With the scaffolding industry at a pivotal point of change, ScaffMag sat down with Mark Parkin — newly appointed Strategic Director of the Scaffolding Association — to explore his remarkable journey, his vision for the future, and why now is the time for the industry to think bigger, act smarter, and work closer together.

From humble beginnings to global influence, Mark’s story is a powerful testament to the values that continue to shape scaffolding today.

Growing up in Whitby, North Yorkshire, Mark Parkin never planned to spend his life in scaffolding. His dream was to become a cabinet maker, crafting timber into something lasting and beautiful. Working with wood, creating objects with meaning—that was the life he envisioned.

Fate, however, and a hard conversation with his scaffolder father, set him on a very different path.

Mark vividly remembers the day that changed everything. After mentioning he’d be applying for a woodworking job “next week,” his father asked a simple but profound question: “Where will you live until then?”

What followed was a conversation that would stick with Mark for the rest of his life—a sharp reminder of responsibility, gratitude, and growing up. His father spoke about the years spent supporting Mark through thick and thin, about the 12 days he spent by his son’s bedside after a near-fatal hit-and-run accident at the age of five.

“There was an easy way to learn things, and a hard way,” his father said. “Sometimes you have to learn the hard way to find the easy way.”

The next morning, Mark walked for over an hour through the rain to meet John Crosby, a family friend, at Whitby Golf Club. A tap on the shoulder, a short conversation, and a job offer. Soaked to the bone but filled with a new sense of purpose, Mark returned home—and into the world of scaffolding.

That long, wet walk marked the beginning of a journey that would shape the rest of his life.

A Brotherhood Forged in Steel

From his first lift to executive leadership roles, Mark’s career has been built on three core values: respect, pride, and purpose.

“This industry teaches you to stand tall, literally and metaphorically,” he says. “Every gang is a brotherhood. Every scaffold, every job, you earn your stripes.”

The early days were tough, but they were formative. Mark learned the trade the traditional way—boots on the ground, shoulder to shoulder with the old-school grafters who didn’t just build scaffolds, they built standards.

It wasn’t just a job. It was a culture. A code.

Respect was earned, not given, and every mistake was a lesson you carried with you. It’s a foundation that’s never left him, no matter how high he’s climbed.

Mark worked his way up through the ranks: advanced scaffolder, supervisor, operations manager, managing director, CEO. But it wasn’t just titles he collected—it was a deep, nuanced understanding of the industry and its people.

“You can’t truly lead an industry like this unless you’ve lived and breathed it,” he reflects. “When you’ve hauled tubes in freezing rain, when you’ve built structures in impossible conditions—that’s where real leadership is forged.”

Along the way, he developed a leadership philosophy he now calls the

LUST Mindset:

Listen, Understand, Structure, Teach.

It’s a simple yet profound approach that starts on-site, not in the boardroom.

“You start by truly listening,” he explains. “Then you work to understand, not assume. Only then can you build real structures—whether that’s scaffolds, systems, or teams. And finally, you pass it on. You teach. That’s how the industry grows.”

Lessons from the Hard Way

Mark’s story isn’t a glossy highlight reel. He openly discusses the mistakes, setbacks, and lonely moments that have shaped him.

When he launched his first business, he admits, he did it without a mentor, without a strong support system, and without fully understanding what was ahead.

“I was full of energy and ambition,” he says. “But passion alone isn’t enough. You need structure, strategy, and people you can trust.”

He describes those years as the toughest and most educational of his life. It’s why, today, he champions the importance of mentorship, and why he sees experience, not perfection, as the real marker of wisdom.

“If I ever write a book, it’ll be called

For All the Wrong Reasons,” he laughs. “Because I learned all the right lessons the hard way.”

These hard-won lessons have become the bedrock of his leadership style: open, honest, and relentlessly focused on lifting others up.

A New Chapter: Strategic Director

When the opportunity arose to become Strategic Director of the Scaffolding Association, Mark didn’t hesitate.

It was more than a new role; it was a natural extension of the work he was already doing through the Global Scaffolding Alliance—an international movement bringing together industry leaders from the UK, Europe, Australia, North America, the Middle East, and beyond.

“What started as conversations has become a true global network,” Mark says. “No matter where you go, the challenges are the same: training gaps, safety standards, respect for the trade. But the solutions come faster when we work together.”

