The Scaffolding Association is a not-for profit organisation which has been founded to improve the understanding, safety and standards of scaffolding across the construction industry, and will be opening its doors for membership today (9th of August 2013).

Membership is open to all companies within the scaffolding industry. The initial level of membership available will be Associate Membership. There are no entry requirements or assessment process for this level of membership.

This is to ensure all companies within the scaffolding industry have access to an organisation which will provide them with guidance and support, irrespective of levels of competence or development. Associate Membership gives entitlement to all the available membership benefits of The Scaffolding Association.

Various membership groups are available at Associate level, including; Scaffold Erection Companies, Scaffold Designers, Training Providers, Health & Safety Advisors, Scaffold Inspectors, Manufacturing Companies, Product Companies, Service Providers and Construction Professionals.

It is the association’s intention to offer assessed levels of membership which will conform to current procurement, and current accredited assessment criteria. Further to this, Individual Membership will be available within some of the membership groups.

If you would like to be a part of an association looking to unite the scaffolding industry and would like more information please visit their website: www.scaffolding-association.org

Do you think the Scaffolding Association could be a viable alternative to the NASC ? let us know in the comments below.

A college refurbishment project in Rutland has thrown the spotlight onto the outstanding levels of customer service for which Harsco Infrastructure is widely recognised, and earned the company high praise from its client.

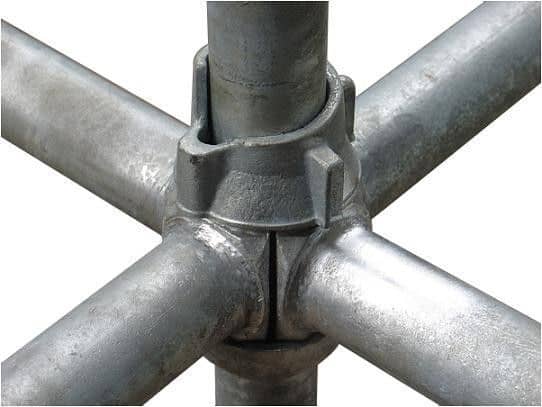

Despite the presence of asbestos and the need for frequent changes during the life of the project, Harsco was able to provide a CUPLOK® scaffolding system which allowed the windows at Uppingham Community College to be replaced in-line with an extremely demanding schedule.

“This was certainly a project which provided its fair share of difficulties, but the Erection and Dismantle team at our Birmingham branch in Tamworth was more than equal to the challenge“ explains Harsco’s Branch Manager Steve Bollans. “The scaffolding system itself was straightforward enough, but there were many other factors which made the job difficult.”

These included the fact that the school was live during the project, which required Harsco to schedule all deliveries to site outside of school hours. Limited road access also meant that delivery vehicles were halted some 70 yards away from the school. The Harsco equipment was then unloaded and transferred to site, past an adjacent nursery school, using lorry-mounted forklift trucks.

“We could only do this when there were no children in the nursery,” adds Steve. “Similarly, when we were installing the scaffolding we had to stop work every time pupils from the main school came outside at break times” Despite this, and the fact that the decision was taken part way through to extend the project to cover the school’s second storey windows, Harsco was able to help the project meet its very demanding 10-week schedule.

“From the outset the Harsco team were extremely professional, pro-active and advisory, managing an extremely short mobilisation period with ease,” says Chris Cuthbert, Project Manager for the main contractor, Kier. “We had regular site meetings to make sure any design changes were dealt with in a timely fashion. Unfortunately one of the three main sub-contractors under-performed drastically which put a lot of pressure on the Harsco team due to late changes. With this in mind, and with the Harsco people being so pro-active and reactive, the project finished on time. Without this support I’m sure the project would have overrun.”

The fact that asbestos was being removed from the building as the windows were replaced meant that Harsco’s scaffolding design had to allow the proper protective sheeting to be installed all round the areas which were being worked on. This also involved Harsco being asked to make frequent changes to the scaffolding as the project progressed, and often at a moment’s notice.

A college refurbishment project in Rutland has thrown the spotlight onto the outstanding levels of customer service for which Harsco Infrastructure is widely recognised, and earned the company high praise from its client.

Despite the presence of asbestos and the need for frequent changes during the life of the project, Harsco was able to provide a CUPLOK® scaffolding system which allowed the windows at Uppingham Community College to be replaced in-line with an extremely demanding schedule.

“This was certainly a project which provided its fair share of difficulties, but the Erection and Dismantle team at our Birmingham branch in Tamworth was more than equal to the challenge“ explains Harsco’s Branch Manager Steve Bollans. “The scaffolding system itself was straightforward enough, but there were many other factors which made the job difficult.”

These included the fact that the school was live during the project, which required Harsco to schedule all deliveries to site outside of school hours. Limited road access also meant that delivery vehicles were halted some 70 yards away from the school. The Harsco equipment was then unloaded and transferred to site, past an adjacent nursery school, using lorry-mounted forklift trucks.

“We could only do this when there were no children in the nursery,” adds Steve. “Similarly, when we were installing the scaffolding we had to stop work every time pupils from the main school came outside at break times” Despite this, and the fact that the decision was taken part way through to extend the project to cover the school’s second storey windows, Harsco was able to help the project meet its very demanding 10-week schedule.

“From the outset the Harsco team were extremely professional, pro-active and advisory, managing an extremely short mobilisation period with ease,” says Chris Cuthbert, Project Manager for the main contractor, Kier. “We had regular site meetings to make sure any design changes were dealt with in a timely fashion. Unfortunately one of the three main sub-contractors under-performed drastically which put a lot of pressure on the Harsco team due to late changes. With this in mind, and with the Harsco people being so pro-active and reactive, the project finished on time. Without this support I’m sure the project would have overrun.”

