It is no secret that Cornish startup ScaffFloat has certainly made waves in the scaffolding industry since it launched its safe floating scaffold access system in 2020. For a Q&A, Scaffmag’s editor Daniel Norton catches up with Toby Budd, founder and managing director of ScaffFloat to find out how it all came to be

DN: Toby, thank you for taking the time to talk to our Scaffmag readers and for taking the time to answer our questions. What inspired you to come up with the idea for ScaffFloat in the first place?

TB: A few years ago we were working on a project to build a folding workboat that fits in a shipping container. We decided to make our own plastic floats for this and it was during the design process my father-in-law asked me to make a netting framework over his fruit bushes to keep the birds out. I figured scaffold and Key Clamps would be easy to use, so I looked on Facebook Marketplace and found a scaffolder down west selling up his business. I drove down and spent a couple of hours chatting with him about beams, tubes, and clips. I had never really looked at scaffolding components before and remember being impressed with the low, mass-produced cost and versatility of the components. I was towing the trailer load of scaffold back up the A30 when I joined the dots and had the idea to make pontoons with scaffold. We moved quickly and launched the first prototype, a 16m x 6.4m ScaffFloat, a few months later after filing a patent and trademark.

DN: Can you tell me about your first job with ScaffFloat?

TB: A local marine contractor, KML, was working in the Port of Felixstowe to demolish an old dolphin. This required access to the steel piles that supported it. Initially, they tried a modular plastic pontoon but it moved around too much in the waves and contractors felt it was unsafe to work from. We mobilised a horseshoe-shaped 4m x 4m ScaffFloat that could fit around the pile. With a dropdown deck section behind the pile, this gave them 365-degree access to the pile from a much more stable platform. It did a great job and stayed for several months. It was a really good first test in the real world.

DN: Since you started your business, how many projects have you been able to deliver?

TB: Well over 50 now. I think in total we have now delivered over 5,000 hours of safe floating access to contractors around the UK.

DN: The idea of ScaffFloat sounds awesome, but what is the business model for the company?

TB: Our floats are available only for hire, and we are very strict about this, even though people constantly ask if they can buy the floats. We do this to maintain control over how the system is used. We make sure that every project has a proper design and stability assessment, and that we have overseen or checked the RAMS. Safety is one of the things our customers like most about ScaffFloat. Therefore, it is vital that we maintain our track record, and to do this we need to retain some control.

DN: I noticed your ScaffFloats are equipped with engines. How did this come about?

TB: Putting propulsion on ScaffFloat was a turning point in the business and now 80% of our ScaffFloats go on hire with outboard engine pods. This adds a huge amount of value to what ScaffFloat can do, and once onsite these workboats are incredibly useful.

We now use high thrust 60 hp Yamaha four strokes which meet all the latest emission standards and are very fuel efficient. We tend to run them as a pair for redundancy and manoeuvrability and can get just under a ton of bollard pull from them for towing and pushing. Like wind farm transfer boats, we also rely on ‘pushing on’ as a method of holding position while contractors work from ScaffFloat. This is normally much safer than using lines, particularly in any wave action.

DN: So, do you operate overseas as well?

TB: Yes, but not properly. We have floats in Australia, Malta and Cyprus but we have not had the time or resources to develop our international offering properly. We get very regular enquiries from overseas, particularly from Europe, the Middle East, Australia and New Zealand. At the moment we don’t have the framework to push ScaffFloat overseas, and this is one of my priorities this year because the demand is there for sure.

DN: Can you tell me what kind of regulations you operate under?

TB: We operate under a range of regulations; for the marine side it is the MCA, PLA & IMO which cover manning, safety equipment, stability standards and minimum freeboards. Most of TG20:13 and other scaffold regulations are not relevant to what we do, but we do use elements of it for things like edge protection. For lifting, we use Lloyd’s Register Code for Lifting Appliances in a Marine Environment and all our cranes are LOLER tested. To assess the structure, if needed, we use EuroCode EN1993-1-1-2005 & DNVGL-T-0378 and also refer to BS5975:2019 for temporary works. On larger projects we can also offer customers an independent Cat 3 check by our partner Richter; this gives our customers reassurance that we have taken a safe and prudent approach to our design and planned method of works.

