Altrad in closing stages of deal to purchase George Roberts

Scaffolding company launches charity initiative

Giant Bear Supports Scaffolders’ Phone Appeal

Formark Scaffolding has launched an appeal for old mobile phones to help raise £50,000 for the UK’s leading hospital radio station. Announcing the initiative Formark Managing Director Mark Coote called on construction companies throughout London and the South East to help support Radio Marsden by collecting phones. The charity run radio station has broadcast to patients at the world-renowned Royal Marsden cancer hospitals in London and Surrey for more than 40-years, but unless it replaces ageing studio equipment the station will go off-air permanently. “To help mark our 21st anniversary as an independent scaffolding contractor we wanted to do something for people across the wide area in which we operate that would make a difference,” said Mark. “When you experience or hear about the fantastic work the radio station does at the Royal Marsden and the support it gives to cancer sufferers, their families and friends, it’s unthinkable that such a well-loved and well-known charity should be in financial difficulty. “But although it broadcasts to patients and on-line 24 hours a day, seven days a week, the station does not receive any grants or funding from the hospital, the NHS or the Government, so relies entirely on donations and fund-raising to run the service.” The station’s plight has led to a host of celebrities, from veteran Radio 2 broadcaster Ken Bruce and Phillip Schofield to David Walliams and Hulk Hogan, having their photograph taken with the Radio Marsden Bear and tweeting details of the appeal to their followers. So it was a bit of a surprise when the life-size mascot turned up at Formark’s main yard in Whyteleafe, Surrey, along with Radio Marsden Chairman Jason Reynolds, to help launch the phone appeal. “We simply want companies throughout the construction industry to put up a poster, provide a collection box and send the phones on to us or call us and we’ll come and collect them,” added Mark. For a poster or further information call Formark Marketing on 07753 374628 or email [email protected]We Need You: Join our ScaffMag Movember Team

To help promote men’s health and raise vital funds and awareness for prostate and testicular cancer Scaffmag is running it’s own Movember team.

“What is Movember i hear you say?”….. Movember is an independent global charity that challenges men to grow a moustache for the 30-days of November, thereby changing their appearance and the face of men’s health. In October, men sign up at Movember.com, and on the 1st of Movember, with a clean-shaven face, start their moustache growing journey. For our ScaffMag team we are calling our moustaches a #ScaffTash. With our “ScaffTash” growing challenge we aim to raise funds for charity and to unite scaffolders with managers and admin staff for the common good.We need you… lets unite under one industry flag !

If you’re up for the challenge to grow a ScaffTash throughout November please join our Scaffmag Team Now ! Once you have joined our band of scaffolding brothers, you will have your own personal profile where you can share your ScaffTash photos with fellow team mates. Ready for the challenge ? then Please Join The ScaffMag Movember Team Here For the people who are unable to participate, you can still help as we also require sponsorship for our challenge and would love your donation however small. Please Donate HereGallery

After we get started on the 1st November a gallery will be placed here showing the progression of our ScaffTashes

Cape secures scaffolding contract in Thailand

Cape plc, the international provider of essential industrial services to the energy and natural resources sectors announces it has been awarded a two-year outline service agreement by STP&I Public Company Limited (STP&I).

Cape will provide scaffolding support services for Package 1, Plot A on the LNG Pre-Module Fabrication activities at the Laemchabang facility in Thailand, prior to their onward shipment to the onshore Ichthys LNG facility in Australia.

Paul Adams, Managing Director of Cape Singapore, Thailand, Malaysia and Indonesia said:

“Given the challenging market conditions in Asia, we are delighted to have secured this important contract which provides a solid base of work in the region in support of our growth strategy. We have worked closely with STP&I and together we have created a strong relationship which has proved instrumental in achieving this significant award.”

Cape plc, the international provider of essential industrial services to the energy and natural resources sectors announces it has been awarded a two-year outline service agreement by STP&I Public Company Limited (STP&I).

Cape will provide scaffolding support services for Package 1, Plot A on the LNG Pre-Module Fabrication activities at the Laemchabang facility in Thailand, prior to their onward shipment to the onshore Ichthys LNG facility in Australia.

