- Ground investigations to assess load-bearing capacity

- Installation of compacted hardcore for kentledge

- Redesign of beam supports due to hollow roof parapets

- Steel RSJ installation to take the lateral load and tie back to the internal structure

South Molton Scaffolding Delivers Complex Temporary Roof Project

Scaffolding Boss to Auction Scotland’s Top Sports Memorabilia Collection for Charity

He added that the auction is not just about raising money, but about honouring the people who helped him and his business over the years.

“The auction will raise funds for the Emmie Smillie Foundation, in memory of a wonderful young girl whose father, Andy, helped us start our company. We’re also supporting MND Scotland in tribute to Aaron Souttar. His parents, Jack and Heather, are dear friends.”

The auction, run by Blue Parrot Events Group via their Event PAL platform, will take place online for two weeks from Monday, 30 June.

To view the items and place a bid, visit: weareeventpal.com/jrgroup – donations to the charities can also be made directly via the site.

He added that the auction is not just about raising money, but about honouring the people who helped him and his business over the years.

“The auction will raise funds for the Emmie Smillie Foundation, in memory of a wonderful young girl whose father, Andy, helped us start our company. We’re also supporting MND Scotland in tribute to Aaron Souttar. His parents, Jack and Heather, are dear friends.”

The auction, run by Blue Parrot Events Group via their Event PAL platform, will take place online for two weeks from Monday, 30 June.

