and Manchester sites based on Cape’s service offering and expertise. This three year contract positions Cape as one of Cargill’s Select Suppliers in Europe.

Vestas, the international wind energy group, has selected Cape to provide the cleaning and painting maintenance services for their UK Wind Turbines, utilising Cape’s extensive in-house rope access knowledge and expertise. The contract is for three years with two additional one year options.

Lukoil, a major international vertically-integrated oil & gas company, has selected Cape to provide refractory services on their new FCCU plant. During this 18 month fixed term project Cape will supply technical expertise, together with the supply and installation of refractory materials for their Stream 2 facility in Nizhny Novgorod, Russia. Stream 1 was completed successfully by York Linings in 2009. This award reflects Cape’s strategic objective to broaden its services portfolio through the extension of specialist refractory linings services across the Group.

Steve Connolly, Managing Director of Cape UK, Europe and CIS commented: “We are delighted to be awarded these contracts in recognition of our commitment to continue to deliver value to our clients through our focus on HSEQ performance, efficiency and sustainability.”

and Manchester sites based on Cape’s service offering and expertise. This three year contract positions Cape as one of Cargill’s Select Suppliers in Europe.

Vestas, the international wind energy group, has selected Cape to provide the cleaning and painting maintenance services for their UK Wind Turbines, utilising Cape’s extensive in-house rope access knowledge and expertise. The contract is for three years with two additional one year options.

Lukoil, a major international vertically-integrated oil & gas company, has selected Cape to provide refractory services on their new FCCU plant. During this 18 month fixed term project Cape will supply technical expertise, together with the supply and installation of refractory materials for their Stream 2 facility in Nizhny Novgorod, Russia. Stream 1 was completed successfully by York Linings in 2009. This award reflects Cape’s strategic objective to broaden its services portfolio through the extension of specialist refractory linings services across the Group.

Steve Connolly, Managing Director of Cape UK, Europe and CIS commented: “We are delighted to be awarded these contracts in recognition of our commitment to continue to deliver value to our clients through our focus on HSEQ performance, efficiency and sustainability.” Cape wins new contracts in the UK and Russia

Cape plc have today announced the award of new contracts with Cargill, Lukoil and Vestas valued at approximately £10m.

Cargill, the international producer and marketer of food, agricultural, financial and industrial products and services, has selected Cape as their chosen supplier for the provision of industrial cleaning services on their Liverpool  and Manchester sites based on Cape’s service offering and expertise. This three year contract positions Cape as one of Cargill’s Select Suppliers in Europe.

Vestas, the international wind energy group, has selected Cape to provide the cleaning and painting maintenance services for their UK Wind Turbines, utilising Cape’s extensive in-house rope access knowledge and expertise. The contract is for three years with two additional one year options.

Lukoil, a major international vertically-integrated oil & gas company, has selected Cape to provide refractory services on their new FCCU plant. During this 18 month fixed term project Cape will supply technical expertise, together with the supply and installation of refractory materials for their Stream 2 facility in Nizhny Novgorod, Russia. Stream 1 was completed successfully by York Linings in 2009. This award reflects Cape’s strategic objective to broaden its services portfolio through the extension of specialist refractory linings services across the Group.

Steve Connolly, Managing Director of Cape UK, Europe and CIS commented: “We are delighted to be awarded these contracts in recognition of our commitment to continue to deliver value to our clients through our focus on HSEQ performance, efficiency and sustainability.”

and Manchester sites based on Cape’s service offering and expertise. This three year contract positions Cape as one of Cargill’s Select Suppliers in Europe.

Vestas, the international wind energy group, has selected Cape to provide the cleaning and painting maintenance services for their UK Wind Turbines, utilising Cape’s extensive in-house rope access knowledge and expertise. The contract is for three years with two additional one year options.

Lukoil, a major international vertically-integrated oil & gas company, has selected Cape to provide refractory services on their new FCCU plant. During this 18 month fixed term project Cape will supply technical expertise, together with the supply and installation of refractory materials for their Stream 2 facility in Nizhny Novgorod, Russia. Stream 1 was completed successfully by York Linings in 2009. This award reflects Cape’s strategic objective to broaden its services portfolio through the extension of specialist refractory linings services across the Group.

