laurenti says he believes that it is better to deliver excellence and reliability in a market you understand than take risks in markets that you don’t know.

But there may be another factor at play here. The Swiss building industry demands high quality and is used to paying high prices for it. “What we offer doesn’t come cheap – and people in other countries might not be prepared to pay for our standards. “We offer a Rolls-Royce type service.”

Nothing really impressive here, or out of the ordinary. I don’t feel enlightend after reading this, only mildly disapointed. These are not the first to put a scaffold round a steeple, or a viaduct and they certainly won’t be the last.

Believe it or not these structures have been sarrounded in scaffold on numerous occassions for many years. It`s hardly advanced nowadays but doff your hat to the guys who just got on with it and done it years ago. That was before the scaffold industry had to support engineers, safety bods, training centres, DVLA to name but a few.

Blake Parata wee scaff an a hunt at lunch

Schweiz låter kul Simon Karlsson – Alexander Olsson! Det är så det borde va!

MartinVit Björn Schwing Lars Schwing…;)