Oxford University, a bastion of academic excellence, is renowned for its architectural beauty. Now, led by Laing O’Rourke, a new state-of-the-art humanities building is taking shape, featuring a spectacular 500-seat concert hall, lecture rooms, and study spaces.

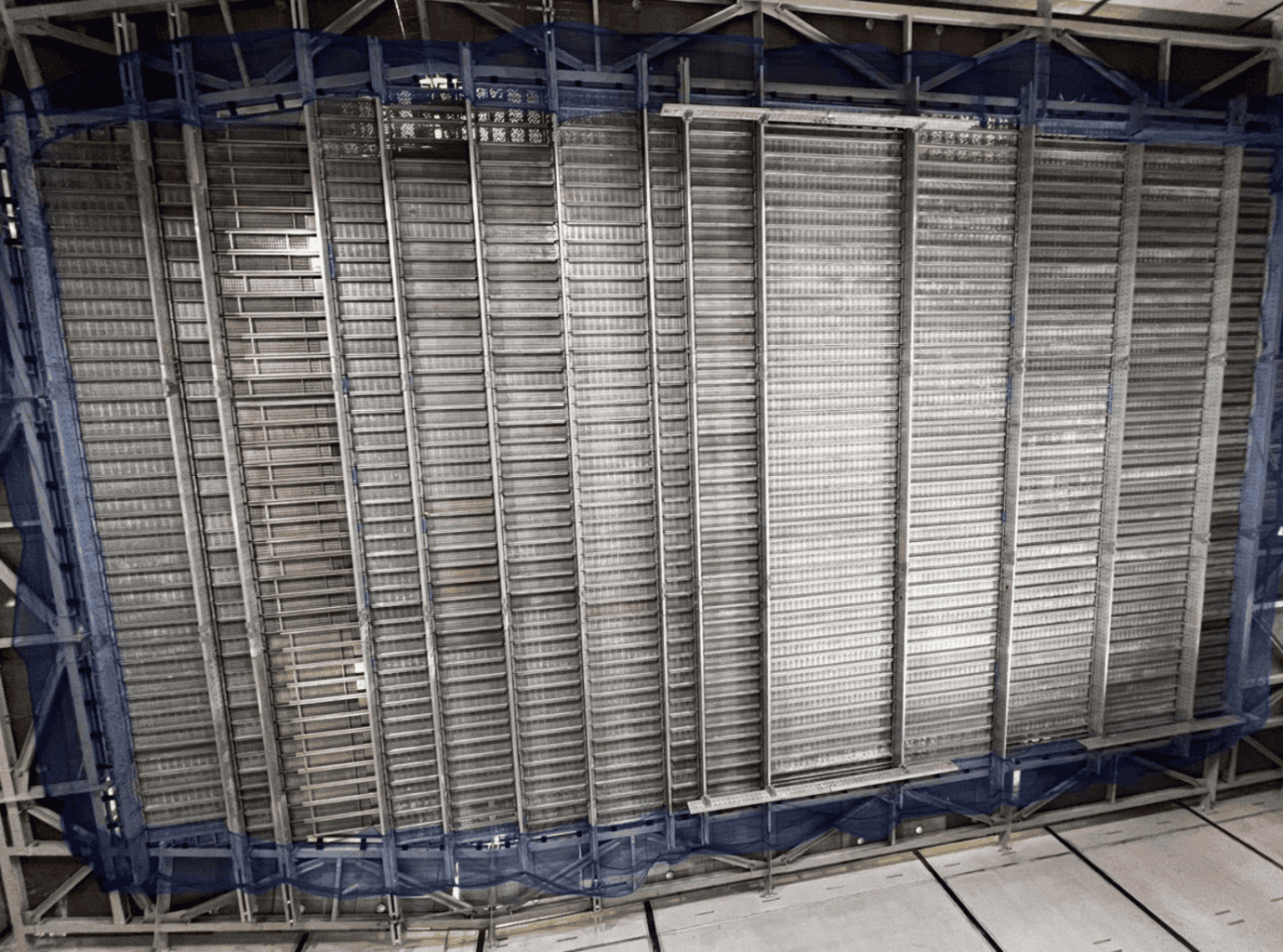

At the core of this ambitious project lies an extraordinary scaffolding access solution for the construction of the auditorium’s intricate ceiling, which is a testament to Layher UK’s ingenuity and the skilful execution by scaffolding experts H&H Contract Scaffolding Ltd.

