An investigation by the Health and Safety Executive found that WH Metals Limited and its director failed to prevent the risk of falls from height during the installation of signs. The scaffolding tower being used lacked edge protection—a basic safety measure that investigators say would likely have prevented the tragedy.

The company’s director was present on site when the incident occurred, adding to the severity of the safety failures identified by HSE inspectors.

Mr Mughal’s son, Asad Iftikar, paid tribute to his father following the court hearing: “My father was like a roof to the family, and since his death, I and my siblings have felt alone. He always supported us in everything we did; he would help us make all the important decisions in our lives.”

WH Metals Limited, based in Preston, pleaded guilty to breaching the Health and Safety at Work Act 1974. The company received a £45,000 fine and was ordered to pay £4,826.21 in costs plus a £2,000 victim surcharge.

Director Waqas Hanif pleaded guilty to breaching the same Act and received a 26-week custodial sentence, suspended for 12 months. He was also ordered to pay £4,846.21 in costs and a £154 victim surcharge.

HSE Inspector David Hobbs emphasised the preventable nature of the tragedy: “Work at height remains one of the leading causes of workplace injury and death. In this case, a fall of six feet was enough to cause death, highlighting the dangers.

“This incident highlights the importance of suitable control measures, such as edge protection, to minimise the risk of serious personal injury.”

The case serves as a stark reminder that even relatively low-level work at height can prove fatal without proper safety measures. HSE guidance clearly states that tower scaffolds should be fitted with suitable guardrails around platforms—a well-established control measure that has been standard practice in the industry for decades.

An investigation by the Health and Safety Executive found that WH Metals Limited and its director failed to prevent the risk of falls from height during the installation of signs. The scaffolding tower being used lacked edge protection—a basic safety measure that investigators say would likely have prevented the tragedy.

The company’s director was present on site when the incident occurred, adding to the severity of the safety failures identified by HSE inspectors.

Mr Mughal’s son, Asad Iftikar, paid tribute to his father following the court hearing: “My father was like a roof to the family, and since his death, I and my siblings have felt alone. He always supported us in everything we did; he would help us make all the important decisions in our lives.”

WH Metals Limited, based in Preston, pleaded guilty to breaching the Health and Safety at Work Act 1974. The company received a £45,000 fine and was ordered to pay £4,826.21 in costs plus a £2,000 victim surcharge.

Director Waqas Hanif pleaded guilty to breaching the same Act and received a 26-week custodial sentence, suspended for 12 months. He was also ordered to pay £4,846.21 in costs and a £154 victim surcharge.

HSE Inspector David Hobbs emphasised the preventable nature of the tragedy: “Work at height remains one of the leading causes of workplace injury and death. In this case, a fall of six feet was enough to cause death, highlighting the dangers.

“This incident highlights the importance of suitable control measures, such as edge protection, to minimise the risk of serious personal injury.”

The case serves as a stark reminder that even relatively low-level work at height can prove fatal without proper safety measures. HSE guidance clearly states that tower scaffolds should be fitted with suitable guardrails around platforms—a well-established control measure that has been standard practice in the industry for decades. Company fined after worker dies in six-foot scaffold fall

An investigation by the Health and Safety Executive found that WH Metals Limited and its director failed to prevent the risk of falls from height during the installation of signs. The scaffolding tower being used lacked edge protection—a basic safety measure that investigators say would likely have prevented the tragedy.

The company’s director was present on site when the incident occurred, adding to the severity of the safety failures identified by HSE inspectors.

Mr Mughal’s son, Asad Iftikar, paid tribute to his father following the court hearing: “My father was like a roof to the family, and since his death, I and my siblings have felt alone. He always supported us in everything we did; he would help us make all the important decisions in our lives.”

WH Metals Limited, based in Preston, pleaded guilty to breaching the Health and Safety at Work Act 1974. The company received a £45,000 fine and was ordered to pay £4,826.21 in costs plus a £2,000 victim surcharge.

Director Waqas Hanif pleaded guilty to breaching the same Act and received a 26-week custodial sentence, suspended for 12 months. He was also ordered to pay £4,846.21 in costs and a £154 victim surcharge.

HSE Inspector David Hobbs emphasised the preventable nature of the tragedy: “Work at height remains one of the leading causes of workplace injury and death. In this case, a fall of six feet was enough to cause death, highlighting the dangers.