We have also always been able to satisfy any of our customers’ structural or safety questions. This includes the Royal Navy, BAE systems, Network Rail, Port of London Authority, MCA, numerous Harbour Authorities and Harbour Masters including QHM (Now KHM), Canal & River Trust, Environment Agency and numerous principal contractors like Volker, Dyer Butler, J Murphy, Amco Giffen, Laing O’Rourke, Balfour Beatty, Story & BAM.

DN: What is your approach to working with scaffolding contractors?

TB: We have a really good relationship with a number of scaffolding companies around the UK and over half of our jobs are delivered in partnership with them. Initially, we had the concept of ‘Approved Installers’ where scaffold companies could hire the floats from us and then build and hire on the pontoons. However, this did not work. We quickly realised customers wanted much more than just a pontoon. They wanted our marine experience to manage the floating element of their project. Now, most of the work we do includes personnel, extra equipment like engines and winches, and the management of that part of the project.

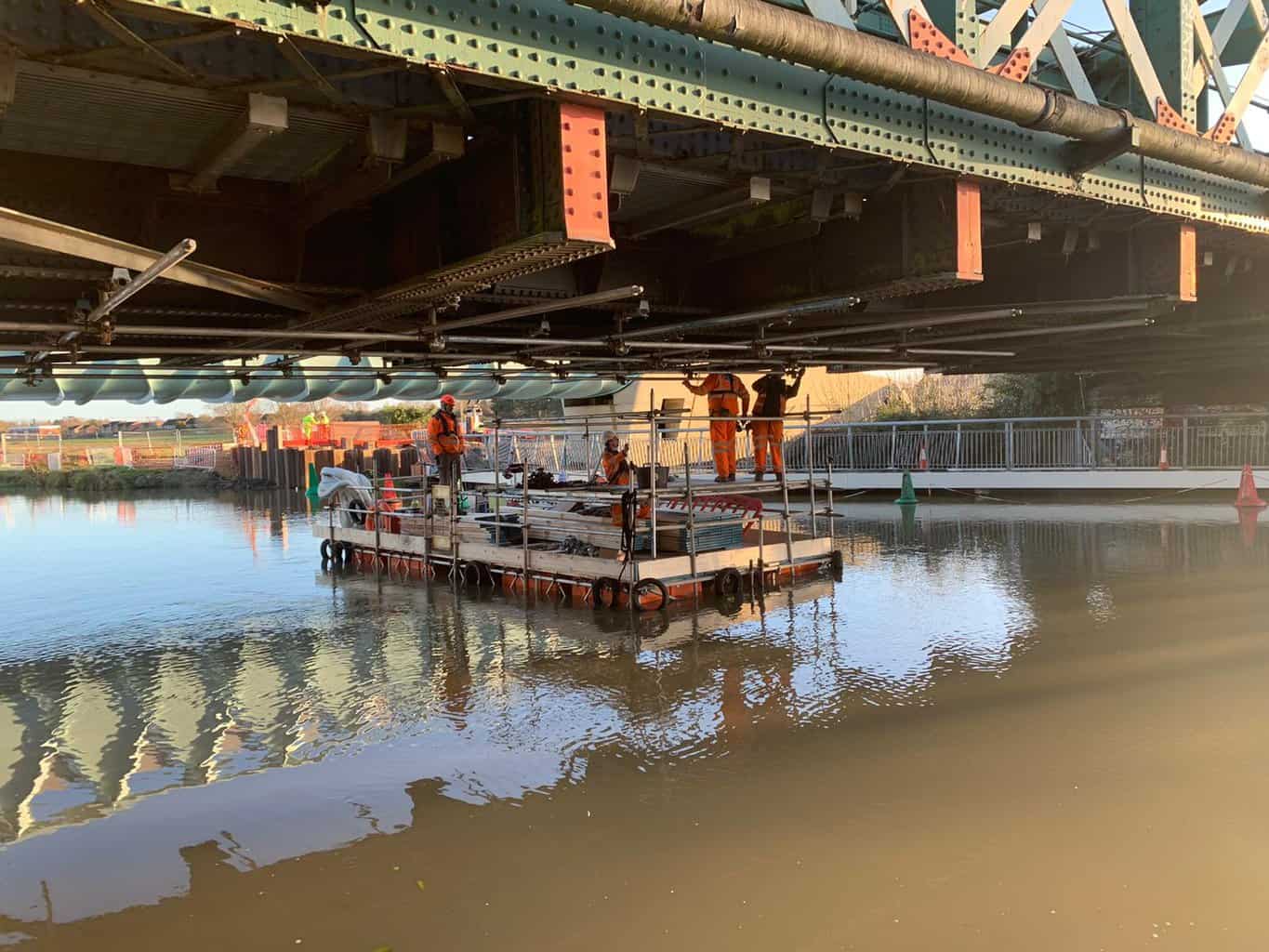

So now we work with scaffold firms in two ways. 1) Bridge Scaffold – We provide floating access, normally from a self-propelled ScaffFloat with a skipper, for them to install a suspended scaffold under the bridge. We can carry the scaffolders and a couple of tons of boards, fittings, beams and tubes onboard and position the ScaffFloat right under the bridge. This saves the scaffolders a significant amount of time compared to if they built from one end. 2) Your Customers – If a scaffolding company has a customer that needs a floating solution, we can work together with them to deliver a ScaffFloat. It is a great partnership because they have the relationship with the customer and also provide scaffolding and help assemble the ScaffFloat. We bring the floats, engines and other equipment and once on hire we can run the floating element of the project.

We are always keen to speak to scaffolding companies that would like to work with us.

DN: It seems to me that you have a pretty good handle on your marketing.

Yes. We get that a lot, which is nice. I have a strong background in simple marketing that works, but the reality is that we can and will do much better in this area going forward. Our website has not been updated for almost a year. We are in the process of setting up a CRM, newsletter, and sales process. We also run no SEO, PPC, or outreach. We have just been too busy. The only thing I have worked hard on is Linkedin, which has been invaluable for us, especially in lockdown. Luckily the product has done very well selling itself. We have grown as much through customers’ positive endorsements and referrals as anything else, which is really pleasing and encouraging. It is abundantly clear already that ScaffFloat is doing a great job of providing a long-needed solution to the well-known problems associated with floating-access works. The surprise so far is just how big the gap is in the market that we are addressing.

