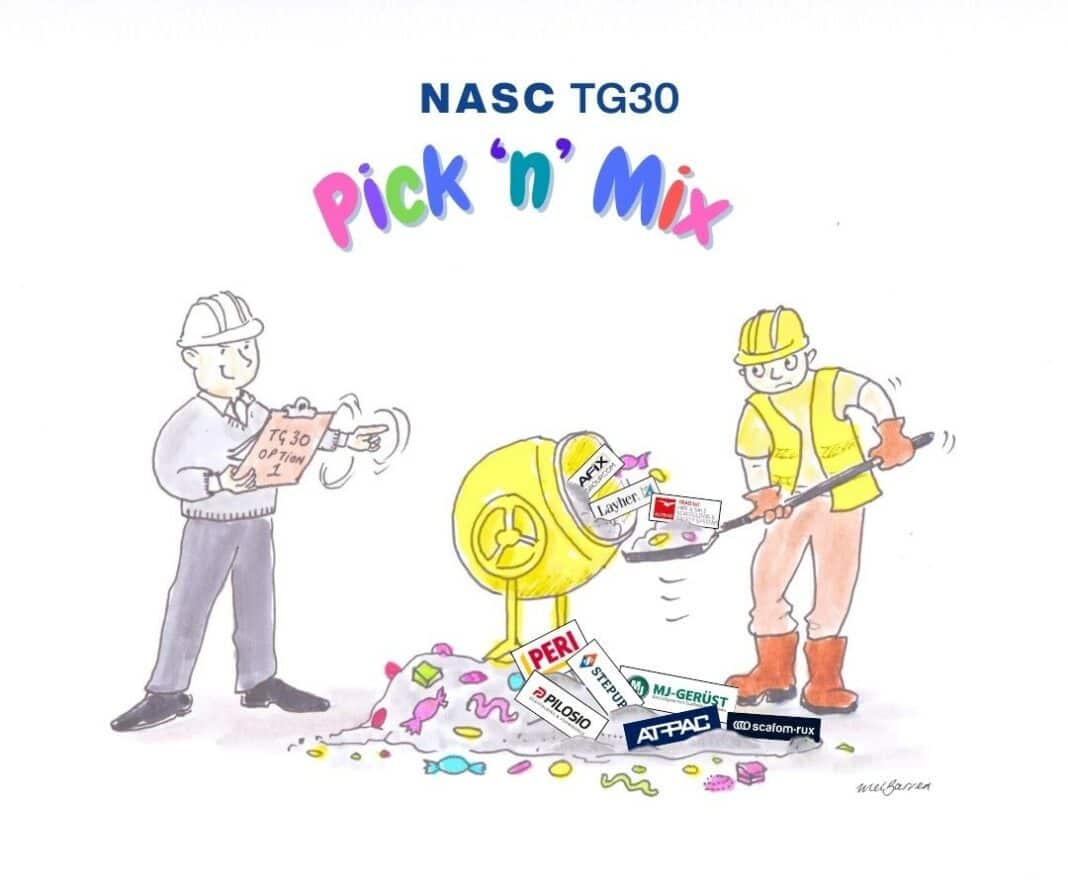

Des Moore asks: “Are we witnessing the legitimisation of system scaffolding mixing through the back door”?

As many of you know, I have strong views on ‘mixing’ in system scaffolding. In fact, the last time I wrote an article on this issue, it reached more than 40,000 people on LinkedIn, 65% of whom are in the wider construction industry.

So it’s clearly an issue of huge interest and concern. And it’s something that contracting customers are picking up on – and Tier 1 and 2 contractors, many of whom follow me, as do many smaller contractors – so both scaffolding contractors and manufacturers need to be very wary of what’s happening in the industry and how it could affect their business.

I believe – although I haven’t specifically been asked to – that I am speaking here on behalf of reputable system scaffolding manufacturers and many, many scaffolding contractors who have invested in any branded system scaffolding.

Maintaining system quality

System scaffolding is categorically NOT a commodity. At the moment, respected and established manufacturers spend a great deal of time and money on research, innovation and customer support. This helps scaffolding contractors to access quality, safe equipment and, most importantly, the product and commercial expertise that allows them to make the most of their investment.