Now, at the Scaffolding Association, Mark is determined to bring those global insights home. His goal? To future-proof the industry by making it more connected, more innovative, and more respected.

“This isn’t about lifting structures. It’s about lifting people, standards, and opportunities.”

His passion is palpable. Whether he’s talking about smarter training, streamlined systems, or building a new generation of leaders, Mark’s vision is bold and clear.

Reforming Training, Reshaping the Future

One of Mark’s first priorities is reforming the training system.

While the UK’s commitment to safety and structure is strong, he argues that scaffolding training needs to be faster, sharper, and more aligned with the realities of today’s sites.

“We’re still teaching techniques that scaffolders will never use again, like putlog scaffolds and raking shores,” he says. “We need to focus on practical, site-ready skills. Every hour in a training centre should bring a scaffolder closer to being promotion-ready, not just site-ready.”

It’s a call for action, not criticism. Mark sees this as one of the greatest opportunities to attract and retain new talent—and to ensure scaffolders feel confident, respected, and future-proofed from the start.

“If we modernise training and build clear career paths, we’ll not just fill the skills gap. We’ll create a new generation of leaders.”

Innovation as the Lifeblood of Progress

Mark is a strong advocate for embracing innovation, and not just for innovation’s sake.

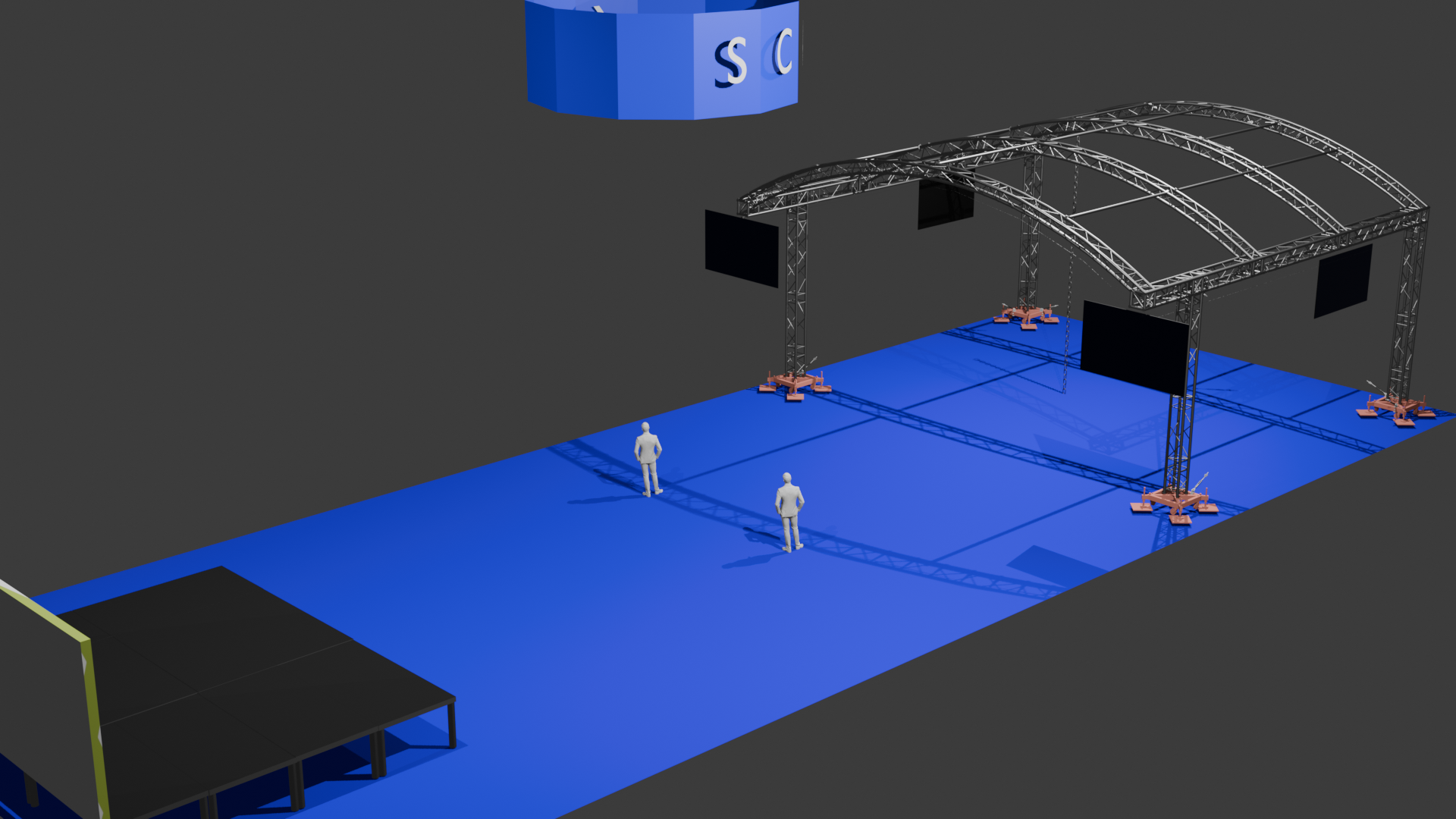

He points to game-changing technologies like ScaffPlan (for digital scaffold design) and Rise VR (for immersive training) as examples of tools already reshaping the industry.

But he’s quick to add: Innovation isn’t just about tech.

“It’s about mindset,” he says. “It’s about asking: is there a smarter, safer, better way to do this?”

He sees the Scaffolding Association playing a crucial role in helping companies, big and small, access the tools, training, and support they need to innovate confidently, not fearfully.

“Technology should feel like an upgrade, not an obstacle,” Mark says. “And if we get it right, it’ll lift everything—safety, profits, morale, and respect for the trade.”

Building a Stronger, More Connected Industry

Looking ahead, Mark’s vision is rooted in collaboration.

Over the next 12 months, he hopes to help break down barriers between organisations, unify scaffolding professionals under a shared mission, and create new pathways for small and independent firms to thrive.

“I want scaffolders to feel seen, supported, and proud,” he says. “Because when you lift people, you lift the whole industry.”

And when asked what he hopes his impact will be?

Mark doesn’t talk about awards or legacy projects.

He talks about opening doors.

“I’m not here to carve my name into the side of a building. I’m here to create momentum—to open the door wider for the next generation.”

