ScaffMag discovers the story behind one of the UK’s most ambitious scaffolding projects—a transformative refurbishment of the iconic former Halifax Building Society’s head office. Crossway Scaffolding has redefined what’s possible in the scaffolding industry with a blend of cutting-edge engineering, collaboration, and a deep respect for heritage.

The former Halifax Building Society’s head office, is a striking example of 1970s architectural ambition, which stands as a landmark in the cityscape. Initially built in 1974 and opened by the Queen, this listed building was one of the most advanced constructions of its time.

Beneath its bold exterior lies a fascinating history. With basements extending nearly 10 meters underground, the building originally housed a deed retrieval system that could deliver documents directly to desks at the press of a button—an innovation unheard of in its time.

Fast forward 50 years, and this architectural marvel required modernisation. It prompted a near to £100 million refurbishment to preserve its historical significance, while preparing it for a new chapter.

The Challenge: Balancing History and Modernity

Taking on a project of this scale and complexity was no small feat. The head office needed a complete overhaul of its glazing system, with glass panels weighing up to half a tonne each. Each panel had to be removed and replaced delicately without compromising the building’s structural integrity or disrupting its iconic appearance.

“The building itself posed unique challenges,” explained Alan Slater, Head of Technical & Product Support at TRAD UK. “The scaffold couldn’t be tied into the structure until it reached circa the 20 metre high mark, meaning everything below had to be buttressed. With roads and public walkways adjacent, this required precise engineering and innovative solutions.”

