Scaffolding firm hits back at €9.2 million lawsuit claims

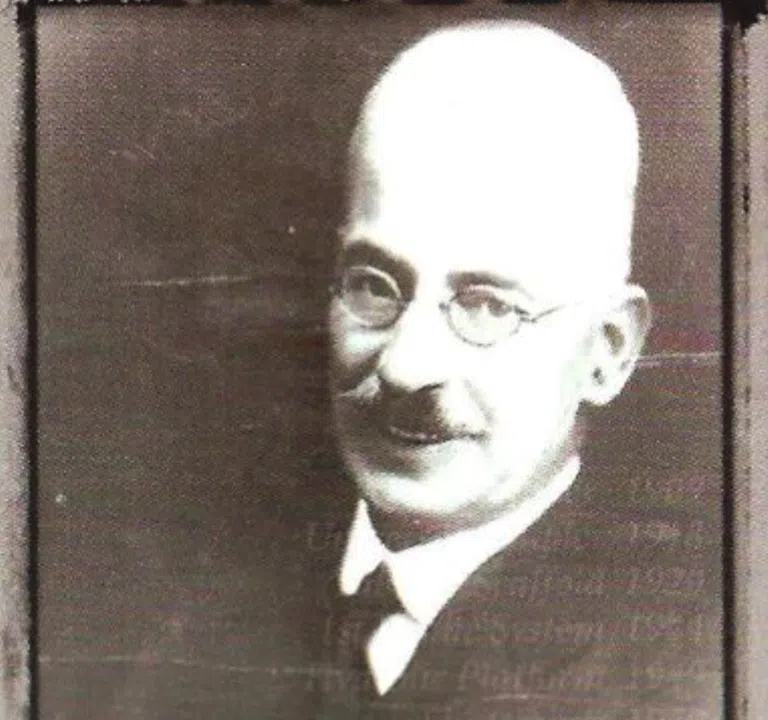

Brand Access renames HQ to honour scaffolding pioneer Daniel Palmer-Jones

The company said the renaming of its Valepits Lane site reflects both its heritage and its ongoing commitment to innovation, safety, and excellence in access engineering.

“From the very beginning, innovation and excellence were at the heart of SGB – and those core values continue to shape everything we do,” the statement continued.

With Daniel House, Brand Access Solutions aims to keep the legacy of its founder alive, recognising over 100 years of scaffolding innovation while continuing to build for the future.

The company said the renaming of its Valepits Lane site reflects both its heritage and its ongoing commitment to innovation, safety, and excellence in access engineering.

“From the very beginning, innovation and excellence were at the heart of SGB – and those core values continue to shape everything we do,” the statement continued.

With Daniel House, Brand Access Solutions aims to keep the legacy of its founder alive, recognising over 100 years of scaffolding innovation while continuing to build for the future. Parking fines cost UK tradespeople more than £119m a year

Government strengthens Planning Bill with powers to fast-track major projects

Key changes proposed

- Faster approval for water schemes: Private developers will be able to bring forward nationally significant reservoir projects to speed up supply resilience efforts.

- More onshore wind power: The bill could unlock around 3GW of renewable energy capacity, worth up to £2bn in investment.

- Planning permission protection: Permissions will no longer expire while projects are tied up in lengthy judicial reviews.

- Streamlined environmental checks: Natural England’s role will be narrowed to focus only on high-risk or high-impact cases.

ScaffFloat innovation takes floating access to new depths in Africa

Before deployment, the system underwent a rigorous verification process in Cornwall. This included a Category 3 structural check by Richter, an inclination test verified by a marine surveyor in Falmouth Harbour, and a full trial build under simulated load conditions. The testing confirmed both the system’s stability and its suitability for repeated lifting operations.

Once verified, ScaffFloat packed the complete access system, including both pontoons and all ancillary equipment, into a single 40-foot shipping container for global shipment. A specialist team was deployed to Africa to oversee assembly, conduct final sea trials, and deliver hands-on training for the client’s engineers.

