ScaffEx25 has now closed its doors in Manchester, and as I reflect on the two days, one thing is clear — this event has marked the beginning of something significant for our industry.

Last year’s ScaffEx in Belfast was an important first step. However, Manchester demonstrated just how far the concept has already progressed. The leap in size, scale, and ambition was evident to everyone.

It wasn’t perfect, and I wouldn’t expect it to be. But that didn’t change the mood. What mattered was the sense that something new and incredibly valuable was taking shape for our industry.

Why Manchester mattered

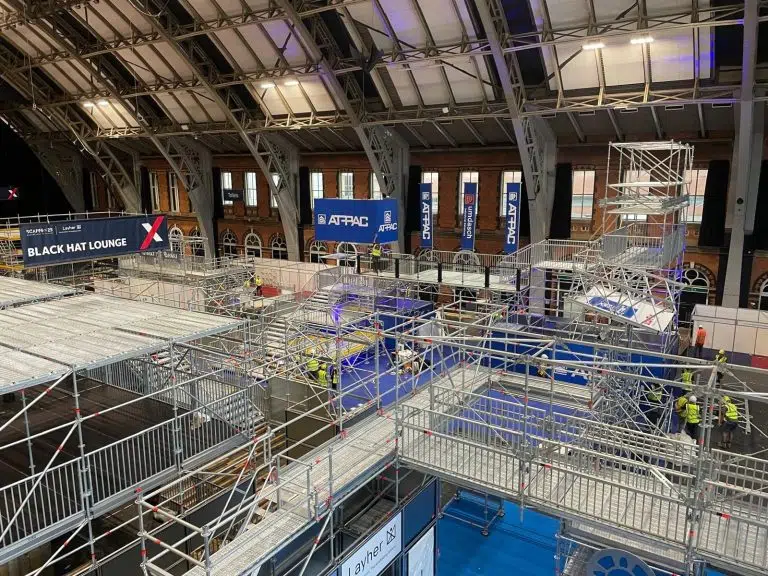

The choice of city and venue did a great deal of work for the event. Manchester understands industry. It’s a city built on making things, rebuilding itself, and moving forward, a good mirror for scaffolding’s own story.

Manchester Central, with its vast single-span hall, kept the show flowing. Clear sightlines, simple navigation, and a location in the heart of the city ensured that foot traffic never dipped on Friday, and meetings ran back-to-back.

Step outside and you’re just minutes from hotels, rail links, and places to keep the conversation going. That matters for a trade show that runs on relationships as much as it does on products.

A global step forward

The launch of the International Access and Scaffolding Association (IASA) was, for me, a defining moment. Although others have tried, for the first time ever, organisations from across the world have chosen to unite under one banner. That’s a historic step, and the fact that it happened on the first day of ScaffEx25 shows how quickly this event has earned credibility.

Additionally, BBC Breakfast broadcasting live from the show floor underlined that the message is cutting through beyond our sector. National media shining a light on skills, economic impact, and the role scaffolding plays in delivery is no small thing. It signals momentum.

Across two days, there were also other significant announcements. The details varied, but the direction was the same: higher standards, better tools, and closer collaboration.

Innovation you could feel — and use

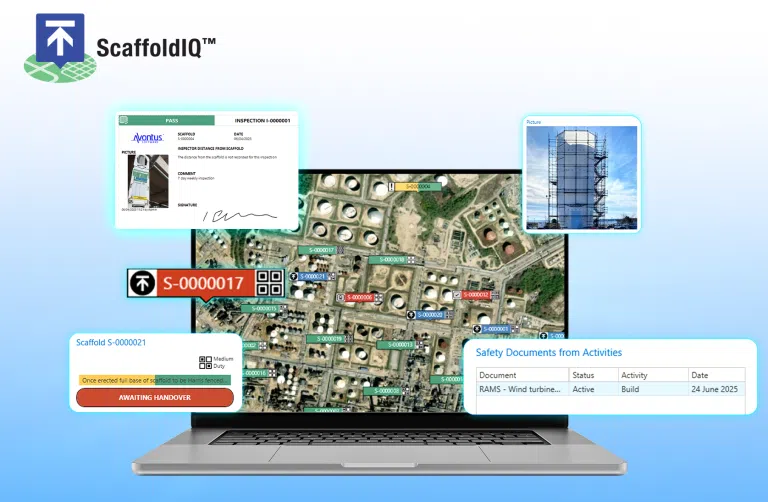

On the exhibition floor, innovation wasn’t just a buzzword; it meant real solutions. Digital platforms to manage inspections and handovers. Access systems built for speed and safety. Integrated tools linking design teams with site operations.

Competitors showcased their latest systems within metres of each other, driving genuine progress. Contractors asked the question that matters: “Does this make my workforce more efficient, safer, and compliant from day one?” Exhibitors proved it with hands-on demonstrations.

