Celebrating three decades of architectural mastery and steadfast growth, GKR Scaffolding stands as a beacon of excellence in the construction industry. Founded on the principles of safety, innovation, and unwavering dedication, this London-based firm has etched its name on some of the most iconic skylines in the UK.

From the soaring heights of The Shard to the historic contours of the Royal Albert Hall, GKR’s contributions have not only reshaped London’s skyline but have also set new benchmarks in scaffolding and structural engineering.

As GKR Scaffolding marks its 30th anniversary, we sit down with the visionary minds behind this monumental success, Lee and Neil Rowswell, to reflect on the journey that has positioned GKR as a leader in one of the most challenging and dynamic sectors. In an industry where the only constant is change, GKR Scaffolding has navigated through economic recessions, material shortages, and the unprecedented challenges of COVID-19, emerging stronger with each hurdle. With a portfolio that boasts participation in landmark projects and a trophy cabinet adorned with multiple business awards, the Rowswell brothers have not just built structures; they have constructed a legacy.

As GKR Scaffolding marks its 30th anniversary, we sit down with the visionary minds behind this monumental success, Lee and Neil Rowswell, to reflect on the journey that has positioned GKR as a leader in one of the most challenging and dynamic sectors. In an industry where the only constant is change, GKR Scaffolding has navigated through economic recessions, material shortages, and the unprecedented challenges of COVID-19, emerging stronger with each hurdle. With a portfolio that boasts participation in landmark projects and a trophy cabinet adorned with multiple business awards, the Rowswell brothers have not just built structures; they have constructed a legacy.

This exclusive Scaffmag Q&A session delves into the milestones, innovations, and relentless pursuit of excellence that defined GKR Scaffolding’s 30-year journey, offering insights into the company’s future directions and continued impact on the construction landscape.

Milestone Moments

Firstly, thank you for taking the time to speak to us. So, thirty years in business in any sector is a massive achievement, so congratulations! Reflecting on those 30 years of GKR Scaffolding, what are the key milestones and decisions that have shaped the company’s journey to becoming one of London’s leading scaffolding contractors?

Lee: Thank you, Dan, and what a 30 years it has been! I can’t believe we are talking about GKR being 30 years old! Reflecting on the past 30 years of GKR, we have achieved so much and have matured as a company. We have been through two recessions, COVID-19, material shortages, Brexit, and so much more and remained strong consistently. Throughout our 30 years, we have built relationships and loyalty with Tier 1 clients, evolved our supply chain, and built an extremely strong and devoted team, which has helped us get to where we are today. Personally, I would say my most iconic project would have been the Shard; it was our first high-rise project and was the pinnacle in showing what we could do as a company. For my own personal reasons, the Tottenham Hotspurs Stadium was another memorable project for me!

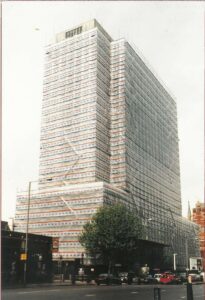

Neil: I also think a crucial milestone for us would have been when we first purchased our own material because like most companies starting out we hired in most of the materials needed for the early projects, which helped to fund our growth through self-funding; it demonstrated that we were able to do it all on our own, I suppose, we wanted to prove ourselves in the industry when we were a young business. It was important for us to purchase our own assets and premises to help give the company the security it needed. Another key milestone for us was when we first landed a main contractor as a client when we were a young business; they saw the potential in us from the early days, which helped us land bigger projects and start showcasing what we were capable of. Our first million-pound project, Shaw Park Plaza, was a great achievement, being our first large-scale project working over 15 floors and demonstrating the scale of work that we could undertake.

Iconic Projects

GKR has been involved in some of London’s most iconic construction projects. Could you share insights into how these opportunities came about and what they meant for the company’s growth and reputation?