“This incident highlights the importance of suitable control measures, such as edge protection, to minimise the risk of serious personal injury.”

The case serves as a stark reminder that even relatively low-level work at height can prove fatal without proper safety measures. HSE guidance clearly states that tower scaffolds should be fitted with suitable guardrails around platforms—a well-established control measure that has been standard practice in the industry for decades.

An investigation by the Health and Safety Executive found that WH Metals Limited and its director failed to prevent the risk of falls from height during the installation of signs. The scaffolding tower being used lacked edge protection—a basic safety measure that investigators say would likely have prevented the tragedy.

The company’s director was present on site when the incident occurred, adding to the severity of the safety failures identified by HSE inspectors.

Mr Mughal’s son, Asad Iftikar, paid tribute to his father following the court hearing: “My father was like a roof to the family, and since his death, I and my siblings have felt alone. He always supported us in everything we did; he would help us make all the important decisions in our lives.”

WH Metals Limited, based in Preston, pleaded guilty to breaching the Health and Safety at Work Act 1974. The company received a £45,000 fine and was ordered to pay £4,826.21 in costs plus a £2,000 victim surcharge.

Director Waqas Hanif pleaded guilty to breaching the same Act and received a 26-week custodial sentence, suspended for 12 months. He was also ordered to pay £4,846.21 in costs and a £154 victim surcharge.

HSE Inspector David Hobbs emphasised the preventable nature of the tragedy: “Work at height remains one of the leading causes of workplace injury and death. In this case, a fall of six feet was enough to cause death, highlighting the dangers.

“This incident highlights the importance of suitable control measures, such as edge protection, to minimise the risk of serious personal injury.”

The case serves as a stark reminder that even relatively low-level work at height can prove fatal without proper safety measures. HSE guidance clearly states that tower scaffolds should be fitted with suitable guardrails around platforms—a well-established control measure that has been standard practice in the industry for decades. ScaffEx25 sets new attendance record in Manchester

Scaffolding makes historic debut at WorldSkills Ireland 2025

Young scaffolders showcase their expertise as the trade is included in the prestigious competition for the first time

Scaffolding has been included in WorldSkills Ireland for the first time, marking a significant milestone for the construction trade at the prestigious vocational skills competition held at Dublin’s RDS last week.

The historic inclusion represents a major step forward in recognising scaffolding as a skilled profession worthy of international competition status, bringing Ireland in line with global efforts to promote construction trades among young people.

Global platform for skills

WorldSkills, founded in 1950, is a global organisation promoting vocational and technological education across 85 member countries on all continents. The competition has evolved into the world’s largest vocational education and skills excellence event, often described as the “Olympics of Skills.”

The Irish iteration attracts around 20,000 senior-level secondary students from over 300 schools nationwide during its three-day programme, making it a crucial recruitment ground for Ireland’s construction industry at a time when skilled trades workers are in high demand.

Teams from three leading access companies—PHD Access Ltd, Celtic Working Platforms Ltd, and JLD Access Limited—took up the challenge to demonstrate the full spectrum of scaffolding expertise required in modern construction.

The competition format required participants to demonstrate not just physical building skills, but also the critical planning and safety management that underpins professional scaffolding work. Teams had to produce comprehensive risk assessments and method statements (RAMS), detailed material lists, and deliver toolbox talks before beginning construction.

The structures themselves presented a complex technical challenge, incorporating an independent scaffold system, integrated staircase access, specialised beam work and a functional seating area, all of which had to meet strict safety standards and be erected within tight time constraints.

Industry collaboration

The successful debut was made possible through extensive collaboration between educational institutions and industry partners. Scaffold manufacturer Layher played a crucial role, supplying not only the materials but also technical drawings and engineering expertise essential for the competition structures.

This partnership model reflects the broader approach to skills development in Ireland, where industry leaders work closely with training providers to ensure apprenticeships meet real-world demands.

John Kelly, Manager of the National Construction Training Campus at Mount Lucas, acknowledged the tight timeline but praised the collaborative effort that made the event possible.

“We were absolutely thrilled to be offered the chance to include scaffolding at WorldSkills Ireland for the first time. We didn’t have a very long lead-in period prior to the event, however, our staff, the employers, the teams and Layher all pulled together to provide an excellent showcase to promote a career in scaffolding,” Kelly said.

