The Link is one of the many residential buildings in central London undergoing remediation since the new building regulations regarding cladding were brought into action.

Scaffolding contractor, Legion Scaffolding, required access to the facades to remove and replace existing cladding. The desired access solution had to accommodate the building’s curved geometry and be mindful of spatial limitations around the site, including live traffic flow on the main road.

Following the success and speedy installation of the PERI UP Easy system on Blake Tower, Legion Scaffolding appointed PERI to supply the same façade access system on a larger scale for this project.

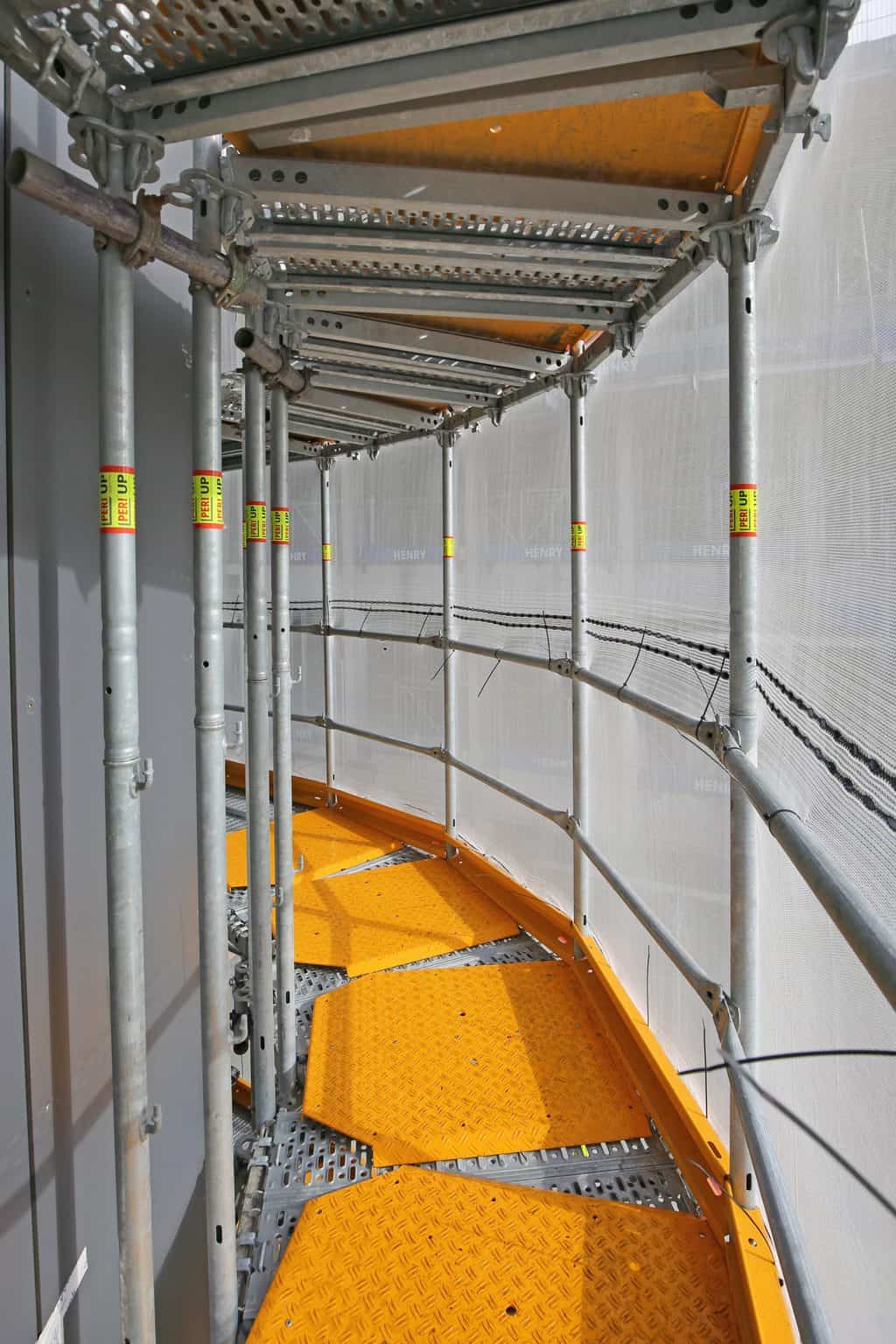

The solution consisted of a full wraparound, providing perimeter access across 10 levels. Varying lift heights were accommodated by integrating PERI UP Easy and PERI UP Flex components, with PERI UP Flex enabling 1m lifts for greater flexibility.

UPD 100 cover plates were used to fill voids between decks to create seamless access platforms around the curved façade.

The main benefit of the system is its advanced guardrail, which was advantageous on a project of this size. The feature, exclusive to the PERI UP Easy system, enables scaffolders to erect the guardrail for the next working level from the platform below, preventing the risk of leading edges.

Fast connections like the guardrail combined with system integration helped outperform the estimated tube and fitting assembly time by 12 weeks.

Shaun Somerton, Director of Assemble Scaffold Solutions Ltd said: “Normally we’re averaging about 10 to 13 sqm a day to install independent scaffolds with tube and fitting. With the PERI UP Easy system, we were able to erect 35 to maybe even 40 sqm a day, making all the difference to prelims and other project costs.

The splay plates in the PERI UP range worked perfectly to accommodate the curved façade, allowing us to achieve a nice flush finish at the front of the building which was important considering the site’s busy location. The way the plates could be adapted and erected around corners is actually unique and something I’ve not seen anywhere else.”