Lee: These opportunities come from our reputation, relationships and experience. Our operational skill set is second to none, and we can undertake high-profile projects to the highest of standards, which helps to set us apart from our competition. Fundamentally, the relationships we have developed with our clients and the trust we have created have helped us form loyalty and repeat business as we have proven that we can provide them with experience and high-performing teams.

Neil: We thrive on high-risk projects; it’s what helps to motivate us and our teams as we like a challenge. Since working on the Shard, a lot of the team wanted to work on high-risk projects and the challenge that comes with it, motivating us to keep reaching for more. We know that we have the ability and the team behind us to undertake high-profile and high-risk projects from our previous experience and successes. We have developed our own control measures, which have allowed us to take these projects on safely and efficiently, such as our Elimin8 tethering system and VR training to ensure that our staff are safe in these high-risk environments. We provide excellent service, and we are still family-run; Lee and I are still contactable with our clients to aid in the smooth running of the business.

Safety & Innovation

The construction industry is known for its challenges, particularly around safety and innovation. How has GKR maintained its commitment to safety and continued to innovate in such a competitive and high-risk environment?

Lee: At GKR, we maintain our commitment to safety whilst encouraging a culture of innovation. Delivering value through our supply chain in what is increasingly becoming a knowledge-based economy is one of our main aims as a leading Scaffolding Contractor. We have continued to innovate and maintain our commitment to safety whilst posed with some clear challenges.

We hold internal pre-start project meetings, ensuring we select the right personnel to deliver our projects and that they have the correct resources and knowledge prior to commencing with works from commercial design to key Health and Safety risks. This is coupled with our internal Health and Safety project audits, where supervisors are measured against a number of health and safety compliance areas, ensuring that a level of competition is brought amongst our projects through a scoring league table to maintain project ownership and commitment to maintaining high performance.

Research also shows that high-performing teams are more likely to feel more psychologically safe. We run an internal audit system for all our projects, continually measuring our performance for consistency across projects and aspiring to achieve high-performing teams on all projects through our scoring matrix against different areas of Health and Safety. This is also recognised annually through internal company Health and Safety Awards. We have recently implemented task video analysis, comparing the methodology of works and safety in different environments, gathering whether there is a change in risk perception and what additional protocols we can put in place where necessary. We are mission-focused on being ahead of the curve where innovation and safety are concerned, which is essential to maintaining our position at the forefront of the scaffolding industry.

Ultimately, we at GKR encourage our industry partners to invest themselves in innovative solutions to combat the challenges we all face. The labour shortage has been exacerbated by the 46,000 workers that The Centre for European Reform estimates we’ve lost through the end of the free movement of labour. We need policies that prioritise a long-term strategy with investment in apprenticeships and training. Adopting a performance mindset to safety whilst continuing to innovate our processes has enabled GKR to meet head-on some of the challenges we are all facing as a collective.

Leadership & Training: The Keys to GKR’s High-Performance Teams

Leadership and training are evidently core to your company’s success. Can you discuss your approach to developing high-performing teams and the impact of your award-winning VR training programs?

Neil: We start by recruiting and employing the right people, those who demonstrate our high standards and value consistently. The GKR Leadership Team has analysed what drives high-performance teams, and we have outlined two main themes: continuous improvement and psychological safety.

Our people are our biggest asset, and it is important that we invest in them to create a strong team. We have multiple ways in which we help to develop high-performing teams. We re-launched our internal GKR Academy, which adopts neuro-inclusive training. Our academy helps to provide our project managers and supervisors with the relevant leadership and management tools that they cannot access with the current standard industry-recognised training. We also equip our teams with any other additional and essential training and tools that are transferable to deliver our projects.

The National Federation of Builders has discovered that neurodiversity is not only common amongst construction workers, but being neurodiverse is actually encouraging people to pursue a career in construction. We at GKR Scaffolding believe that a diverse team that includes neurodiverse individuals can offer unique perspectives, problem-solving abilities, and attention to detail, which can lead to improved safety practices and reduced accidents on the job site. With one in four construction workers identifying as neurodiverse, we ensure that we adapt to these different learning styles where possible to increase performance amongst our workforce. At GKR, training is conducted via simulated learning experiences related to management theory and practice. In addition, we have an industry-leading Apprenticeship programme, actively supporting trainee scaffolders with personal development plans that develop skills outside technical training. This is supplemented with our bespoke training plans that we also deliver to our project supervisors.