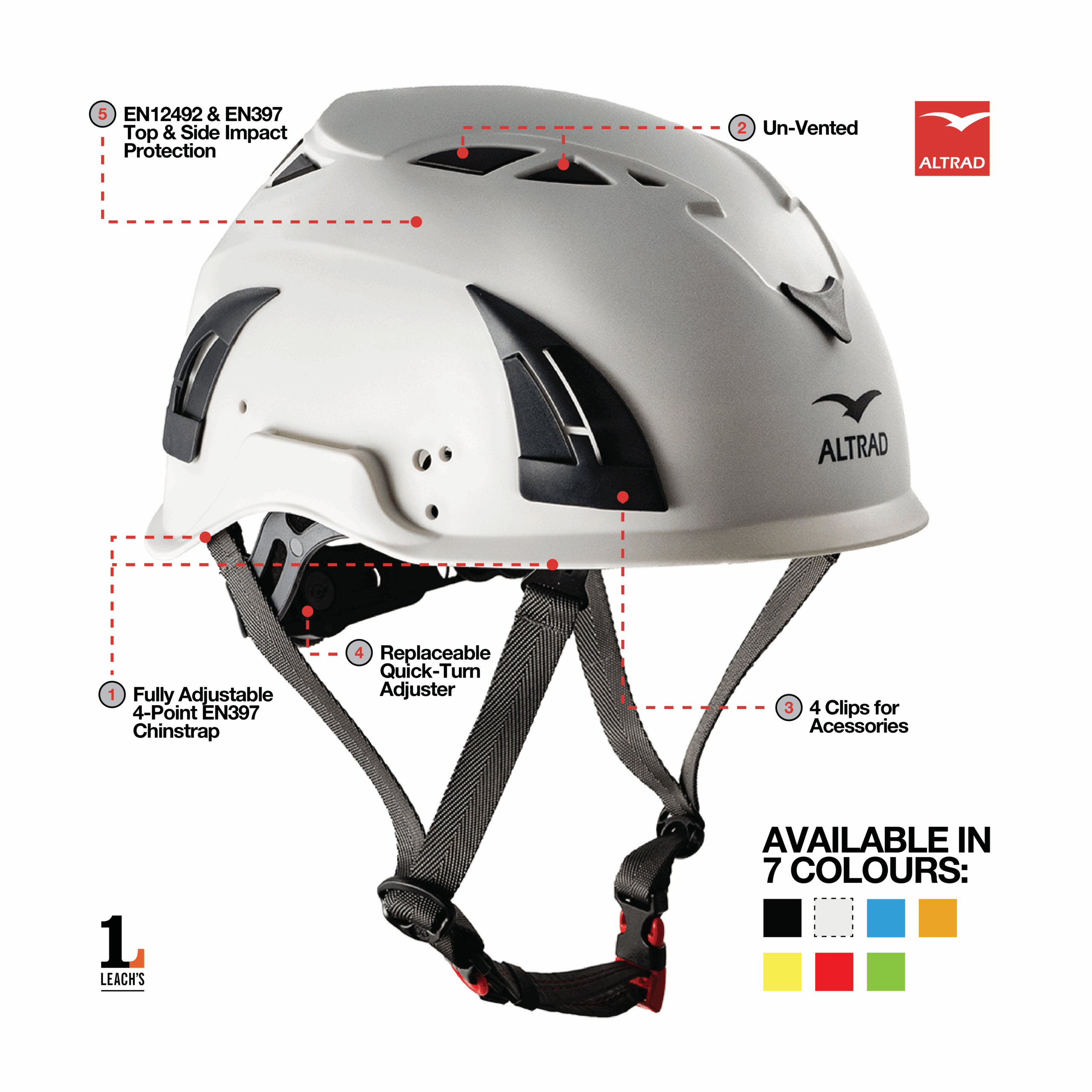

To view the items and place a bid, visit: weareeventpal.com/jrgroup – donations to the charities can also be made directly via the site. Altrad Teams Up with Leach’s to Boost Helmet Safety for Scaffolders

Altrad, one of the world’s leading industrial services providers, has collaborated with specialist supplier Leach’s to upgrade helmet safety for its scaffolding workforce.

The partnership has led to the development of a new high-specification helmet, designed to offer better protection, comfort and visibility on site.

The rollout follows months of design improvements, testing, and collaboration between Altrad’s Technical Authorities and Leach’s, the well-known UK-based firm with over 100 years of expertise in height safety.

Altrad, which employs more than 65,000 people globally and operates across 59 countries, first approached Leach’s in September 2023 seeking a better-styled helmet tailored to the needs of its scaffolding teams.

By May 2025, Leach’s had finalised a revamped design incorporating an upgraded chin strap, improved performance features, and a more modern look aligned with Altrad’s branding. The company worked directly with the helmet manufacturer to ensure the final product met strict safety standards.

Adrian Tennent, Global Sales Manager at Leach’s, said: “This is what it’s all about – identifying a problem and then finding a solution.

Leach’s was born with the ethos of making scaffolding safer, so this is where our passion lies. We feel very privileged to be part of such a rewarding and exciting project and thank Altrad for approaching and trusting us.”

The newly developed helmets have now been distributed to Altrad’s UK scaffolding workforce, with initial feedback reported to be extremely positive.

The move is part of Altrad’s broader commitment to safety and innovation across its global operations, and further cements Leach’s position as a trusted partner for height safety solutions worldwide.

Construction Skills Drive Targets 100,000 New Recruits

A new Construction Skills Mission Board meets for the first time today with an ambitious aim of attracting 100,000 new workers into the industry.

Co-chaired by Deputy Prime Minister Angela Rayner and Mark Reynolds, Co-Chair of the Construction Leadership Council, the board will spearhead efforts to tackle labour shortages and future-proof the workforce.

The board will work closely with industry leaders and government departments to develop initiatives that encourage recruitment, training, and long-term careers in construction. It will focus on five key areas:

-

Boosting confidence to employ and invest

-

Creating clear pathways for new entrants

-

Improving access to training and support

-

Developing more effective funding mechanisms

-

Promoting construction as a reliable and rewarding career

The Department for Work and Pensions has also announced that Jobcentres will strengthen their links with construction employers, helping jobseekers access work experience and tailored placements.

Education Secretary Bridget Phillipson said: “The construction sector is on the frontline in our mission to grow the economy, giving more people skilled jobs building the homes and infrastructure we need.

The Construction Skills Mission Board will make sure we hear directly from employers about what their skills needs are, driving our reforms and helping more young people achieve and thrive.”

From August, a new wave of construction foundation apprenticeships will launch as part of the government’s Youth Guarantee initiative. Backed by an additional £40 million in funding, the programme will offer practical, early-career training in trades such as bricklaying and carpentry.

Mark Reynolds said: “The Construction Skills Mission Board represents a new partnership between industry and government, working together to find industry-led, collaborative solutions to delivering the workforce of the future.

I am delighted that we have seen such strong support from Ministers and some of the most important leaders in our sector – and I hope everyone will play their part in the delivery of this essential mission.”

The board’s launch follows growing concerns across the construction sector about an ageing workforce and increasing demand for skilled labour.

The new initiatives are designed to bridge the skills gap and build a pipeline of talent equipped to support the UK’s long-term housing and infrastructure goals.

