First Female Scaffolding Apprentice for AIS

Claudia Ferguson.

A North East training company is welcoming its first ever female scaffolding apprentice and is urging others to follow to help address the dramatic gender imbalance in the construction sector.

Only 12% of construction workers are female with less than 2% working manually on construction sites, according to statistics by the CITB, so training and skills specialist AIS Connect was delighted when Claudia Ferguson enrolled onto its CITB-endorsed scaffolding apprenticeship scheme. Claudia, aged 22, from Sunderland works for scaffolding company ISL and will undertake a full CITB scaffolding apprenticeship with AIS Connect. The unique programme takes wannabe scaffolders, aged 16-24, through a minimum of 18 months of comprehensive skills training and on-the-job experience to qualify as a CISRS (Construction Industry Scaffolders Record Scheme) scaffolder able to safely erect, alter and dismantle scaffolding structures. After leaving school, Claudia was unsure of the right career path to follow. Despite studying photography and art and design at college no suitable jobs were available and Claudia ended up working in a call centre to earn money. But Claudia knew this wasn’t for her and after several discussions with a family friend set her sights on the construction industry. Claudia said: “When I heard about what a job in scaffolding involves it immediately appealed. You get to work outside in lots of different locations and it’s very physical so you can keep fit without going to the gym. The lack of women in the sector made me want to rise to the challenge even more and show people I was capable of doing the job. “I can’t deny it was hard at first but now I love it. The banter is fantastic and the guys I work with are extremely supportive and treat me like one of their own. My boss in particular has been there for me all the way and the company has really helped me progress. Once I complete my apprenticeship with AIS Connect, I want to go into a supervisory role – possibly offshore. I can’t see myself doing anything else and would encourage women to look at construction as a viable career option. Because women are rare in the sector, companies are much keener to take you on and there are lots of potential jobs out there.” Head of partnerships and strategic development at AIS Connect, Kate Lovelock said: “It’s important to get the message out that the construction sector offers lots of rewarding and exciting career paths for women as well as men. AIS Connect is working with the region’s key educational establishments to raise awareness of the opportunities available in the construction, engineering and energy sectors and it’s great to see a female as enthusiastic and motivated as Claudia coming through our doors. Hopefully her story will inspire others and we urge any woman wanting to find out more about how to get into industry to get in touch.” Kevin Hartburn, apprenticeships officer from the CITB said: “There is a terrific future for women in the construction industry and enlightened employers will be the ones to reap the benefits of having a higher proportion of females in their workforce. We’re delighted to see a female in the scaffolding industry being trained with AIS Connect. The company has an excellent reputation for developing tailored training programmes for industry and has heavily invested in a new state-of-the-art training facility for young people.”Scaffolding Prices Set to Rise in 2017

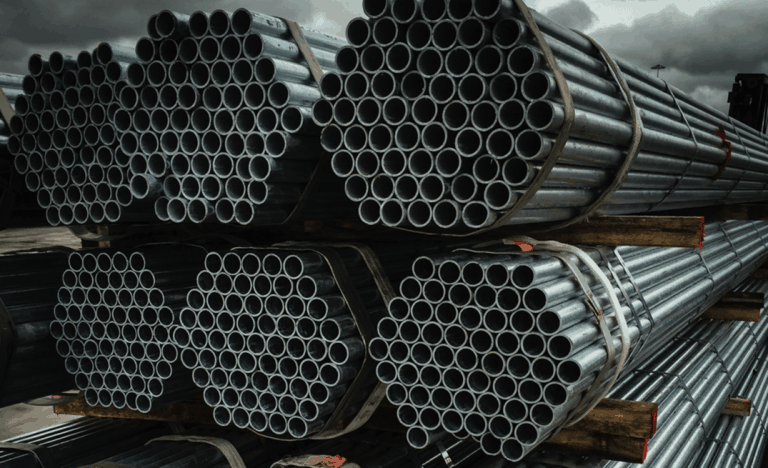

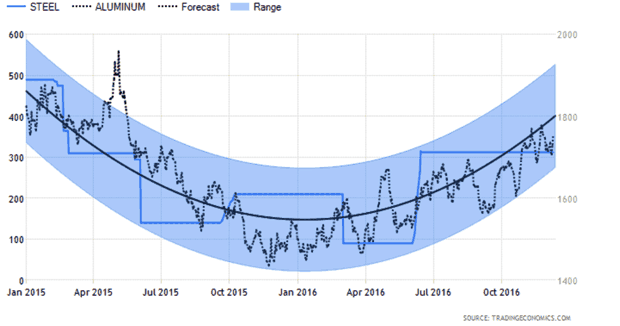

The 16% post Brexit fall in the Pound against the Dollar and Euro has also made things worse for UK scaffolders. As raw materials are priced in Dollars and Euros this has raised the cost of raw materials and made imported scaffolding products more expensive to buy.