Award-Winning VR: How GKR is Transforming Safety

We’ve become leaner by becoming more digital, helping to optimise our operations and minimising wastage of time and resources. Virtual Reality has been a fantastic risk aversion tool for recreating real-life scenarios without causing potential harm. We put our people in an environment where they can positively intervene to prevent a person from being harmed, but they do get to experience what would have happened if they had not intervened. They then get the option to decide if they should report the near miss or incident. Our discussions with our team after the VR experience are extremely powerful as we focus on the importance of not walking by an unsafe act, reporting incidents and understanding why high-performing teams record more incidents than low-performing teams. The impact of VR is that we are now recording more near-miss incidents than ever because our high-performing teams understand the importance of incident reporting. We can then learn and share those learnings and implement corrective measures to prevent a reoccurrence.

This contributes to our aim to be a learning organisation where we actively measure and encourage feedback to improve what we do. Continuous improvement is embedded in our culture, and its process is applied to everything we do, from planning and implementation to measuring the impact and using the results to learn and improve.

GKR has achieved Carbon Neutral status and has a strategic roadmap to reach Net Zero Carbon. What inspired this ambitious sustainability goal, and what challenges and opportunities have you encountered along the way?

Neil: The inspiration to achieve a carbon-neutral status came naturally from the recent data and the effects climate change has had on our planet, such as extreme weather and rising sea levels. We are in a strong position as a leading subcontractor to set an example to others that good progress can be made in a short time with the proper assistance, encouragement, education and motivation. We have also measured all three scopes and have published our Net Zero targets on the SBTI website; as well as pledging to Net Zero, we continue to measure all three scopes manually. With very little offset under Scopes 1&2 to become Carbon Neutral, we are still struggling to find a zero-submission solution with our fleet. As technology evolves, we hope that there will be more opportunities for this within the next five years. Until these advancements arise, we will continue to keep our fleet fuelled with HVO Biofuel. The challenge for 2024 will be carbon onboarding our supply chain to think with the same carbon mindset that we at GKR have adopted. We are still setting out a plan to tackle this with support from our partners at Equans; without the supply chain onboard, Net Zero is impossible, which creates a challenge for us.

In a rapidly evolving industry, technology plays a crucial role. How has GKR integrated new technologies into its operations, and what benefits have you observed, both on-site and in management processes?

Neil: We have recently digitalised every element of our Health and Safety operation through the SafetyCulture application, which Premier League and Formula 1 teams also use. Our Supervisors are now proficient with conducting audits, inspections, and checklists online, allowing immediate data capture and communication for the Health and Safety Team. The predictive capabilities of new technology coupled with the large amount of data now available through the ‘Internet of Things’ has helped transform our business from a safety point of view.

The company prides itself on a unique approach to service quality. Can you elaborate on the pillars of this approach and how they contribute to the exceptional service GKR is known for?

Neil: Lee and I obviously both started on the tools. From a young age, we were both motivated to create the best possible standard of service and quality for our clients and for the industry. I believe we have maintained this throughout the past 30 years, and we have been able to engrain this mindset into all our staff at present. It can be a hard industry to be involved in, but I like to think we do it differently and provide our staff with the best people, training, safety and culture. We set a standard that is measured against our KPIs in terms of health and safety, productivity and more to ensure that we are continuing the standard that Lee and I started with and maintaining this with our current members or staff and supply chain.

Lee: All scaffolding firms use the same products, tube and fitting or system; what sets you apart is your team, your delivery, and your relationships, which I believe we have built to an exceptional standard, and it helps to set us apart from our competition. Our quality of service is not down to specific individuals; it’s because of the teams we have built. One of my favourite quotes is, “You are only as good as your weakest link”; therefore, we ensure that we nurture and grow our teams to a high standard.

GKR Scaffolding has been honoured with multiple business awards throughout its history, showcasing its excellence in the scaffolding and construction industry. Can you share what these awards mean to the company?

Neil: Winning awards is always a proud moment for us; it helps us get recognised for our service and shows that we are doing it right. We are up against great competition, so it is nice to know we stand out against others in our industry. We push boundaries within our sector and want to show that the industry is a professional and skilled environment to be in, which these awards help to illustrate. Along with our competition, we can showcase that scaffolding is a skilled and important trade within the industry that should be recognised for the hard work that goes into it.

The Future of Scaffolding: GKR’s Vision for the Next Decade

How do you foresee the scaffolding and construction industry changing in the next decade, and what steps is GKR taking to stay at the forefront of these changes?

Neil: I do see AI becoming a huge advancement within our industry in terms of design, estimating and document writing. I think in the not-so-distant future, we could see AI having the ability to scan a building from Google Earth and produce the dimensions to assist with creating designs; this could then generate load sheets for our yard to calculate required materials and then further help to generate calculations and health and safety documentation. I still believe that this will require some form of human intervention to input parameters and check for accuracy. I think, as an industry, we have somewhat stood still in terms of innovations when it comes to the mechanical side of things in comparison to the demolition works and what they have created.

I do believe that, as an industry, we need to create a more seamless way of accessing materials and can transport scaffolding up and down a building safely and easily. I think, as a sector, we have the ability to create some form of lifting kit to help with the transportation of scaffolding through a project, which I believe is something that our industry needs. We have lots of new and young scaffolders who help give us new and exciting ideas on what we could do differently in our operations, which we always acknowledge and see if we can take these ideas on board.

GKR Scaffolding remains owner-operated after three decades. How has this influenced the company’s values, culture, and decision-making processes?

Neil: I think this is a massive part of our success. Lee and I are still massively involved in GKR and still undertake critical roles within the business. Our clients know that they can come to us, and we will react positively and get any problems solved. We can respond to situations quickly as there are only a few layers of management to go through; therefore, communication externally and internally is a lot more seamless and efficient in comparison to more giant corporations. We are still investing in GKR constantly, and we are still looking at what we can do for the future of the business, like looking at new premises to keep up with expansion and our apprenticeship schemes. I think keeping the “family run” morals and culture has been beneficial for our employees as it helps to create a physically and mentally safe environment for everyone; they are comfortable talking to us and feel more like a member of the team rather than just an employee. We have seen the third generation start to make their way into the business, which is exciting, and we hope to see the longevity of the “family-run” business continue.

Lee: As much as we are a family-run business, our success comes from the teams we have built; everyone we have ever employed has played an important role and contributed to our growth. Our clients like the business model of owner-operated businesses as I believe it helps to form stronger and more loyal relationships.

Lastly, looking forward, what are the long-term goals for GKR Scaffolding, and how do you plan to continue contributing to the London skyline and the broader construction industry?

Neil: Well, Lee and I are not planning on going anywhere anytime soon. We are still committed to GKR and the scaffolding industry; we want to see us excel in the industry for many more years to come. We have a great team behind us who can achieve anything they get tasked with to a high standard. We are committed to our operatives; we want to continue to give them the best support, the best training, and the best team to help them become the best that they can be. We want to nurture the next generation to help form a strong team for the future of the scaffolding industry, which is why we have focused on apprenticeships in recent years. I would like to invest in more stock and innovations to see what we can achieve as a scaffolding contractor. As an industry, we have a very tarnished “look” about us, and it’s very stereotypical, which I would like to see change. I worked on the tools for 18 years, and I know from experience that it is a very highly skilled profession. I would like to see this showcased and have these stereotypes of scaffolding change to show what a great industry it is to work in.

This article was originally published in Issue 21 of the ScaffMag magazine.