Think Outside the Birdcage

The initial plan involved erecting a traditional 36m x 15m birdcage scaffold with eight 2m lifts, projected to take approximately two months for construction. This timescale conflicted with the project timeline, prompting the search for a more efficient solution.

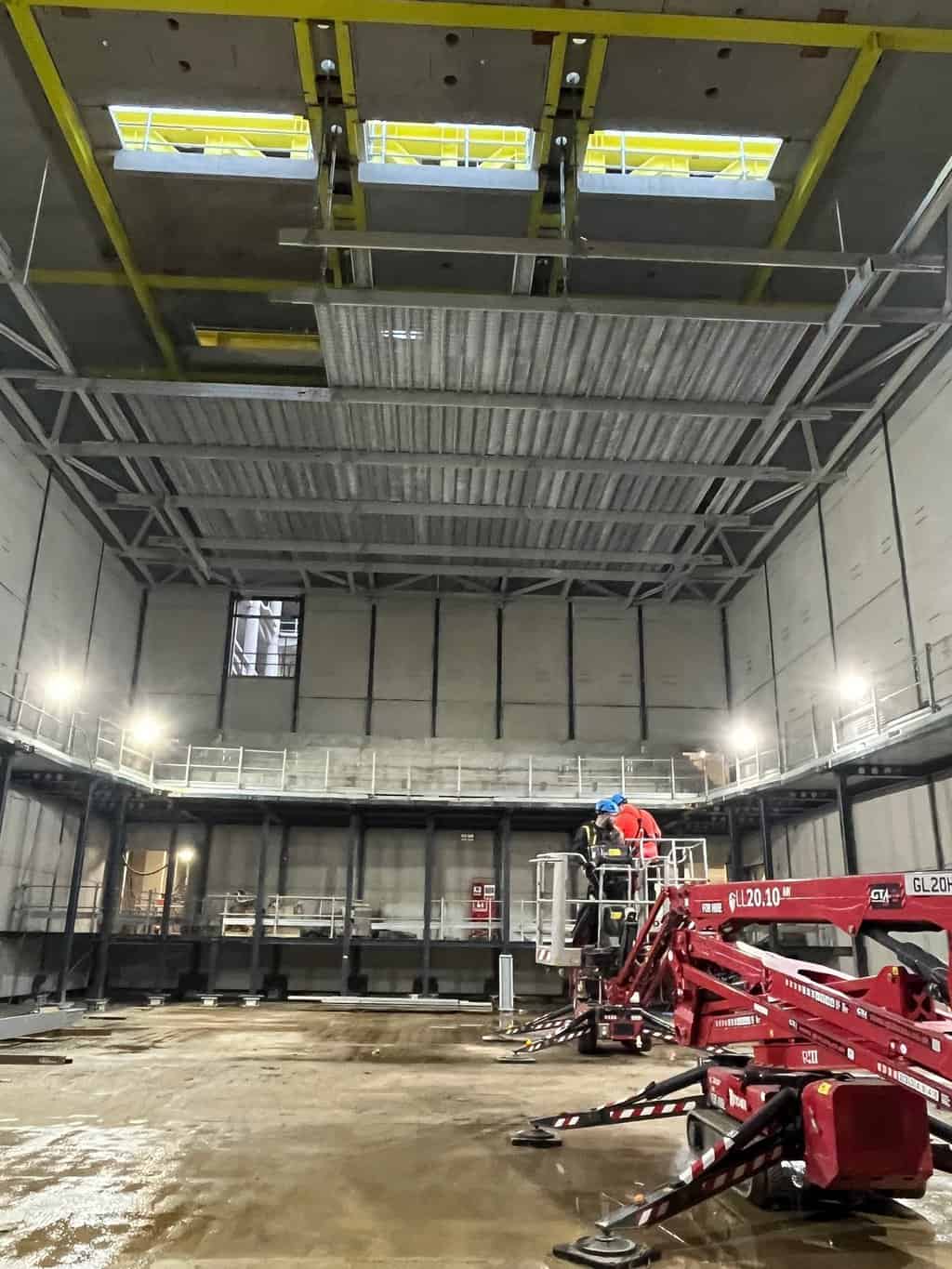

The objective shifted towards a ‘hanging scaffold’ design, suspended directly from the concrete roof slab via preformed lighting holes. This unprecedented approach aimed to free up valuable ground-level space, enabling construction work to continue unhindered.

