It’s known that the use of scaffolding dates way back to prehistoric times because holes still exist in the walls of Palaeolithic caves at Lascaux in south-western France that were used for staging to enable the primitive occupants to paint their famous wall paintings over 17,000 years ago.

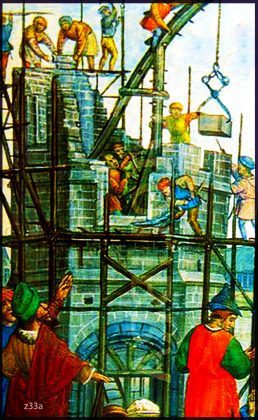

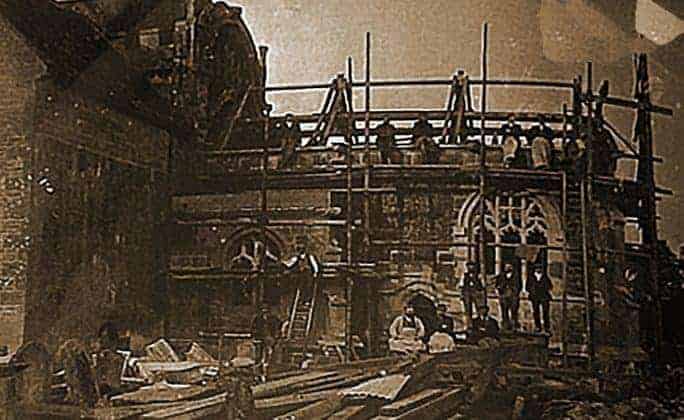

There’s also strong documentary evidence that the Egyptian pharaohs used wooden scaffolding for buildings associated with the pyramids. Later in Medieval times, specialised bands of monks were trained as scaffolders to construct abbeys and churches, a trend that continued well into the 20th century when scaffolder monks were photographed building Buckfast Abbey.

Early Days

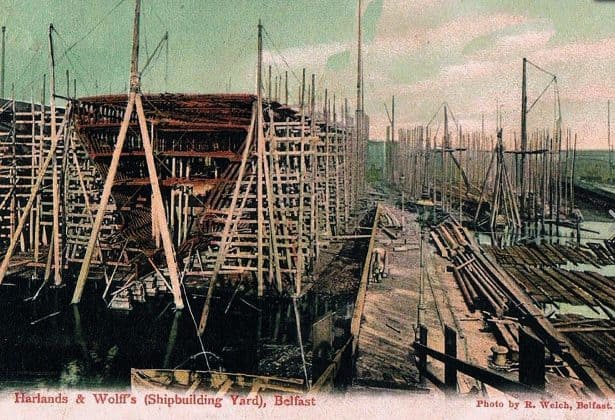

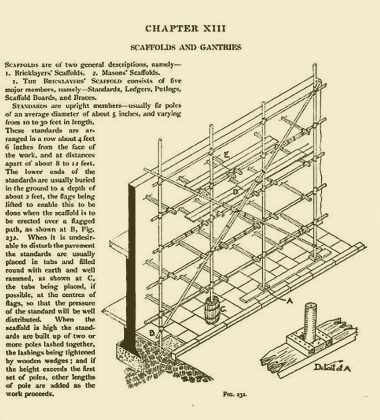

Before the introduction of metal tubes in the early 1900’s, wooden branches or lengths of bamboo were widely used as a method of scaffold construction.

The practice of using tubes tied together with ropes made of hemp (hemping) is still used throughout Eastern countries and even nearer to home in Spain and Italy today.

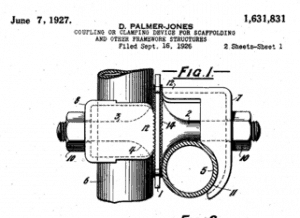

It was in the early 1900’s when Daniel Palmer-Jones (affectionately known as the ‘Grandfather of Scaffolding’) and his brother David were involved in the trade. They realised that a standard set of fixings was needed that would hold together not only the traditional wooden poles, but also the newly introduced metal scaffolding which had a tendency to slip when tied together with ropes.

