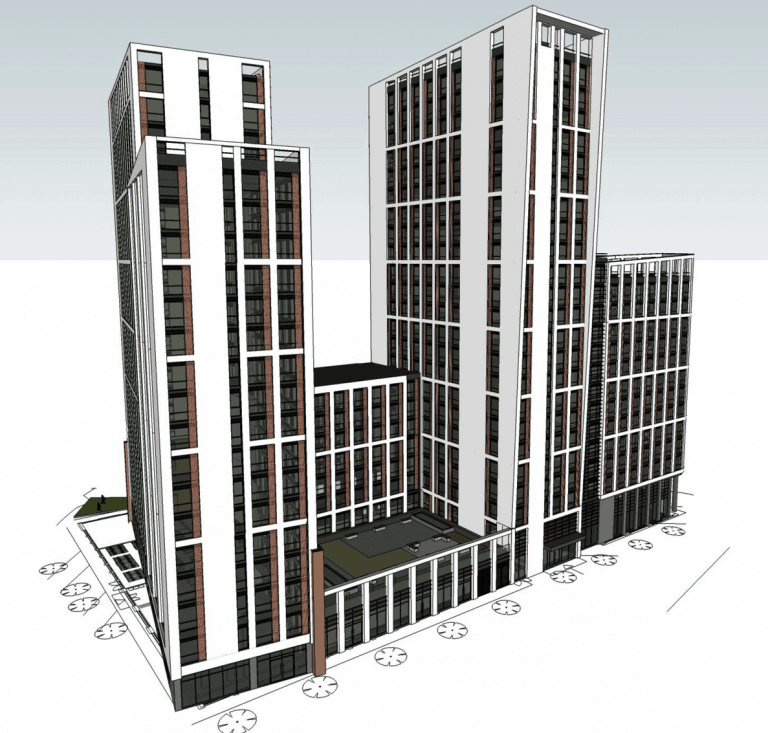

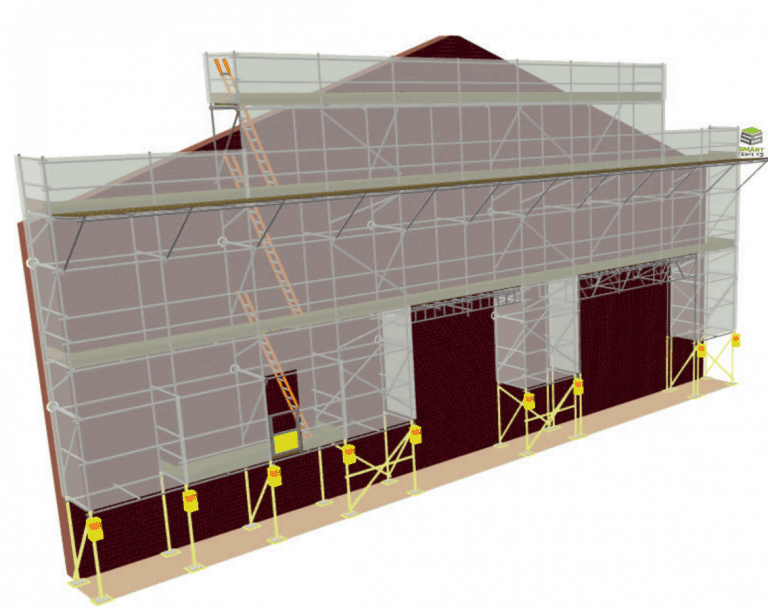

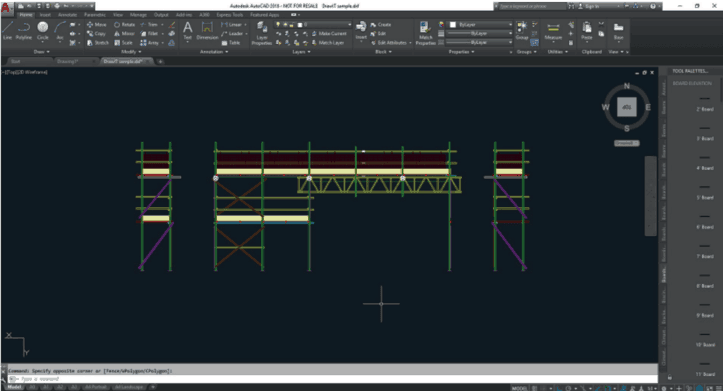

SMART Scaffolder launches 2018 update

Software giants CADS SMART Scaffolder have just released their latest update for 2018.