The competition received high-level political support, with Minister James Lawless of Fianna Fáil launching WorldSkills Ireland 2025. As Minister of Higher Education, Research, Innovation and Science, Lawless emphasised the event’s role in addressing Ireland’s skills needs.

“This event offers a valuable, hands-on opportunity for students, parents, and teachers to engage directly with employers and education providers from across the country. It showcases apprenticeships and traineeships in action and highlights clear pathways to internationally recognised qualifications and highly sought-after skills,” the Minister said.

The political endorsement reflects the growing recognition by the government of the construction industry’s importance to Ireland’s economic development, particularly as the country faces ongoing challenges in housing and infrastructure.

Expert validation

The competition’s credibility was enhanced by the presence of Dave Mosley, an international scaffolding competency and safety consultant who served as Chief Examiner.

Mosley has been instrumental in developing Ireland’s scaffolding apprenticeship programme, serving as both subject matter expert during development and External Authenticator since its launch.

His assessment of the participants was overwhelmingly positive, noting not just their technical competence but also their professional approach to health and safety—crucial factors in an industry where lives depend on proper procedures.

“It’s very pleasing to see scaffolding being considered a relevant and viable career option for young people in Ireland, which is now taking its rightful place at the WorldSkills event,” Mosley said.

“The knowledge, competence and work ethic displayed by all the teams highlighted that the introduction of the apprenticeship in Ireland has proven to be very positive. They took the event seriously, worked safely, were polite, easy-going and showed a good sense of humour, which was handy, considering the weather at times.”

Building for the future

The success of this inaugural scaffolding competition has already sparked ambitious plans for expansion. Mount Lucas is planning a significantly enhanced scaffolding element for WorldSkills 2026, with the ultimate goal of preparing Irish competitors for the international stage.

The international WorldSkills competition, set to take place in Japan in 2027, represents the pinnacle of vocational skills competition. Ireland’s participation in scaffolding would mark another milestone in the country’s commitment to excellence in construction trades.

“We will be looking to build on our success this year to provide a bigger and better scaffolding experience for all at future WorldSkills events,” Kelly confirmed, signalling the long-term commitment to developing this aspect of the competition.

Scaffolding work pipeline shrinks as construction starts drop 22%

- Fewer enquiries – With 22% fewer projects starting, scaffolding contractors can expect significantly reduced enquiry levels through Q4 and into 2026

- Price pressure – Competition for remaining work will intensify, likely forcing day rates down

- Delayed payments – Main contractors under financial pressure may extend payment terms beyond the standard 30 days

- Equipment utilisation drops – Lower demand means scaffolding gear sitting idle, hitting rental companies particularly hard

Housing Sector Hit Hardest

The residential sector downturn is especially concerning for scaffolding contractors, as housing work – from new builds to refurbishments – typically provides steady, predictable income. With housing project starts down 10% and main contract awards falling 44%, many scaffolding firms that focus on residential work are looking at a significant revenue gap.

“Residential scaffolding is our bread and butter,” explains one Midlands-based scaffolding contractor. “When house builders pull back, we feel it immediately. Projects that were supposed to start in October are now pushed to spring, if they happen at all.”

The residential sector downturn is especially concerning for scaffolding contractors, as housing work – from new builds to refurbishments – typically provides steady, predictable income. With housing project starts down 10% and main contract awards falling 44%, many scaffolding firms that focus on residential work are looking at a significant revenue gap.

“Residential scaffolding is our bread and butter,” explains one Midlands-based scaffolding contractor. “When house builders pull back, we feel it immediately. Projects that were supposed to start in October are now pushed to spring, if they happen at all.”

The Regional Picture

While the overall picture is grim, the data shows stark regional differences that scaffolding contractors need to understand:- Wales – Bucking the trend with 25% of total project approvals worth £3bn, mainly driven by infrastructure work

- North-West – Seeing a massive 423% increase in project values to £2.7bn compared to 2024

- Other regions – Struggling with significant project cancellations and delays For scaffolding contractors with national coverage, this suggests a potential shift of resources toward Wales and the North-West.