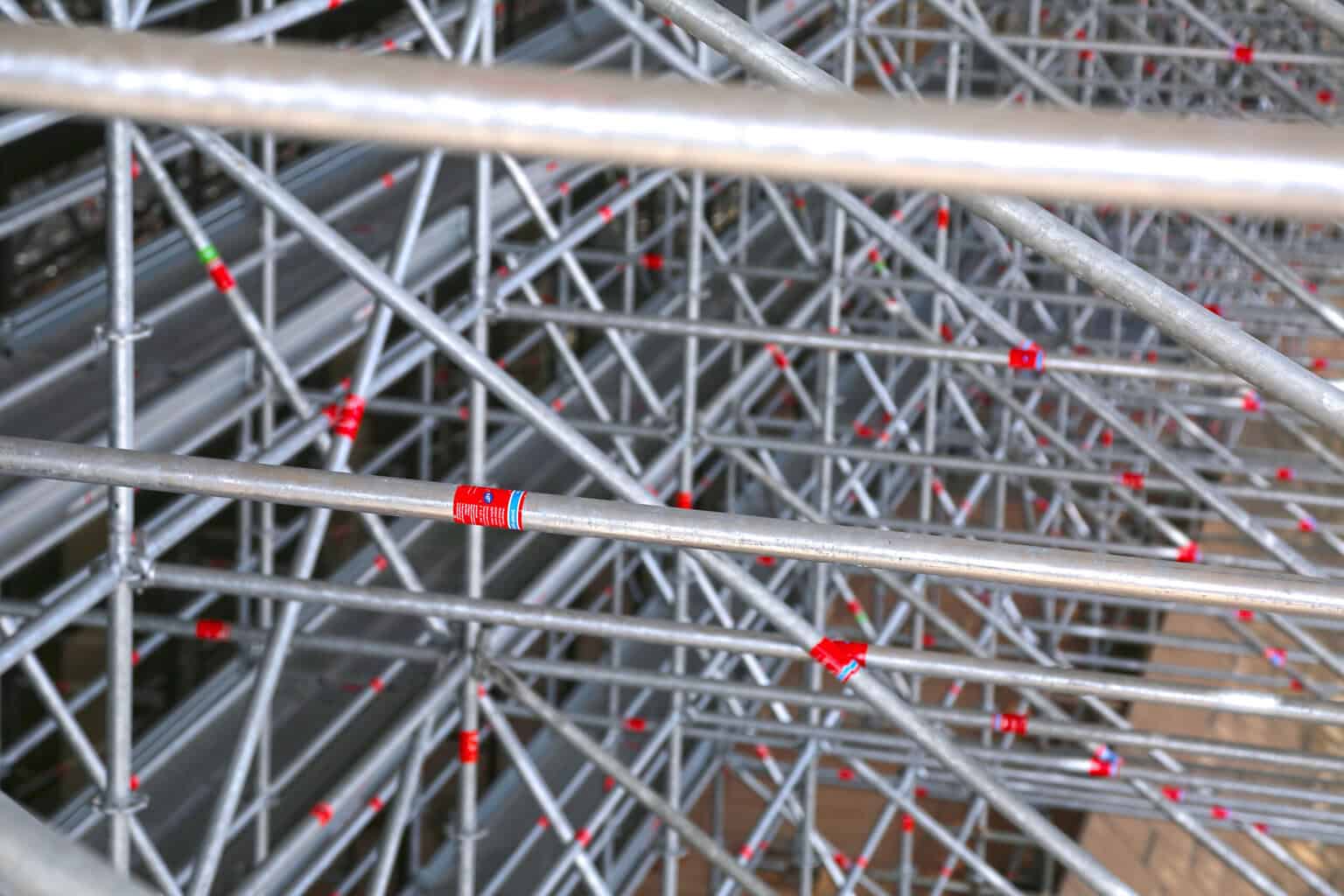

Crossway Scaffolding installed 20,000 square meters of Plettac Metrix System Scaffold, a cutting-edge system selected for its efficiency and adaptability.

In partnership with TRAD UK, the company invested over £1 million in scaffolding materials. This was Crossway’s largest project using the Plettac Metrix system, and its success left a lasting impression.

Crossway’s Contract Manager Luke Schofield highlighted the system’s advantages: “One of our most seasoned scaffolders, who had been using tube and fitting for 25 years, didn’t want to go back after working with this system. The precision and speed it offers are game-changers.”

Innovative Redesigns

The project demanded creativity and precision, starting with a reworking of the initial designs. Crossway was initially provided with 73 scaffold drawings but ultimately required 174 due to the complexity of the structure.

Working in partnership with Manchester-based Buckley Design Solutions to redesign key elements, utilising advanced bracing techniques, which saved both time and resources.

The installation of a 350-meter NIKO rail system around the building was another standout feature. This system supported the weight of the massive glass panels, which were transported along a 2.5-meter-wide scaffold walkway to hoist locations. The operation was seamless, aided by meticulous planning and the use of innovative equipment described as “sucker machines” for the glass.

Supporting the Community

Crossway’s commitment to social value was evident throughout the project. Five apprentices worked on-site, three of whom lived within 15 minutes of the project. This not only fostered local employment but also provided invaluable hands-on experience.

“This is the kind of project that shapes careers,” said Steve Fearnehough, Managing Director at Crossway. “Our apprentices gained exposure to some of the most advanced scaffolding techniques and learned to adapt to the unique challenges of a listed building.”