The fact that asbestos was being removed from the building as the windows were replaced meant that Harsco’s scaffolding design had to allow the proper protective sheeting to be installed all round the areas which were being worked on. This also involved Harsco being asked to make frequent changes to the scaffolding as the project progressed, and often at a moment’s notice.

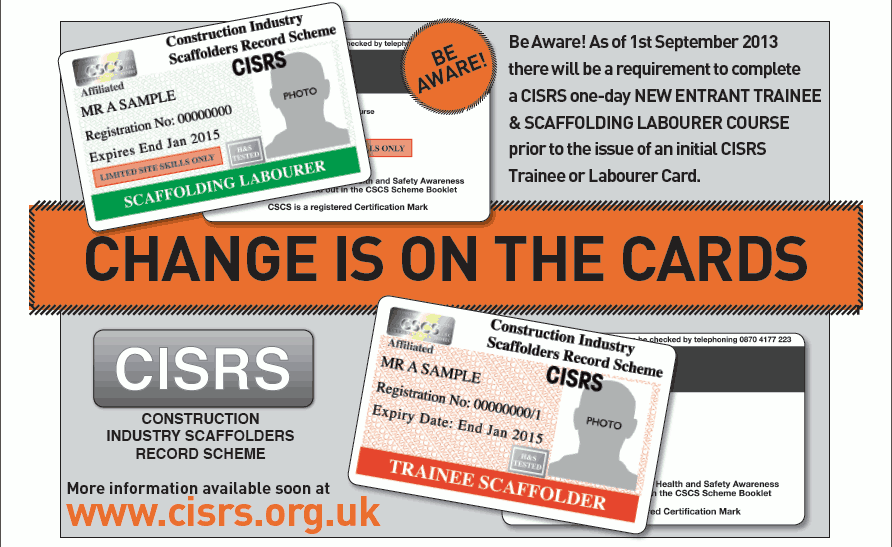

Safety & Access have appointed new scaffolding instructors to meet industry demands within the UK and Overseas.

The Nottingham and Humberside based training firm has appointed Terry Sennett, Steve Gregory and John Hall, all of whom have a wealth of experience and knowledge within the industry and bring with them skills within management, practical application and health and safety.

Safety & Access was the first UK training provider to be delivering CISRS Training over three continents from centres at Nottingham and Humberside and the recently opened facilities within the United Arab Emirates and South Korea.

The company has also stated that they have plans to develop new training courses around Scaffold Awareness, Work at height Rescue and System Scaffold Inspection as well as the new CISRS Operative and Supervisor refresher courses.

Safety & Access have appointed new scaffolding instructors to meet industry demands within the UK and Overseas.

The Nottingham and Humberside based training firm has appointed Terry Sennett, Steve Gregory and John Hall, all of whom have a wealth of experience and knowledge within the industry and bring with them skills within management, practical application and health and safety.

Safety & Access was the first UK training provider to be delivering CISRS Training over three continents from centres at Nottingham and Humberside and the recently opened facilities within the United Arab Emirates and South Korea.

The company has also stated that they have plans to develop new training courses around Scaffold Awareness, Work at height Rescue and System Scaffold Inspection as well as the new CISRS Operative and Supervisor refresher courses.

Guest Technical Article By IDH, The Independent Design House

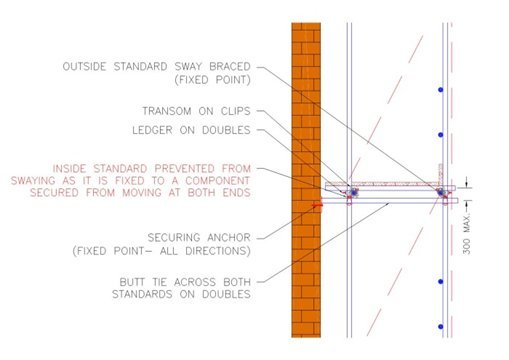

Guest Technical Article By IDH, The Independent Design House Sway stability parallel to the building is provided by a combination of the tie tube and the face brace. By installing the correct sway bracing, the outside line is prevented from moving parallel to the building. By securing the tie tube to the building façade and the outside line we now have a tube which is prevented from movement at both ends. When the inside line is now secured to this tube (with doubles) the inside line is now also prevented from moving parallel to the building by the bending resistance of this tie tube. This is why inside lines are not sway braced!

In some designed circumstances it may be a requirement to tie to the inside line only or miss ties altogether. When these scenarios occur the scaffold should be designed as we no longer have that sway restraint present and alternative measures need to be considered such as plan bracing or V-ties.

For more explanation on this and other technical scaffold design subjects visit the IDH blog:

Sway stability parallel to the building is provided by a combination of the tie tube and the face brace. By installing the correct sway bracing, the outside line is prevented from moving parallel to the building. By securing the tie tube to the building façade and the outside line we now have a tube which is prevented from movement at both ends. When the inside line is now secured to this tube (with doubles) the inside line is now also prevented from moving parallel to the building by the bending resistance of this tie tube. This is why inside lines are not sway braced!

In some designed circumstances it may be a requirement to tie to the inside line only or miss ties altogether. When these scenarios occur the scaffold should be designed as we no longer have that sway restraint present and alternative measures need to be considered such as plan bracing or V-ties.

For more explanation on this and other technical scaffold design subjects visit the IDH blog: