Hong Kong launches construction safety drive after serious incidents

4D Structures and PERI UK join forces to build one of Glasgow’s tallest towers

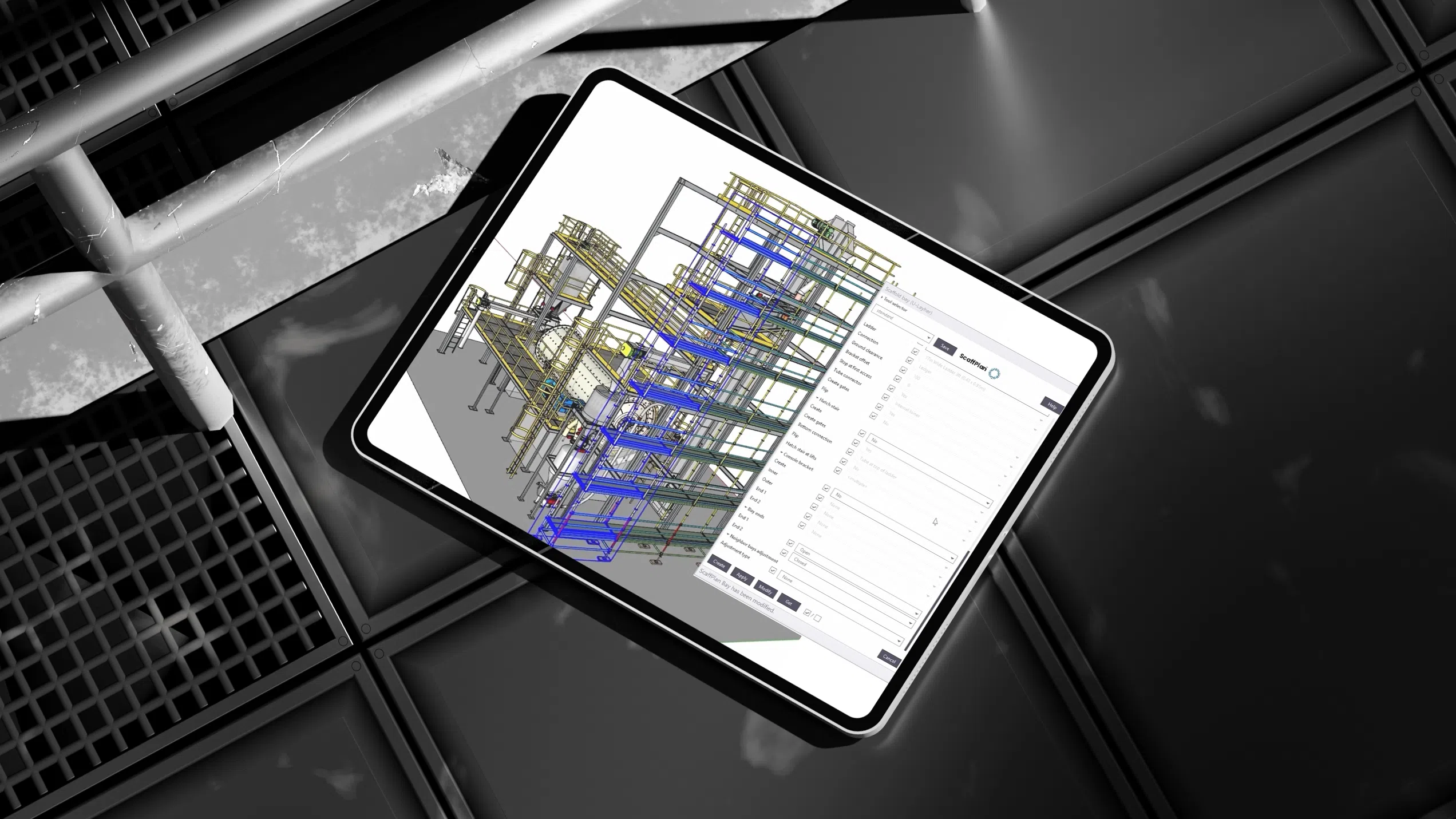

ScaffPlan launches 3D scaffold design tool within SketchUp

“Every wasted hour on site starts with unclear planning,” Boyes added. “ScaffPlan gives scaffolders full control over design and communication, ensuring everyone, from estimator to crew, works from the same clear plan.”

The company says the SketchUp version is best suited for residential, commercial, and industrial access projects. Larger contractors managing BIM-integrated workflows may prefer ScaffPlan for Tekla.

ScaffPlan for SketchUp launched globally on 10 November 2025.

Watch the demo: scaffplan.com/demo/sketchup

“Every wasted hour on site starts with unclear planning,” Boyes added. “ScaffPlan gives scaffolders full control over design and communication, ensuring everyone, from estimator to crew, works from the same clear plan.”

The company says the SketchUp version is best suited for residential, commercial, and industrial access projects. Larger contractors managing BIM-integrated workflows may prefer ScaffPlan for Tekla.

ScaffPlan for SketchUp launched globally on 10 November 2025.

Watch the demo: scaffplan.com/demo/sketchup Scaffolding contractors boost profits with building wrap partnership programme

Growing demand creates opportunity

Building wraps have become increasingly common on construction sites across the UK, serving multiple purposes beyond hiding scaffolding. They contain dust and debris, reduce noise pollution, provide weather protection and create advertising space. Clients now regularly specify building wraps in their tender documents, particularly for high-profile developments where site presentation matters to planning authorities and local communities. For scaffolding contractors, this represents a commercial opportunity. However, taking on unfamiliar services without the right capabilities can bring complications.How the partnership works

Lavastar’s model removes those complications. When a scaffolder receives a tender requiring a building wrap, they contact the company for pricing, which can be included in their overall package. The scaffolder marks up the service as they would any subcontractor element. If the work must be quoted directly through Lavastar, the company builds commission into its costs for the referring contractor. Once a contract is won, Lavastar conducts a free site survey and provides drawings showing what framework will be added to the scaffolding structure, along with calculations for the additional loading. The scaffolder’s only responsibility is ensuring their scaffold design can accommodate those loads, which is standard practice for any structural addition. Everything else, the artwork development, client liaison, printing, framework installation, and wrap fitting all remain with Lavastar.In-house capability

The company handles all stages internally. Its design team works with clients’ marketing departments to develop graphics at no extra charge. Printing uses ultra UV-resistant inks on PVC mesh materials that allow wind and light through whilst reducing structural loading. Installation teams fit Kee Klamp framework systems 300mm proud of the scaffolding, creating what the industry calls a drum-skin finish. This taut, professional appearance extends the wrap’s lifespan by preventing contact with scaffold tubes. All projects include risk assessments and method statements meeting site safety requirements. Recent work includes a collaboration with Sky Scaffolding on a wrap for Warwick Castle, where Lavastar’s services were included in the scaffolder’s tender package.

Track record

Based on the outskirts of London, Lavastar has worked on building wraps for over 25 years. The firm recently won gold at the UK Sign & Graphic Awards for transforming scaffolding around Wakehurst’s Elizabeth Mansion during roof restoration. Other projects include 2,400 square metres of wrap at Mayfair’s Lazari Building and various heritage sites requiring trompe l’oeil treatments—photographic reproductions of building facades used during restoration work. The company operates nationwide, covering Birmingham, Manchester, Liverpool, Leeds and Glasgow. Different installation methods suit varying budgets and project durations, from premium long-term solutions with full framework systems to simpler direct-fix approaches for shorter contracts. Scaffolding contractors can contact Lavastar on 01252 850818 or visit: https://www.lavastar.co.uk/building-wraps/ for more information.Equinor awards £1.25bn scaffolding and maintenance contracts for onshore plants

Subscription required

- Hammerfest LNG: KAEFER Energy AS

- Kårstø: Bilfinger ISP Offshore Norway AS

- Mongstad and Tjeldbergodden: Beerenberg / Linjebygg (Altrad)

- Sture and Kollsnes: StS-ISONOR AS

Scaffolders’ tough day as runaway lorry crashes into house

A lorry loaded with scaffolding has collided with a house near Bristol, damaging two cars before coming to rest against the property.

The incident happened at around 10 am on Friday in Oldland Common, a residential area on the outskirts of Bristol.

Avon and Somerset Police said the lorry was unoccupied at the time and confirmed that no one was injured.

Photographs from the scene show the scaffolding vehicle lodged against the front of a house, with visible damage to the structure. Two cars parked nearby also appear badly damaged, one with a broken bumper and another with deep scrapes along its side.