Dorset based company SMART Scaffolder are constantly adding new functionality to their estimating and TG20:13 compliance software. In their latest release, they have added some exciting features that mean you can input your scaffold in seconds, just take a tender schedule and simply key in the dimensions to produce automated drawings, precise quotes, accurate load lists, 3D visuals and TG20:13 summary reports. Commenting on the update Ian Chambers, Sales and Marketing Director at SMART Scaffolder, said “We always listen to what our customers tell us and this year’s release means any sized firm can quickly produce a quote they can be confident in”. The software firm say there are plenty of other improvements, including a new report to show the costs involved in a project, clearer quotations and improved client data sharing across a company network. They have also updated Draw IT, a free bolt on for Autodesk AutoCAD 2018, which provides blocks, guides and tools for editing scaffold drawings in AutoCAD. According to the firm, when combined with the existing powerful functionality, the new features make SMART Scaffolder the most comprehensive estimating software scaffolders can buy.

To see more details, visit the SMART Scaffolder website.

According to the firm, when combined with the existing powerful functionality, the new features make SMART Scaffolder the most comprehensive estimating software scaffolders can buy.

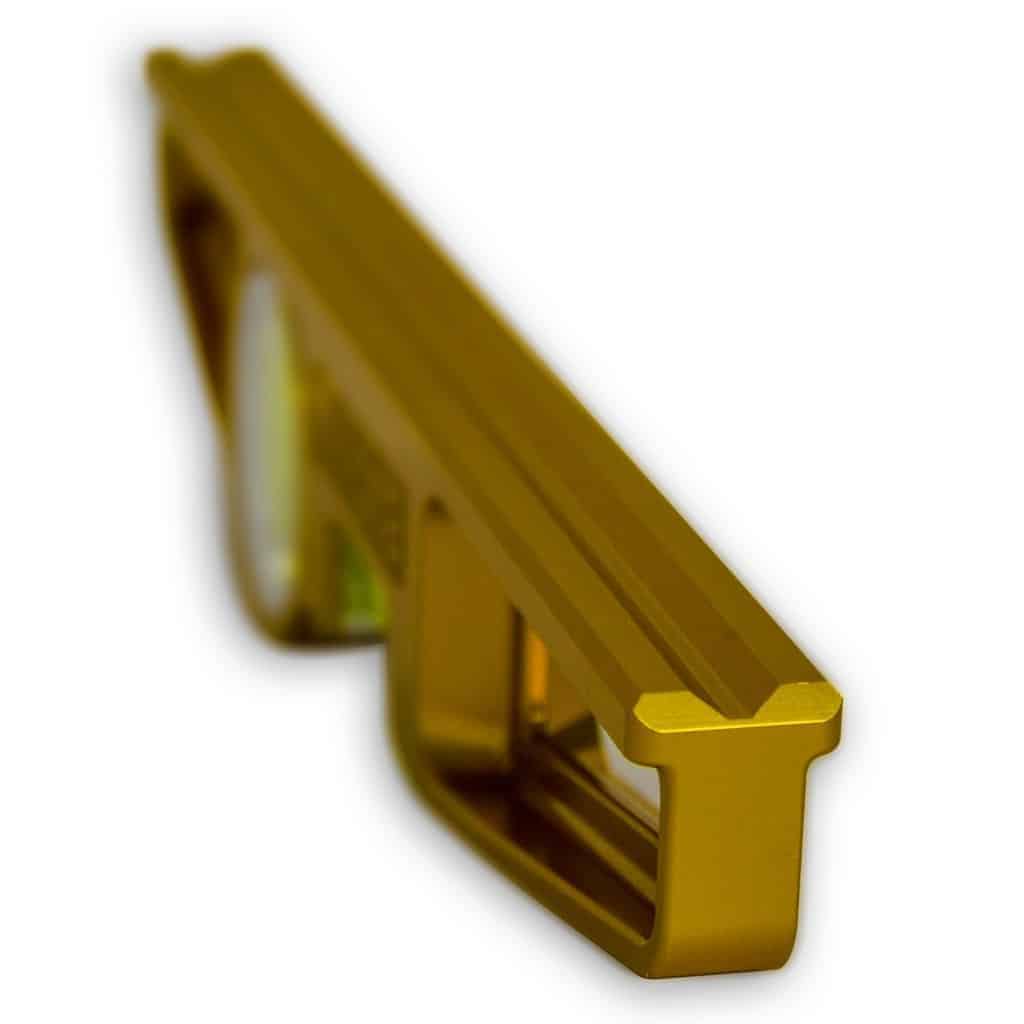

To see more details, visit the SMART Scaffolder website. Big Ben launches new Gold Groove™ Level