Some Bright Spots Amid the Gloom

While the overall picture is concerning, the full data reveals some opportunities for scaffolding contractors willing to adapt:- Offices surging – Office project starts jumped 125% compared to last year, offering opportunities for scaffolding contractors specialising in commercial work

- Hotels and leisure up 23% – This sector’s growth could benefit scaffolding firms with hospitality project experience

- Community projects strong – A 30% increase in community and amenity project starts, largely driven by prison and emergency services buildings

- Civil engineering boom – Planning approvals in civils jumped 171%, though much of this work requires specialist scaffolding capabilities

Regional Opportunities

The regional breakdown shows where scaffolding contractors might find work:- Wales dominates – 25% of all approvals worth £3bn, suggesting strong opportunities for scaffolding contractors operating in Wales

- North-West surge – 22% of approvals totalling £2.7bn, representing a massive 423% increase on 2024 levels

Bottom Line

This isn’t just another monthly dip – the 22% decline in project starts represents a fundamental shift in market conditions that will directly impact scaffolding demand through the remainder of 2025 and likely into 2026. However, opportunities exist for contractors who can pivot to growing sectors and regions where work is still flowing.AT-PAC accelerates European expansion with strategic German launch

Scaffolding specialist establishes key operations in Germany as part of continental European growth strategy

AT-PAC, part of umdasch Industrial Solutions, is ramping up its European operations with Germany taking centre stage in the company’s expansion plans.

The scaffolding specialist has established a strategic base in Windhagen near Bonn, bringing experienced personnel and technical expertise to support German scaffolding contractors, asset owners, and EPCs in the industrial sector.

Making a Statement at bauma 2024

The company made an unmistakable impression at this year’s bauma trade fair in Munich, where visitors couldn’t miss AT-PAC’s towering 30-meter scaffolding demonstration.

This full-scale debut marked the company’s serious commitment to the German market, following successful operations in the USA, Canada, Australia, Latin America, and the UK.

AT-PAC’s comprehensive offering serves scaffolding companies across multiple sectors, from industrial applications to conventional façade work, interior projects, and specialised applications.

The company provides end-to-end project support encompassing technical documentation, consulting, engineering, and reliable delivery – all underpinned by an unwavering focus on user safety.

Strong Market Position

Leading AT-PAC Germany’s operations is Matthias Neurohr, a seasoned industry veteran who highlights the company’s competitive advantages. “What sets us apart is our strong delivery capabilities combined with high-quality user documentation,” Neurohr explains. “A major draw for many customers is that our complete product portfolio carries DIBT approval and is available for both purchase and rental.”

The company plans to further enhance its service offering, with multiple training sessions scheduled to begin in winter 2025, designed to help users work more safely, efficiently, and effectively.

Innovation and Growth Plans

AT-PAC’s German launch represents just the opening phase of broader ambitions.

“Our goal is to establish widespread operations across Germany, providing flexible and efficient scaffolding solutions to our customers nationwide,” says Neurohr. “We’re simultaneously developing our next generation of product innovations.”

Some of these innovations were already on display at bauma, including the MPBS aluminium Multi-Purpose Beam System and Public Access Stairs. These developments signal AT-PAC’s intention to establish itself as a leading name in innovative scaffolding solutions throughout Germany.

The company’s European expansion through Germany positions AT-PAC to leverage the country’s central location and strong industrial base as a springboard for further continental growth, bringing its proven international expertise to new markets while maintaining its commitment to safety and innovation.

Scottish scaffolding apprentices to compete at ScaffChamp 2026

A team of young scaffolders from Scotland and Northern Ireland are set to represent the region at the international competition ScaffChamp in Lithuania next year.

The all-apprentice squad, aged between 16 and 21, will compete at the event in what organisers say is a first for the industry.

I-Scaff Director Ross Brown is spearheading the initiative following discussions about attracting young people to the scaffolding trade at the recent industry event ScaffEx in Manchester.

He is now seeking sponsorship to cover travel costs and equipment for the team.

The ScaffChamp competition, powered by scaffolding system manufacturer Layher, will take place in Lithuania next year.

Mr Brown said the idea emerged from the “Employability in the Scaffolding Industry” panel at the recent ScaffEx event, where youth recruitment was identified as a key challenge.

“We already have some incredible young talent in the industry, and with the right support, even more will join,” he said.

‘Once-in-a-lifetime experience’

The team will be supervised by a qualified team leader but all competitors will be current apprentices, showcasing what Mr Brown describes as the “skill and determination” of young workers in the trade.

“Competing on the global stage will give them a once-in-a-lifetime experience of international competition, camaraderie, and community,” he said.