Steve Connolly, Managing Director of Cape UK, Europe and CIS commented: “We are delighted to be awarded these contracts in recognition of our commitment to continue to deliver value to our clients through our focus on HSEQ performance, efficiency and sustainability.”

and Manchester sites based on Cape’s service offering and expertise. This three year contract positions Cape as one of Cargill’s Select Suppliers in Europe.

Vestas, the international wind energy group, has selected Cape to provide the cleaning and painting maintenance services for their UK Wind Turbines, utilising Cape’s extensive in-house rope access knowledge and expertise. The contract is for three years with two additional one year options.

Lukoil, a major international vertically-integrated oil & gas company, has selected Cape to provide refractory services on their new FCCU plant. During this 18 month fixed term project Cape will supply technical expertise, together with the supply and installation of refractory materials for their Stream 2 facility in Nizhny Novgorod, Russia. Stream 1 was completed successfully by York Linings in 2009. This award reflects Cape’s strategic objective to broaden its services portfolio through the extension of specialist refractory linings services across the Group.

Steve Connolly, Managing Director of Cape UK, Europe and CIS commented: “We are delighted to be awarded these contracts in recognition of our commitment to continue to deliver value to our clients through our focus on HSEQ performance, efficiency and sustainability.”

and Manchester sites based on Cape’s service offering and expertise. This three year contract positions Cape as one of Cargill’s Select Suppliers in Europe.

Vestas, the international wind energy group, has selected Cape to provide the cleaning and painting maintenance services for their UK Wind Turbines, utilising Cape’s extensive in-house rope access knowledge and expertise. The contract is for three years with two additional one year options.

Lukoil, a major international vertically-integrated oil & gas company, has selected Cape to provide refractory services on their new FCCU plant. During this 18 month fixed term project Cape will supply technical expertise, together with the supply and installation of refractory materials for their Stream 2 facility in Nizhny Novgorod, Russia. Stream 1 was completed successfully by York Linings in 2009. This award reflects Cape’s strategic objective to broaden its services portfolio through the extension of specialist refractory linings services across the Group.

Steve Connolly, Managing Director of Cape UK, Europe and CIS commented: “We are delighted to be awarded these contracts in recognition of our commitment to continue to deliver value to our clients through our focus on HSEQ performance, efficiency and sustainability.” Senior Scaffolding Training Instructor Retires After 17 Years Of Service

Gifts and best wishes were presented to Safety and Access employee John Campbell after 17 years of service to the company.

Staff at Safety and Access Ltd were together to wish Senior Instructor, John Campbell their best wishes for his recent retirement. John is one of the longest serving employees with the company at 17 years and is looking forward to pursuing his hobby of carp fishing.

John has delivered CISRS and other training to thousands of people over the years ranging from scaffolder skills and management and supervisory training.

At an informal gathering at the Nottingham Centre John was presented with several gifts from his colleagues. The staff and directors of Safety and Access would like to thank John for his invaluable contribution to the development and success of the company and wish him a long and happy retirement as well as a successful carp fishing career!

Guest design article: What is Effective Length ?

Guest Technical Article By IDH, The Independent Design House

IDH was incorporated in July 2011 and established to provide specialist Scaffold Design, Formwork Design & general Temporary Works Design consultancy serving Sub-Contractors, Main Contractors and Client developers.

What is Effective Length?

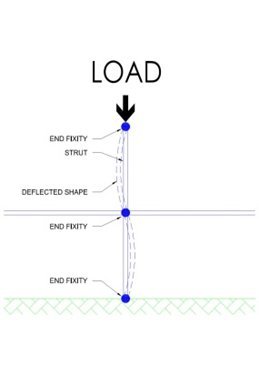

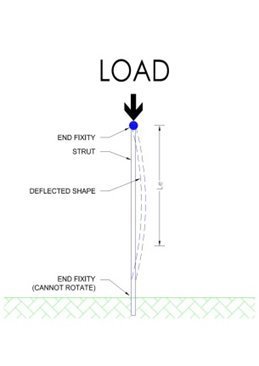

Effective length is a critical concept in Structural Design for all structural members such as Steel UC and UB sections, reinforced concrete columns and scaffold tubes. Its technical definition is ‘the length of a component which is effectively restrained’. When designing structural members they can be subject to a number of forces such as Shear, Tension, Compression, Torsion and combinations of these to name but a few. Generally speaking, when we look at structural members, be it beams or struts, the Compressive force element is predominant in determining the structural capacity and the failure mechanism.Example 1:

In this example, if the ends of the strut are held in place in all directions then the effective length Le is equal to the length of strut.