Before deployment, the system underwent a rigorous verification process in Cornwall. This included a Category 3 structural check by Richter, an inclination test verified by a marine surveyor in Falmouth Harbour, and a full trial build under simulated load conditions. The testing confirmed both the system’s stability and its suitability for repeated lifting operations.

Once verified, ScaffFloat packed the complete access system, including both pontoons and all ancillary equipment, into a single 40-foot shipping container for global shipment. A specialist team was deployed to Africa to oversee assembly, conduct final sea trials, and deliver hands-on training for the client’s engineers.

“This project really highlights what’s possible with modular design and proper engineering,” said ScaffFloat Managing Director, Toby Budd. “It’s about solving real-world access problems safely and efficiently — wherever they are.”

ScaffFloat continues to provide remote support as the project progresses, marking another milestone for the company’s expanding portfolio of international marine and infrastructure projects.

A short video showcasing the system in action is available here.

“This project really highlights what’s possible with modular design and proper engineering,” said ScaffFloat Managing Director, Toby Budd. “It’s about solving real-world access problems safely and efficiently — wherever they are.”

ScaffFloat continues to provide remote support as the project progresses, marking another milestone for the company’s expanding portfolio of international marine and infrastructure projects.

A short video showcasing the system in action is available here. CISRS appoints academic leader to steer quality and standards

The Construction Industry Scaffolders Record Scheme (CISRS) has appointed Professor David Wooff JP as the first chair of its newly established Quality Assurance Committee (QAC).

Professor Wooff, Director of Apprenticeship Quality and Regulation at BPP Education Group, brings more than 30 years of experience in education and quality regulation. He has worked with national bodies including the Office for Students (OfS), the Quality Assurance Agency for Higher Education (QAA) and the Nursing and Midwifery Council (NMC).

He also serves as lead external examiner for access courses accredited by the University of Ulster, vice-chair of the Frank Field Education Trust, and a governor of the Royal Humane Society.

The QAC has been created as part of CISRS’s modernisation plans to strengthen its approach to quality, oversight and continuous improvement across all training and certification. The committee will advise the CISRS Board on training standards, assessment practices and centre accreditation to ensure alignment with industry and regulatory expectations.

Wayne Connolly, Chair of the CISRS Board, said: “The creation of this new role is fuelled by the desire to bring in some independent and fresh thinking, drawing on experiences and knowledge from industries beyond our own. Construction is sometimes seen as being behind other sectors in respect of approaches to modernisation, digitisation and best working practices.

“A fresh, unbiased perspective will help balance the work of the Quality Assurance Committee and guide it on training, business development and operational issues.”

Professor Wooff said he was pleased to take on the position: “I am delighted to have been appointed as Chair of the newly established CISRS QAC. This role presents a valuable opportunity to strengthen quality standards and promote excellence across the scaffolding sector.

I look forward to working with colleagues to deliver meaningful improvements that support both industry and workforce development.”

The committee will now begin its initial work under Professor Wooff’s leadership, including the appointment of representatives from across the industry as outlined in its terms of reference.

Onboard weighing systems help scaffolding firms stay safe and compliant

That’s why many companies are now fitting onboard weighing systems such as the VanWeigh Smart-Weigh. The system uses sensors to measure a vehicle’s axle loads and overall weight, giving drivers live feedback on an in-cab display or mobile app. If the weight gets too high, they get an instant alert before they hit the road.

It can be fitted to almost any type of van or truck and is designed to be simple to use and maintain. Drivers can also print or save weight records to help with compliance checks or audits.

As enforcement tightens and insurance firms pay closer attention to overloading, tools like these are quickly becoming essential. They not only prevent fines and downtime but also help keep staff and other road users safe.

A spokesperson for VanWeigh said: “Overloading is still one of the biggest risks for operators, especially in scaffolding where loads change from job to job. Our system gives drivers a clear picture of what’s happening with their vehicle before they leave site. It’s about making life easier, safer and more compliant.”

By fitting onboard weighing systems, scaffolding firms can avoid penalties, protect their reputation, and keep their vehicles running safely and legally.