“We aim to demonstrate that talent, efficiency, and mastery of the Layher system have no age limit.”

The scaffolding industry has faced ongoing challenges in attracting younger workers, with concerns about skills shortages affecting construction projects across the UK.

Mr Brown hopes the high-profile competition will inspire other young people to consider scaffolding as a career while demonstrating the industry’s commitment to supporting apprentices.

Funding sought

The initiative requires funding for travel expenses, personal protective equipment, tools, training, and media coverage.

Mr Brown is approaching potential sponsors across the construction industry, offering them visibility at one of scaffolding’s premier international events.

“This is a unique opportunity to support and promote the next generation of scaffolders while raising visibility for your brand on an international stage,” he said.

The team registration process is currently underway, with training expected to begin early next year ahead of the competition.

Companies interested in sponsoring the team have been invited to contact Mr Brown to discuss partnership arrangements.

Pontefract scaffolding director hit with £100k Covid loan repayment order

A West Yorkshire scaffolding contractor has been ordered to repay over £100,000 after fraudulently claiming government Covid-19 support loans, in a case that highlights ongoing enforcement action against construction industry fraud.

Mark Degnan, 56, director of MBL Scaffolding Services Ltd based in Pontefract, was told by Leeds Crown Court he must return nearly £60,000 within six months or face imprisonment, having already repaid around £55,000.

The case centres on Degnan’s fraudulent applications for two £50,000 Bounce Back Loans in 2020, which he secured by inflating his company’s annual turnover. Under the scheme rules, businesses were limited to a single loan worth up to 25 per cent of their annual revenue, capped at £50,000.

Degnan received a two-year suspended sentence earlier this year and has been disqualified from acting as a company director for five years—a ban that will prevent him from holding senior positions in any scaffolding or construction firm during this period.

He must also complete 50 hours of community service.

The Bounce Back Loan Scheme, launched in May 2020, provided crucial lifelines to thousands of construction and scaffolding businesses during the pandemic lockdowns. However, the case demonstrates how some operators exploited emergency support measures designed to protect legitimate firms and their workforces.

Alexander Grierson from the Insolvency Service’s Asset Recovery team said the confiscation order sends a clear message to the industry. “Mark Degnan cynically exploited a scheme designed to help small businesses during the pandemic,” he stated.

The enforcement action forms part of wider government efforts to recover fraudulently claimed pandemic support funds across the construction sector, with authorities continuing to investigate suspicious applications made during 2020-2021.

Scaffolding boss raises £35k with sports auction

A charity auction of rare sports memorabilia has raised over £35,000 to mark the 30th anniversary of a Scottish scaffolding company.

John Horne, managing director of JR Scaffold, part of The JR Group, sold more than 80 items from a personal collection he has built up over nearly three decades.

Highlights included a framed Celtic shirt signed by club legend Jimmy “Jinky” Johnstone, which fetched more than £5,000, and a signed Lionel Messi Barcelona top, which attracted a bid of £1,300.

The two-week sale, hosted online by Blue Parrot Events Group through its Event PAL fundraising platform, drew interest from collectors around the world. More than 200 bids were placed on items ranging from football shirts signed by Graeme Souness and Messi to memorabilia bearing the signatures of Muhammad Ali, Tiger Woods and Diego Maradona.

All proceeds will go to the Emmie Smillie Foundation and MND Scotland, charities which hold personal significance for Mr Horne and his family.

He said the response had been overwhelming and that parting with the memorabilia had been an emotional decision but “the right one” as the company marked its 30-year milestone.

Some items from the collection have also been donated to support the Prince and Princess of Wales Hospice. Others will feature at the December to Remember charity ball in Glasgow later this year, which Mr Horne is set to host.

Pilosio announces UK partnership with JMAC Group and Creator at ScaffEx25

Pilosio UK has announced a new partnership with JMAC Group Hire & Sales and Creator Scaffold Designs and Temporary Works Consultants Ltd, in a move aimed at strengthening support for contractors and engineers across the country.