Scaffolding Team Raises Over £36K for Cancer Charity with West Highland Way Trek

A team from Scottish scaffolding business JR Scaffold has raised more than £36,000 for a cancer charity after completing the West Highland Way.

Led by managing director John Horne, five team members walked the full 96-mile route from Milngavie to Fort William in aid of the Emmie Smillie Foundation. The six-day trek raised £36,850 for the charity, which supports cancer patients and care facilities across Glasgow and the Central Belt.

The group included father and son James Martin Sr and Jr, Gordon Davidson, and Andrew Simpson. They took on the challenge to mark JR Scaffold’s 30th anniversary and to honour a long-standing connection with the Smillie family.

“This was about much more than just completing a walking challenge,” said Mr Horne. “It was about honouring a remarkable young woman, supporting families facing cancer, and giving something meaningful back in our anniversary year.”

The Emmie Smillie Foundation was set up in 2016 in memory of Emmie Smillie. Her father, Andy Smillie, who founded the charity, praised the team’s efforts.

“Their drive, their heart, and their endurance have helped raise vital funds and awareness for the work we do in Emmie’s memory,” he said. “Every pound raised will go directly to supporting cancer patients and families when they need it most.”

Mr Horne said the trek was challenging but the group was kept going by “camaraderie and a sense of purpose”.

Founded in Govan in 1995, JR Scaffold is part of The JR Group and now employs around 200 staff. The business has grown to become one of Scotland’s largest construction firms, working across the country and in northern England.

Mr Horne added: “Community support and giving back have always been part of our DNA. I couldn’t be prouder of what we’ve done together – and we’re just getting started.”

ITP launches ‘Zero to Landfill’ scheme to recycle scaffold sheeting

A Yorkshire-based manufacturer has launched a new initiative to stop end-of-life scaffold sheeting ending up in landfill.

Industrial Textiles and Plastics (ITP) Ltd, based in Easingwold, North Yorkshire, has unveiled its Zero to Landfill programme in partnership with secure waste management specialist Avena.

The scheme allows customers to return used scaffold sheeting for environmentally responsible disposal through repurposing, remanufacturing, or energy recovery.

The move is part of ITP’s wider commitment to reducing carbon emissions and waste across the construction industry.

Carl Morse, Managing Director of ITP, said: “Around 350,000 tonnes of textiles are sent to landfill each year, producing more than 26 million tonnes of CO2. Construction is a major consumer of energy and raw materials, and we have a responsibility to do better.

Our Powerclad scaffold sheeting is made from 100% polyolefin, which can be diverted from landfill and reused or converted into energy. This programme helps our clients contribute to that mission.”

Under the scheme, Avena will collect scaffold sheeting from ITP’s customers, transport it to dedicated facilities, and track its disposal. Customers will receive certificates of destruction and detailed reports showing the carbon savings achieved.

“Around 350,000 tonnes of textiles are sent to landfill each year, producing more than 26 million tonnes of CO2.”

Recyclable material will be assessed by plastics reprocessing firm Vanden, which will match it with approved recycling partners in the UK and abroad.

ITP Sales Director, Matt Thompson, added: “Scaffold contractors and suppliers who participate in the scheme are not only helping the environment, but also gaining certified evidence of their sustainability efforts. This supports clients’ own environmental policies and reporting.”

ITP manufactures a wide range of protective construction textiles, including debris netting, sound barrier sheeting, insulated coverings, and printed scaffold wraps. All production is carried out in-house at its North Yorkshire facility.

The company says the Zero to Landfill programme reflects its ongoing aim to help drive sustainability across the supply chain.

Scaffolder wins record-breaking £11.5m jackpot from £1.50 bet

A scaffolder from Norfolk has become one of the UK’s biggest-ever online gambling winners after scooping a record £11.5 million jackpot from a £1.50 stake.

Arron Freeman, 44, who runs ASL Scaffolding, landed the life-changing sum while playing the popular Mega Moolah slot game on Betfred’s online platform.

The win, which took place on 5 June, is the largest in Betfred’s 58-year history.

Speaking to the Eastern Daily Press, Freeman said he was still coming to terms with the shock of the win and hinted at plans to give back: “I am in shock, but I am not gonna say too much at the minute.”

He added that proceeds from selling his story would be used to help build a homeless shelter.

Freeman’s partner, Kelly Dighton, has publicly documented her personal recovery journey on social media, and the couple are reportedly considering a holiday while they plan their next steps.

A close friend, who asked not to be named, said the win had left Freeman “in shock” and described the payout as “life-changing”.

