A new online platform designed to help scaffolding companies buy and sell surplus equipment has officially launched today in the UK.

ScaffCycle aims to reduce waste in the scaffolding sector by connecting businesses holding unused stock with others seeking cost-effective and sustainable alternatives to buying new.

The platform has been developed by industry veteran Tony Stevens, who has spent more than 50 years in scaffolding. It offers firms a dedicated digital space to list, search and trade second-hand scaffolding materials, with the goal of improving efficiency and supporting the construction sector’s shift towards a circular economy.

“There’s a huge amount of perfectly usable scaffolding sitting idle in yards across the country,” said Tony. “ScaffCycle gives companies a smarter way to manage their stock — and make better use of what’s already out there.”

From International Export to Domestic Reuse

ScaffCycle was created following the success of Worldwide Scaffold and Access Ltd (WWSA), a business Tony founded with his wife Karen in 2017. WWSA initially focused on exporting new scaffolding materials to global markets such as Trinidad & Tobago, South Africa, and Nigeria.

Over time, the business began facilitating deals for used scaffolding — brokering stock sales between major UK suppliers and European buyers. A high-value transaction in 2024 between a national sales business and a Somerset-based contractor helped shape the concept for a permanent, scalable solution.

“That deal made it clear how much demand there is for used scaffold — and how disconnected the market still is,” said Tony. “ScaffCycle is about bridging that gap.”

A Circular Solution to a Growing Problem

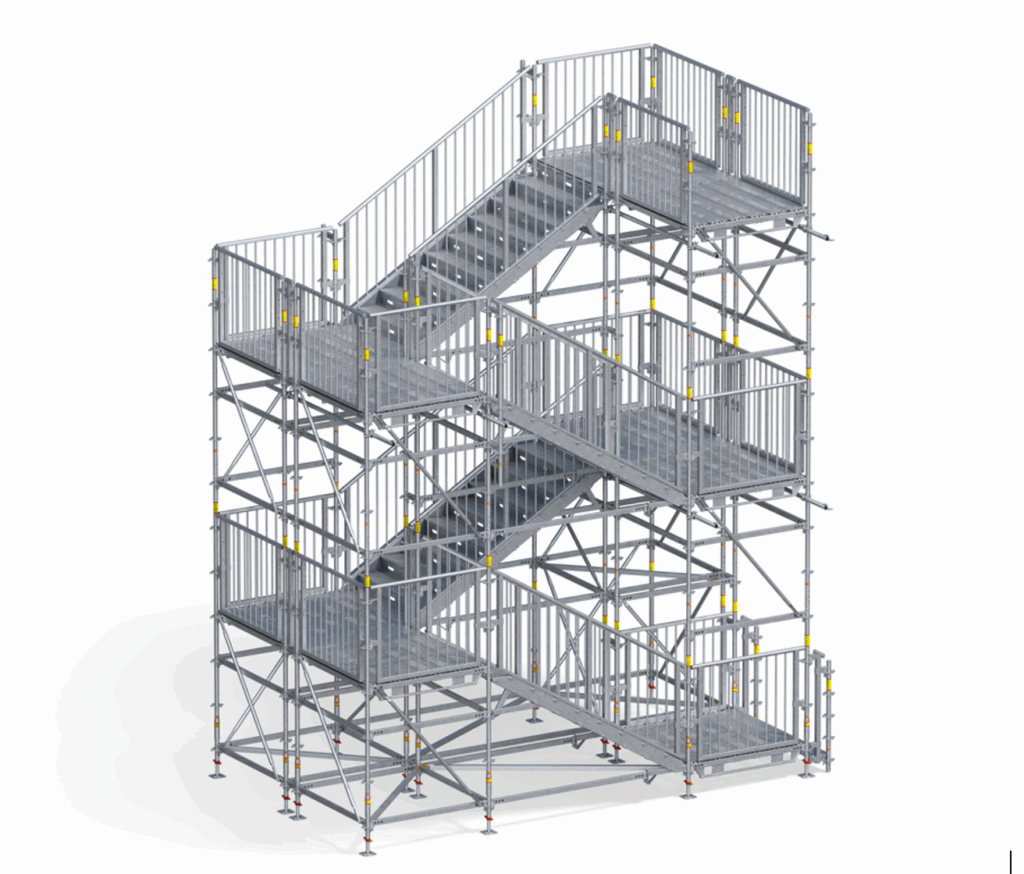

According to industry estimates, thousands of tonnes of scaffolding equipment are scrapped in the UK each year due to a lack of space, surplus stock or changing project needs — despite much of it remaining fit for use.

Research from the Carbon Trust suggests reusing scaffolding materials can reduce carbon emissions by up to 85% compared with manufacturing new equipment.

“The construction sector has a huge role to play in driving the circular economy,” said Keith James, Head of Public Sector Partnerships at WRAP. “ScaffCycle is a practical tool that helps extend the life of materials, reduce environmental impact, and deliver economic value.”

Industry Backing

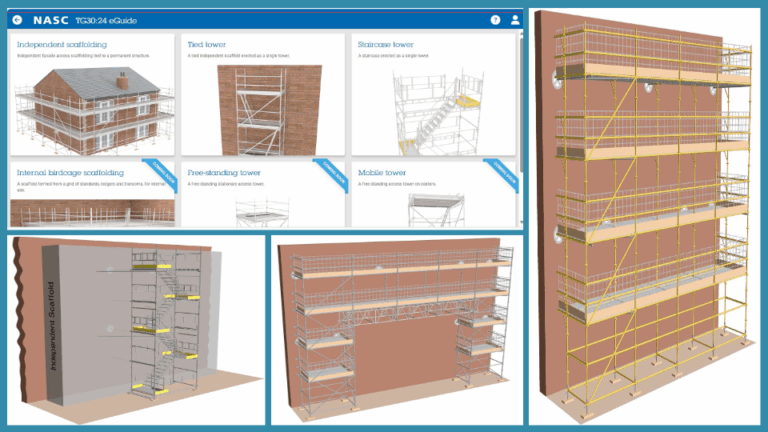

The platform has been welcomed by the National Access and Scaffolding Confederation (NASC), which supports efforts to make the sector more efficient and sustainable.

“This is exactly the type of innovation we want to see,” said Clive Dickin, NASC Chief Executive. “ScaffCycle provides a real-world solution to challenges around surplus kit, stock management, and sustainability.”

The platform is available now, with registration open to scaffolding suppliers, contractors, and asset managers across the UK.

“It’s about more than just buying and selling,” said Tony. “It’s about helping the industry work smarter — and greener.”

Clive Dickin, Chief Executive of NASC, described the update previously as a “game-changer”.

Clive Dickin, Chief Executive of NASC, described the update previously as a “game-changer”.