Austrian formwork and scaffolding giant Doka is preparing to make a bold statement at Bauma 2025 in Munich, with more than 40 product innovations to revolutionise construction site productivity and support a more sustainable construction future.

Visitors to the world-renowned construction trade fair will find Doka’s sprawling outdoor stand (FN.420 – FN.423) transformed into a high-tech showcase, where automation, robotics, digital tools, and climate-conscious construction materials take centre stage.

Speaking ahead of the exhibition, Robert Hauser, CEO of Doka, said:

“We cannot build the future with yesterday’s methods. The construction industry is facing enormous challenges – above all, it must overcome its productivity stagnation. Through consistent digitalisation and new technologies, we aim to create real value for our customers.”

Among the headline announcements is the re-engineered DokaXbot Lift – an automated lifting assistant for formwork installation. First unveiled as a prototype in 2022, the upgraded version now offers intuitive ground-level controls, automatic fine-tuning, and the ability to compensate for uneven flooring.

Capable of positioning formwork up to 5.7 metres high, the DokaXbot Lift enhances safety and efficiency on high-rise builds and will feature in live demonstrations throughout the show.

Another key innovation making its global debut is Doka LeanForm, an assembly method that enables complete wall formwork units to be safely pre-assembled at ground level. Once complete, units are lifted into place via crane – reducing risk, saving time, and improving site ergonomics.

Doka’s commitment to greener building practices is also clear, with the introduction of an intelligent heated formwork prototype. The technology supports the curing of low-carbon, CO?-reduced concrete by applying targeted heating to accelerate strength development – addressing a key challenge in the transition to more climate-friendly materials. Embedded digital sensors provide real-time monitoring, offering contractors valuable data on concrete performance.

“CO?-reduced concrete is a key driver of change,” Mr Hauser added. “With our heated formwork, we are showing that formwork can be a powerful tool in the decarbonisation of construction sites. It’s more than just support – it’s an enabler.”

Also on display will be Doka’s new FormDrive system – a mobile, automated control unit that lifts and manoeuvres climbing systems and wall formwork, reducing manual effort and increasing on-site safety.

Visitors can also explore the next generation of slab and wall formwork, including the DokaXdek, Xlife, and heavy-duty shoring systems like DokaXshore and UniKit.

Scaffolding solutions

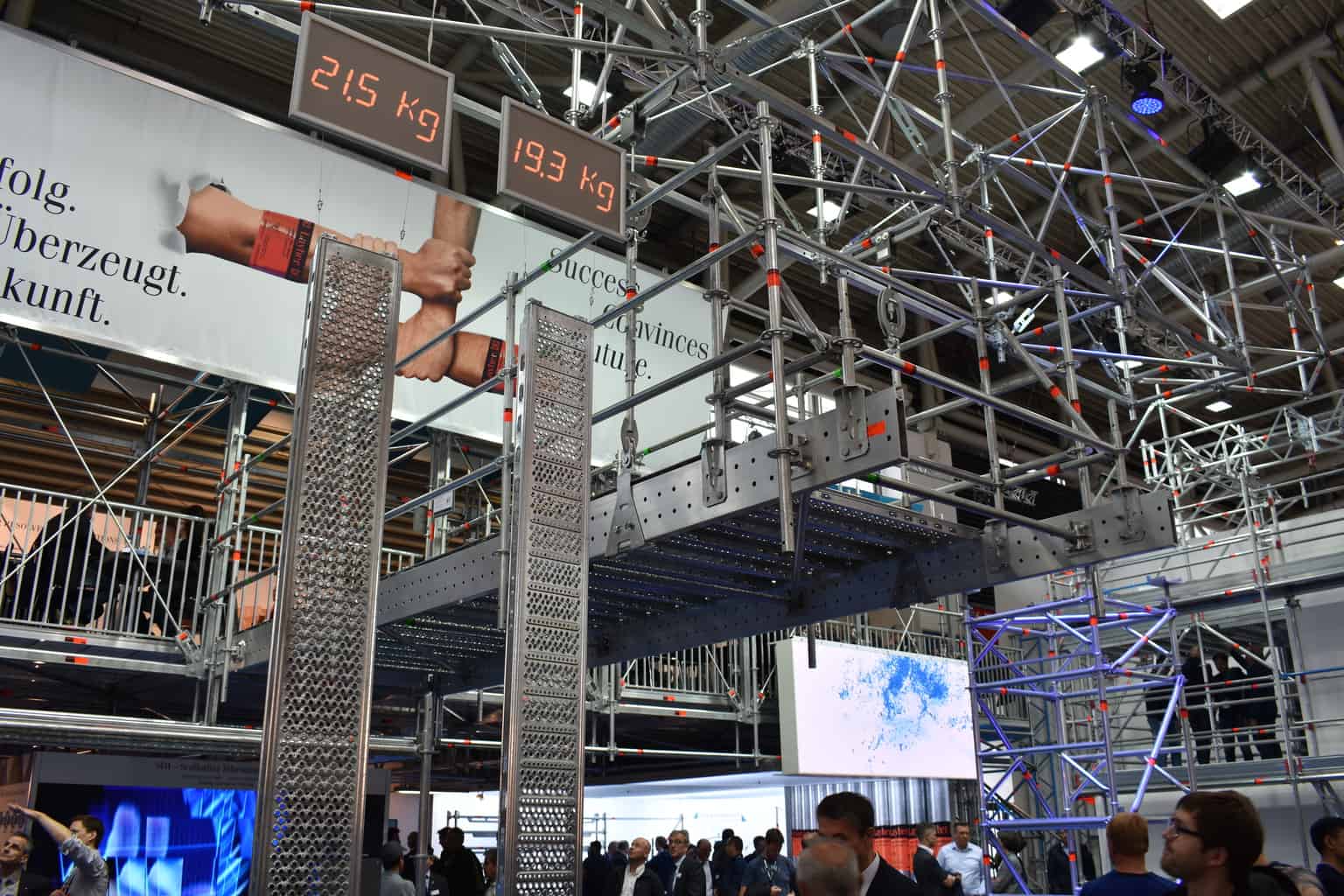

In partnership with AT-PAC, Doka will spotlight a range of new scaffolding solutions, targeting both the construction and industrial sectors. These include advancements in façade scaffolding, access systems, and shoring applications. A dedicated scaffolding zone will feature a towering 30-metre Ringlock scaffold structure with an integrated viewing platform, offering panoramic views of the Bauma grounds.

Bauma 2025 takes place from April 7–13 in Munich and is expected to attract hundreds of thousands of visitors from across the globe.