I-Scaff Access Solutions Ltd has demonstrated its innovative approach while making history by using Layher’s award-winning TwixBeam during a pipe bridge refurbishment project at a Whisky distillery.

Scottish scaffolding specialists I-Scaff Access Solutions Ltd, based in Fife, is renowned for its innovative approach to scaffolding. Their constant willingness to embrace cutting-edge new technologies and scaffolding products has resulted in a long history of exceptional customer service, creative solutions, and first-class advice for their portfolio of blue-chip clients.

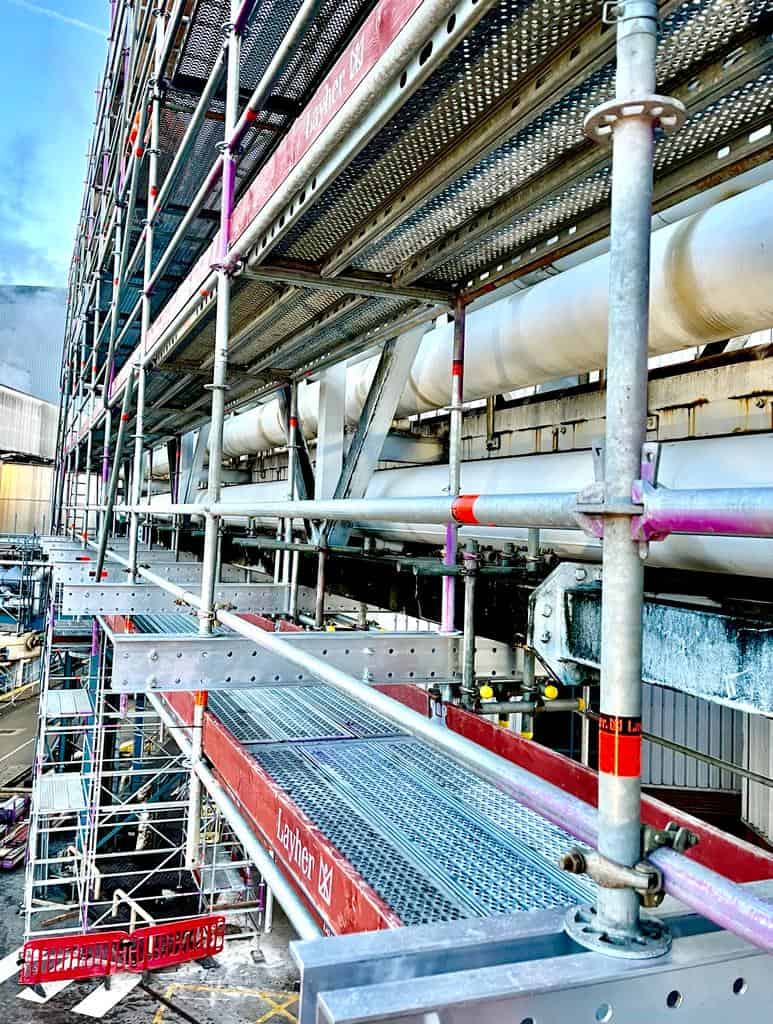

They have recently proven their innovative spirit once again and, while doing so, made history by being the first in the UK to use Layher’s award-winning new TwixBeam during a significant pipe bridge refurbishment project at a Whisky distillery.

The project presented the Scottish scaffolders with a challenge in that the pipe bridge project required a 29m span and had to remain operational around the clock, with minimal disruption to the distillery’s operations.

I-Scaff’s team quickly set to work following approval of the Layher design, and the TwixBeams were installed swiftly. The integrated Allround access scaffold was suspended below and punched off the beams upwards, allowing sections of the roadway to remain open during the build. The overall disruption was only two days, which was a remarkable achievement.

“The TwixBeam played a critical role in the project’s success”

Ross Brown, Managing Director of I-Scaff, explained that they were tasked with providing full access and encapsulation for blasting and painting operations during the bridge refurbishment project. They had previously undertaken two other bridge access projects on the same site, but this was their first time using TwixBeam.

“An important factor was that during the build and after, the section of road that the 29m span covered had to remain operational 24/7,” Brown explained.

“In addition to this, there was a desire for safety and speed of erection reasons to reduce the contact points and have the roadway closed the least amount of time possible during the erection process.”

Brown further explained that the TwixBeam played a critical role in the project’s success.

“There were material savings from using the TwixBeam. At first, the design consisted of 1.25mm deep HD aluminium beams, tubes fittings and Allround scaffolding. However, following a design desktop audit of materials, self-weight, deflection, and build time, it was decided that the Layher TwixBeam integrated with Layher Allround would not only be lighter but also stronger, faster, and at only 280mm in depth, [instead of 1.25mm depth] with the dual ability to hang off the bottom and punch upwards off the top of the beam in the same axis, provided much more flexibility, but also equated to a time saving of some +30% over the more traditional deep HD beam method.”

Brown continued, “Logistic and handling advantages were also seen in addition to those already mentioned. The logistic benefit is due to the variable lengths, and at only 280mm deep; TwixBeams are compact, with easier manual handling, and so many more fit onto your truck than much wider and cumbersome beams.

As a result, the TwixBeams is much more operative-friendly, in that the assembly methodology is a systematic installation procedure, with no time-consuming measuring required due to the integration and use of standard Allround components.”

I-Scaff’s use of TwixBeam resulted in physical benefits, such as keeping the roadway open, and minimising the potential for complications due to its quick and safe erection process.

Brown stated: “Due to the successful method with TwixBeam, planning is underway again using TwixBeam for the fourth installation over the river that runs into the plant.”

As with this project and many before, I-Scaff Access Solutions Ltd has proven time and time again to be a leader in the scaffolding industry thanks to its outside-the-box thinking and innovative approach to scaffolding by utilising products from Layher the world’s leading system scaffolding manufacturer.

Brown concluded: “The TwixBeam played a critical role in the project’s success, and with the use of this technology, the roadway remained open, safety was a top priority, and the time savings made the project much more operative-friendly.”