Scaffolding manufacturers have started to pass on the costs and UK suppliers are reporting their wholesale prices for a foot of tube has risen by over 60% since March this year.

The price rises come at an uncertain time for the construction Industry after the recent years of fast growth. Government data shows that construction activity shrank by 0.8% between July-September 2016. This represents the sectors worst performance since 2012.

The 16% post Brexit fall in the Pound against the Dollar and Euro has also made things worse for UK scaffolders. As raw materials are priced in Dollars and Euros this has raised the cost of raw materials and made imported scaffolding products more expensive to buy.

Scaffolding manufacturers have started to pass on the costs and UK suppliers are reporting their wholesale prices for a foot of tube has risen by over 60% since March this year.

The price rises come at an uncertain time for the construction Industry after the recent years of fast growth. Government data shows that construction activity shrank by 0.8% between July-September 2016. This represents the sectors worst performance since 2012. When contacted about the rising prices, Generation Commercial and Finance Director, Alan Wilkinson, said:

“Our customers report that they are busy through the early part

of 2017 but concerned about the increasing costs of scaffolding. As the UK’s largest purchaser and supplier of scaffolding products we have also experienced the rapid price rises. Our aim is to support and provide our customers with the best quality and value scaffolding. To protect our customers from sudden price rises we have invested heavily in new hire stock throughout 2016 to keep prices as low as we can.”

“This investment means we can guarantee the ability to freeze our hire rates at 2016 levels for the whole of next year, for all existing customers and any new accounts opened before the 31st January 2017. This is all part of Generation’s aim to ensure that our scaffolding customers consistently get the best value, service and support.”

When contacted about the rising prices, Generation Commercial and Finance Director, Alan Wilkinson, said:

“Our customers report that they are busy through the early part

of 2017 but concerned about the increasing costs of scaffolding. As the UK’s largest purchaser and supplier of scaffolding products we have also experienced the rapid price rises. Our aim is to support and provide our customers with the best quality and value scaffolding. To protect our customers from sudden price rises we have invested heavily in new hire stock throughout 2016 to keep prices as low as we can.”

“This investment means we can guarantee the ability to freeze our hire rates at 2016 levels for the whole of next year, for all existing customers and any new accounts opened before the 31st January 2017. This is all part of Generation’s aim to ensure that our scaffolding customers consistently get the best value, service and support.” NASC Apprentice of the Year Award Presentation

NASC Apprentice of the Year 2016 Award winner Kier Phur of TRAD Scaffolding Co Limited has been presented with his winner’s trophy and a cash prize of £500.

