Leading training provider, AIS Survivex, has sealed a deal with the British Forces Resettlement Service (BFRS) to support those looking to work in the global energy sector after leaving military life.

The deal will see AIS Survivex become BFRS Gold Plus Sponsors and work closely with BFRS to help former military personnel retrain for new careers in the energy industry, particularly wind and renewables.

As well as attending a series of military careers events across the UK to promote energy sector careers and provide advice and guidance to BFRS members, AIS Survivex is developing tailored training packages to give ex-forces the right skills to get their first energy opportunity.

BFRS works with companies across the UK looking to hire, retrain and offer career advice to the armed forces community leaving service.

Neil Dean, operations director at BFRS, said: “This is an extremely important partnership for us and together with AIS Survivex, we want to lead the market in transitioning ex-military into new and meaningful energy sector careers through the launch of Military2Energy, which is specifically designed to filter people from the military to careers in energy.

“The energy sector has always been a popular career choice for ex-armed forces and even more so in the current market, which offers lots of opportunities. The UK wind industry alone needs more than 43,000 new workers by 2026 according to the Offshore Wind Industry Council.

“AIS Survivex is helping us to raise awareness of these opportunities at a series of military careers events. The next event will take place in Leicester on 16th June and after that Tidworth on 15th September so I’d urge people to come along to find out more.”

Linzi Ryan, Head of Marketing at AIS Survivex, said: “We are delighted to sign this agreement with BFRS and become the partner of choice for military personnel looking to successfully transition their skills into the global energy sector.

“We have extensive experience of training people for energy and work closely with key employers to develop career opportunities for those going through the resettlement process. As well as ensuring former military personnel have a smooth transition into civilian life, this also opens up the possibility of securing a full-time job within the exciting and dynamic energy sector. We are an ELCAS-approved supplier so ex-forces personnel can also access funding to help pay for training.”

There are lots of synergies between military life and working in the global energy sector and AIS Survivex has a proven track record of helping former military personnel transition into new careers. One example is former Royal Marine, Jonathan Askew.

Cramlington-born, Jonathan was a mortarman working with rifles and mortars but, after developing tinnitus, was medically discharged. After training with AIS Survivex, Jonathan secured a full-time job as a wind technician.

Jonathan said: “Coming out of the Royal Marines with no technical experience felt very much like starting from scratch and it was a huge transition to where I am now. I’ve now got extremely marketable skills and feel completely prepared for my wind career.”

AIS Survivex has set up a dedicated hotline to provide specialist help and advice for military personnel thinking about an energy sector career. Email [email protected] or call +44 (0) 191 3410 395.

G&M Group Managing Director, Mark Pickles said: “The G&M Safe Deck Hybrid system is the next generation of our market-leading, highly cost-effective working platform system that’s taken the UK construction scene by storm. It offers quick and simple superior protection of site personnel whilst working at height and the ability to be able to dovetail with existing scaffold temporary works, safely and compliantly.

“Along with G&M Safe Deck freestanding and our Modular Access Platform (MAP) system, this new hybrid system is the third major product launch since the pandemic and showcases the prolific safety innovation we offer our housebuilding, timber frame, scaffolding and other construction clients right across the country. It’s cost effective, quick and easy to use we are excited to launch it to our nationwide clients.”

The all-new G&M Safe Deck Hybrid system is available for hire and sale nationwide now.

G&M Group Managing Director, Mark Pickles said: “The G&M Safe Deck Hybrid system is the next generation of our market-leading, highly cost-effective working platform system that’s taken the UK construction scene by storm. It offers quick and simple superior protection of site personnel whilst working at height and the ability to be able to dovetail with existing scaffold temporary works, safely and compliantly.

“Along with G&M Safe Deck freestanding and our Modular Access Platform (MAP) system, this new hybrid system is the third major product launch since the pandemic and showcases the prolific safety innovation we offer our housebuilding, timber frame, scaffolding and other construction clients right across the country. It’s cost effective, quick and easy to use we are excited to launch it to our nationwide clients.”

The all-new G&M Safe Deck Hybrid system is available for hire and sale nationwide now.

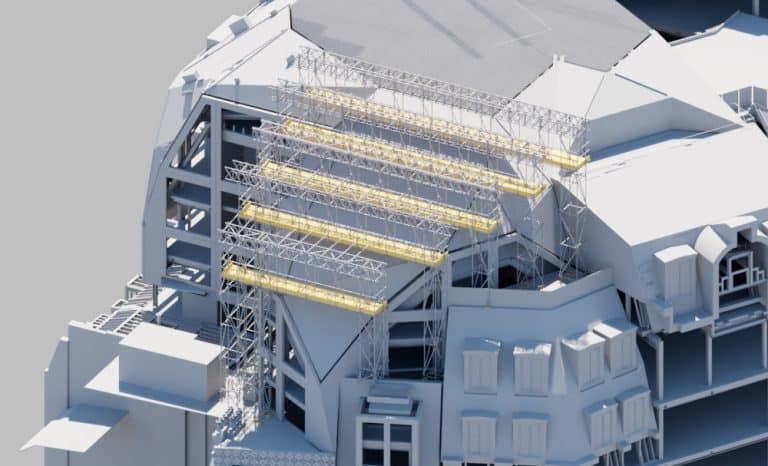

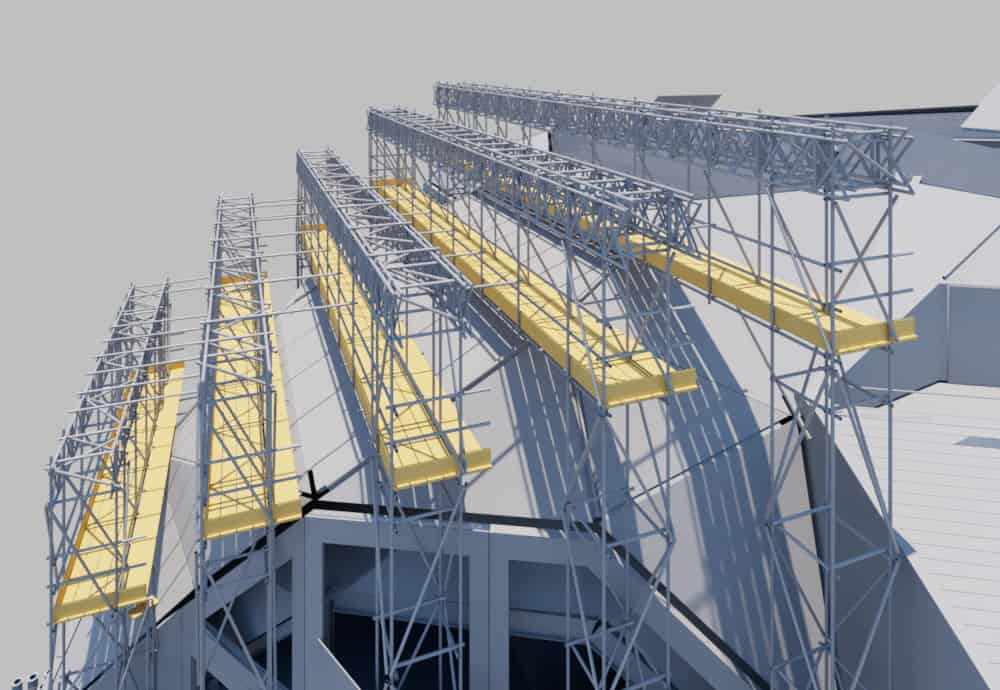

In terms of its repair, it needed a project team well versed in such emergencies – a group of highly skilled, specialist contractors able to handle the pressure to enable the dome to re-open safely in a short timeframe.

These essential repairs would not have been possible without a protective temporary gantry to allow safe pedestrian and emergency service vehicles access to enable the arena to reopen as quickly as possible.

In terms of its repair, it needed a project team well versed in such emergencies – a group of highly skilled, specialist contractors able to handle the pressure to enable the dome to re-open safely in a short timeframe.

These essential repairs would not have been possible without a protective temporary gantry to allow safe pedestrian and emergency service vehicles access to enable the arena to reopen as quickly as possible.

WellMax added: “We installed a 5kn/m2 protection deck with a mono-pitched temporary roof, tied back to the main structural foundations with a bespoke beamed raking system. By developing and installing this tying in system, we were able to remove the need for 100T of kentledge.

“Throughout the entire challenge, everybody worked with the sole objective of delivering the project for the Friday 12pm deadline. There was no status/hierarchy amongst any of the trades, everybody got involved and every trade pulled together.”

WellMax added: “We installed a 5kn/m2 protection deck with a mono-pitched temporary roof, tied back to the main structural foundations with a bespoke beamed raking system. By developing and installing this tying in system, we were able to remove the need for 100T of kentledge.

“Throughout the entire challenge, everybody worked with the sole objective of delivering the project for the Friday 12pm deadline. There was no status/hierarchy amongst any of the trades, everybody got involved and every trade pulled together.”

Behind the scenes back at WellMax offices, the yard staff, drivers, management and engineers were all busy ensuring a smooth flow of support and resources needed by the team working on site.

The company continued work on the emergency project as everyday business carried on. Thanks to an impressive and well-managed labour resource allocation and owned stock, WellMax were able to mobilise teams and materials quickly to site for the Monday morning start.

Behind the scenes back at WellMax offices, the yard staff, drivers, management and engineers were all busy ensuring a smooth flow of support and resources needed by the team working on site.

The company continued work on the emergency project as everyday business carried on. Thanks to an impressive and well-managed labour resource allocation and owned stock, WellMax were able to mobilise teams and materials quickly to site for the Monday morning start.

The timescale of Friday was critical as the venue was due to host a UB40 concert that evening – no pressure then!!

Incredibly, the 12pm deadline was met by all the trades to enable a full multi-disciplined inspection and sign off to be achieved. What’s more no remedial works were required.

In terms of the UK scaffolding industry, once again proof positive emerged, we have some of the best scaffolders and construction workers on the planet.

Russell Maxwell-Smith told us: “I would like to thank everyone involved on this project including, but not limited to the client’s team, Deconstruct (UK), other subcontractors, our supply chain and lastly, most importantly for me, the WellMax team both on and off site for their cohesive teamwork and approach to this timely critical project.”

And so, Former UB40 member Ali Campbell was able to “tear the roof off” again in the nicest possible sense when he reopened the venue in a show honouring his late bandmate Astro.

Raise a glass to WellMax – Red Red Wine anyone?

This article was first published in the

The timescale of Friday was critical as the venue was due to host a UB40 concert that evening – no pressure then!!

Incredibly, the 12pm deadline was met by all the trades to enable a full multi-disciplined inspection and sign off to be achieved. What’s more no remedial works were required.

In terms of the UK scaffolding industry, once again proof positive emerged, we have some of the best scaffolders and construction workers on the planet.

Russell Maxwell-Smith told us: “I would like to thank everyone involved on this project including, but not limited to the client’s team, Deconstruct (UK), other subcontractors, our supply chain and lastly, most importantly for me, the WellMax team both on and off site for their cohesive teamwork and approach to this timely critical project.”

And so, Former UB40 member Ali Campbell was able to “tear the roof off” again in the nicest possible sense when he reopened the venue in a show honouring his late bandmate Astro.

Raise a glass to WellMax – Red Red Wine anyone?

This article was first published in the

Training and skill development at a senior level within Millcroft delivers value for the business and our clients in multiple ways. As a dynamic and ambitious business, learning is part of our commitment to delivering best practice and offering a smooth and efficient service for our clients. It is integral to quality-oriented operational management and our culture of continuous improvement. Learning is the process of questioning everything, so, when our directors invest time in training, it develops their ability to problem-solve and innovate in an ingrained discipline that influences the way they lead the business.

The senior team’s commitment to learning also influences the rest of our team. For many businesses, there is an emphasis on staff training, but the mandate is not carried through to management level. This can be especially true of family businesses where the leadership team has been born and bred in the scaffolding sector and does not perceive a need for training at director level. At Millcroft, we have seen the value of training for the senior team not only in building the skills and knowledge of directors and heads of departments, but also in inspiring the whole team about the benefits and value it brings.

When we developed our mental health awareness training and rolled this out to the whole team, we ensured that the initiative involved everyone at all levels. Our Group Head of HSEQ Mike Wright developed and delivered the training in a workshop style so that he was personally involved in exploring the topic with each cohort of staff, and all the directors also completed the course, establishing the importance of both training and mental health within the business.

Finally, it is our clients who benefit most from the training that our directors and senior managers complete. For them, this investment means that we offer a service that provides a best practice approach across all areas of project planning and delivery, operational management, financial management and collaboration. The skills our senior team develop when they pursue advanced learning permeate through the company, along with a culture of always being the best that we can be.

Fundamentally, therefore, at the successful completion of every job, we are firmly focused on what we have learned and how those lessons can be applied to do even better on our next project.

This article was first published in the

Training and skill development at a senior level within Millcroft delivers value for the business and our clients in multiple ways. As a dynamic and ambitious business, learning is part of our commitment to delivering best practice and offering a smooth and efficient service for our clients. It is integral to quality-oriented operational management and our culture of continuous improvement. Learning is the process of questioning everything, so, when our directors invest time in training, it develops their ability to problem-solve and innovate in an ingrained discipline that influences the way they lead the business.

The senior team’s commitment to learning also influences the rest of our team. For many businesses, there is an emphasis on staff training, but the mandate is not carried through to management level. This can be especially true of family businesses where the leadership team has been born and bred in the scaffolding sector and does not perceive a need for training at director level. At Millcroft, we have seen the value of training for the senior team not only in building the skills and knowledge of directors and heads of departments, but also in inspiring the whole team about the benefits and value it brings.

When we developed our mental health awareness training and rolled this out to the whole team, we ensured that the initiative involved everyone at all levels. Our Group Head of HSEQ Mike Wright developed and delivered the training in a workshop style so that he was personally involved in exploring the topic with each cohort of staff, and all the directors also completed the course, establishing the importance of both training and mental health within the business.

Finally, it is our clients who benefit most from the training that our directors and senior managers complete. For them, this investment means that we offer a service that provides a best practice approach across all areas of project planning and delivery, operational management, financial management and collaboration. The skills our senior team develop when they pursue advanced learning permeate through the company, along with a culture of always being the best that we can be.

Fundamentally, therefore, at the successful completion of every job, we are firmly focused on what we have learned and how those lessons can be applied to do even better on our next project.

This article was first published in the

Dave Mosley, CISRS Managing Director, was also in attendance at the course last week, assessing the delivery of the proposed programme and also renewing his CISRS card. He said: “The course went well but still requires a few minor tweaks which Tony is already addressing. Once these have been completed, he will deliver a webinar for CISRS-approved providers in order to bring them up to speed with the changes prior to the launch of phase 2.”

The new course will go live from Monday 1st August 2022.

Dave Mosley, CISRS Managing Director, was also in attendance at the course last week, assessing the delivery of the proposed programme and also renewing his CISRS card. He said: “The course went well but still requires a few minor tweaks which Tony is already addressing. Once these have been completed, he will deliver a webinar for CISRS-approved providers in order to bring them up to speed with the changes prior to the launch of phase 2.”

The new course will go live from Monday 1st August 2022.