DN: Can you tell me how safe ScaffFloat is?

TB: Safety is the cornerstone of what we do. We provide a number of services but the core of what we do is getting contractors access to the work they need to do, and then keeping them safe while they do it. Whether it be cutting, drilling, welding, electricals, coring, surveying, scaffolding or painting, we want the workers that operate from ScaffFloat to be able to work efficiently and safely, and as they are normally used to working from land, a big part of what we do is taking care of them when they work afloat.

DN: What does the future hold for ScaffFloat?

In the medium term, the big focus is on developing processes with particular emphasis on developing our marketing, sales, project management systems and SOPs thus ensuring that the business is well-equipped and resourced to continue its scale-up. We have a great team of dedicated professionals that have enabled us to get this far in such a short period of time. However, in the near future, we plan to expand the team in all of these specialist areas to ensure that human capacity doesn’t become the limiting growth factor. We are also working towards various accreditations including ISO 45001.

Long-term is a very tough question because, given how busy we currently are, it’s proving difficult for me to lift my head up out of the day-to-day to really take a view of where we will be beyond this year’s growth. But if I am being honest with myself I suspect we will ‘outgrow the pot’ we are in within the next year or two. I really love innovation and solving problems, and in some ways, I have reluctantly learned to do the business bit. At the moment we are pumping in value with lots of exciting ‘firsts’ planned for this year, but after that, I suspect the business will shift, become less of a start-up and more of a mature business where it’s about photocopying services and designs and growing to the next level. We have some strong IP and patents and so the future commercial possibilities for our innovative business are clearly very significant.

DN: Last but not least, do you regret anything?

TB: That’s a good question. No. Well, hindsight is a wonderful thing and I am sure I would do some things differently but I am not one for regret. Mistakes are an inevitable and valuable part of the innovation process. You minimise them, fix them, learn from them and move on. Every day is a school day and we’re on a steep learning curve. I don’t know what this year will hold. However, if I look back in our wake and what we have done in the last 12 months, I suspect it’s going to be busy. January revenue is already up tenfold on last year.

This article was first published in the ScaffMag Magazine Issue 18