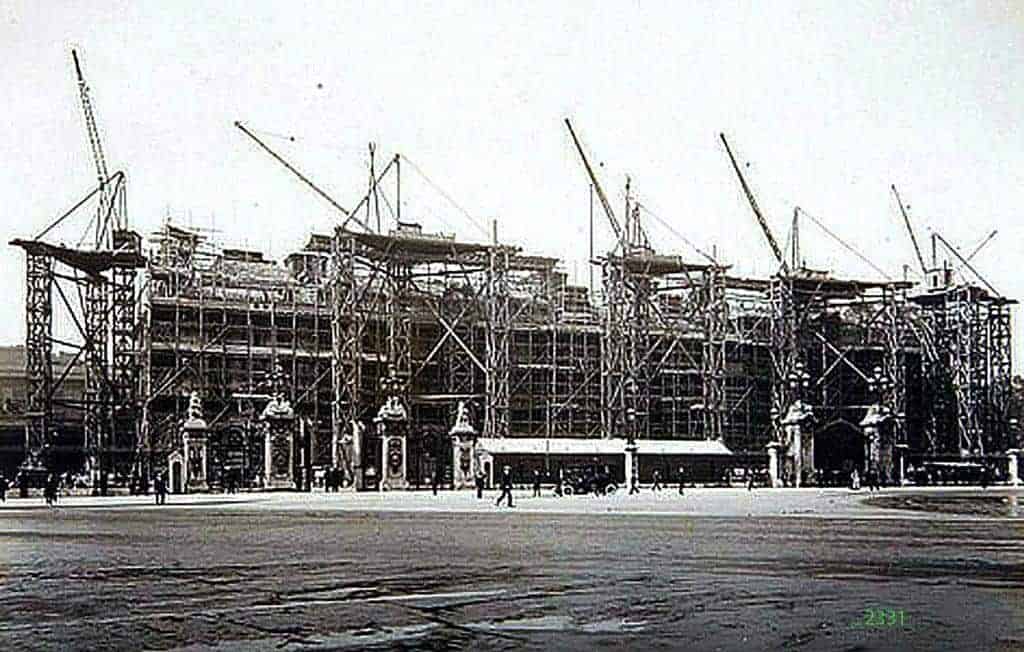

After a number of experiments, they came up with their patented ‘Rapid Scaffixers’ which proved so popular that the invention led to the brothers being awarded a contract involving the remodelling of Buckingham Palace in 1913.

Six years later Palmer-Jones invented the ‘Improved Universal Coupler’ which soon became a standard pattern used by the industry right up to the present day.

By the 1920’s metal poles were being used in the form of two inch water pipes which because of their standard dimensions allowed other parts to be similarly standardised, leading to greater stability and safety.

Post War Construction

Following World War II, a massive building program was begun to reconstruct many of the bombed areas of Britain. The first frame system was introduced by SGB, in 1944, and a year later its use was adopted for rebuilding projects throughout the nation, allowing the company to become the successful construction company it is today.

Lots of other scaffold companies owe their success to the post-war building boom. Coventry Scaffolding for instance, started in a small way In 1950 when Pat Hannifan, a former Royal Navy recruit worked as a fruit and vegetable seller and part time scaffolder.

Together with five other brothers he rented a bombed-out Catholic Church and using a second-hand lorry, began trading as the Coventry Scaffolding Company.

They went on to attract major contracts and by the 1970’s Coventry Scaffolding were building stands for the UK visit of US President Nixon; the repair of the BT Tower previously damaged in an alleged IRA bomb plot; and the building of cradles and scaffolding for a number of prominent London buildings.

More impressive high profile jobs came their way in the 1980’s and by 2005; the company had become the first scaffolding company to be granted a Royal Warrant. You can read more about their impressive rise from humble origins on their web page.

Safety

Safety has always been a priority for scaffolders, but apparently not always for employers. In the early years following WW2, men were recruited to work on building sites where unskilled labourers ‘cut their teeth’ as rookie scaffold workers.

On the The Oral History Noticeboard website we’re told a 1960’s scaffolder, George Garnham recalls not wearing any gloves, clips, harnesses or other safety gear. He also tells how workers froze as they climbed the scaffolding.

Much earlier during the reconstruction of the Hyde Park Crystal Palace in 1853, 7000 workers were taken on, including lots of scaffold workers. Whether these men were really qualified for the job has often been queried because on the 15th of August in that year tons of scaffolding supporting one of the main parts of the structure collapsed killing twelve workers.

Not all such accidents involving scaffold failure involved the workers themselves. In 1855 for example, excited crowds were watching troops re-enact the Crimean War battle of Sebastopol in Cremorne Gardens in Chelsea when the scaffold set up for the enactment collapsed allegedly due to the sheer weight of the marching soldiers. Horrified onlookers watched on as the soldiers fell, many of them becoming impaled on their own bayonets.

Modern Times

Though scaffolding methods and equipment have become standardised over the years, this doesn’t mean that there hasn’t been continual improvements (e.g. scaffold netting). In Coventry and other places during the 1960’s for instance, ‘Operation Winter Working’ was introduced by the Ministry of Public Buildings and Works in order to extend working hours for those in the construction industry. Innovations included the cladding of towers in plastic sheeting and the use of heaters installed at their bases so that work could continue during inclement weather.

Despite these modern improvements many old working practices are still evident in the industry today. As an example the block and tackle system was just as familiar to Roman scaffold workers as it is in modern times.

Chris Warburton whose job involves the restoration of old buildings is quoted on the Health and Safety at Work website as saying “Once, I was working on a church. We were around 12 lifts up on scaffolding, and we had to lift the blocks of stone up there, using a modern electric hoist…But when we positioned them, we were back to Roman technology – using blocks and tackles and chain hoists…”

Terms and expressions used by scaffolders have also changed considerably. Lots of old hands have fond memories of working on early construction jobs and recall the old terms they used for equipment, many of which are often lost on younger men in the trade.