One supplier told me on Friday they’d been “flat out since the doors opened”. A young scaffolder said it was “inspiring to see the tech and training in one place”. Those remarks stayed with me because they captured the tone: serious, optimistic, and focused on outcomes.

A community coming together

The headline wasn’t a product. It was the people. ScaffEx brought together contractors, suppliers, trainers, and designers in a way rarely seen. Conversations turned into collaborations, and challenges became shared solutions.

One contractor from the North West caught the mood: “There’s been a real buzz — you don’t often get everyone together like this.” Another phrase echoed across the floor: “You can see this getting bigger every year.” That’s the truth. ScaffEx is fast establishing itself as the dedicated stage our trade has needed for years.

My take

ScaffEx25 marked a major leap from Belfast. It delivered not only scale but maturity — a credible stage, national attention, and a unique blend of rivalry and collaboration.

Having covered the sector for years, I can say this event felt different. Manchester demonstrated that ScaffEx is more than just another date. It is fast becoming the dedicated arena where the future of scaffolding is defined.

Yes, the format can still evolve. But the trajectory is unmistakable. ScaffEx25 has established momentum. The task now is to build on it.

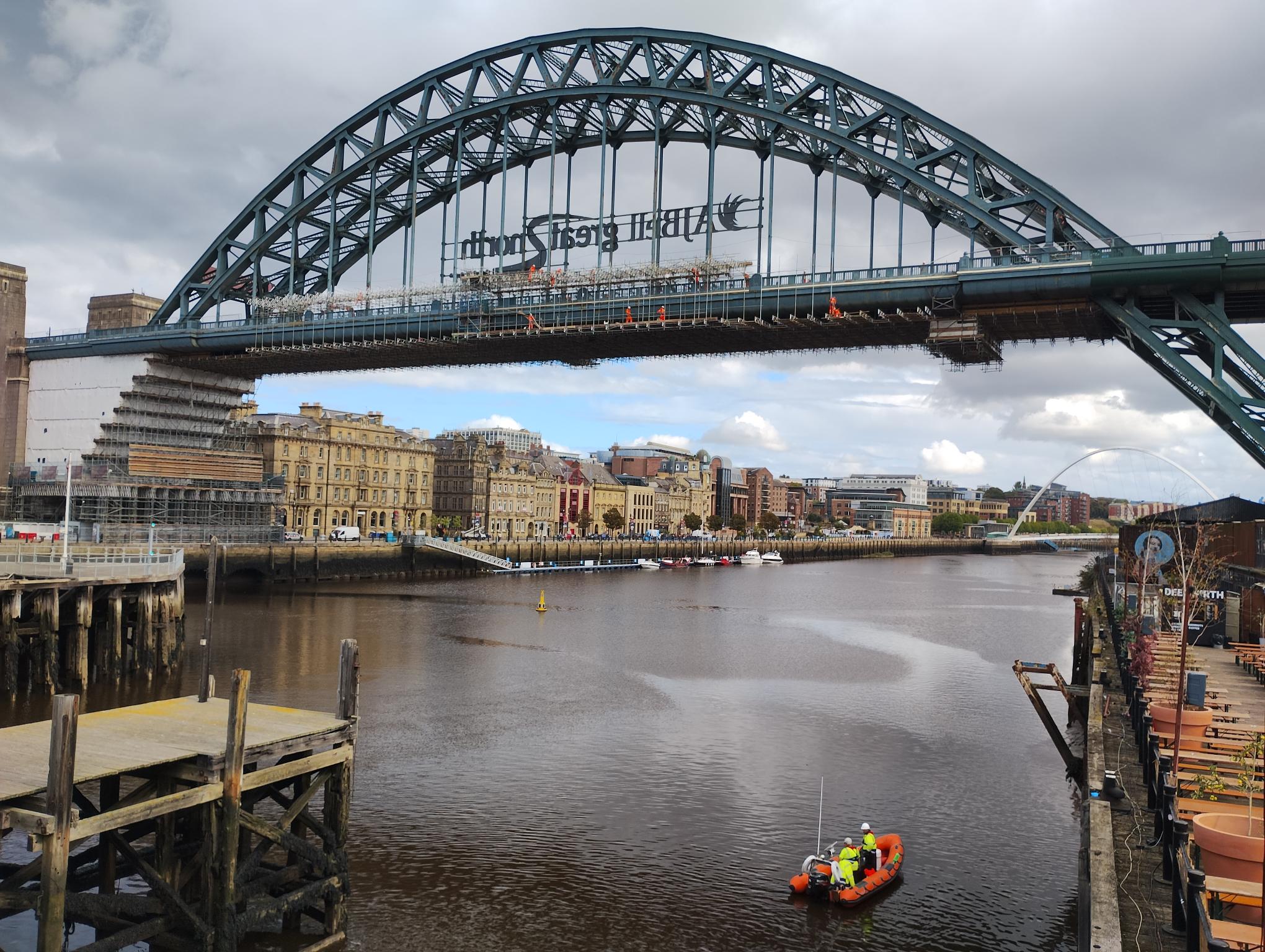

Once the parapet and screen plate work is finished, the scaffolding will be removed, making way for a safety deck to be built on the bridge deck. This will allow work to begin on the bridge’s central arch.