If system scaffolding was allowed to become a commodity – effectively homogenised so that everything is either similar, the same, or interchangeable – there is absolutely no incentive for businesses to offer this support or to invest in new product development. So, system scaffolding specialists effectively just become ‘traders’. They might as well be selling oranges as opposed to system scaffolding and solutions. And at the end of the day, a tube is a tube, a scaffold board is a board etc., complete with a narrow margin to suit, hence no real design changes to either of these two items in the last 50 years.

If system scaffolding becomes referred to as generic, the quality will undoubtedly deteriorate, manufacturers will stop supporting their clients, and customers will get a lower standard of service, if any at all.

What’s wrong with NASC TG30: Compliant Rosette System, Option 1?

The Oxford English Dictionary defines generic as: ‘not specific or special; having no brand name nor protected by a registered trade mark.’ In my view, moving towards generic system scaffolding is not in the interests of scaffolding contractors, and it’s also obviously detrimental to manufacturers. It might suit scaffolding businesses that are acquiring other contractors and want to mix systems, but otherwise, I feel it’s a trend that will probably benefit a few at the very real expense of the many.

But for me, the most important reason why moving towards a generic system scaffolding market is potentially dangerous is because quality is set by the lowest common denominator. I certainly feel that’s a problem with the NASC’s proposed TG30: Compliant Rosette System, Option 1. Essentially this compliance sheet, which is specifically for rosette system scaffolding, assumes that all rosette systems are the same.

All system scaffolding types are not equal

They clearly are not the same. Components within each brand have different loading capacities, for example. I assume the NASC guidance for mixing these scaffolding brands is essentially to design using the component that is the ‘weakest’ across all the brands: weakest standard, weakest transom, weakest deck etc.

In my opinion, this will result in the poorest combination of components being used across the board, and a sub-standard design produced as opposed to the best application from each manufacturer. This completely misses the point of painstakingly-designed system scaffolding equipment, and is particularly worrying for those who are working at height, and for customers who are naturally concerned about health and safety. My experience is that clients – especially Tier 1 and 2 contractors – want to know exactly which brand is being used on site.

What’s more, will the NASC tell manufacturers which of their components has been identified as the ‘base’ model? And will the guidance tell scaffolding contractors which brand is responsible for each ‘low standard’ component? This could be potentially damaging to all brands on the market, not to mention the potential adverse effect on the reputation of the NASC, which is currently seen as the gold standard for guidance in the industry.

Many positives from the NASC

I think the NASC, under the guidance of current President David Brown and the other non-executive directors, together with the executive role that Clive Dickin has as CEO, has resulted in some amazing changes for the better, and I am overall supportive of its objectives. But in my view – and I suspect this is shared by system scaffolding manufacturers and scaffolding companies alike that have made significant investments – the production of this Option 1 compliance sheet is just wrong and totally unnecessary. I believe that it will be seen this way by the majority of system users.

In fact, I believe that manufacturers are currently producing their own individual versions of TG30 that are specific to their own products. It’s clearly severely misguided, in my view, to encourage scaffolding contractors to mix systems. It will only serve to reduce quality across the industry and, at its worst, could potentially result in real problems for site safety – is that what we – you – want?

I know this opinion might not be popular – I can see that some scaffolding contractors will want to look for easy, cost-effective ways to make savings on equipment, and that some manufacturing companies have a ‘mixing’ business model to promote. But I genuinely feel that this is the thin end of a very thick wedge, and that once we start going down the ‘all sorts’ route, we all stand to lose a great deal – and there will be no turning back.

I’d call on all NASC members to table a request at the AGM that the introduction of TG30 be delayed until there has been a full consultation with the membership. I believe that the NASC has the industry’s best interests at heart, so if we stand up and voice our concerns, we are truly contributing to the future success of both manufacturers and contractors. Guidance that has such potentially far-reaching consequences shouldn’t be imposed on us. I hope to hear many of you contribute at the AGM in Belfast!