The National Access & Scaffolding Confederation and Construction Industry Scaffolders Record Scheme have signed their first-ever national licensing agreement with an entire country, marking a significant step in the international rollout of UK scaffolding standards.

The agreement follows Malaysia’s formal adoption of NASC’s TG20 guidance into law in 2024. The country’s Department of Occupational Safety and Health (DOSH) also formally recognises NASC standards, providing a regulatory foundation for the partnership.

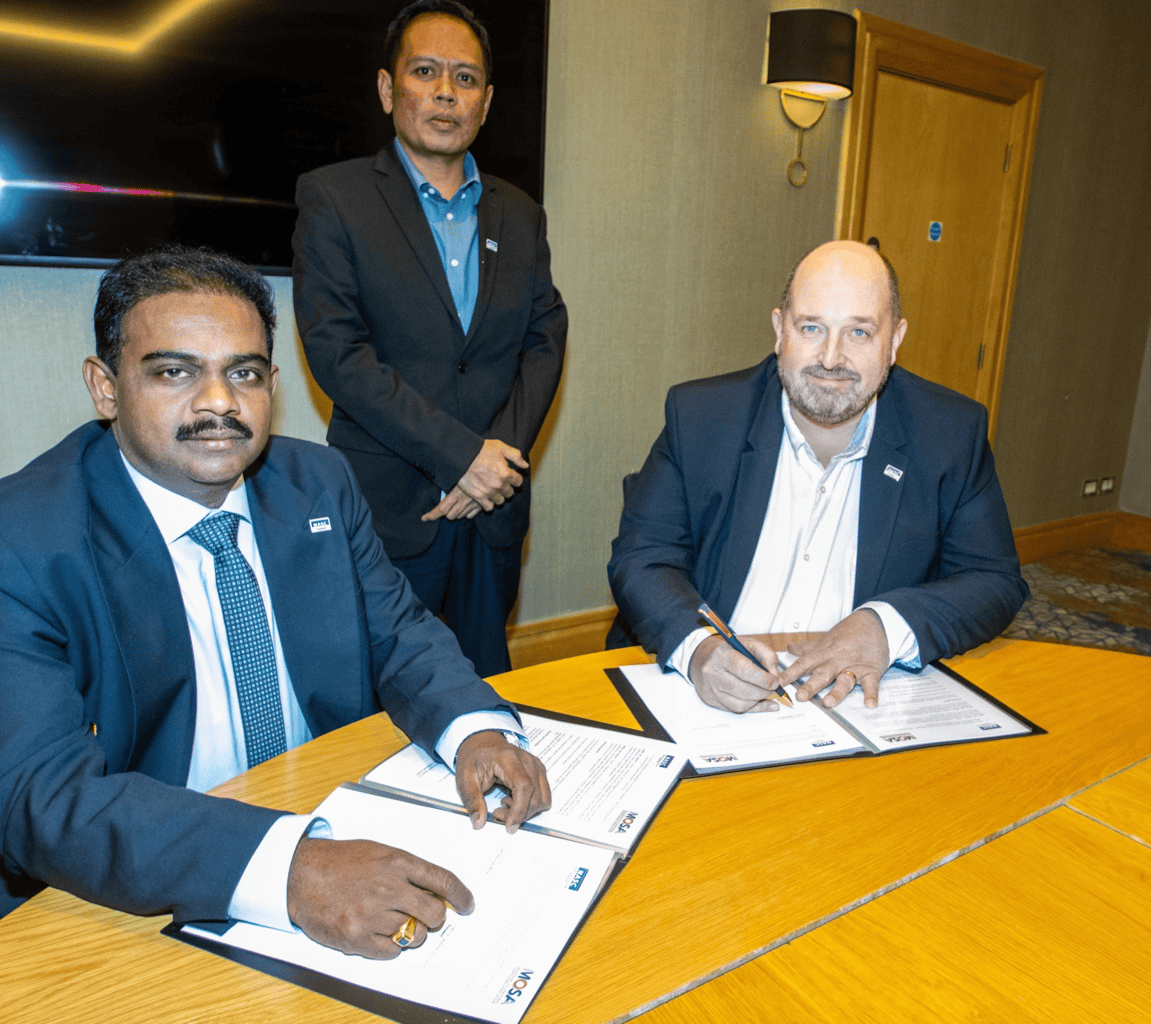

The deal builds on a Memorandum of Understanding signed in 2025 between NASC and the Malaysian Occupational Scaffolding Association (MOSA).

Under the agreement, MOSA will deliver the NASC TG20 and TG30 ePortal systems, alongside CISRS training and certification, under licence across Malaysia.

NASC and CISRS will retain oversight through an audit and assurance regime, as MOSA works towards establishing up to 40 licensed centres nationwide.

Clive Dickin, Group CEO of NASC, said the agreement reflected “the strength of our systems and the international confidence in TG20, TG30 and CISRS”.