Betfred founder Fred Done personally called Freeman to congratulate him, offering VIP hospitality at a Manchester United match.

“He’s a sensible chap and is planning to invest some of his winnings into property for his family,” Mr Done told the Eastern Daily Press. “But not before enjoying a holiday of a lifetime.”

He also advised Freeman to stop gambling altogether following the extraordinary win.

Industry Pays Tribute to Former NASC President Brian Houston MBE

Tributes have been shared from across the scaffolding and access sector following the passing of Brian Houston MBE, a highly respected former President of the NASC and long-standing contributor to the organisation.

Born in 1944 – the same year the NASC was founded – Brian played a significant role in shaping the confederation over many decades. He served as NASC President from 2001 to 2003, held the position of regional chair multiple times, and sat on the NASC Board of Directors between 2003 and 2006.

Later, he became a compliance officer and auditor, earning a reputation as the NASC’s “most experienced auditor” by the time of his retirement in 2019.

In 2008, Brian was awarded an MBE for services to the construction industry, recognising his long-standing commitment to scaffolding and access safety and standards.

The NASC paid tribute to Brian’s contribution and legacy, stating:

“We are saddened by the news this weekend of the death of our past President Brian Houston. Brian went on to play an integral part in NASC’s history – not only as President, but also in a number of senior roles. His experience and dedication left a lasting impact on the organisation. Our thoughts go out to his wife Pat, his sons Paul and Stephen, and his granddaughters, Jessica and Rebecca.”

David Mosley, former Managing Director of CISRS, said:

“Brian was a great ambassador for the scaffolding industry. He was articulate, knowledgeable and passionate about the sector, particularly training. He did a huge amount to raise the profile of NASC and ensure that CISRS remained robust and relevant. He will be greatly missed.”

Jamie McGuire, former Head of Business Development at NASC, shared his own memories:

“If ever there was a Mr NASC. I worked closely with this great man for years and he was so generous with his teaching and advice. I learned a lot from him. RIP Brian.”

Paul Richards, Managing Director at CWR Scaffolds, commented on social media:

“Sad news. Brian did a few of our audits. When you sit with someone of his knowledge you just listen and take as much in as you possibly can.”

Brian’s funeral will take place at 1 pm on Friday, 27th June at Bishopbriggs Crematorium, Crosshill Road.

He is fondly remembered by colleagues and friends across the industry for his professionalism, generosity, and commitment to raising standards in scaffolding.

Altrad Raises €1.25bn in Debut Bond Offering Amid Strong Investor Demand

Industrial services giant Altrad has successfully raised €1.25 billion through its first-ever public bond issuance, following its recent investment-grade rating from S&P Global Ratings.

The Montpellier-based company, known for its work across energy, infrastructure, and construction, attracted overwhelming interest from investors, with the order book exceeding €6 billion, more than five times oversubscribed.

Originally expected to raise €1 billion, Altrad upsized the offering in response to demand, issuing:

-

€550 million in a 4-year tranche at 3.704%

-

€700 million in a 7-year tranche at 4.429%

Both tranches were significantly oversubscribed.

Mohed Altrad, Founder and President of the Group, called it a “landmark achievement”, adding that the bond success reflected confidence in Altrad’s strategy, performance, and long-term vision.

The proceeds will be used to refinance an existing bridge facility and for general corporate purposes, with the transaction marking a shift towards a more diversified financing model.

The move reinforces Altrad’s position as a financially disciplined global operator in industrial services, including scaffolding and access solutions.

“Keeping It Real” — Joe Carr on Building Stellar Scaffolding and Becoming a YouTube Hit

Scaffmag’s Editor, Daniel Norton, sat down with Joe Carr, the energetic founder and MD of Stellar Scaffolding, whose bold move to launch a YouTube channel has turned heads across the industry. In just 12 months, the channel has racked up over 1.5 million views by ‘keeping it real’, offering an unfiltered, behind-the-scenes look at life on site, the challenges of growing a business, and Joe’s mission to build the UK’s best scaffolding firm — all while inspiring a new generation along the way.

When Joe Carr set out to start a scaffolding company back in 2018, he didn’t come from a background of tube and fitting. In fact, he had zero experience in the industry. What he did have was an opportunity. His brother, who runs a demolition company, had a client looking for a reliable scaffolder—and just like that, the seed was planted.