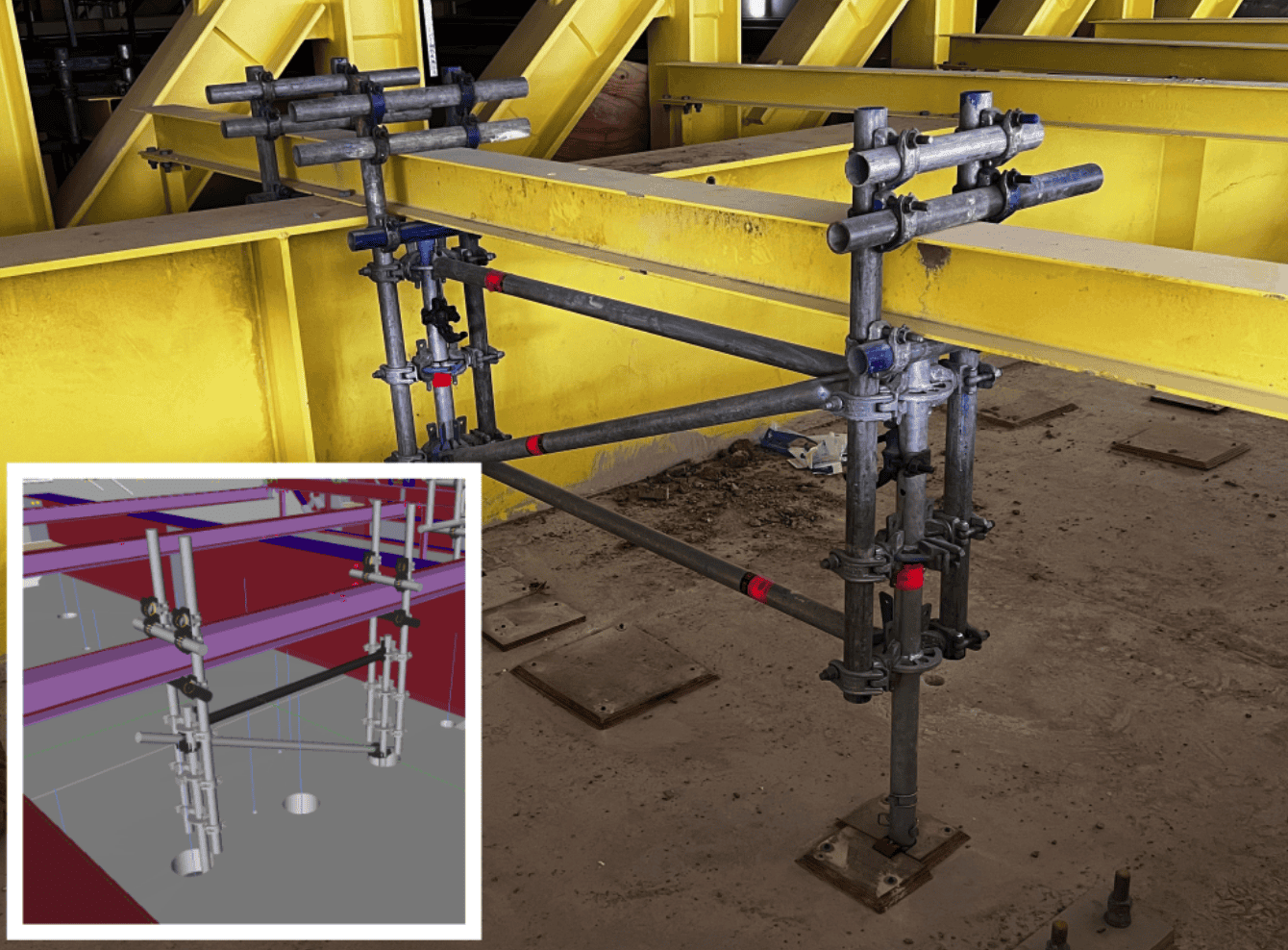

A conventional tube and fitting approach was deemed too complex to accommodate the required 2kNm2 loading. The solution arrived with Layher UK’s modular Allround system, which is world-renowned for its versatility and strength.