A police spokesperson said: “An unoccupied lorry has reportedly rolled into a house on Malvern Drive in Warmley. Thankfully there are no reported injuries. Police are at the scene pending the attendance of a structural engineer to assess the safety of the building and recovery of the vehicle.”

Officers remain on site on Friday as engineers assessed the damage before the lorry could be safely removed.

Kirtanlal and Al Masaood partnership set to reshape the Middle East scaffolding sector

ULMA Construction eyes UK expansion with Des Moore leading setup

PERI UK’s Terry Hall recognised as ‘Unsung Hero’ for driving formwork safety reform

Over the past year, Hall has trained and upskilled more than 120 individuals through PERI UK’s accredited programmes, which can be delivered both on-site and at the company’s training and exhibition facility in Brentwood, Essex.

Ian Hayes, Managing Director of PERI UK, said: “We’re incredibly proud of Terry and this well-deserved recognition. His determination has enhanced our service and set a new benchmark for safety and professionalism across the concrete structures industry.”

The CONSTRUCT Day awards celebrate excellence within the in-situ concrete sector, recognising individuals and teams who make significant contributions to safety, innovation, and skills development.

Over the past year, Hall has trained and upskilled more than 120 individuals through PERI UK’s accredited programmes, which can be delivered both on-site and at the company’s training and exhibition facility in Brentwood, Essex.

Ian Hayes, Managing Director of PERI UK, said: “We’re incredibly proud of Terry and this well-deserved recognition. His determination has enhanced our service and set a new benchmark for safety and professionalism across the concrete structures industry.”

The CONSTRUCT Day awards celebrate excellence within the in-situ concrete sector, recognising individuals and teams who make significant contributions to safety, innovation, and skills development. Scaffolders urged to tighten safety as climate change brings fiercer storms

Common shortcuts that extreme weather can expose include mixing components from different manufacturers, failing to follow assembly guidelines, inadequate checks of mudsill anchorage or scaffold Ties, and using damaged components, such as cracked boards or rusted elements. Poor safety culture, where workers aren’t encouraged to report concerns, compounds these problems.

Planning and design failures present particular risks. Strength and stability calculations must be completed for any scaffolding that doesn’t conform to recognised standard configurations. Complex designs require competent persons to draw up assembly, use and dismantling plans, with documentation available to all workers on the project.

Foundation-level checks are frequently overlooked, according to McCarron Coates. Ground conditions, particularly areas with drains or rain-softened soil, may not support the weight of scaffolding structures. Similarly, attaching sheeting or netting to scaffolds not designed for these additions creates instability. Even when designs allow for sheeting, it must be fitted to become sacrificial in high winds, preventing suction forces from toppling the entire structure.

The firm emphasises that compliance with NASC’s TG20 guidance is essential for structures to withstand severe weather. The guidance enables contractors to determine maximum safe heights and proper configurations for scaffolding, sheeting and debris netting.

Post-storm inspections are equally critical. Following each weather event, competent persons must reinspect scaffolding structures, complete written reports, and implement corrective actions immediately.

Common shortcuts that extreme weather can expose include mixing components from different manufacturers, failing to follow assembly guidelines, inadequate checks of mudsill anchorage or scaffold Ties, and using damaged components, such as cracked boards or rusted elements. Poor safety culture, where workers aren’t encouraged to report concerns, compounds these problems.

Planning and design failures present particular risks. Strength and stability calculations must be completed for any scaffolding that doesn’t conform to recognised standard configurations. Complex designs require competent persons to draw up assembly, use and dismantling plans, with documentation available to all workers on the project.

Foundation-level checks are frequently overlooked, according to McCarron Coates. Ground conditions, particularly areas with drains or rain-softened soil, may not support the weight of scaffolding structures. Similarly, attaching sheeting or netting to scaffolds not designed for these additions creates instability. Even when designs allow for sheeting, it must be fitted to become sacrificial in high winds, preventing suction forces from toppling the entire structure.

The firm emphasises that compliance with NASC’s TG20 guidance is essential for structures to withstand severe weather. The guidance enables contractors to determine maximum safe heights and proper configurations for scaffolding, sheeting and debris netting.

Post-storm inspections are equally critical. Following each weather event, competent persons must reinspect scaffolding structures, complete written reports, and implement corrective actions immediately.