That’s why many companies are now fitting onboard weighing systems such as the VanWeigh Smart-Weigh. The system uses sensors to measure a vehicle’s axle loads and overall weight, giving drivers live feedback on an in-cab display or mobile app. If the weight gets too high, they get an instant alert before they hit the road.

It can be fitted to almost any type of van or truck and is designed to be simple to use and maintain. Drivers can also print or save weight records to help with compliance checks or audits.

As enforcement tightens and insurance firms pay closer attention to overloading, tools like these are quickly becoming essential. They not only prevent fines and downtime but also help keep staff and other road users safe.

A spokesperson for VanWeigh said: “Overloading is still one of the biggest risks for operators, especially in scaffolding where loads change from job to job. Our system gives drivers a clear picture of what’s happening with their vehicle before they leave site. It’s about making life easier, safer and more compliant.”

By fitting onboard weighing systems, scaffolding firms can avoid penalties, protect their reputation, and keep their vehicles running safely and legally. PERI UP system supports cladding remediation at Hilton Hotel

For the first lift, engineers combined PERI UP Easy with Flex components to create the necessary clearance. This allowed subsequent two-metre Easy lifts to be safely installed around the rest of the structure.

A hybrid approach was also adopted at the rear of the building, where air vents and shafts had to remain accessible. Here, PERI UP was combined with traditional tube-and-fitting beams to maintain continuous access while spanning the obstacles.

Thomas Bellis, Design Manager and Senior Scaffold Design Engineer at PSD, said the project demonstrated the versatility and engineering advantages of the PERI UP Easy system.

For the first lift, engineers combined PERI UP Easy with Flex components to create the necessary clearance. This allowed subsequent two-metre Easy lifts to be safely installed around the rest of the structure.

A hybrid approach was also adopted at the rear of the building, where air vents and shafts had to remain accessible. Here, PERI UP was combined with traditional tube-and-fitting beams to maintain continuous access while spanning the obstacles.

Thomas Bellis, Design Manager and Senior Scaffold Design Engineer at PSD, said the project demonstrated the versatility and engineering advantages of the PERI UP Easy system.

“The system’s wide range of compatible components enabled us to develop a scaffold layout that was not only structurally robust but also efficient to configure around the changing building profile,” he explained. “We were able to adapt quickly to evolving requirements without compromising safety or buildability.”

The project highlights how modern system scaffolding can combine modular design with adaptable engineering to meet the challenges of complex refurbishment work while maintaining full site safety and operational access.

“The system’s wide range of compatible components enabled us to develop a scaffold layout that was not only structurally robust but also efficient to configure around the changing building profile,” he explained. “We were able to adapt quickly to evolving requirements without compromising safety or buildability.”

The project highlights how modern system scaffolding can combine modular design with adaptable engineering to meet the challenges of complex refurbishment work while maintaining full site safety and operational access. Midland Scaffolding staff go the distance in charity challenge for Poppy

Midland Scaffolding Services (MSS) has raised an impressive £20,000 for Caudwell Children after completing a gruelling ultra-marathon challenge from Birmingham to Northampton.

The event named “50 Miles for Poppy” was inspired by baby Poppy, daughter of MSS colleague Gary Rouse, who was born with Down syndrome and a heart condition requiring major surgery earlier this year.

Led by MSS Contracts Director Ben Ekins and Estimator Jordan Harrison, the pair completed the 50-mile run, cheered on by family, friends, and supporters as they crossed the finish line at a special family fun day at Northampton Town Football Club.

The challenge brought together staff, suppliers, and customers who donated money, raffle prizes, and time to support the cause, helping the company smash its fundraising target.

Gary, who has worked at MSS for several years, said: “It’s a fantastic achievement — thank you all very much. It’s been a tough year for me and my family, but we battle on every day. I must say a massive thank you to MSS, they’ve supported me all this year and helped me out more than I could have possibly imagined.”

He added that Poppy is now recovering well from her operation: “She’s a really special part of our family, and we all love her to the moon and back.”

