London-based leaders GKR Scaffolding Ltd has partnered with Construction Health and Wellbeing Ltd to pioneer a transformative approach to manual handling within the construction industry, addressing a critical issue that affects thousands of workers annually.

With the introduction of advanced wearable technology, GKR is set to revolutionise manual handling training, significantly reducing the prevalence of musculoskeletal disorders (MSDs) and enhancing worker health, wellbeing and productivity.

The Challenge of Manual Handling in Construction

Manual handling has long been a challenging aspect of the construction industry. It is a major contributor to musculoskeletal disorders, which account for a significant portion of work-related ill health.

These disorders not only lead to substantial days lost but also impact workers who continue their duties despite suffering from chronic pain. According to the Health and Safety Executive (HSE), 53% of all work-related ill health is due to MSDs. In 2018, the ICE estimated that occupational ill-health costs construction employers approximately £848 million annually, 75% (646m) of these were down to MSDs (ICE2018).

GKR’s Groundbreaking Initiative

GKR Scaffolding has partnered with Construction Health and Wellbeing Ltd to address this pervasive issue by embracing a revolutionary manual handling technology platform. This initiative is designed to teach workers correct manual handling techniques, encourage proper posture, and reduce the risk of injury.

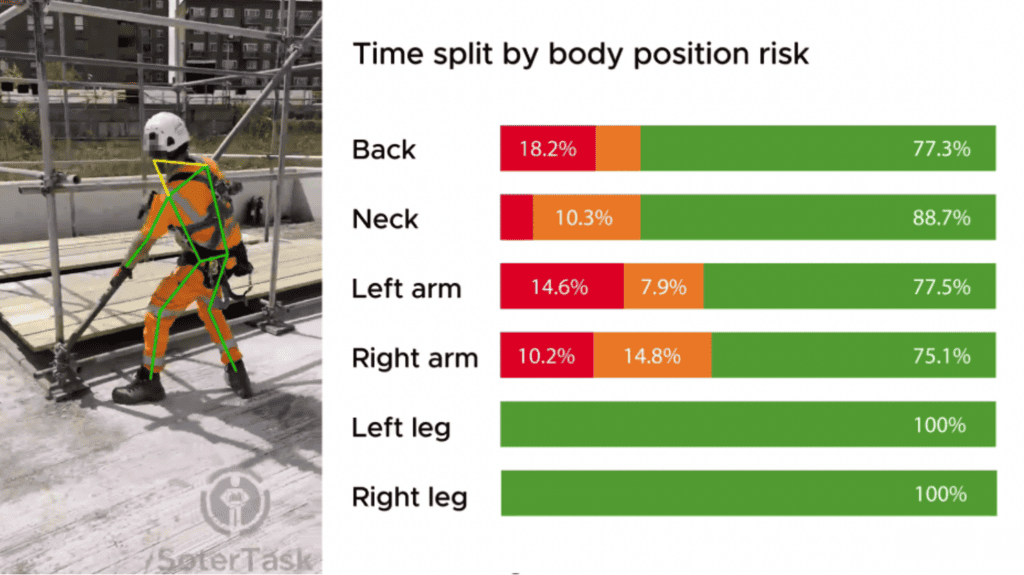

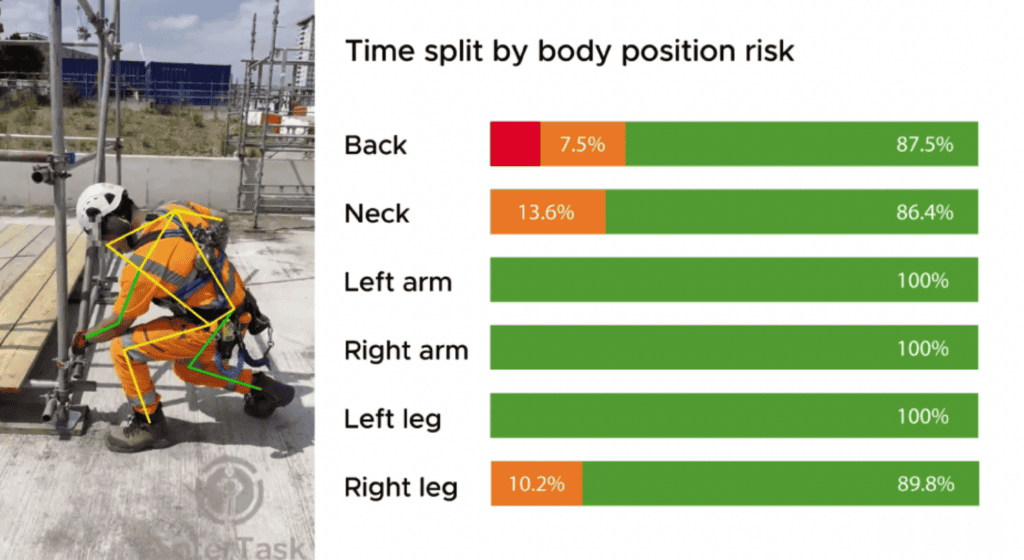

Over the past six weeks, GKR has piloted advanced wearable devices designed to provide workers with real-time feedback about their movements, helping them adopt safer manual handling practices.

Lee Rowswell, MD at GKR, with over 35 years of industry experience and personal insight into the impact of manual handling injuries, passionately supports this initiative.

He explained, “We are the first scaffolding business in Europe to use this technology. The wearables provide our workers with real-time feedback on their manual handling techniques, and the data gives us confidence that we can significantly reduce their risk of musculoskeletal disorders, both now and in the future.

In some cases, we have seen a 61% improvement in hazardous movements. This will enhance the longevity of their careers within our company and the industry as a whole.”

The Technology Behind the Innovation

Heather Chapman from the technology provider elaborated on the practical advantages of the device: it requires no Wi-Fi or smartphone connection and has a battery life of about three weeks. The data captured also allows management to identify the most hazardous tasks, which can then be improved through engineering controls.

“Over the course of two weeks, it helps change people’s behaviours. It teaches them how to move in a way that reduces those high-risk movements,” Chapman explained.

Benefits and Future Direction

GKR’s initiative is not merely a pilot project but a vision for the construction industry’s future. By integrating wearable technology into its training programs, GKR aims to set a new standard for manual handling. This initiative is expected to enhance worker well-being and bring substantial economic benefits by reducing injury-related costs and improving productivity.

Rowswell emphasised that the collaboration with Construction Health and Wellbeing and the use of AI-driven training are key components of their strategy.

“We recognise that each person has different capabilities and a one-size, fits-all training course will not meet everybody’s needs. We’ve engaged with this unique opportunity to see what AI can bring to our people and our business,” he stated.

Industry-Wide Implications

GKR Scaffolding’s commitment to innovation and safety sets an exemplary model for the construction industry. GKR hopes to encourage other companies to adopt similar technologies and practices by sharing their findings and advancements, fostering a safer and more productive working environment industry-wide.

“We have not solved the challenges yet, but we wanted to share our current learnings and future direction,” Rowswell concluded, inviting industry stakeholders to join in the effort to create safer workplaces.

Pioneering a Safer Future in Construction

GKR Scaffolding is yet again helping to revolutionise the industry, this time by addressing manual handling practices within the construction industry. Using advanced wearable technology, GKR is tackling the critical issue of musculoskeletal disorders, improving worker health and wellbeing, and setting new industry standards.

As this technology becomes more widely adopted, the future of construction looks to be healthier and more efficient, benefiting workers and employers alike.