Swiss tool manufacturers Big Ben® have launched a new eye-catching magnetic level made from aircraft alloy with a smart grooved base.

According to stockists Leach’s, the golden coloured scaffolders level called Gold Groove™ is proving popular amongst scaffolders across the country, and we can see why! This ultra-tough, top shelf premium level has been machined from aircraft alloy and is said to be the perfect size and shape for scaffolders, weighing only 240g. The Gold Groove™ level also boasts a top class Vistatech™ vial which is far easier to read in various light conditions making the level far faster to work with and more accurate to work with. Apart from the level having the beautiful looks of a Italian supercar, Gold Groove has the addition of a smart groove along it’s base which ensures it always sits straight on the scaffold tube and has Induction magnetics technology™ which is guaranteed for life ! Leach’s say the development of this groundbreaking level is the result of very much research and input from Scaffolders over the years. Eventually after a lot of investments, new technology has made it possible to machine this simply beautiful tool out of a single piece of solid material.

With it’s golden colour the level comes with a golden price for it’s premium features and exquisite design expect to pay £79+VAT.

However as the saying goes ‘you buy cheap you buy twice’.

Leach’s say the development of this groundbreaking level is the result of very much research and input from Scaffolders over the years. Eventually after a lot of investments, new technology has made it possible to machine this simply beautiful tool out of a single piece of solid material.

With it’s golden colour the level comes with a golden price for it’s premium features and exquisite design expect to pay £79+VAT.

However as the saying goes ‘you buy cheap you buy twice’.

One-legged Scaffolder in battle to keep his car

A Barnsley scaffolder who suffered three amputations on the same leg along with a damaged hand has been refused higher rate mobility benefit and could lose his adapted car.

Paul Tate from Langsett Road, New Lodge in the town, fell about 12ft from a scaffold in September 2000. But it wasn’t until a few years later part of his leg had to be amputated following complications, and he’s lost even more of the same leg since. The 46-year-old was in and out of hospital, and about eight years after his accident, received the devastating news his leg would have to be amputated six inches below the knee. Despite this major setback, he carried on working as and when he could. He remained in the scaffolding trade, confined largely to driving rather than climbing ladders. Paul said: “I only fell about 12ft, but I landed badly, just on my left leg,” said Paul, 46, of Langsett Road, New Lodge. “I lost about eight inches of shin bone, it just shattered basically. They put me one of those big frames on which I had for a few years. But it kept getting infected. I worked and kept involved as much as I could, but the infection would flare up and wipe me out, sometimes for months at a time. They then had to take another inch off my leg, but I still kept working. It was totally devastating as it keeps flaring up and I’m still in and out of hospital.” Finally two years ago, surgeons had to amputate for a third time – this time above the knee. A fall , when his knee gave way, resulted in surgery to a hand needing total reconstruction. The metal plate inserted restricting it’s use, means he cannot push himself in a wheelchair and can’t use crutches. He also struggles to walk more than a few metres and only on to his flat. Paul has been entitled to a car under the Motability scheme for 15 years, which is replaced every three years. He’s always chosen to pay a contribution himself to upgrade to a larger and higher car – a Ford Cougar – as it’s easier for him to get in and out of. Last year however, he had to apply again for the benefit, but was refused on the basis he did not need the ‘higher rate mobility allowance’. A second application was also rejected, and and next month he will have to take his fight to a tribunal. “If they read my history over the last 15 years, and read what I’ve gone through, surely they can see I’ve got a mobility problem, added Paul. I’m knackered without my car basically, it gives me independence. I pull the car up the side of the house, and it’s one step from my kitchen into my car. It gets me out and about, I can get out and see the grand-kids, see friends, and get to hospital when I need to. I physically cannot get about without my car.” Paul’s twin brother Graham said: “That car is his lifeline. I just can’t believe they want to take it off him. You see people who can walk about getting cars. He can’t walk, he can’t go out without someone else with him. He’s absolutely terrified he’s going to lose it, and I think it’s just disgusting.” A spokesman for the Department for Work and Pensions said: “Decisions for PIP are made following consideration of all the information provided by the claimant, including supporting evidence from their GP or medical specialist. Anyone who is unhappy with a decision can appeal, and may submit additional evidence. “Most people leaving the Motability scheme are eligible for a one-off payment of up to £2,000 to help meet their needs.”Safety alert issued for Acrow Props

Expert calls for people to check any recent deliveries of Acrow Props.