Paul Adams, Managing Director of Cape Singapore, Thailand, Malaysia and Indonesia said:

“Given the challenging market conditions in Asia, we are delighted to have secured this important contract which provides a solid base of work in the region in support of our growth strategy. We have worked closely with STP&I and together we have created a strong relationship which has proved instrumental in achieving this significant award.” Warning: High winds expected in the UK

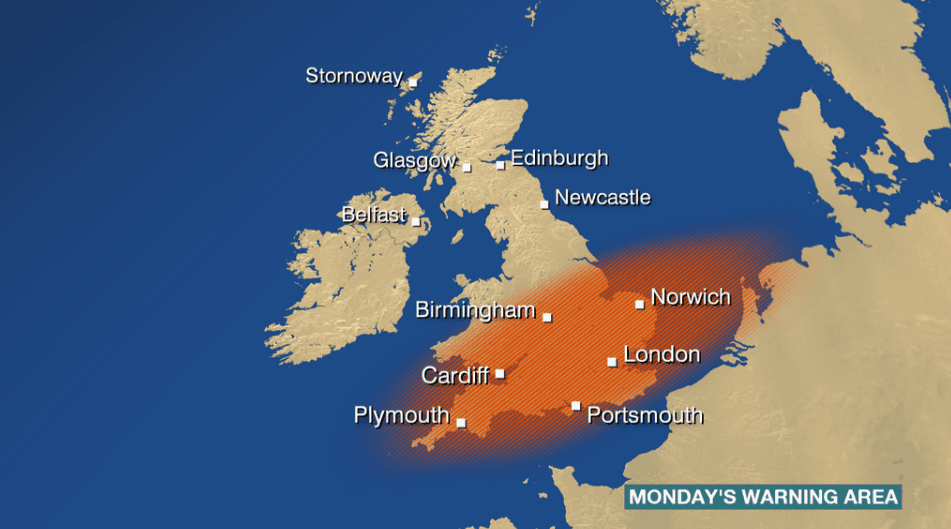

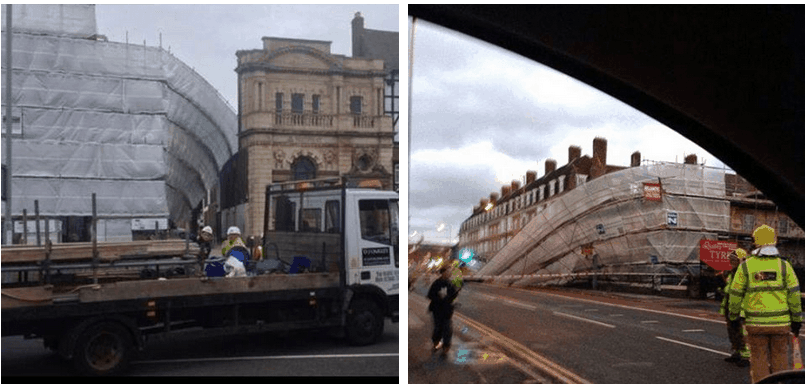

High winds have been forecast for this evening (27th October) across the southern half of the UK

A Met Office amber alert for high winds in southern Wales, southern England, much of the Midlands, the East, and London and the South East is in place.

Now is the perfect time to think about the dangers of high wind and the precautions to take with scaffolding structures over the coming days.

The scaffold designers at 48.3 Scaffold Design have put together a great article that’s very informative on the subject of Scaffolding Precautions for High Winds

High winds have been forecast for this evening (27th October) across the southern half of the UK

A Met Office amber alert for high winds in southern Wales, southern England, much of the Midlands, the East, and London and the South East is in place.

Now is the perfect time to think about the dangers of high wind and the precautions to take with scaffolding structures over the coming days.

The scaffold designers at 48.3 Scaffold Design have put together a great article that’s very informative on the subject of Scaffolding Precautions for High Winds The Scaffolding Association adds free seminar on Scaffolding Ties to roadshow

Rumours Confirmed: Altrad NSG announces acquisition of Spectra Scaffolding Ltd

Altrad NSG have today confirmed the rumours and officially announced the acquisition of Spectra Scaffolding Ltd

Scaffolding and industrial access specialist Altrad NSG has announced the acquisition of Greater Manchester-based Spectra Scaffolding Ltd for an undisclosed sum.

