Safety, agility, and innovation are of utmost importance when building the first of a new generation of nuclear power stations. Industrial services specialist KAEFER UK & Ireland was tasked with delivering the Containment Liner Coating Package for the Hinkley Point C build, which involved blasting and specialist coatings of internal surfaces of both nuclear reactor containment buildings and providing the necessary access to undertake these operations.

Each containment liner is composed of five components and stands 65m tall when fully assembled. For this monumental task, KAEFER used the world-renowned Layher Allround scaffolding system, supported by Layher UK throughout the project.

Layher Precision in Practice

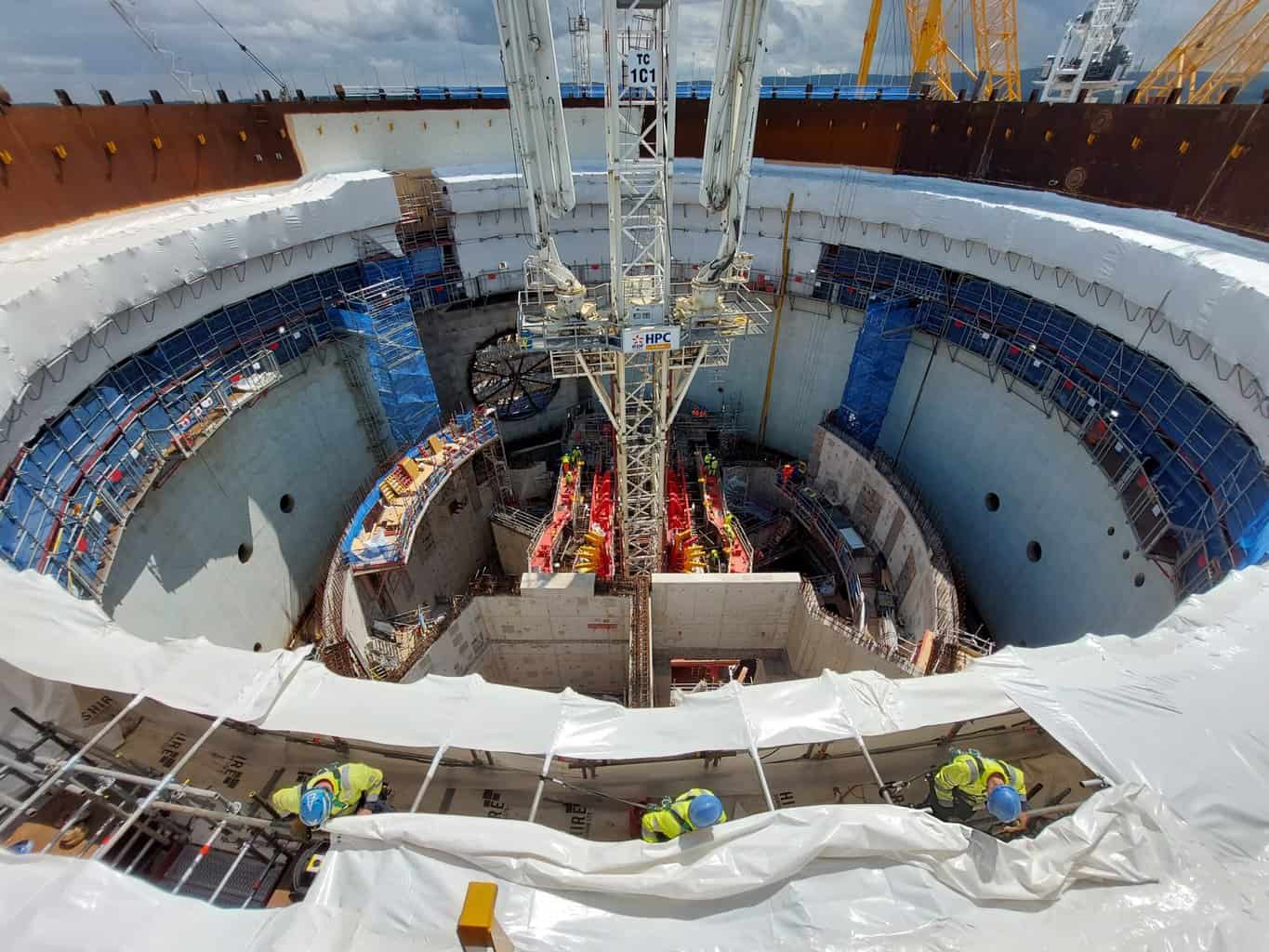

In April 2021, KAEFER built a 171-tonne, 160m circumferential scaffold on the Slab 8 construction area at Hinkley Point C, using the Layher Allround system. This allowed the second 17m high liner ring for Hinkley Reactor 1 to be lifted over it, providing access for contractors, including the KAEFER painting team, before it was lifted into its final position on top of Liner 1 in November 2021.