Advice for the Next Generation

If he could give one piece of advice to someone starting out in scaffolding today, it would be simple:

“Find a mentor. Surround yourself with people who will challenge you, guide you, and believe in you.”

And never stop learning.

“In scaffolding, you never stop learning. Stay curious. Stay humble. And always ask questions. That’s how you build a career—not just with tools and tubes, but with trust, teamwork, and time.”

It’s a philosophy born from the rain-soaked streets of Whitby, tempered on windswept sites across the UK, and now set to shape the future of scaffolding for years to come

ScaffCycle enters the market at a time when sustainability is high on the agenda for the construction and access industries. Thousands of tonnes of scaffolding are scrapped annually due to overstock or logistical challenges, despite being in usable condition.

According to research from the Carbon Trust, reusing scaffolding materials can reduce associated carbon emissions by up to 85% compared to buying new.

“The construction sector has a huge opportunity to lead the shift to a circular economy,” said Keith James, Head of Public Sector Partnerships at WRAP.

“Platforms like ScaffCycle help reduce waste and environmental impact while offering clear financial benefits.”

ScaffCycle enters the market at a time when sustainability is high on the agenda for the construction and access industries. Thousands of tonnes of scaffolding are scrapped annually due to overstock or logistical challenges, despite being in usable condition.

According to research from the Carbon Trust, reusing scaffolding materials can reduce associated carbon emissions by up to 85% compared to buying new.

“The construction sector has a huge opportunity to lead the shift to a circular economy,” said Keith James, Head of Public Sector Partnerships at WRAP.

“Platforms like ScaffCycle help reduce waste and environmental impact while offering clear financial benefits.”

One unexpected highlight was an on-the-spot decision during the dismantling phase. “We tried a new technique mid-round, something we hadn’t rehearsed. It came from instinct and experience, and it worked so well that other teams started copying it. That moment said a lot about who we are.”

This year wasn’t RNDV’s first ScaffChamp. They debuted in 2024 and came fourth, a strong start that fuelled their determination to improve. “We took the lessons seriously. We reviewed everything, from blueprint interpretation to time management, and adjusted our training approach for 2025. Nothing was left to chance.”

One unexpected highlight was an on-the-spot decision during the dismantling phase. “We tried a new technique mid-round, something we hadn’t rehearsed. It came from instinct and experience, and it worked so well that other teams started copying it. That moment said a lot about who we are.”