Layher’s innovative new Twix and Flex beams, integrated with their standard steel decks, provided the backbone for the suspended working platform. To ensure safe and efficient assembly, the entire scaffold was designed to be erected from spider MEWPs, and materials were craned into the concert hall before the roof slab was completed.

A Triple Win for Laing O’Rourke

“The innovative scaffolding solution we’ve implemented at Oxford Humanities has been a game-changer, providing a triple win for our project,” said Jack Higgins, Construction Manager at Laing O’Rourke.

“Compared to a traditional birdcage scaffold, this suspended platform allowed us to maximise productivity by working simultaneously above and below the structure. The rapid installation time significantly minimised disruption to our construction schedule, and the reduced material requirement simplified logistics and mitigated the risk of damage to finishes.

Put simply, delivering this project on our tight timeline wouldn’t have been possible without this impressive scaffolding solution.”

More Possibilities with Layher

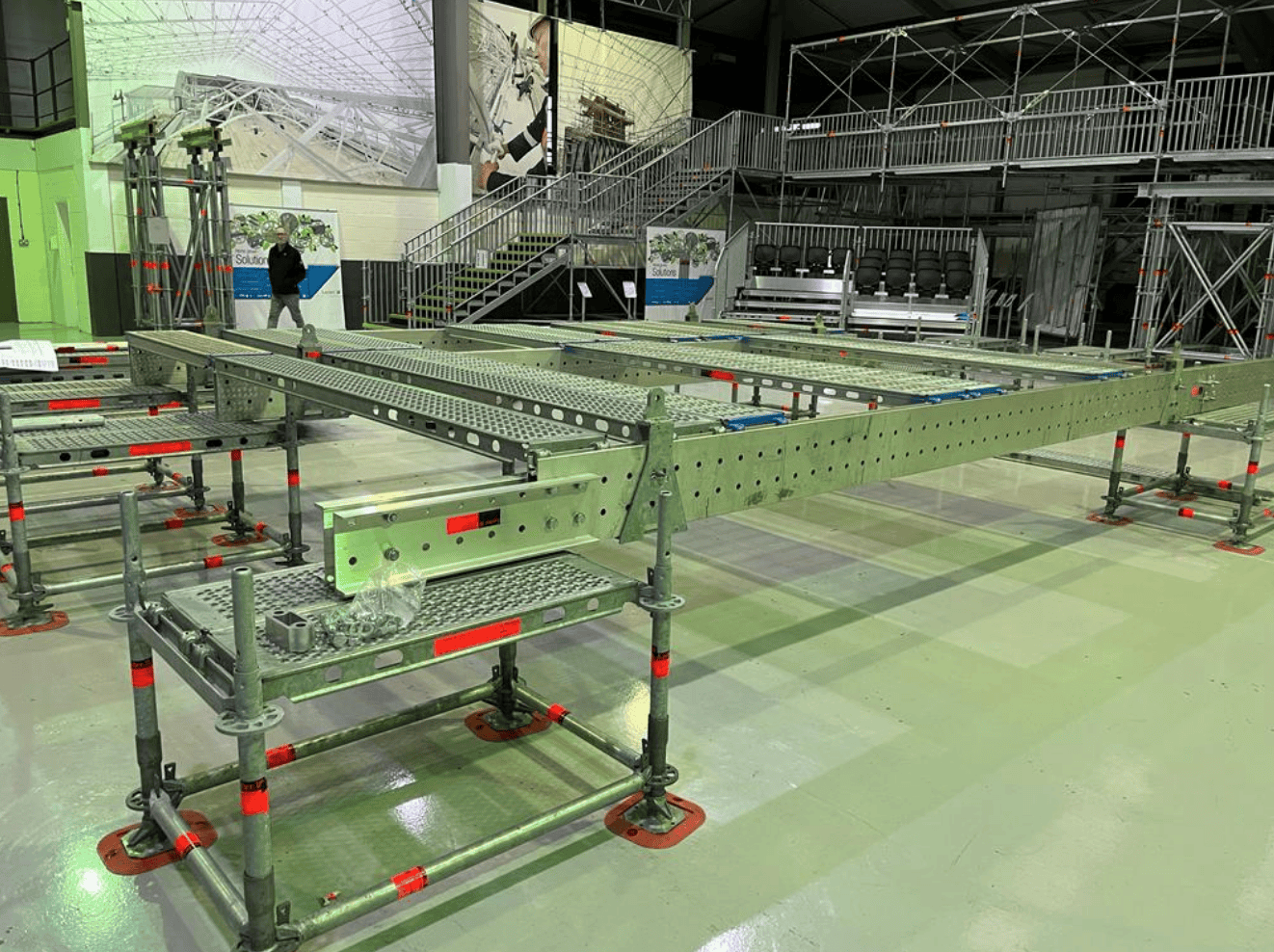

Underscoring the collaborative spirit of this project, during the planning phase, H&H Contract Scaffolding Ltd. was invited to Layher UK headquarters in Letchworth for a pre-build test of the scaffold design with, Layher’s After Sales Specialist Support provider.

This proactive approach ensured a seamless and efficient real-world installation, which Layher further supported during the actual build too.

However, this wasn’t just a courtesy visit; it was a chance for H&H Scaffolding’s team to work through the plans and assemble the structure on the ground under controlled conditions, ironing out any unforeseen complications before the actual installation began at the Oxford University site. This minimised risks ensured a flawless assembly process and saved valuable time on the project.

Powered by Layher’s Expertise

At the heart of this impressive structure are Layher’s renowned Allround system scaffolding and the integration of their versatile Flex and Twix beams. This combination represents the pinnacle of Layher’s engineering expertise.

The Allround system is a modular scaffolding solution renowned for its versatility, strength, and ease of use. Its components can be swiftly configured into a wide range of structures, making it ideal for complex projects like this one.