Spectra Scaffolding Ltd is an NASC accredited company which has been in operation for nine years, working across major construction projects, restoration, refurbishment and civil engineering project work. The firm also holds preferred contractor status with leading contractors such as Kier Construction and Morgan Sindall.

All employees of Spectra Scaffolding – previously owned by directors Colin Dean, Alan McDonald and Kevin Jennings – will continue to work in the business, which will now operate as a wholly owned subsidiary of Altrad NSG from its current base in Bury, Greater Manchester.

Deeside headquartered Altrad NSG works across the UK, providing specialist scaffolding and industrial access solutions as well as insulation, painting, coatings, blasting and industrial cleaning.

Mike Carr, Altrad NSG Managing Director, said: “I am extremely pleased with this acquisition; the directors of Spectra Scaffolding have over 100 years’ combined experience in the scaffolding industry. Their wealth of experience will further complement the offering of Altrad NSG Ltd to clients within the construction industry and other markets.

“The team at Spectra Scaffolding share our ethos of delivering high quality work with a commitment to excellent health and safety practices. They have completed some very prestigious projects to date – including historic restorations with the National Trust and the CTP Office Development in Manchester City Centre – and we look forward to exploring further opportunities across their key markets.”

Mr Carr added: “There is a tremendous opportunity for Altrad NSG to expand in the UK organically or through strategic acquisitions of companies with similar activities to provide customers with full UK coverage as well as the Altrad international support that already exists.

“With the support of our parent company Altrad SA which has over 70 subsidiaries worldwide, Altrad NSG is well positioned to continue to grow and trade profitably throughout the current financial year.”

Altrad NSG have today confirmed the rumours and officially announced the acquisition of Spectra Scaffolding Ltd

Scaffolding and industrial access specialist Altrad NSG has announced the acquisition of Greater Manchester-based Spectra Scaffolding Ltd for an undisclosed sum.

Spectra Scaffolding Ltd is an NASC accredited company which has been in operation for nine years, working across major construction projects, restoration, refurbishment and civil engineering project work. The firm also holds preferred contractor status with leading contractors such as Kier Construction and Morgan Sindall.

All employees of Spectra Scaffolding – previously owned by directors Colin Dean, Alan McDonald and Kevin Jennings – will continue to work in the business, which will now operate as a wholly owned subsidiary of Altrad NSG from its current base in Bury, Greater Manchester.

Deeside headquartered Altrad NSG works across the UK, providing specialist scaffolding and industrial access solutions as well as insulation, painting, coatings, blasting and industrial cleaning.

Mike Carr, Altrad NSG Managing Director, said: “I am extremely pleased with this acquisition; the directors of Spectra Scaffolding have over 100 years’ combined experience in the scaffolding industry. Their wealth of experience will further complement the offering of Altrad NSG Ltd to clients within the construction industry and other markets.

“The team at Spectra Scaffolding share our ethos of delivering high quality work with a commitment to excellent health and safety practices. They have completed some very prestigious projects to date – including historic restorations with the National Trust and the CTP Office Development in Manchester City Centre – and we look forward to exploring further opportunities across their key markets.”

Mr Carr added: “There is a tremendous opportunity for Altrad NSG to expand in the UK organically or through strategic acquisitions of companies with similar activities to provide customers with full UK coverage as well as the Altrad international support that already exists.

“With the support of our parent company Altrad SA which has over 70 subsidiaries worldwide, Altrad NSG is well positioned to continue to grow and trade profitably throughout the current financial year.” Safety & Access offer Free Scaffolder Rescue Training

Leading CISRS Scaffolding training and Work at Height training and consultancy provider Safety & Access Ltd are offering a Free pilot course in Humberside.

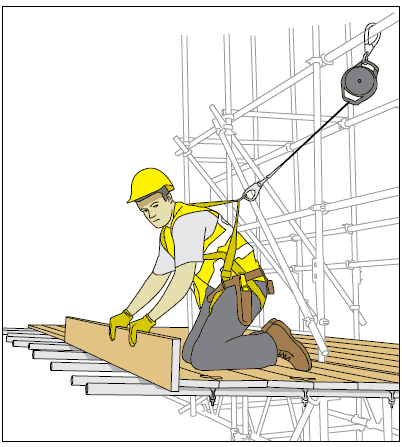

Safety & Access have teamed up with Honeywell Safety Products, experts in fall protection and rescue to present a day focusing on rescue planning and compliance to SG4:10, and the Working at Height Regulations 2005.