In this example, if the ends of the strut are held in place in all directions then the effective length Le is equal to the length of strut.

Example 2:

Now if we introduce a support in the middle and prevent it from moving in all directions, the Le becomes half the strut length. This is critical, if we started for example with a scaffold tube of 2m it would have a strut capacity of 29.1 kN (TG20:08 Table 20). By reducing the effective length to 1.0m the strut capacity increases to 58.6 kN.

Now if we introduce a support in the middle and prevent it from moving in all directions, the Le becomes half the strut length. This is critical, if we started for example with a scaffold tube of 2m it would have a strut capacity of 29.1 kN (TG20:08 Table 20). By reducing the effective length to 1.0m the strut capacity increases to 58.6 kN.

Example 3:

If we now fix one end of the tube in to concrete say so that it cannot pivot or rotate, although the length of the tube is still 2m, it now has an Le of 1.4m. So our 2m tube in the last example can carry 45.3 kN – much more than a tube of the same length restrained as the first example.

In scaffolds, the same principles apply. If we have a 2m lift ledger braced pair of standards, with each end of each pair prevented from moving left and right, the effective length would be 2.0m. However we seldom have this scenario in scaffolds – we have every other pair of standards ledger braced, we have ties on varying lifts and we typically only sway brace the outside face. Meaning, on closer review, we have lots of different standards with lots of different end fixity conditions resulting in lots of different effective lengths throughout the scaffold arrangement. This results in different standards having different load capacities and the global capacity of the scaffold limited to the single standard with the worst leg load / effective length ratio.

For more explanation on this and other technical scaffold design subjects visit the IDH blog: http://www.idh-design.co.uk/blog/

Author: Tim Burt

If we now fix one end of the tube in to concrete say so that it cannot pivot or rotate, although the length of the tube is still 2m, it now has an Le of 1.4m. So our 2m tube in the last example can carry 45.3 kN – much more than a tube of the same length restrained as the first example.

In scaffolds, the same principles apply. If we have a 2m lift ledger braced pair of standards, with each end of each pair prevented from moving left and right, the effective length would be 2.0m. However we seldom have this scenario in scaffolds – we have every other pair of standards ledger braced, we have ties on varying lifts and we typically only sway brace the outside face. Meaning, on closer review, we have lots of different standards with lots of different end fixity conditions resulting in lots of different effective lengths throughout the scaffold arrangement. This results in different standards having different load capacities and the global capacity of the scaffold limited to the single standard with the worst leg load / effective length ratio.

For more explanation on this and other technical scaffold design subjects visit the IDH blog: http://www.idh-design.co.uk/blog/

Author: Tim Burt

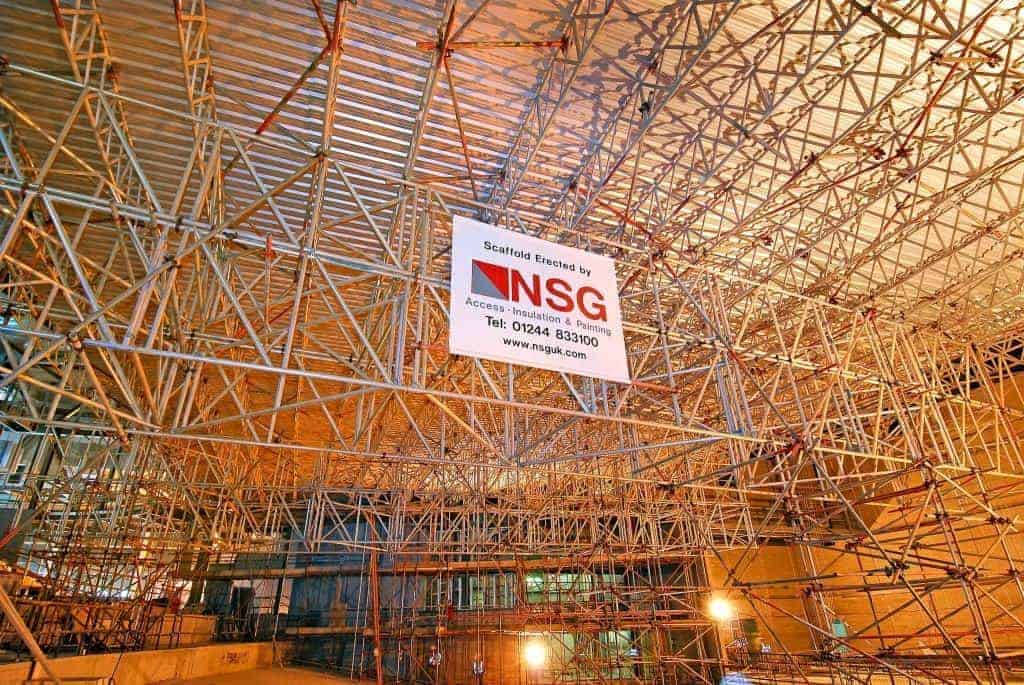

Altrad NSG Gains Gold Medal For Safety Excellence

Scaffolding and industrial services firm Altrad NSG has achieved its eighth consecutive Gold Standard for excellence in health and safety.

The Deeside based firm, which operates at sites across the UK, was awarded a Gold Medal for Occupational Health & Safety, by the Royal Society for the Prevention of Accidents (RoSPA).

The award was presented by RoSPA to recognise the company’s achievement and commitment to raising the standards of health and safety management at its Ineos Chlor site in Runcorn. Altrad NSG is now setting its sights on two more years of continuous health and safety success to achieve a RoSPA President’s Award – presented to organisations who achieve 10 or more years of consecutive Gold standard.

Paul Hemingway, Health and Safety Advisor at Altrad NSG, said: “Safety is paramount to the business so we are delighted to be recognised with our eighth consecutive RoSPA Gold Award. Alongside our British Safety Council Five Star Award and Sword of Honour, it demonstrates to our clients and potential customers that we are a responsible and conscientious business that places health and safety as top priority.

“We have 140 staff at our Ineos Chlor site, providing multi-discipline maintenance works including scaffolding, rope access, painting and industrial cleaning, as well as thermal insulation and sheet metal work, together with road gritting, rigging and slinging and high pressure water jetting. We had to provide RoSPA with strong evidence of best practice health and safety management, highlighting our excellent track record over the past year. This continuing success has only been achievable because of the commitment to health and safety from all site operatives and the Site Management Team.”

David Dawlins, RoSPA Award Manager, said: “RoSPA firmly believes that organisations that demonstrate commitment to continuous improvement in accident and ill health prevention deserve recognition. Altrad NSG Limited – Ineos Site Runcorn has shown that it is committed to striving for such continuous improvement and we are delighted to honour it through the presentation of an award.”

Ineos Chlor is a leading global manufacturer of chlorine and PVC – its Runcorn site is the company’s biggest in the UK.

Will Gretton, Altrad NSG Health and Safety Manager, added: “We have also had our Asbestos Ancillary Licence for scaffolding renewed until 2016 – few other scaffolders hold this license and we have had to undergo rigorous assessment by the HSE. This means we are able to continue to provide access to asbestos removal sites and is another endorsement of our quality and robust health and safety procedures.

“We are continuing to invest in training across the workforce and have just completed Asbestos Awareness, Risk Assessment and Manual Handling training courses for the whole of the Altrad NSG workforce.”

Altrad NSG works with a range of blue chip construction clients, providing scaffolding and rope access systems, insulation, painting, coatings, blasting and industrial cleaning. Core sectors include on and offshore oil and gas, petrochemical, pharmaceutical, power generation (including nuclear), steel production, shipbuilding, rail and civil infrastructure.

In 2011 the business was purchased by French based multinational Altrad SA.

Scaffolding and industrial services firm Altrad NSG has achieved its eighth consecutive Gold Standard for excellence in health and safety.

The Deeside based firm, which operates at sites across the UK, was awarded a Gold Medal for Occupational Health & Safety, by the Royal Society for the Prevention of Accidents (RoSPA).

The award was presented by RoSPA to recognise the company’s achievement and commitment to raising the standards of health and safety management at its Ineos Chlor site in Runcorn. Altrad NSG is now setting its sights on two more years of continuous health and safety success to achieve a RoSPA President’s Award – presented to organisations who achieve 10 or more years of consecutive Gold standard.

Paul Hemingway, Health and Safety Advisor at Altrad NSG, said: “Safety is paramount to the business so we are delighted to be recognised with our eighth consecutive RoSPA Gold Award. Alongside our British Safety Council Five Star Award and Sword of Honour, it demonstrates to our clients and potential customers that we are a responsible and conscientious business that places health and safety as top priority.

“We have 140 staff at our Ineos Chlor site, providing multi-discipline maintenance works including scaffolding, rope access, painting and industrial cleaning, as well as thermal insulation and sheet metal work, together with road gritting, rigging and slinging and high pressure water jetting. We had to provide RoSPA with strong evidence of best practice health and safety management, highlighting our excellent track record over the past year. This continuing success has only been achievable because of the commitment to health and safety from all site operatives and the Site Management Team.”

David Dawlins, RoSPA Award Manager, said: “RoSPA firmly believes that organisations that demonstrate commitment to continuous improvement in accident and ill health prevention deserve recognition. Altrad NSG Limited – Ineos Site Runcorn has shown that it is committed to striving for such continuous improvement and we are delighted to honour it through the presentation of an award.”

Ineos Chlor is a leading global manufacturer of chlorine and PVC – its Runcorn site is the company’s biggest in the UK.

Will Gretton, Altrad NSG Health and Safety Manager, added: “We have also had our Asbestos Ancillary Licence for scaffolding renewed until 2016 – few other scaffolders hold this license and we have had to undergo rigorous assessment by the HSE. This means we are able to continue to provide access to asbestos removal sites and is another endorsement of our quality and robust health and safety procedures.

“We are continuing to invest in training across the workforce and have just completed Asbestos Awareness, Risk Assessment and Manual Handling training courses for the whole of the Altrad NSG workforce.”

Altrad NSG works with a range of blue chip construction clients, providing scaffolding and rope access systems, insulation, painting, coatings, blasting and industrial cleaning. Core sectors include on and offshore oil and gas, petrochemical, pharmaceutical, power generation (including nuclear), steel production, shipbuilding, rail and civil infrastructure.

In 2011 the business was purchased by French based multinational Altrad SA.

Cape announces collaborative supply agreement with HAKI

Official confirmation has been announced today that Cape will be supplying and installing the HAKI system scaffolding over other systems.

It’s official.. Cape plc have today confirmed with a press release that the firm will be using HAKI system scaffolding over other competing system products.

Cape Plc today released this statement:

Cape plc, the international provider of essential support services to the energy and mineral resources sectors, is pleased to announce that it has entered into a collaborative supply agreement with the system scaffolding specialist HAKI.

Cape erects or dismantles over 2,000 individual scaffolds a day. Any efficiency that can be introduced to that process will ultimately improve the service clients receive. In early 2013 Cape carried out a robust review of various scaffolding systems in the UK market. ‘’Our scaffolding teams work in a huge variety of different locations, each with their own particular technical challenges.’’ explains Simon Hicks, Capes UK Head of Strategic Development. ‘’Finding an intelligent solution that could improve our performance in a safe and reliable way was key.’’

After a thorough review, the HAKI® Universal System was selected to be the best solutions that meet the needs and requirements of Cape and its clients. The HAKI system benefits from many unique features such as fewer contact points and larger bay sizes which help increase productivity. As Simon explains, ‘’we chose HAKI because of the excellent safety features of the system. It’s a high-quality, Swedish-engineered product, and we get great technical support from HAKI’s UK-based team. Deployed in the right place, we believe that the HAKI system is more efficient and delivers greater productivity gains than other systems on the market, and our people really like using it.’’

HAKI’s Vice President of Marketing and Business Development, Chris Stokes commented:

‘’HAKI is proud to be chosen as Cape’s principle supplier of system scaffold, after a demanding selection process this is a great endorsement. This investment reinforces Cape’s powerful scaffolding and access service offering and demonstrates the effectiveness of HAKI for demanding industrial applications.’’

Case Study

Cape has already started to implement the HAKI system, with the south sphere on the Polimeri Europa site in Hythe, being one of the notable successes. Access was required to the sphere structure to remove its fireproof coating and to carry out radiography testing. The Cape team built a large internal scaffold using collective measures and meeting requirements of SG4:10. Feedback from the client was positive, who told cape they were impressed with the ‘’monstrous but beautiful scaffold’’.

Press release source: http://www.capeplc.com/news-and-media/news-announcements/2013/6/cape-enters-collaborative-supply-agreement-with-haki.aspx

Official confirmation has been announced today that Cape will be supplying and installing the HAKI system scaffolding over other systems.

It’s official.. Cape plc have today confirmed with a press release that the firm will be using HAKI system scaffolding over other competing system products.

Cape Plc today released this statement:

Cape plc, the international provider of essential support services to the energy and mineral resources sectors, is pleased to announce that it has entered into a collaborative supply agreement with the system scaffolding specialist HAKI.

Cape erects or dismantles over 2,000 individual scaffolds a day. Any efficiency that can be introduced to that process will ultimately improve the service clients receive. In early 2013 Cape carried out a robust review of various scaffolding systems in the UK market. ‘’Our scaffolding teams work in a huge variety of different locations, each with their own particular technical challenges.’’ explains Simon Hicks, Capes UK Head of Strategic Development. ‘’Finding an intelligent solution that could improve our performance in a safe and reliable way was key.’’

After a thorough review, the HAKI® Universal System was selected to be the best solutions that meet the needs and requirements of Cape and its clients. The HAKI system benefits from many unique features such as fewer contact points and larger bay sizes which help increase productivity. As Simon explains, ‘’we chose HAKI because of the excellent safety features of the system. It’s a high-quality, Swedish-engineered product, and we get great technical support from HAKI’s UK-based team. Deployed in the right place, we believe that the HAKI system is more efficient and delivers greater productivity gains than other systems on the market, and our people really like using it.’’

HAKI’s Vice President of Marketing and Business Development, Chris Stokes commented:

‘’HAKI is proud to be chosen as Cape’s principle supplier of system scaffold, after a demanding selection process this is a great endorsement. This investment reinforces Cape’s powerful scaffolding and access service offering and demonstrates the effectiveness of HAKI for demanding industrial applications.’’

Case Study

Cape has already started to implement the HAKI system, with the south sphere on the Polimeri Europa site in Hythe, being one of the notable successes. Access was required to the sphere structure to remove its fireproof coating and to carry out radiography testing. The Cape team built a large internal scaffold using collective measures and meeting requirements of SG4:10. Feedback from the client was positive, who told cape they were impressed with the ‘’monstrous but beautiful scaffold’’.

Press release source: http://www.capeplc.com/news-and-media/news-announcements/2013/6/cape-enters-collaborative-supply-agreement-with-haki.aspx

Harsco opens new scaffolding training center in Immingham

Turner Access announce the retirement of its Managing Director

Scaffolder’s lack of safety measures put lives at risk

A scaffolder has been prosecuted for neglecting vital safety measures that put himself, his staff and passing members of the public at risk.

Truro Magistrates’ Court heard on Friday (24 May) that an inspector from the Health and Safety Executive (HSE) saw workers on scaffolding with no edge protection at a property in Cranberry Road, Camborne, in March 2012. They were not wearing any harnesses or lanyards to protect them from falls.

The Inspector issued an immediate Prohibition Notice on Anthony Dale scaffolding, halting any further work at the site until improvements were made.

The court was told that following an investigation into Mr Dale on another matter, Cornwall Council sent pictures to HSE showing him again working on scaffolding without any edge protection or harnesses.

Workers for Anthony Dale and Dale himself were seen twice on scaffolding with no edge protection or safety equipment that could have helped them in the event of a fall at sites in Chapel Street, Penzance, and Coinagehall Street, Helston, in 2012.

Anthony Dale of Roskear Parc, Tuckingmill, Camborne, pleaded guilty to breaching Section 2(2) and Section 3(1) of the Health and Safety at Work etc Act 1974 and was fined a total of £8,000 and ordered to pay £4,114 in costs.

Speaking after the hearing, HSE Inspector Barry Trudgian, said:

“Work at height is the biggest single cause of fatal and serious injury in the construction industry. Anthony Dale’s reckless disregard of basic safety precautions demonstrates a totally a cavalier approach to the health and well-being of his workers and of passers-by, let alone himself.