“I had no experience at all at the time,” Joe admits. “But someone I knew from training had been in the industry for years. I offered him half the company, started out as his labourer, and we hit the ground running. From that small opportunity, Stellar was born.”

At the beginning, Joe wasn’t thinking about building the UK’s best scaffolding company. He just knew he could make it work. “Now we’re off the ground,” he says, “becoming the best is my one and only mission.

Lights, Camera… Scaffold

Fast-forward to 2024, and Joe isn’t just running a fast-growing scaffolding business—he’s documenting the entire journey on YouTube, where Stellar Scaffolding has racked up over 1.5 million+ views and 16,500+ subscribers in less than a year.

“I always felt like scaffolding—and the reputation that comes with it—would make for really good content,” Joe explains. “And I’ve always liked being on camera. The two just worked perfectly together. Even though, at first, everyone was against the idea.”

That included his team.

“Yeah, the lads weren’t having it initially,” Joe laughs. “Apart from one or two, they couldn’t see the vision. But they’ve all gone full circle now—they love it. I think they actually enjoy being on camera more than they admit!”

Joe didn’t force it. “I just mic’d them up and told them to carry on as normal. Nothing’s scripted. We roll each episode as it happens. What goes down, goes out.”

With his partner Abbey behind the camera—and handling post-production—Joe credits the quality of their videos as a big part of the channel’s success. “She’s amazing,” he says. “I do the pre-edit and check I’m happy with everything, then she brings it to life.”

That production value, paired with an honest, unscripted look at daily life in a scaffolding firm, is what makes Stellar’s content stand out. But the channel isn’t just entertaining—it’s educational.

“I was advised early on by Daniel at Ashville that value is key,” Joe says. “Luckily, I’ve got some very good people around me who are backing what we’re doing. The boys at GKR have been great, too.”

Championing the Industry

The response has been huge. And not just from within the industry.

“It’s a real mix,” Joe says of his audience. “A lot of support from scaffolders, yeah, but loads of subscribers are people who you’d think wouldn’t be interested in scaffolding at all—but they love what we’re doing.”

That broad appeal has had an unexpected knock-on effect: people are being drawn into the trade.

“We get messages every day from people saying they’re now considering scaffolding as a career. I don’t think we’ve even scratched the surface of how big this could get. I’ve always said—this channel is for the whole industry. And week by week, we prove that.”

The impact goes beyond career inspiration, too. Joe often touches on mental health in his videos, and it’s something that’s clearly resonating.

“There’s been a lot of messages that have stuck with me,” he says. “It’s why I speak on mental health regularly. People are struggling out there, and I want our platform to help. Even on a small scale, I know we’re already making a difference.”

Behind the Growth

Despite the success, Joe is quick to acknowledge the challenges that come with scaling a business at this pace.

“The cost of growth is mad,” he says. “We’re constantly reinvesting and managing cash flow. Even though we’re profiting, the more we grow, the more we spend. Pressure and growth go hand in hand.”

Then there’s the extra scrutiny that comes from filming everything.

“You can’t please everyone. And in scaffolding, you’ve got to be so on it with health and safety. One minor slip on camera and someone will call it out. But it’s a good thing—it pushes us to improve and give 100% every day.”

That drive is helped massively by his team. “From the labourers to the office team, to my supervisor Shaun—none of this works without them,” Joe says. “And of course, Abbey. She’s the cheat code. We’re also mentored by Mark Parkin, and that brings huge value too.”

What’s Next?

With Stellar Scaffolding now firmly in the spotlight, Joe has big plans.

“In 3 to 5 years? I want us to be playing with the big boys. Making a real difference. Inspiring people from all walks of life. This is still a baby—we’re only just getting started.”

And as for the YouTube channel?

“I want it to be as big as Matt Armstrong,” he grins. “Maybe I’m dreaming, who knows? But we’ve got a long way to go, and we’re documenting it all.”

Success for Joe isn’t just about numbers or client wins. It’s about legacy. “I want to build one of the best scaffolding businesses in the country. But more than that—I want to inspire others to do the same.”

Final Words

If there’s one thing Joe wants other business owners in the trade to take away, it’s this:

“Get on social media. Tell your story. Be honest. Try to move forward every day. People will connect with it. Our platform proves that.”

And if he could go back and give himself advice on day one?

“Run!” he jokes. “But honestly—I wouldn’t change a thing. I’ve taken every opportunity, and I love this game. Growth takes time, and everything’s happening as it should.”