“We are absolutely delighted to formalise this partnership with MOSA and to extend NASC and CISRS standards into Malaysia under our first national licensing arrangement,” he said.

“The fact that TG20 has already been written into Malaysian law, and that DOSH recognises NASC standards, speaks volumes about the credibility of our guidance.

“This agreement reflects our shared commitment to raising scaffolding and access standards globally.”

Dato’ Dr. Saravanan Karrupayah, representing MOSA, described NASC as “the gold standard for scaffolding guidance and governance” and CISRS as “the world’s most respected scaffolder training and certification scheme”.

He said the partnership would elevate safety, competence, and professionalism across Malaysia’s scaffolding sector.

The framework will allow Malaysian asset owners, principal contractors and scaffolding providers to operate under a single national standard for scaffold design, erection, inspection and training.

TG20 will continue to govern tube-and-fitting scaffolds, while TG30 supports compliance for system scaffolds. Together, the standards provide a structured pathway for competence assurance across complex access works.

Members of NASC, CISRS and MOSA will receive preferential access and pricing under the licence. Non-members will still be able to access the services, but at higher commercial rates.

NASC indicated the Malaysian model could be replicated in other territories, alongside its existing CISRS international delivery arrangements.

The AFIXFAST X37 system received NF certification in France in 2022 through Afnor Certification, while the X52 system has now been formally approved in Germany.

He said the extensive testing and audit programme meant the technical data for AFIXFAST X52 had been independently validated, giving engineers and clients confidence that structural calculations are fully substantiated.

“This validation is a fundamental prerequisite for the safety of temporary structures,” he said.

The new German branch will support customers across Germany, Austria, and Switzerland, supplying system scaffolds and compatible solutions for scaffolding, stages, and grandstands.

Operations will be led by Christian Spies, managing director of AFIX GmbH, who brings extensive experience and regional industry contacts.

He said the DIBt approval would act as a gateway to wider market adoption, supported by local sales, service, and logistics.

Through its AFIX Finance unit, the group will also offer purchase, rental and tailored financing options, including export-backed funding solutions for customers in the DACH market.

The AFIXFAST X37 system received NF certification in France in 2022 through Afnor Certification, while the X52 system has now been formally approved in Germany.

He said the extensive testing and audit programme meant the technical data for AFIXFAST X52 had been independently validated, giving engineers and clients confidence that structural calculations are fully substantiated.

“This validation is a fundamental prerequisite for the safety of temporary structures,” he said.

The new German branch will support customers across Germany, Austria, and Switzerland, supplying system scaffolds and compatible solutions for scaffolding, stages, and grandstands.

Operations will be led by Christian Spies, managing director of AFIX GmbH, who brings extensive experience and regional industry contacts.

He said the DIBt approval would act as a gateway to wider market adoption, supported by local sales, service, and logistics.

Through its AFIX Finance unit, the group will also offer purchase, rental and tailored financing options, including export-backed funding solutions for customers in the DACH market.

Asia will again be represented by Mongolia, a returning team that has proved popular with spectators in previous editions.

Despite strong interest, no African team will take part in 2026. Organisers said discussions had taken place with teams from the region and expressed hope that Africa would be represented at a future event.

While organisers have confirmed which countries will be represented, individual company names have not yet been released.

With less than 120 days to go, ticket sales are already underway. Capacity is limited due to venue and crowd safety requirements, and organisers have warned that tickets could sell out. Discount codes are expected to be released through event partners in the run-up to the competition.

Asia will again be represented by Mongolia, a returning team that has proved popular with spectators in previous editions.

Despite strong interest, no African team will take part in 2026. Organisers said discussions had taken place with teams from the region and expressed hope that Africa would be represented at a future event.

While organisers have confirmed which countries will be represented, individual company names have not yet been released.

With less than 120 days to go, ticket sales are already underway. Capacity is limited due to venue and crowd safety requirements, and organisers have warned that tickets could sell out. Discount codes are expected to be released through event partners in the run-up to the competition.

For the scaffolding and access sector, the forecast points to a sustained uplift in workload from 2026, particularly from housing starts, civil engineering schemes, utilities projects and refurbishment-led commercial work.

Longer-term infrastructure programmes and increased public sector investment are expected to shape workload profiles across the supply chain as construction activity gathers pace through 2026 and 2027.

Glenigan said firms that align resources with sectors showing the strongest growth, while managing risks around skills availability, costs and planning delays, are best placed to benefit from the recovery.

For the scaffolding and access sector, the forecast points to a sustained uplift in workload from 2026, particularly from housing starts, civil engineering schemes, utilities projects and refurbishment-led commercial work.

Longer-term infrastructure programmes and increased public sector investment are expected to shape workload profiles across the supply chain as construction activity gathers pace through 2026 and 2027.

Glenigan said firms that align resources with sectors showing the strongest growth, while managing risks around skills availability, costs and planning delays, are best placed to benefit from the recovery.