After crossing the finish line, Ben said: “Now I’ve completed the ultra-marathon, I’m very tired, very sore and quite emotional. But it’s been a massive achievement, and I am very proud of what we’ve done.”

Jordan added, “The running was pretty hard. I feel emotional, but it’s all for a great cause, so I’m happy.”

Caudwell Children’s Marketing Operations Manager, Amy Helliwell, praised the company’s efforts:

“A huge thank you to Ben, Jordan, everybody at Midland Scaffolding Services and to everyone who donated. It’s incredible they ran 50 miles all in aid of Caudwell Children. Their passion and commitment show the real power of community in helping children and families thrive.”

In recognition of their efforts, Caudwell Children presented MSS with its Fundraising for Change award.

Amie Bailey, Commercial Director at MSS, said the team’s achievement reflected the company’s strong sense of community and teamwork: “It’s fantastic to receive the award from the charity in recognition of everyone’s efforts. We would like to thank all our customers and suppliers who donated prizes and helped us reach the £20,000 target. We couldn’t ask for better people to be surrounding us and Gary’s family.”

Funds raised will go towards supporting disabled and neurodivergent children and their families through Caudwell Children — including Poppy and the Rouse family.

Donations can still be made at 50 Miles for Poppy – fundraising for Caudwell Children.

AT-PAC names new UK MD as ScaffEx25 showcases national ambitions

After unveiling a wave of new systems at Bauma 2025, AT-PAC used ScaffEx25 in Manchester to shift focus closer to home, demonstrating its UK capability, setting out a clear national service promise, and introducing Charles Stratford as its new Managing Director for the UK.

Earlier this year, Scaffmag reported from Bauma, where AT-PAC showcased a series of new modular systems, including MPBS, the PAS Escape Stair, and Ringshore. Sharing a joint stand with Doka, the display was dominated by a 30-metre Ringlock tower, underlining AT-PAC’s role within umdasch Industrial Solutions and its ambition to become one of the world’s top three scaffolding brands. At ScaffEx25, the focus was different. Rather than a global pitch, the company used the UK’s largest scaffolding event to show how that innovation translates into delivery on the ground. Andrew Boynton, who has been with AT-PAC for a decade and previously served as Managing Director of the UK business, has now stepped up to become Regional Director for Europe. Speaking at the show, he told Scaffmag that ScaffEx25 “came at exactly the right time.” It allowed AT-PAC to demonstrate its systems, people, and vision directly to the UK market, while connecting to its broader European strategy of opening new branches and staying closer to customers. His own move into the European role reflects that focus. Appointing Charles Stratford to lead AT-PAC UK, he added, is “key to ensuring we translate those ambitions into consistent, reliable delivery.”A milestone moment for UK operations

For Stratford, the event doubled as an introduction. “ScaffEx25 was a milestone,” he said. “It gave AT-PAC the platform to show not only our product range, from Ringlock to MPBS and our Public Access System, but also the strength of our team and our ability to support the UK industry nationwide.” Many visitors, he noted, were seeing how far AT-PAC had advanced in the UK for the first time. “It underlined our commitment to being a long-term partner in an ever-changing scaffolding landscape, with the right people, the right product and the right commercial offerings to support the scaffolding sector.” Stratford joins AT-PAC from PERI UK, where he worked as Sales and Business Development Manager. He describes his approach as an “outside-in” perspective, shaped by experience both on the operational side and in client-facing roles. “From the outside, AT-PAC always stood out for its strong business model, proven products and consistent growth,” he said. “My role now is to build on that foundation while strengthening an already outstanding team with respected industry professionals and ensuring we scale in a way that delivers predictable, nationwide coverage.”

The year ahead

Stratford is clear about his headline goal: “Nationwide coverage, zero excuses.” He breaks that down into four priorities:- Stock where the work is – repositioning inventory so key hubs and industrial corridors are always within rapid-response range.

- Engineering at speed – fast-turn temporary works and application design, backed by standardised calculation packs.

- Digital transparency – giving customers real-time visibility of kit availability, order status and compliance documents.

- One safety standard – applying the same procedures whether on a public access job or a heavy industrial scaffold.