Layher’s Flex and Twix beams add another adaptability dimension to the equation. These new innovative beams offer exceptional load-bearing capacities. They can be seamlessly integrated with the Allround system, creating expansive working platforms that can handle significant weight, whilst providing additional flexibility and solutions to difficult aspects of any site requirements

Oxford Expertise: H&H Contract Scaffolding

The Oxford-based firm H&H Contract Scaffolding Ltd has a proven track record, having collaborated with the main contractor on numerous projects. This auditorium marks their 18th project at Oxford University, showcasing their in-depth understanding of the university’s unique requirements.

“My guys have done an incredible job on this project,” remarked Andy Thomas, Managing Director of H&H Contract Scaffolding Ltd.

“The Layher system and both the Flex beam and Twix beam are fantastic bits of kit, and Layher UK have supported us every step of the way. From the incredible engineering of the scaffold design to the support we received in understanding what can be achieved with the Flex and Twix beams with creating a test rig at Letchworth.”

“We intend on entering this project for the forthcoming NASC awards for Project of The Year,” Thomas added proudly.

Designed to Perfection

The intricate design, expertly crafted by the Design Engineering team at Layher UK’s Eggborough Depot, is a sight to behold. A massive hanging scaffold platform measuring 15m x 24m is suspended with remarkably minimal support, a testament to engineering brilliance at Layher UK.

Extensive use of Navisworks modelling ensured every element was seamlessly integrated for optimal stability and functionality.

The result is a visually striking scaffold that provides rock-solid support for the construction of the auditorium’s intricate ceiling, including its expensive wood panel feature.

Beyond Boundaries

As the university’s construction project progresses, the scaffolding stands as a shining example of how forward-thinking design and cross-industry collaboration can transform the construction landscape.

And as the auditorium nears completion, it stands as a testament to the power of innovation and the boundless possibilities that arise when leaders in the field push conventional boundaries and work in cross collaboration to create the right result.