A leading industry Health and Safety expert has reported a potentially life threatening issue with Acrow Props being supplied into the UK market. These uncertified Props are exhibiting various degrees of misalignment, in certain cases preventing the locating pin from passing fully through the inner and outer tubes leading to the load being unevenly and inadequately distributed. This could potentially lead to a catastrophic collapse of the supported structure. A leading technical expert comments: “This is a very serious issue that should not be understated. This is a product often bought “On Line” or hired for DIY, by individuals who are not trained experts and who would be unlikely to realise the Prop was not functioning correctly until it was too late.”Rilmac Scaffolding round off successful year with nationwide training event

Lincolnshire based Rilmac Scaffolding rounded off an excellent year with a highly successful group wide training day at the end of December.

Rilmac Employees from all across the country converged on the Epic Centre, at the Lincolnshire Showground for sessions on Health & Safety, Behavioural Change, and Working At Height. Rilmac Scaffolding say they have a history of running their own training days, but this was the first time all the Rilmac Companies have met together en masse, and it proved to be very successful according to the firm. Rilmac’s Group chairman Paul Walker opened the day addressing their 250 employees in attendance, the largest gathering of Rilmac staff in its 60-year history. Guest speakers from Clarkes Health & Safety Consultants, Kier, Galliford Try, ARCA and Lincolnshire Road Safety Partnership presented throughout the day along with individuals from the Rilmac Group.

Speaking after the event Rilmac Scaffolding Managing Director, Des Booth said, “We value all our staff and aim to grow from within. Most of our supervisors, managers, estimators plus our directors have all worked as scaffolders. Days like these aid in the development and growth of all our employees.”

“Safety is our first priority,” added Contracts Manager Dave Clarke, “and it is fantastic to see it approached from different and worthwhile directions. This really has been an excellent day for everyone at Rilmac Scaffolding.”

The Directors and Management across all the Rilmac companies expressed their thanks and gratitude to Mark Clarke, Clare Davey, Steve Spedding, Geoff Silver and John Siddle for their excellent contribution on the day.

Rilmac say they are determined to grow on the success of their first group wide training day and plans are already underway for the next one in December 2018.

Rilmac’s Group chairman Paul Walker opened the day addressing their 250 employees in attendance, the largest gathering of Rilmac staff in its 60-year history. Guest speakers from Clarkes Health & Safety Consultants, Kier, Galliford Try, ARCA and Lincolnshire Road Safety Partnership presented throughout the day along with individuals from the Rilmac Group.

Speaking after the event Rilmac Scaffolding Managing Director, Des Booth said, “We value all our staff and aim to grow from within. Most of our supervisors, managers, estimators plus our directors have all worked as scaffolders. Days like these aid in the development and growth of all our employees.”

“Safety is our first priority,” added Contracts Manager Dave Clarke, “and it is fantastic to see it approached from different and worthwhile directions. This really has been an excellent day for everyone at Rilmac Scaffolding.”

The Directors and Management across all the Rilmac companies expressed their thanks and gratitude to Mark Clarke, Clare Davey, Steve Spedding, Geoff Silver and John Siddle for their excellent contribution on the day.