Many firms make the mistake of believing that a generic rescue plan is sufficient without understanding the consequences of poor planning.

The Free training course will focus on the effectiveness of correct planning for emergencies at height, the reality of it going wrong, and how to prevent mistakes being made.

Course start date : 23rd October 2013 (AM & PM Sessions)

The session will be ideal for those people responsible for:

Leading CISRS Scaffolding training and Work at Height training and consultancy provider Safety & Access Ltd are offering a Free pilot course in Humberside.

Safety & Access have teamed up with Honeywell Safety Products, experts in fall protection and rescue to present a day focusing on rescue planning and compliance to SG4:10, and the Working at Height Regulations 2005.

Many firms make the mistake of believing that a generic rescue plan is sufficient without understanding the consequences of poor planning.

The Free training course will focus on the effectiveness of correct planning for emergencies at height, the reality of it going wrong, and how to prevent mistakes being made.

Course start date : 23rd October 2013 (AM & PM Sessions)

The session will be ideal for those people responsible for:

- Writing rescue plans; or

- Approving rescue plans as part of a method statement.

Rumour: Altrad adds yet another firm to it’s portfolio Spectra Scaffolding Ltd

Rumours are emerging that French firm Altrad have added yet another scaffolding firm to its portfolio of businesses

Manchester based Spectra Scaffolding Ltd is rumored to have been sold to Altrad for £1.2m, this acquisition comes just weeks after Altrad bought Trad Scaffolding Ltd.

Spectra Scaffolding Ltd was formed in 2005, and operates primarily within the Construction, Restoration, Demolition and Commercial Service Industries, providing general access requirements, temporary roof structures and specifically designed integrated access systems.

Previous UK acquisitions by Altrad include Trad, BarOmix, Belle Group, Beaver 84, NSG, Generation and MTD.

Rumours are emerging that French firm Altrad have added yet another scaffolding firm to its portfolio of businesses

Manchester based Spectra Scaffolding Ltd is rumored to have been sold to Altrad for £1.2m, this acquisition comes just weeks after Altrad bought Trad Scaffolding Ltd.

Spectra Scaffolding Ltd was formed in 2005, and operates primarily within the Construction, Restoration, Demolition and Commercial Service Industries, providing general access requirements, temporary roof structures and specifically designed integrated access systems.

Previous UK acquisitions by Altrad include Trad, BarOmix, Belle Group, Beaver 84, NSG, Generation and MTD. Trad Scaffolding Sold To Altrad

Trad Scaffolding group has been sold for an undisclosed amount to the French company Altrad.

Trad Scaffolding was the largest privately-owned scaffolding contractor in the country was formed in 1971.

The firm employs 450 people and has a turnover of £45m from its focus on scaffolding work across London and South East alongside a national hire network.

Reports suggest Trad will continue to operate from the current locations around the UK and be run by the existing management team.

Trad Group Chairman, Hayden Smith said:

“Opportunities have been numerous over the years to sell the Trad Group but were never seriously considered as it would have led to changes in our successful management team followed by the loss of our long established and well respected identity.

“The Altrad Group offer made it very clear that they wanted the Trad Group but were very insistent that the team stayed intact long term to continue with our successful strategy of providing quality service and materials which is instrumental in both client satisfaction & retention.

“I am very impressed on this focus by the Altrad Group and my team and I are all very motivated going forward to continue our profitable growth with the knowledge that we have the full support of not only a major manufacturer of access products but a successful group with the same ethos which creates success”.

Ray Neilson MD of Altrad Belle UK said: “This acquisition forms part of the bigger plan to provide the large UK market with products and services from Altrad who specialise in the manufacturing and sales of scaffolding, cement mixers and wheelbarrows, together with providing additional contracting services in the scaffolding sector”

Previous UK acquisitions by Altrad include BarOmix, Belle Group, Beaver 84, NSG, Generation and MTD.