Councillor Juna Sathian, Newcastle City Council’s cabinet member for transport and climate, said the progress was welcome: “It’s great to see such fantastic progress being made on the Tyne Bridge, as we restore an icon to its former glory.

With 20 different phases of scaffolding required, this is a complex programme designed to keep the bridge open while the restoration continues.”

Councillor John McElroy, Gateshead Council’s cabinet member for environment and transport, added: “The detailed work completed on the bridge structure is so impressive. When the programme is complete, we will see the bridge looking fantastic, like new.”

Once the parapet and screen plate work is finished, the scaffolding will be removed, making way for a safety deck to be built on the bridge deck. This will allow work to begin on the bridge’s central arch.

Councillor Juna Sathian, Newcastle City Council’s cabinet member for transport and climate, said the progress was welcome: “It’s great to see such fantastic progress being made on the Tyne Bridge, as we restore an icon to its former glory.

With 20 different phases of scaffolding required, this is a complex programme designed to keep the bridge open while the restoration continues.”

Councillor John McElroy, Gateshead Council’s cabinet member for environment and transport, added: “The detailed work completed on the bridge structure is so impressive. When the programme is complete, we will see the bridge looking fantastic, like new.”

Esh Construction, which is delivering the scheme on behalf of Newcastle and Gateshead councils, confirmed more than 2,000 rivets have been replaced and 420 separate repairs carried out during the latest stage.

Esh Construction, which is delivering the scheme on behalf of Newcastle and Gateshead councils, confirmed more than 2,000 rivets have been replaced and 420 separate repairs carried out during the latest stage.

More than 350 repairs have already been made to the bridge’s under-arch on the Newcastle quayside, with the distinctive Hollybush Green paintwork now being applied.

The £multi-million restoration is being funded by the UK Government, the North East Combined Authority, Newcastle City Council and Gateshead Council.

Overnight closures of the Tyne Bridge will be required later this year to allow the pedestrian tunnel works to go ahead.

More than 350 repairs have already been made to the bridge’s under-arch on the Newcastle quayside, with the distinctive Hollybush Green paintwork now being applied.

The £multi-million restoration is being funded by the UK Government, the North East Combined Authority, Newcastle City Council and Gateshead Council.

Overnight closures of the Tyne Bridge will be required later this year to allow the pedestrian tunnel works to go ahead.