Rilmac say they are determined to grow on the success of their first group wide training day and plans are already underway for the next one in December 2018. Scaffolder dies instantly after dumper truck crush

Top Construction And Engineering Firms Awaiting Sentencing Following Tragic Death Of Scaffolder

Sentencing over serious health and safety breaches involving Both housebuilder Redrow and sub-contractor WPI Civil Engineering has been adjourned until February 9th. Liverpool Crown Court heard how Harry Jones a 67-year-old scaffolder was killed instantly after a dumper truck driven by an unqualified driver reversed into him. The tragedy in August 2013 was also witnessed by Mr Jones’s son Christopher, who was working at the construction site of Redrow Homes’ Summerhill Park housing development in Knotty Ash. Mr Jones suffered fatal crush injuries when he went under the wheels of the truck and was pronounced dead at the scene. Following an investigation by the Health and Safety Executive (HSE), the companies pleaded guilty to the health and safety breaches, involving the 43-ton six wheeled truck. The court was told it was driven by an inexperienced, unqualified driver and was being reversed because the turning circle was full of building detritus. Although its reverse alarm was sounding, Mr Jones suffered serious hearing problems and had his back to the vehicle when he was hit. Kevin Donnelly, prosecuting, said safety procedures were not followed at the building site, which meant vehicles – including heavy plant machinery – and workers on foot were not kept apart. He said: “Both employees and non-employees were exposed to significant risk of harm. “There was inadequate management of site activity to minimise the risk of collision between pedestrians and vehicles. “This placed those who were working on site at risk of being struck by site vehicles, which could and should have been avoided.” John Cooper, QC, representing Redrow Homes, said: “The company recognises its safety responsibilities and is anxious about those who work on its sites, from the top down. This was a rare and regrettable failure.” Dominic Kay, QC, representing WPI, said: “It’s a source of enormous regret to WPI that someone lost their life as a result of its failings. It’s a family business and has been hit very hard indeed by the accident. It has been trading for 40 years without a previous conviction and takes health and safety very seriously.” Following the case, HM Inspector of Health and Safety Jacqueline Western said: “It’s entirely foreseeable that if traffic management and pedestrian segregation is not properly implemented on site, that incidents like this will occur.” Mr Jones leaves three children, 11 grandchildren and seven great-grandchildren. Family members from Westhoughton near Bolton were present at the proceedings. The recorder, Judge Clement Goldstone, QC adjourned sentencing until next month.ScaffMag’s most read stories of 2017

As 2017 edges ever closer to an end, we take a look back at what most attracted your attention during the year.

This year has been another busy news filled year for the scaffolding industry as ScaffMag continues to keep you updated with what’s going on. Either on desktop, mobile, tablet or in our digital magazine, we have you covered. During the year we saw several stories that stood out and received a lot of attention. One of which was our tongue-in-cheek April fools post on London based MR Scaffolding Services winning the scaffolding contract for the controversial President Donald Trump’s wall between the United States and Mexico. In addition also on our list of the biggest stories of 2017 were; Altrad’s purchase of Cape plc, news of London’s Big Ben project, the death of Safelinx inventor and the closure of Bircham Newton to name a few. For a full rundown of ScaffMag’s top 10 biggest stories including page views and social shares see below.Best read stories of 2017

1. Pageviews: 23,322 | Facebook Shares: 1,462 | Linkedin: 878

UK Scaffolding Company Seal Biggest Ever Scaffolding Contract

2. Pageviews: 11,968 | Facebook Shares: 364 | Linkedin: 475

Shocking Video: Man Pulls Scaffolding Over onto Busy Street

3. Pageviews: 9,894 | Facebook Shares: 8 | Linkedin: 379

Scaffolder loses leg and arms after being electrocuted

4. Pageviews: 9,537 | Facebook Shares: 445 | Linkedin: 337

Three-year Scaffolding Project Gets Underway at Big Ben

5. Pageviews: 9,212 | Facebook Shares: 528 | Linkedin: 332

Three plunge into water after bridge scaffolding collapses

6. Pageviews: 8,947 | Facebook Shares: 380 | Linkedin: 298

Worker killed after falling from scaffolding in Kensington

7. Pageviews: 6,321 | Facebook Shares: 287 | Linkedin: 677

Industry Stunned After Death of Safelinx Inventor

8. Pageviews: 5,782 | Facebook Shares: 515 | Linkedin: 218

Scaffolder fighting brain tumour warns others to have a health check

9. Pageviews: 4,678 | Facebook Shares: 153 | Linkedin: 1,015

SGB Wins Major Scaffold Contract Worth £13M

10. Pageviews: 4,450 | Facebook Shares: 380 | Linkedin: 196

Bircham Newton to Close After Major CITB Shake-UpThe website will be updated with any major stories over the christmas period until the 3rd January when full service will resume. We would like to wish all our valued readers a very Merry Christmas and very happy New Year.