A college refurbishment project in Rutland has thrown the spotlight onto the outstanding levels of customer service for which Harsco Infrastructure is widely recognised, and earned the company high praise from its client.

Despite the presence of asbestos and the need for frequent changes during the life of the project, Harsco was able to provide a CUPLOK® scaffolding system which allowed the windows at Uppingham Community College to be replaced in-line with an extremely demanding schedule.

“This was certainly a project which provided its fair share of difficulties, but the Erection and Dismantle team at our Birmingham branch in Tamworth was more than equal to the challenge“ explains Harsco’s Branch Manager Steve Bollans. “The scaffolding system itself was straightforward enough, but there were many other factors which made the job difficult.”

These included the fact that the school was live during the project, which required Harsco to schedule all deliveries to site outside of school hours. Limited road access also meant that delivery vehicles were halted some 70 yards away from the school. The Harsco equipment was then unloaded and transferred to site, past an adjacent nursery school, using lorry-mounted forklift trucks.

“We could only do this when there were no children in the nursery,” adds Steve. “Similarly, when we were installing the scaffolding we had to stop work every time pupils from the main school came outside at break times” Despite this, and the fact that the decision was taken part way through to extend the project to cover the school’s second storey windows, Harsco was able to help the project meet its very demanding 10-week schedule.

“From the outset the Harsco team were extremely professional, pro-active and advisory, managing an extremely short mobilisation period with ease,” says Chris Cuthbert, Project Manager for the main contractor, Kier. “We had regular site meetings to make sure any design changes were dealt with in a timely fashion. Unfortunately one of the three main sub-contractors under-performed drastically which put a lot of pressure on the Harsco team due to late changes. With this in mind, and with the Harsco people being so pro-active and reactive, the project finished on time. Without this support I’m sure the project would have overrun.”

The fact that asbestos was being removed from the building as the windows were replaced meant that Harsco’s scaffolding design had to allow the proper protective sheeting to be installed all round the areas which were being worked on. This also involved Harsco being asked to make frequent changes to the scaffolding as the project progressed, and often at a moment’s notice.

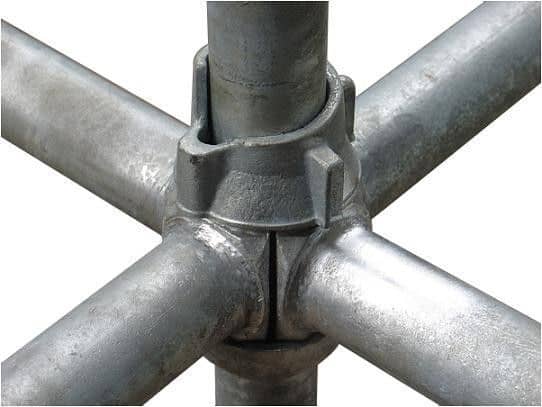

CUPLOK®

Harsco’s CUPLOK® is a multi-purpose steel scaffold system which is ideal for general access, shoring and vertical load support duties. A unique node point design allows up to four components to be connected in one fastening action, making CUPLOK® quick and simple to erect and strike. The fully galvanised, high grade tube is 20% lighter than conventional alternatives, has high resistance to damage and is compatible with up to 3 kN/m² platform loadings, making it strong enough for use in the most demanding applications.