Reaching for the sky – A potted history of scaffolding

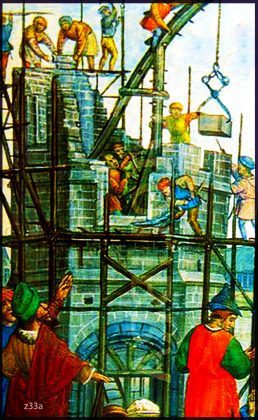

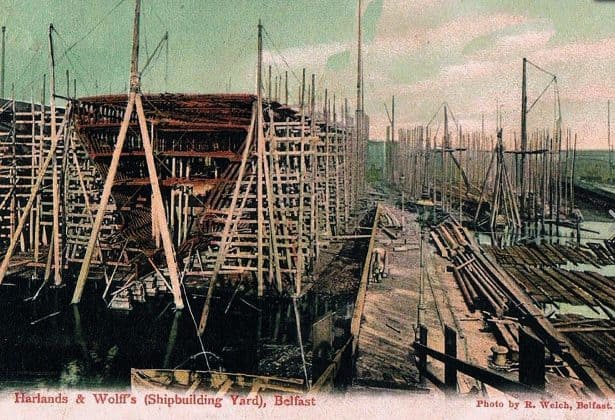

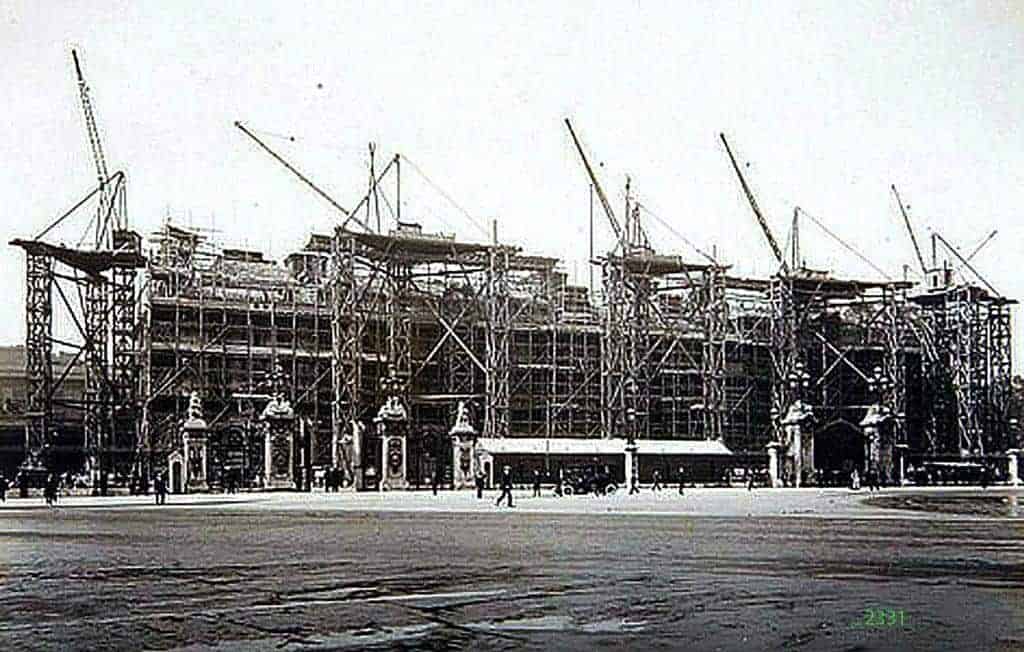

It’s known that the use of scaffolding dates way back to prehistoric times because holes still exist in the walls of Palaeolithic caves at Lascaux in south-western France that were used for staging to enable the primitive occupants to paint their famous wall paintings over 17,000 years ago.

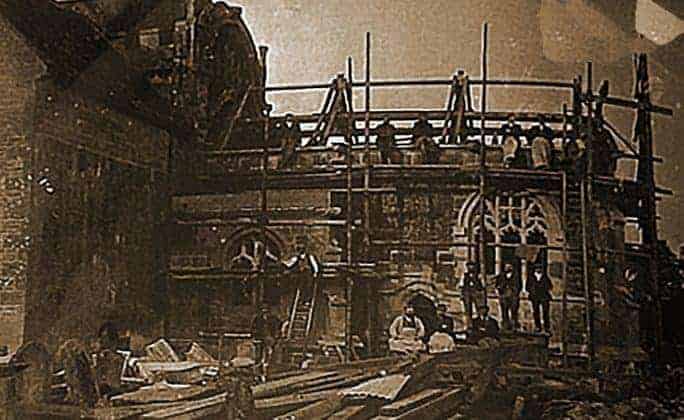

There’s also strong documentary evidence that the Egyptian pharaohs used wooden scaffolding for buildings associated with the pyramids. Later in Medieval times, specialised bands of monks were trained as scaffolders to construct abbeys and churches, a trend that continued well into the 20th century when scaffolder monks were photographed building Buckfast Abbey.

Early Days

Before the introduction of metal tubes in the early 1900’s, wooden branches or lengths of bamboo were widely used as a method of scaffold construction.

The practice of using tubes tied together with ropes made of hemp (hemping) is still used throughout Eastern countries and even nearer to home in Spain and Italy today.

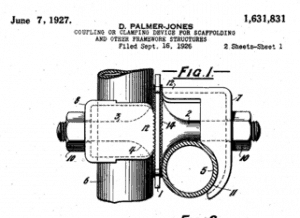

It was in the early 1900’s when Daniel Palmer-Jones (affectionately known as the ‘Grandfather of Scaffolding’) and his brother David were involved in the trade. They realised that a standard set of fixings was needed that would hold together not only the traditional wooden poles, but also the newly introduced metal scaffolding which had a tendency to slip when tied together with ropes.

