In a move aimed at boosting on-site safety and practical knowledge, PERI recently hosted a hands-on training workshop for Laing O’Rourke’s engineers and temporary works designers.

This marked the first time the formwork and scaffolding specialist delivered its product awareness training to Laing O’Rourke, one of the UK’s leading construction companies.

The one-day workshop, held at PERI’s training facility in Brentwood, was designed to help participants get a deeper understanding of the formwork and scaffolding systems they work with on a daily basis. Combining theory with practical exercises, the session focused on making sure attendees could confidently handle, assemble, and inspect key systems used in temporary works.

A Focus on Practical Learning

Led by PERI’s Field Services Manager and a team of experienced scaffolding instructors, the workshop covered several key areas:

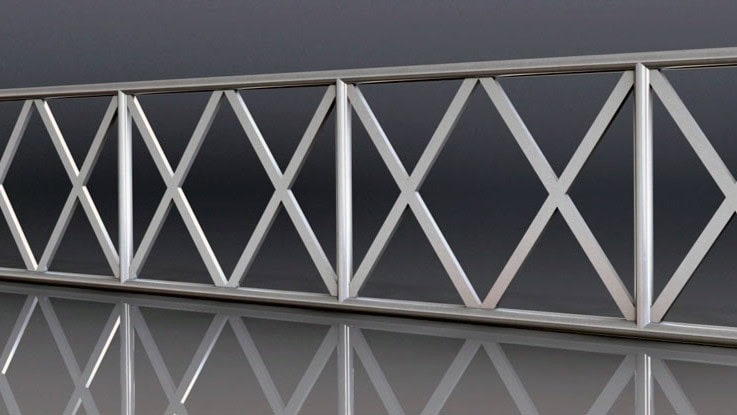

- Participants assembled two types of PERI system scaffolds: a birdcage scaffold and a stair tower

- They inspected a tube and fitting structure to learn how to identify potential issues

- They installed the SKYDECK system, gaining valuable hands-on experience with decking

- A full walkaround of PERI’s products helped them understand how different solutions are used in real-world applications

- The group also learned how to reference drawings correctly, spot deviations, and ensure safe practices

The session catered to engineers and temporary works designers at different stages of their careers, reinforcing the importance of continuous development across all levels. The practical experience was especially useful for those who are responsible for checking temporary works on-site, ensuring everything is safe before crucial activities like concrete pours.

Bridging the Gap Between the Office and the Site

Terry Hall, PERI UK’s Field Services Manager, emphasized the importance of hands-on training. “A lot of engineers only have classroom-based learning or experience with 3D drawings. It’s critical for them to see and handle the actual materials and equipment they’ll come across on projects. This training helps bridge that gap,” he explained.

The benefits were clear for Laing O’Rourke’s team. Anu Adeyemi, a Graduate Engineer at Laing O’Rourke, said, “My role involves carrying out temporary works checks, and this workshop really helped simplify the terms and system components you come across on-site. Everything was broken down in a way that makes it much easier to understand.”

Terry Hall added, “When you see real-life issues on-site—like deviations from drawings or improper practices—you gain a much better understanding of how to ensure safety and quality. That’s why this practical experience is so valuable.”

This session marks a significant step in what’s likely to be an ongoing collaboration between PERI and Laing O’Rourke, with both companies committed to raising the bar on site safety and efficiency through tailored training initiatives.

For more information about PERI’s training programmes, visit PERI UK.