Industrial Textiles and Plastics (ITP) Ltd, a Yorkshire-based manufacturer specialising in protective textiles for the construction sector, has announced a major investment to expand its production capacity.

The Easingwold company has installed a new state-of-the-art large-format digital printer, a move it says will enhance the quality and efficiency of its printed scaffold sheeting and temporary containment products.

ITP said the investment, which forms part of a wider plan to upgrade its infrastructure and resources, will allow it to meet growing demand for high-resolution, wide-format printing across a range of construction applications.

“We have experienced growing demand for extra-large logos, high-impact visuals, and intricate detailing, particularly for full-scale façade reproductions on historic building refurbishments,” said Carl Morse, Managing Director of ITP.

“The addition of another digital printer at our factory will enable us to further develop our offering for applications such as scaffold sheeting, vented sheeting, PVC banners, air mesh banners, and keder sheeting.”

As well as installing the new printer, ITP has carried out factory refurbishments and upgraded its flexographic printing facilities. It has also committed to additional training and the recruitment of extra resources as part of its growth strategy.

The firm’s Sales Director, Matt Thompson, said the enhanced capability would help meet the rising demand for certified flame-retardant products.

“Reliable fire protection is critical in the construction industry,” he said. “Our printed sheeting is third-party certified to meet flame retardancy standards for both external and internal use, helping contractors to comply with regulations on major projects.”

Founded in North Yorkshire, ITP manufactures a broad range of temporary site protection products, including debris netting, filter sheeting, insulated sheeting and acoustic barriers. It also produces a variety of construction membranes designed for building envelope protection, such as breather membranes, vapour control layers, and roofing underlays.

The company supplies its products globally through a growing export division, with an expanding presence in multiple international markets.

With just 1.8 metres of usable space on the footpath for the scaffold base—and no encroachment allowed onto the road—counterbalance became a key challenge.

To solve this, Sky deployed 20 tonnes of specially purchased flat steel ballast, chosen for its high density. This approach allowed maximum counterweight performance within minimal space. The ballast was positioned with precision to achieve structural stability by maximising the lever arm of the cantilever—demonstrating the level of innovation required to work within tight spatial constraints.

The scaffold itself was constructed using the world-renowned Layher Allround system, which provided the flexibility, load capacity, and efficiency required for such a complex structure. The system’s modularity enabled a custom configuration tailored to the bridge’s historic form.

Crucially, the scaffold’s engineering and safety design was carried out by SDC Scaffold Design Consultants Ltd, who worked closely with Sky to deliver a scheme that met both structural demands and heritage preservation requirements.

With just 1.8 metres of usable space on the footpath for the scaffold base—and no encroachment allowed onto the road—counterbalance became a key challenge.

To solve this, Sky deployed 20 tonnes of specially purchased flat steel ballast, chosen for its high density. This approach allowed maximum counterweight performance within minimal space. The ballast was positioned with precision to achieve structural stability by maximising the lever arm of the cantilever—demonstrating the level of innovation required to work within tight spatial constraints.

The scaffold itself was constructed using the world-renowned Layher Allround system, which provided the flexibility, load capacity, and efficiency required for such a complex structure. The system’s modularity enabled a custom configuration tailored to the bridge’s historic form.

Crucially, the scaffold’s engineering and safety design was carried out by SDC Scaffold Design Consultants Ltd, who worked closely with Sky to deliver a scheme that met both structural demands and heritage preservation requirements.

Pedestrian safety was a top priority, with segregated walkways, protective barriers, and clearly marked signage in place. Night-time road closures were used for scaffold installation and maintenance to avoid daytime traffic disruption.

“This was one of the most technically demanding scaffolds we’ve delivered,” said a spokesperson from Sky Scaffolding Midlands Ltd. “The combination of the Layher Allround system and the expertise of SDC Scaffold Design Consultants Ltd made it possible to deliver a solution that balances heritage protection with public convenience.”

The restoration works are expected to conclude in Spring 2025. By maintaining full use of the bridge while supporting intricate repair work, the project has already been hailed as a model of engineering excellence and cross-disciplinary collaboration.

Pedestrian safety was a top priority, with segregated walkways, protective barriers, and clearly marked signage in place. Night-time road closures were used for scaffold installation and maintenance to avoid daytime traffic disruption.

“This was one of the most technically demanding scaffolds we’ve delivered,” said a spokesperson from Sky Scaffolding Midlands Ltd. “The combination of the Layher Allround system and the expertise of SDC Scaffold Design Consultants Ltd made it possible to deliver a solution that balances heritage protection with public convenience.”

The restoration works are expected to conclude in Spring 2025. By maintaining full use of the bridge while supporting intricate repair work, the project has already been hailed as a model of engineering excellence and cross-disciplinary collaboration.