Before lifting the second 47m ring into position in November, an equipment hatch needed to be welded to the liner by the Hinkley Point C team. KAEFER stepped in to provide a solution where others said it was impossible, with design support from experts at Layher UK in Letchworth the team devised an innovative suspended scaffold for the ring in March 2022. This suspended structure allowed for welding the equipment hatch onto the ring liner, keeping the project on schedule.

In August 2022, the same KAEFER scaffold on Slab 8 was reused, and the 12m-high liner ring three was lifted over it, again allowing access for the KAEFER team and other contractors before it was lifted to its final position on top of ring two in December 2022.

Overcoming Challenges

Hinkley Point C project milestones required the planned timeline to be shortened, and when the third ring was lifted into position in December 2022, it still needed additional work. The KAEFER temporary works team, with support from Layher UK, were tasked with designing a scaffold to allow for the blasting and painting operations to ring three and provide access for the installation of the polar crane and the final dome top.

Initial discussions began in November 2022 and involved multiple stakeholders. Design considerations included loading onto the existing platforms in the liner, the available weight loadings of the liner itself due to the concrete pours on the external sides of the liner, suitable access for the range of trades needed to work on the ring, and the tie points for the scaffold.

Paul Ferrand, Operational Delivery Lead for KAEFER UK & Ireland at Hinkley Point C, explained the challenges faced during the project. “A challenge presented itself when the planned crane was moved out of service for several weeks, meaning a new crane and material store had to be arranged,” he said. “This required daily coordination with several stakeholders to organise deliveries with crane time booked in advance: on a busy site like Hinkley Point C, this can be difficult.”

The availability of Hinkley Point C riggers to support the crane tasks was also limited during the day; combined with working at height safety requirements, minimising available working areas below the scaffold meant the KAEFER team moved to night shifts.

Incident first response manpower availability at Hinkley Point C is reduced overnight, so KAEFER collaborated with Bylor’s HSE team, creating a viable rescue plan from the working platform to ensure the safety of the KAEFER team members.

Keeping the Motion Going

With the scaffold build now fully underway, it was crucial to maintain momentum. “We attended daily coordination meetings during the day and ensured this information was handed over to the night shift teams,” said Paul. “Ongoing design amendments continued throughout the programme to modify the scaffold for crane operations.”

Thanks to the agility of the KAEFER temporary works team, disruption to other trades was minimised, allowing project timelines to be met.

Once the scaffold build was completed, it was handed over to the KAEFER containment team to encapsulate the structure. Over 2,400m2 of flame-retardant shrink wrap material was used to create an enclosed habitat for the KAEFER coatings team to complete blasting works.

This habitat contained the garnet blasting medium used in the coating’s preparation works and also protected the three-coat phenolic epoxy-polyamide PIC 100 coatings scheme as it cured. The KAEFER coatings team applied this scheme to 26,000m2 of steel across the inside of both containment liners.

The scaffold build and containment took 52 nights, including downtime due to bad weather and crane availability. “These efforts allowed project-critical operations to continue, meaning Hinkley Point C is one step closer to providing zero-carbon electricity for around six million homes,” said Paul. “We’re proud to be playing our part, and it’s a good feeling to know that whatever challenges we’re set, our team is equipped and ready to handle them.”

Conclusion

The success of the Hinkley Point C project demonstrates the importance of safety, agility, and innovation in large-scale infrastructure projects. With the support of Layher UK and the use of the Layher Allround scaffolding system, KAEFER UK & Ireland was able to overcome significant challenges and meet critical project milestones.

This collaborative effort has brought Hinkley Point C one step closer to providing zero-carbon electricity to millions of homes, highlighting the crucial role that innovative engineering solutions play in addressing global energy challenges.

This article was originally published in Issue 20 of the ScaffMag magazine.