SG4:10 (Preventing Fall’s in Scaffolding) the Safety Guidance was released in December 2010 by the NASC (National Access and Scaffolding Confederation) which has become the the established minimum standard for fall prevention in the scaffolding industry.

The new revision of the guidance saw the removal of the ‘tunneling unprotected traversing element’ and saw the introduction of the ‘Scaffolders Safe Zone’.

ScaffMag.com has gained an exclusive interview with Simon Hughes who is the Technical Author of the SG4 Working Party. We gave you our loyal readers and our 2,000 strong facebook fan page followers the chance to ask the questions.

We read through your questions and picked the best 10 to be answered by the man in the know Simon Hughes CMIOSH, MIIRSM

Q – Dave Asks: “SG4:10 is it Guidance or Law ?”

A – “SG4 is not law, it is simply industry guidance. However HSE and the courts might make reference to it as an example of good practice. In your defence you would have to demonstrate that you did something as good as or better than, if choosing not to comply with SG4. In simple terms you would be better off working to the principles of SG4 rather than risking injury/enforcement action or trying to reinventing the wheel.

Q – Steve Asks: “What powers have the HSE got if your found to be not working to SG4:10?”

A – “The HSE will enforce the Work at Height Regs as the law and not SG4, however they may cite SG4 as an example of how you can comply. They can stop you working, and even prosecute you as an individual and your employer.

Q – Andy Canning Asks : “What is the proposed weight which would be exerted on a scaff hook by a fall by average joe ?”

A – “Scaffold hooks (connectors) are designed and tested to the British and European Standard (BS EN 362:2004) and must have a minimum static load rating of 20kN (approximately 2 tonnes of force). Also the shock absorber on your lanyard (BS EN 355: 2002) must reduce the load imposed to no more than 6kN (approximately 600kg) in a fall.

The test mass used to test personal fall protection equipment and anchor points is 100kg (approximately 15 ½ stone) which is based on (believe it or not) a European ergonomic model for an average Joe. I appreciate that there are many scaffolders using this equipment that weigh considerably more than 15 ½ stone and some manufacturers offer supersized harnesses for example, but this should not affect the strength of the connectors. Your main concern as a scaffolder should be the suitability of anchor point, providing your connector is in good working order.”

Q – Mark Wilkinson Asks: “I work offshore and do a lot of hop up and various scaffolds which are only 2 to 4ft off the ground also lots of pipes and things in the way you can hardly get up there yourself to put a handrail up in the first place. How can we get this advanced handrail up there for us to put handrail on ?”

A –“I agree, trying to weave a scaffold through complex pipework and plant off-shore or on an industrial plant is difficult and that most proprietary advanced guardrail systems are indeed unsuitable for such applications due to the amount of obstructions.

The collective guardrail options in SG4:10 were designed to provide a range of solutions available to the scaffolder to suit most scaffolding applications. As consultants and inspectors we are tending to see more industrial and off-shore scaffolders opting for the short-lift system of work to provide collective protection in advance and where this cannot be achieved resorting to double lanyard methods to ensure they are continually attached until the guardrails are installed.

I do appreciate that most of these short ‘hop-up’ scaffolds would not provide a suitable anchor-point for a conventional scaffolders lanyard and I share scaffolders frustrations when clients insist on 100% clipping on even when the equipment would be ineffective.”

Q – Martin Forsythe Asks: “What was wrong with SG4:05? Why did SG4:10 have to be such a radical change to SG4:05? Why cant scaffolders and scaffolding companies have some consultation where they can express their views in the hope that we can find easier solutions before these guidance notes get foisted upon us ?”

A – “SG4 revisions in 2000 and subsequently in 2005 were effectively a compromise agreement between the HSE and NASC, permitting scaffolders to traverse out on a boarded lift without fall protection which didn’t comply with the law at that time.

The HSE accepted our argument that scaffolders needed to transfer themselves and materials along a lift and that clipping on and off with double lanyards at every transom was impractical, in the absence of any other technology. However, the guide was viewed as a significant step forward by the industry on the basis that it is reviewed at least every 5 years, with changes in legislation or technology, or following any significant accident learning.”

In the lead up to the 2010 revision, HSE made their views very clear to the industry that they were unhappy with certain elements of the old tunnelling principle and that by the time of the next revision (2010), the unprotected traversing would no longer be considered acceptable. This was communicated via the NASC in SG4:05 Appendix A in 2008, some 2 years before the latest revision.

Prior to the 2010 revision, there was extensive consultation with in the NASC and at HSE scaffolding events (Safety and Health Awareness Days, Working Well Together campaigns etc.) and exhibitions (IOSH, H&S Expo, Access Industry Forum). I personally delivered two rounds of presentations at all of the NASC regional meetings in 2009 and 2010 to seek input from the membership. Ultimately Safety Guidance Number 4 is an NASC publication and the NASC is the only nationally recognised industry association and thereby viewed by many as the representative body for the scaffolding trade.”