“The risks of working at height are widely-known and recognised and there is a wealth of guidance available from HSE and the industry. There can really be no excuse for not putting basic precautions in place.

“Simple measures such as providing guardrails and having the correct safety equipment could save someone’s life.”

Further information on safe scaffolding can be found on the HSE website at:http://www.hse.gov.uk/construction/faq-scaffold.htm

A scaffolder has been prosecuted for neglecting vital safety measures that put himself, his staff and passing members of the public at risk.

Truro Magistrates’ Court heard on Friday (24 May) that an inspector from the Health and Safety Executive (HSE) saw workers on scaffolding with no edge protection at a property in Cranberry Road, Camborne, in March 2012. They were not wearing any harnesses or lanyards to protect them from falls.

The Inspector issued an immediate Prohibition Notice on Anthony Dale scaffolding, halting any further work at the site until improvements were made.

The court was told that following an investigation into Mr Dale on another matter, Cornwall Council sent pictures to HSE showing him again working on scaffolding without any edge protection or harnesses.

Workers for Anthony Dale and Dale himself were seen twice on scaffolding with no edge protection or safety equipment that could have helped them in the event of a fall at sites in Chapel Street, Penzance, and Coinagehall Street, Helston, in 2012.

Anthony Dale of Roskear Parc, Tuckingmill, Camborne, pleaded guilty to breaching Section 2(2) and Section 3(1) of the Health and Safety at Work etc Act 1974 and was fined a total of £8,000 and ordered to pay £4,114 in costs.

Speaking after the hearing, HSE Inspector Barry Trudgian, said:

“Work at height is the biggest single cause of fatal and serious injury in the construction industry. Anthony Dale’s reckless disregard of basic safety precautions demonstrates a totally a cavalier approach to the health and well-being of his workers and of passers-by, let alone himself.

“The risks of working at height are widely-known and recognised and there is a wealth of guidance available from HSE and the industry. There can really be no excuse for not putting basic precautions in place.

“Simple measures such as providing guardrails and having the correct safety equipment could save someone’s life.”

Further information on safe scaffolding can be found on the HSE website at:http://www.hse.gov.uk/construction/faq-scaffold.htm Layher introduces Allround Lightweight system scaffolding

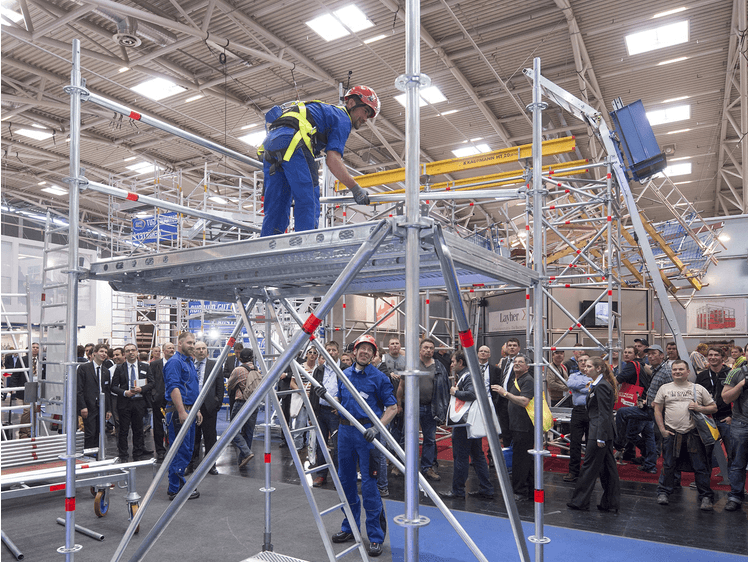

KHL.com has reported that Layher has debuted a new, lighter scaffolding solution – Allround Lightweight. Shown for the first time at Bauma 2013 in Munich, the Allround Lightweight modular scaffolding system features lighter components, increased load-bearing capacity and an AUtoLock function for wedge-head connectors.

According to Layher, Allround Lightweight can be assembled 10 percent faster than competitive scaffold systems and transport is 12 percent more efficient.

“Since assembly, dismantling and transport still account for 80 percent of the costs for scaffolding construction, three factors are critically important: design, functionality and component weight,” said Layher’s marketing director Franz Greisinger. “The focus is on making scaffolding construction easier, safer, and above all more economical. Studies have clearly shown that a significant reduction in assembly and dismantling time can be achieved by cutting back on component weight.”