This year wasn’t RNDV’s first ScaffChamp. They debuted in 2024 and came fourth, a strong start that fuelled their determination to improve. “We took the lessons seriously. We reviewed everything, from blueprint interpretation to time management, and adjusted our training approach for 2025. Nothing was left to chance.”

He said the win had boosted morale and reinforced what they stand for. “It’s one thing to be valued by your company, but to be recognised by the wider industry – that’s powerful. It shows that our standards, our work ethic, our culture, they’re visible beyond our own sites.”

He said the win had boosted morale and reinforced what they stand for. “It’s one thing to be valued by your company, but to be recognised by the wider industry – that’s powerful. It shows that our standards, our work ethic, our culture, they’re visible beyond our own sites.”

So what’s next? RNDV say they’ll be back in 2026 and ready to defend their title. “We know the bar is now higher, but we’re ready for the challenge.”

Vitkevicius also offered some advice for any teams thinking of entering for the first time: “Approach it like a real championship. Train hard, build cohesion, and don’t cut corners on preparation. But also – enjoy it.

It’s more than a competition. It’s a celebration of our craft. Whether you come to win or just to be part of it, it’s an experience you won’t forget.”

So what’s next? RNDV say they’ll be back in 2026 and ready to defend their title. “We know the bar is now higher, but we’re ready for the challenge.”

Vitkevicius also offered some advice for any teams thinking of entering for the first time: “Approach it like a real championship. Train hard, build cohesion, and don’t cut corners on preparation. But also – enjoy it.

It’s more than a competition. It’s a celebration of our craft. Whether you come to win or just to be part of it, it’s an experience you won’t forget.”

“It was a well-attended event that

“It was a well-attended event that

When the opportunity arose to become Strategic Director of the Scaffolding Association, Mark didn’t hesitate.

It was more than a new role; it was a natural extension of the work he was already doing through the Global Scaffolding Alliance—an international movement bringing together industry leaders from the UK, Europe, Australia, North America, the Middle East, and beyond.

“What started as conversations has become a true global network,” Mark says. “No matter where you go, the challenges are the same: training gaps, safety standards, respect for the trade. But the solutions come faster when we work together.”

Now, at the Scaffolding Association, Mark is determined to bring those global insights home. His goal? To future-proof the industry by making it more connected, more innovative, and more respected.

“This isn’t about lifting structures. It’s about lifting people, standards, and opportunities.”

His passion is palpable. Whether he’s talking about smarter training, streamlined systems, or building a new generation of leaders, Mark’s vision is bold and clear.

When the opportunity arose to become Strategic Director of the Scaffolding Association, Mark didn’t hesitate.

It was more than a new role; it was a natural extension of the work he was already doing through the Global Scaffolding Alliance—an international movement bringing together industry leaders from the UK, Europe, Australia, North America, the Middle East, and beyond.

“What started as conversations has become a true global network,” Mark says. “No matter where you go, the challenges are the same: training gaps, safety standards, respect for the trade. But the solutions come faster when we work together.”

Now, at the Scaffolding Association, Mark is determined to bring those global insights home. His goal? To future-proof the industry by making it more connected, more innovative, and more respected.

“This isn’t about lifting structures. It’s about lifting people, standards, and opportunities.”

His passion is palpable. Whether he’s talking about smarter training, streamlined systems, or building a new generation of leaders, Mark’s vision is bold and clear.

“We’re still teaching techniques that scaffolders will never use again, like putlog scaffolds and raking shores,” he says. “We need to focus on practical, site-ready skills. Every hour in a training centre should bring a scaffolder closer to being promotion-ready, not just site-ready.”

It’s a call for action, not criticism. Mark sees this as one of the greatest opportunities to attract and retain new talent—and to ensure scaffolders feel confident, respected, and future-proofed from the start.

“If we modernise training and build clear career paths, we’ll not just fill the skills gap. We’ll create a new generation of leaders.”

“We’re still teaching techniques that scaffolders will never use again, like putlog scaffolds and raking shores,” he says. “We need to focus on practical, site-ready skills. Every hour in a training centre should bring a scaffolder closer to being promotion-ready, not just site-ready.”

It’s a call for action, not criticism. Mark sees this as one of the greatest opportunities to attract and retain new talent—and to ensure scaffolders feel confident, respected, and future-proofed from the start.

“If we modernise training and build clear career paths, we’ll not just fill the skills gap. We’ll create a new generation of leaders.”