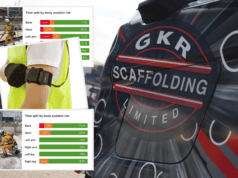

Q – Stewart Quinney Asks: “Why is scaffolding an easy target yet not many scaffolders have accidents ?”

A – “I agree the scaffolding trade is an easy target, especially when you consider how few accidents occur compared with other high risk trades such as demolition or roofing. However, if you look at the NASC and HSE statistics it was not always the case and reputations and perceptions take a long time to change.

The gap between the professional contractors wanting to do the right thing and everyone else is growing, which I personally support, as it will drive contractors to improve safety or compete further down the food chain. Client’s expectations for health and safety performance is also increasing, despite the difficult economic climate.

Looking at the impact of SG4 and falls, which is perceived to be our biggest risk, there has been a significant reduction in the number of falls since 2000. However, we still see too many examples of unsafe practice by certain elements of our industry that will ensure our trade continues to receive a disproportionate amount of attention.

Ultimately, we are an easy target and very visible, by the nature of the job.”

Q – Tony Warburton Asks: “Is advanced guard rails a legal requirement ?”

A – “No Advanced Guardrail Systems are not specifically a legal requirement, but the use of collective protection over personal protection is. How you, as a scaffolder, maintain collective protection during erection, altering and dismantling scaffold was the challenge faced by the NASC when considering the legal changes brought about by the Work at Height Regulations 2005 and to a certain degree the previous Construction (Health, Safety and Welfare) Regulations 1996.

SG4:10 focuses on creating a scaffolders’ safe zone and features a range of solutions for the majority of scaffolding applications.

At some point, in most jobs, the scaffolder will be faced with a risk of a fall and will need to resort to his personal fall protection equipment (harness). However, if you were to choose harnesses and lanyards over the collective protection achieved by a guardrail, then you would have to justify why. Given the range of technology and low cost solutions available and featured in SG4:10 you would have to go a long way to satisfy the HSE and possibly the court that a guardrail collective protection method of working was not justifiable.”

Q – Curt Willetts Asks: “When I did my scaff step course our instructor told us we should not top out over the handrail. so what we should do is top out stood on a 2ft square platform! in my eyes its safer to do it stood on the boarded lift before the handrails gone in.”

A – “I agree fully that topping out from a scaffolders step should be avoided. I appreciate that it may be unavoidable with some system scaffolds and that hemping over a guardrail introduces additional hazards.

Especially where you are topping out with long tube to a short hemp. Scaffolders and employers should consider this additional hazard and assess the length of tube and the height of the temp being negotiated. Although I do also appreciate that joint positions and staggers also need to be considered. In any case working from a fully boarded platform will allow better movement, good balance and posture for what is one of the most strenuous manual handling tasks a scaffolder performs.”

Q – Shaun Barrett Asks: Sg4.10 “It isn’t just about advanced guard rails and using hop ups the way around it is to use a double landyard (crabbing) your clipped on at all times, is this correct ?”

A – “Using collective protection to create a safe zone is the priority for typical scaffolds founded on the ground. In my opinion, the protected traverse using double guardrails is a last resort, as you would be relying upon personal fall protection as your primary means of protection, when other safer collective measures may be available. I have used the double lanyard system and it is easier, especially with karabiners that are designed to clip to the standards, but the law requires us to consider collective protection first.”

Q – Shaun Farmer Asks: “How can we use an advanced guardrail on a hanger ?”

A – “I’m not aware of an advanced guardrail method for a hanger. Typically you’d rig up retrievable inertia blocks for working from droppers. As a priority you should fix guardrails as soon as the lift is formed.

Interestingly I did see a truss-out being erected where the scaffolders assembled a frame and pushed it out horizontally as an advanced guardrail prior to boarding out and fixing the puncheons. The best ideas and innovations come from the scaffolders themselves, so I’m sure it’s only a matter of time before some comes up with something for a hanger.”

Q – Steve Asks: “What powers have the HSE got if your found to be not working to SG4:10?”

A – “The HSE will enforce the Work at Height Regs as the law and not SG4, however they may cite SG4 as an example of how you can comply. They can stop you working, and even prosecute you as an individual and your employer.”

I would like to thank Simon Huges for his time in taking part in this Q&A.

If you require more information regarding SG4:10 please visits www.nasc.org.uk

is there a legal requirement to physically tie a scaffold if it is only at 3.5 high to the working lift ?.

How do u erect a 0.800 bay in kwikstage as Scaff step is to big .just got a ear full from nhbc for hook on and erecting it