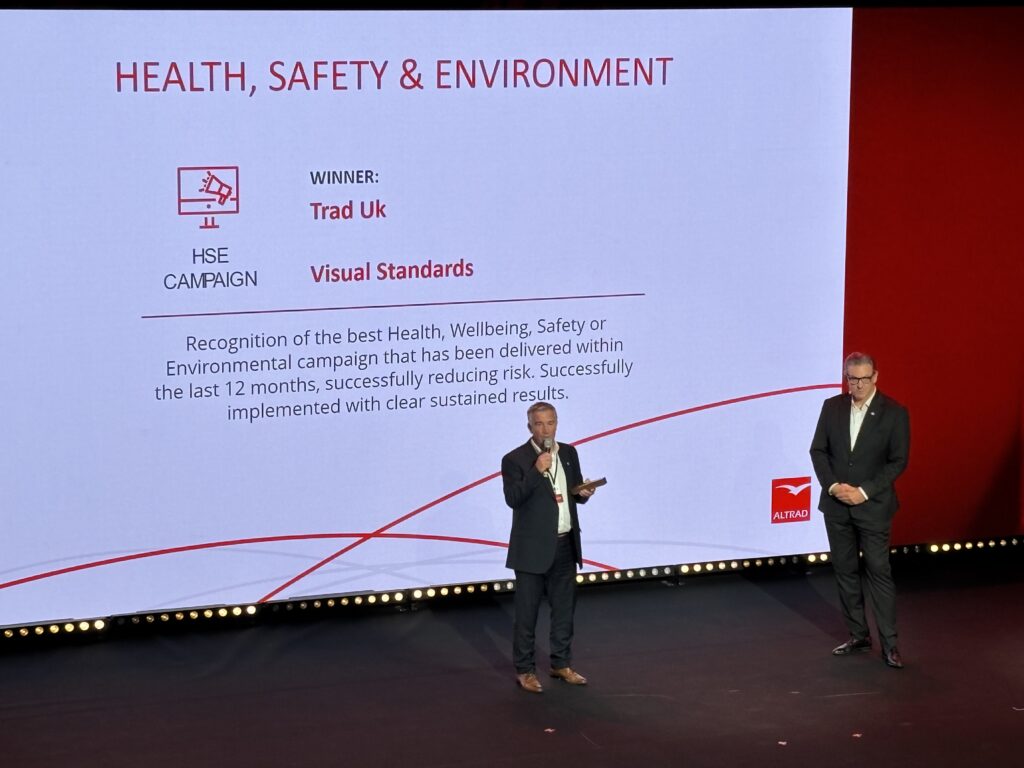

“We’ve listened to our people, and their input has help shape this entire project.” said Nick. “Our objective was to introduce a simple way of communicating good practices and what better way is there to show ‘what good looks like’ than through pictures. Simple, effective communication and engagement with the workforce is key to changing behaviours, which is paramount to a safe and risk free working environment.”

The campaign builds on TRAD UK’s broader efforts to promote safety within its business and wider operations, including developing the TRAD Operative Training Scheme (TOTS), and the introduction of the Personal Engagement Programme (PEP), while achieving FORS accreditation at all of its depots. The company has also reported over one million man-hours without a reportable accident and no lost time injury incidents since May 2022.

The booklets have been widely welcomed across the workforce, with positive feedback from operatives, yard managers and drivers alike. The Transport edition, completed in early 2025, includes QR codes linking to further resources from TRAD UK, Altrad, the HSE and industry bodies.

TRAD UK’s campaign also earned the 2024 FASET Health, Safety and Environmental Achievement Award, highlighting its impact into the broader construction and access sector.

“We’ve listened to our people, and their input has help shape this entire project.” said Nick. “Our objective was to introduce a simple way of communicating good practices and what better way is there to show ‘what good looks like’ than through pictures. Simple, effective communication and engagement with the workforce is key to changing behaviours, which is paramount to a safe and risk free working environment.”

The campaign builds on TRAD UK’s broader efforts to promote safety within its business and wider operations, including developing the TRAD Operative Training Scheme (TOTS), and the introduction of the Personal Engagement Programme (PEP), while achieving FORS accreditation at all of its depots. The company has also reported over one million man-hours without a reportable accident and no lost time injury incidents since May 2022.

The booklets have been widely welcomed across the workforce, with positive feedback from operatives, yard managers and drivers alike. The Transport edition, completed in early 2025, includes QR codes linking to further resources from TRAD UK, Altrad, the HSE and industry bodies.

TRAD UK’s campaign also earned the 2024 FASET Health, Safety and Environmental Achievement Award, highlighting its impact into the broader construction and access sector.