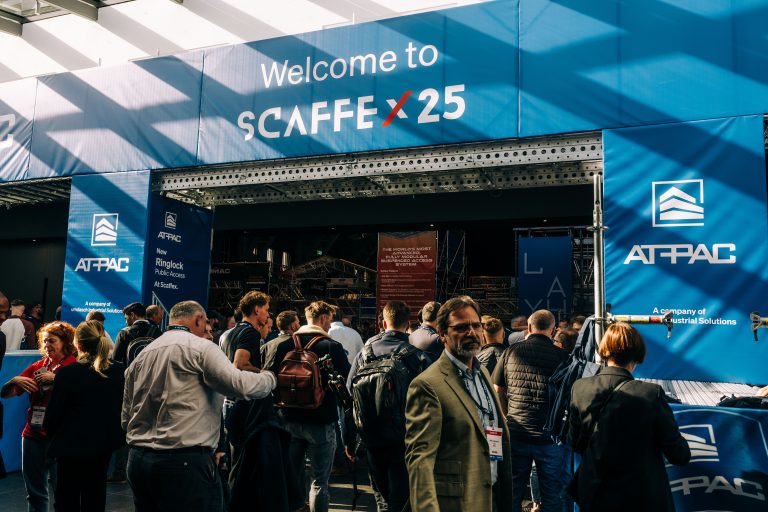

The agreement was unveiled last week at ScaffEx25 in Manchester, where industry leaders gathered for two days of exhibitions, product launches and networking.

Under the partnership, Pilosio’s scaffolding and access systems will be distributed through JMAC Group Hire & Sales’ established UK network. Creator Scaffold Designs will provide technical expertise and design support, offering contractors a fully integrated service.

The companies said the collaboration combines product innovation, distribution strength and engineering capability, with the aim of delivering smoother and more efficient project outcomes.

Pilosio UK described the agreement as a significant step in expanding its presence in the British market. JMAC Group highlighted the benefit of adding advanced products to its supply chain, while Creator Scaffold Designs emphasised the importance of technical support in ensuring safe and successful projects.

The announcement was among several major developments revealed at ScaffEx25, reflecting the industry’s focus on collaboration and innovation.

Scaffolding industry celebrates at Manchester awards night

The UK scaffolding and access industry gathered in Manchester on Friday to celebrate its leading figures and landmark projects at the Scaffolding Excellence Awards 2025.

The event, held at Manchester Central to mark the close of the ScaffEx25 exhibition, brought together contractors, suppliers and guests from around the world.

Television presenters Alex Jones and Clare Balding co-hosted the ceremony, joined on stage by Leigh Francis, Mike Tindall and Shaun Ryder.

Major winners

The night’s standout prize went to Allen & Foxworthy for its work on the Blenheim Palace Roof Restoration. The company collected both Design of the Year and Project of the Year – Large.

Judges described the scheme as the “project of a lifetime” and praised its “innovation, creativity and problem-solving on a job that demanded genuine out-of-the-box thinking”.

Other notable winners included:

-

Apprentice of the Year: Rhys Bennett of JMAC

-

Lifetime Achievement: Rob West of Benchmark Scaffolding

-

Product of the Year: Staht

-

Service of the Year: Leach’s

Rob West, who received the Lifetime Achievement Award, was commended for his role in raising industry standards, strengthening safety culture and mentoring the workforce. Judges said his influence had extended beyond his own company, helping shape “industry thinking” across commercial, rail, infrastructure and heritage sectors.

Clive Dickin, Group Chief Executive of NASC and CISRS, described the evening as a highlight of the industry calendar. “It’s a great opportunity for the industry to get together and celebrate the achievements of the brilliant people in the industry.

The winning projects are remarkable examples of what this industry can and does achieve every day,” he said.

Full list of winners

-

Apprentice of the Year (CISRS): Rhys Bennett, JMAC (runner-up John Stokes, Shield Services Group)

-

Service of the Year (NASC Insurance Services): Leach’s

-

Project of the Year – Small (Southern Hoist Services): Proplant Scaffolding (highly commended: Malvern Scaffolding)

-

Product of the Year (Step-Up Scaffold UK): Staht

-

Design of the Year (Worldwide Scaffold and Access): Allen & Foxworthy

-

Project of the Year – Medium (JR Scaffold Services): Rose System Scaffolding (highly commended: Chris Sedgeman Scaffolding)

-

Project of the Year – Large (Trad UK): Allen & Foxworthy (highly commended: Inner City Scaffolding)

-

Project of the Year – Major (AT-PAC): ISS

-

Lifetime Achievement (Leach’s): Rob West, Benchmark Scaffolding

The awards, organised by the NASC, capped a week that saw Manchester host the largest scaffolding and access expo held in the UK to date.