Collaboration at the Core

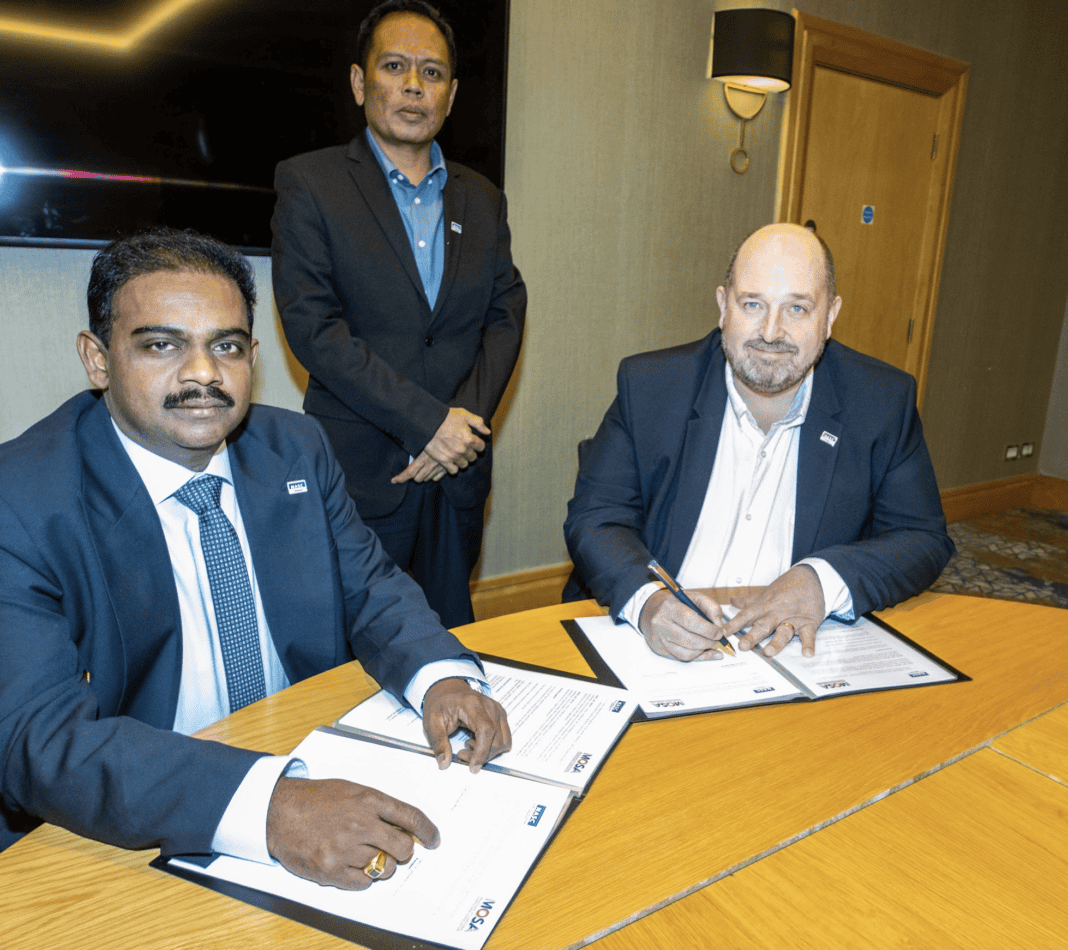

The partnership between Crossway and TRAD UK was a cornerstone of the project’s success. With regular site visits and constant communication, both companies worked together to address challenges and ensure smooth progress.

“We’ve been working with Crossway for over 25 years,” said Alan Slater, Head of Technical & Product Support at TRAD UK. “The mutual trust and open dialogue between our teams made all the difference. This level of collaboration and partnership is what complex projects like this need.”

The proximity of Crossway’s base and TRAD UK’s Leeds depot, just 5 miles and 20 miles from the site respectively, also played a vital role in minimising environmental impact. “Every delivery was carefully coordinated,” Stewart Quinn, TRAD UK’s Regional Director added. “This approach allowed us to collectively reduce our carbon footprint while keeping the project on schedule.”

Environmental Responsibility: A Greener Future

Crossway implemented Just-In-Time deliveries, reducing transport emissions and storage demands. Additionally, using steel decks instead of traditional timber further highlighted the company’s commitment to sustainability.

As the former Halifax Building Society’s head office undergoes its transformation, the project stands as a testament to Crossway Scaffolding’s ingenuity and dedication. By blending advanced engineering, innovative design, and a commitment to people and the planet, Crossway has helped in the restoration of an architectural icon and set a new benchmark for scaffolding excellence.

This scaffolding excellence has also recently been recognised `by the National Access and Scaffolding Confederation (NASC), with the project being a finalist in the Project of the Year (Major) category at their recent annual awards ceremony in Belfast, which is a true testament to the dedication of all involved, in making such a complex and innovative scheme work.

“This was a monumental task, but our team rose to the occasion,” said Steve Fearnehough. “It’s a proud moment for us to see this project come together so beautifully.”

With the external refurbishment nearing completion, this isn’t just another scaffolding job—it’s a masterclass in innovation, collaboration, and community-focused construction, a legacy that will endure for years to come.