To get Allround Lightweight as light as possible, Layher used high-tensile steel that allowed the company to make components with thinner walls. The wall thickness of the new ALlround standards LW has been reduced from 3.2mm to 2.8 mm.

“Depending on the length of the components, scaffolding erectors have up to 14 percent less weight to handle when transporting components by truck to the construction site and in scaffolding assembly itself,” the company said. “The wall thickness has been reduced in Allround O-ledgers LW as well, saving up to 1.6 kg while increasing bending stress capacity by 24 percent.”

To make transportation more efficient, Layher lowered the structural height of the product which reduces storage volumes. With the additional reduction in weight, scaffolders have faster loading and unloading time.

“With its 12 percent higher transport efficiency, Allround Lightweight requires fewer trips, which reduces transport costs for medium-size and large projects,” the company said. “In this way it is also friendlier to the environment.”

Also new is the AutoLock function that creates a positive connection between ledger and rosette. To bring the self-locking wedge into position, the fitter gives the ledger a quick turn and tips it forward. Then they place the wedge-head above the rosette of the Allround standard. When the wedge makes contact with the standard, it is automatically activated and falls into the recess provided for it. A hammer blow then creates a force transmitting connection. This saves one operation for each ledger connection and allows ledgers to be fitted from a secure position.

Lastly, the new U-ledgers LW are one-fourth lighter because the high-tensile steel makes V-reinforcement unnecessary, the company said. The structural height of the ledgers has been reduced by 4.5 cm. The new reinforced Allround U-ledgers LW have 10 cm more clearance than the previous U-bridging ledgers without compromising on load-bearing capacity.

Story Via: KHL.com

KHL.com has reported that Layher has debuted a new, lighter scaffolding solution – Allround Lightweight. Shown for the first time at Bauma 2013 in Munich, the Allround Lightweight modular scaffolding system features lighter components, increased load-bearing capacity and an AUtoLock function for wedge-head connectors.

According to Layher, Allround Lightweight can be assembled 10 percent faster than competitive scaffold systems and transport is 12 percent more efficient.

“Since assembly, dismantling and transport still account for 80 percent of the costs for scaffolding construction, three factors are critically important: design, functionality and component weight,” said Layher’s marketing director Franz Greisinger. “The focus is on making scaffolding construction easier, safer, and above all more economical. Studies have clearly shown that a significant reduction in assembly and dismantling time can be achieved by cutting back on component weight.”

To get Allround Lightweight as light as possible, Layher used high-tensile steel that allowed the company to make components with thinner walls. The wall thickness of the new ALlround standards LW has been reduced from 3.2mm to 2.8 mm.

“Depending on the length of the components, scaffolding erectors have up to 14 percent less weight to handle when transporting components by truck to the construction site and in scaffolding assembly itself,” the company said. “The wall thickness has been reduced in Allround O-ledgers LW as well, saving up to 1.6 kg while increasing bending stress capacity by 24 percent.”

To make transportation more efficient, Layher lowered the structural height of the product which reduces storage volumes. With the additional reduction in weight, scaffolders have faster loading and unloading time.

“With its 12 percent higher transport efficiency, Allround Lightweight requires fewer trips, which reduces transport costs for medium-size and large projects,” the company said. “In this way it is also friendlier to the environment.”

Also new is the AutoLock function that creates a positive connection between ledger and rosette. To bring the self-locking wedge into position, the fitter gives the ledger a quick turn and tips it forward. Then they place the wedge-head above the rosette of the Allround standard. When the wedge makes contact with the standard, it is automatically activated and falls into the recess provided for it. A hammer blow then creates a force transmitting connection. This saves one operation for each ledger connection and allows ledgers to be fitted from a secure position.

Lastly, the new U-ledgers LW are one-fourth lighter because the high-tensile steel makes V-reinforcement unnecessary, the company said. The structural height of the ledgers has been reduced by 4.5 cm. The new reinforced Allround U-ledgers LW have 10 cm more clearance than the previous U-bridging ledgers without compromising on load-bearing capacity.

Story Via: KHL.com Major scaffolding collapse could’ve happened in Manchester