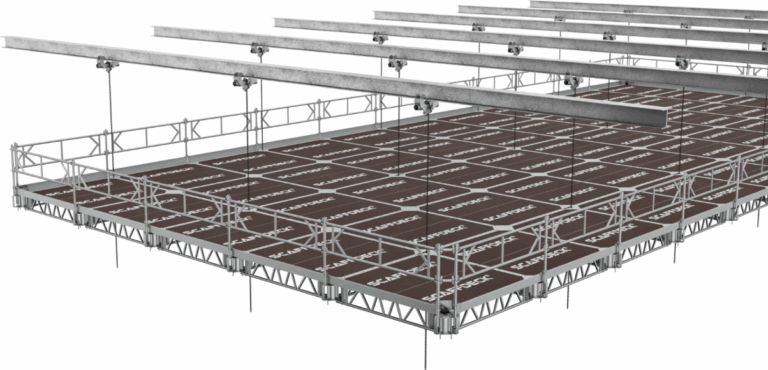

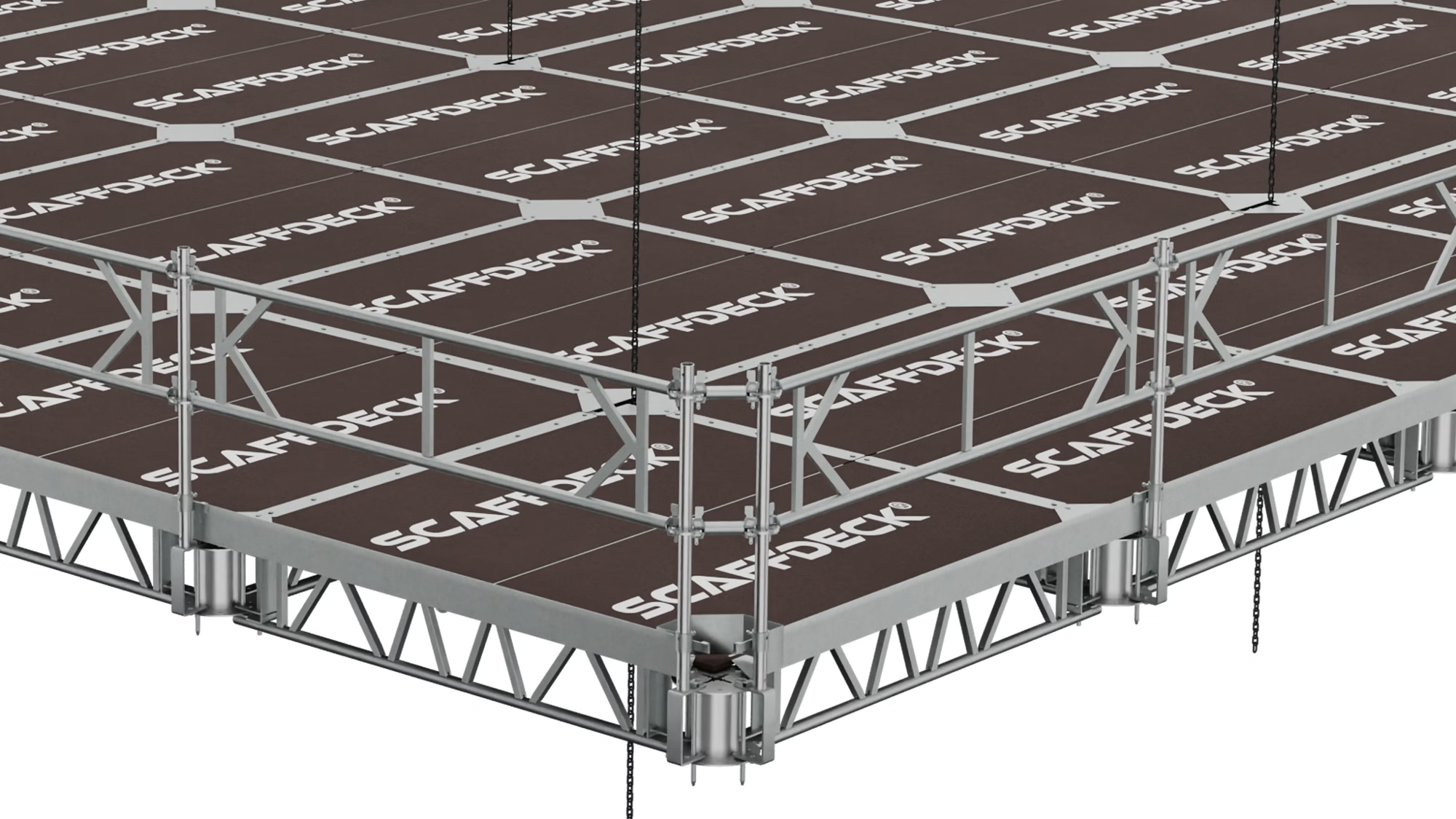

ScaffDeck uses up to 75% fewer components than traditional hanging scaffolds and around 15% fewer than other modular alternatives, enabling faster assembly and easier transport. The decking boards are tested to R13 slip resistance to further improve safety and during working in wet conditions.

The system has been internally tested and third party certified by SGS and TÜV Rheinland, and is compliant with BS EN1090, DIN 4420-3, and other relevant industry standards.

Founded in Dubai in 2015, Kirtanlal Scaffolding & Formwork has become a key supplier of access and formwork solutions across the Middle East and India. As part of its international rollout, the company has partnered with Leach’s, which will act as the exclusive distributor for the UK, offering ScaffDeck for both purchase and rental.

The partnership brings together Kirtanlal’s product engineering with Leach’s established distribution network and expertise in the working-at-height sector. According to both companies, the collaboration will ensure contractors across the United Kingdom can access ScaffDeck with full product support and regional availability.

ScaffDeck will be available via two distribution routes:

ScaffDeck uses up to 75% fewer components than traditional hanging scaffolds and around 15% fewer than other modular alternatives, enabling faster assembly and easier transport. The decking boards are tested to R13 slip resistance to further improve safety and during working in wet conditions.

The system has been internally tested and third party certified by SGS and TÜV Rheinland, and is compliant with BS EN1090, DIN 4420-3, and other relevant industry standards.

Founded in Dubai in 2015, Kirtanlal Scaffolding & Formwork has become a key supplier of access and formwork solutions across the Middle East and India. As part of its international rollout, the company has partnered with Leach’s, which will act as the exclusive distributor for the UK, offering ScaffDeck for both purchase and rental.

The partnership brings together Kirtanlal’s product engineering with Leach’s established distribution network and expertise in the working-at-height sector. According to both companies, the collaboration will ensure contractors across the United Kingdom can access ScaffDeck with full product support and regional availability.

ScaffDeck will be available via two distribution routes: