In an industry-first, specialist contractors have utilised a floating bridge crafted entirely from standard scaffolding to complete the demolition of the Hams Hall Bridge over the River Tame in Birmingham.

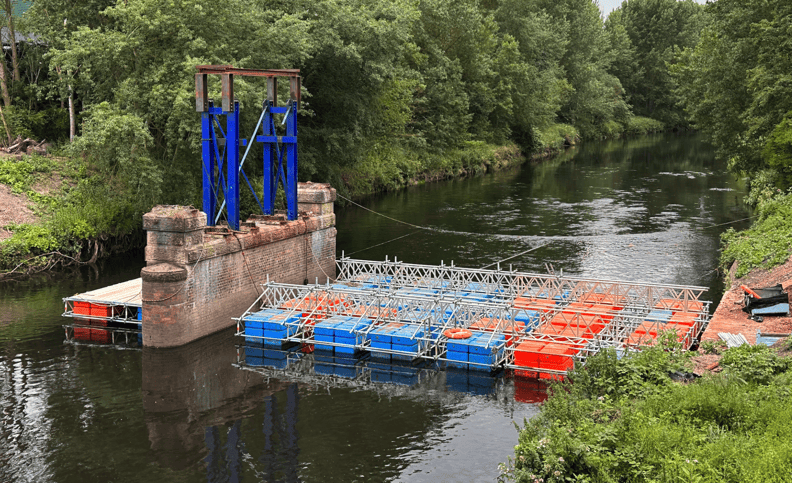

Following a multiphase demolition project on the disused railway bridge by AR Demolition, the final phase required the brick pier in the middle of the river to be broken out and removed.

To accomplish this, AR Demolition teamed up with the experts at ScaffFloat, a firm already reputed for guaranteeing a safe floating pathway after being involved during the primary bridge demolition phase.

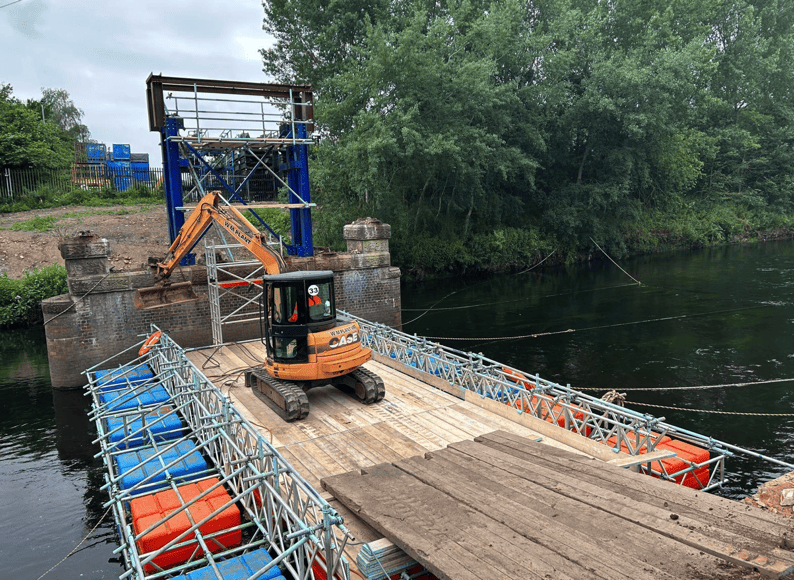

The brief was to provide floating access for a 9t long reach machine to track out from the bank and remove the pier.

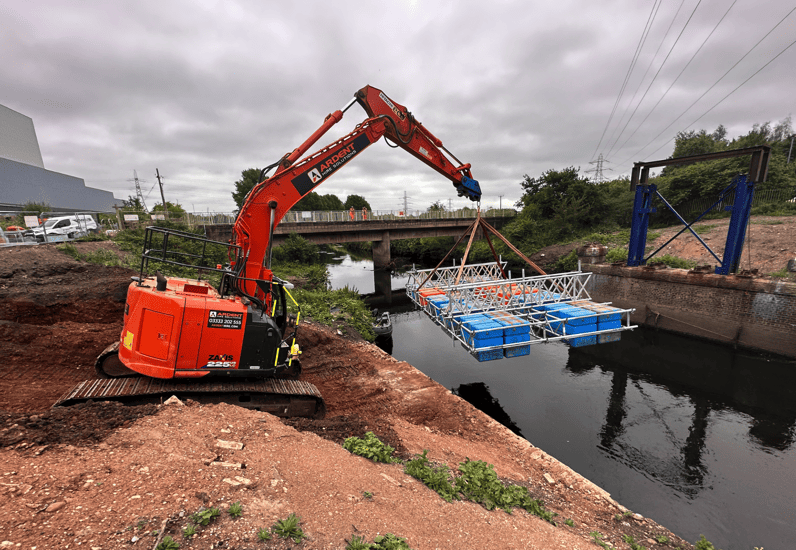

The phase presented a myriad of challenges, including restricted river access and low-hanging power cables that ruled out the use of cranes for pontoon section placements. Undeterred, ScaffFloat brainstormed a revolutionary concept, which was later honed into a concrete design by engineers at Richter.

Paul Boddy of Richter elaborated on the collaboration’s depth: “We’ve worked with ScaffFloat over the last three years assisting with schemes for access, moving and storing materials, floating welfare facilities and lifting operations. With this buildup of knowledge and expertise, we had the confidence to help Toby with this next logical way of using ScaffFloat for plant operations.”

The design underwent a meticulous Cat 2 check to validate its structure, buoyancy, stability, and minimum freeboard. The resultant modular pontoon boasted three distinct modules, each 8m in length and 4m in breadth, meticulously crafted using 450mm lattice beams, 13ft scaffold tubes, and 0.5m^3 ScaffFloats. Their relatively lightweight nature at 1.2 tons per module permitted an effortless launch using a 20t swing shovel. Once launched, the modules combined to form the main body of the floating bridge, further fortified with a layer of scaffold boards.

The Contracts Director of Midlands Scaffolding, Ben Ekins said, “We have been providing scaffold access on the Hams Hall demolition project from the start. We are always trying to come up with innovative solutions to our customers’ problems, and it was great to be able to help solve the last piece in the puzzle by building a floating bridge from scaffold for the pier removal.”

Nathan Taylor, the vigilant Project Manager at AR Demolition, commended the spirit of innovation that permeated the Hams Hall project, saying, “Innovating to provide the right solution is what we do, and working with ScaffFloat at Hams Hall has ensured we delivered a workable solution in challenging conditions.”

This landmark achievement not only sets a high standard for future demolition projects but also highlights the boundless possibilities of scaffolding innovations in modern construction.