After a number of experiments, they came up with their patented ‘Rapid Scaffixers’ which proved so popular that the invention led to the brothers being awarded a contract involving the remodelling of Buckingham Palace in 1913.

Six years later Palmer-Jones invented the ‘Improved Universal Coupler’ which soon became a standard pattern used by the industry right up to the present day.

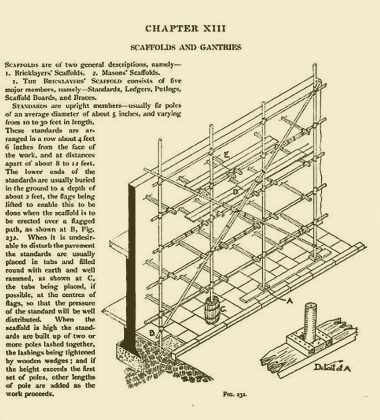

By the 1920’s metal poles were being used in the form of two inch water pipes which because of their standard dimensions allowed other parts to be similarly standardised, leading to greater stability and safety.

Post War Construction

Following World War II, a massive building program was begun to reconstruct many of the bombed areas of Britain. The first frame system was introduced by SGB, in 1944, and a year later its use was adopted for rebuilding projects throughout the nation, allowing the company to become the successful construction company it is today.

Lots of other scaffold companies owe their success to the post-war building boom. Coventry Scaffolding for instance, started in a small way In 1950 when Pat Hannifan, a former Royal Navy recruit worked as a fruit and vegetable seller and part time scaffolder.

Together with five other brothers he rented a bombed-out Catholic Church and using a second-hand lorry, began trading as the Coventry Scaffolding Company.

They went on to attract major contracts and by the 1970’s Coventry Scaffolding were building stands for the UK visit of US President Nixon; the repair of the BT Tower previously damaged in an alleged IRA bomb plot; and the building of cradles and scaffolding for a number of prominent London buildings.

More impressive high profile jobs came their way in the 1980’s and by 2005; the company had become the first scaffolding company to be granted a Royal Warrant. You can read more about their impressive rise from humble origins on their web page.

Safety

Safety has always been a priority for scaffolders, but apparently not always for employers. In the early years following WW2, men were recruited to work on building sites where unskilled labourers ‘cut their teeth’ as rookie scaffold workers.

On the The Oral History Noticeboard website we’re told a 1960’s scaffolder, George Garnham recalls not wearing any gloves, clips, harnesses or other safety gear. He also tells how workers froze as they climbed the scaffolding.

Much earlier during the reconstruction of the Hyde Park Crystal Palace in 1853, 7000 workers were taken on, including lots of scaffold workers. Whether these men were really qualified for the job has often been queried because on the 15th of August in that year tons of scaffolding supporting one of the main parts of the structure collapsed killing twelve workers.

Not all such accidents involving scaffold failure involved the workers themselves. In 1855 for example, excited crowds were watching troops re-enact the Crimean War battle of Sebastopol in Cremorne Gardens in Chelsea when the scaffold set up for the enactment collapsed allegedly due to the sheer weight of the marching soldiers. Horrified onlookers watched on as the soldiers fell, many of them becoming impaled on their own bayonets.

Modern Times

Though scaffolding methods and equipment have become standardised over the years, this doesn’t mean that there hasn’t been continual improvements (e.g. scaffold netting). In Coventry and other places during the 1960’s for instance, ‘Operation Winter Working’ was introduced by the Ministry of Public Buildings and Works in order to extend working hours for those in the construction industry. Innovations included the cladding of towers in plastic sheeting and the use of heaters installed at their bases so that work could continue during inclement weather.

Despite these modern improvements many old working practices are still evident in the industry today. As an example the block and tackle system was just as familiar to Roman scaffold workers as it is in modern times.

Chris Warburton whose job involves the restoration of old buildings is quoted on the Health and Safety at Work website as saying “Once, I was working on a church. We were around 12 lifts up on scaffolding, and we had to lift the blocks of stone up there, using a modern electric hoist…But when we positioned them, we were back to Roman technology – using blocks and tackles and chain hoists…”

Terms and expressions used by scaffolders have also changed considerably. Lots of old hands have fond memories of working on early construction jobs and recall the old terms they used for equipment, many of which are often lost on younger men in the trade.

Gallery

Scaffolder falls 30ft at Fawley refinery

An HSE investigation has been launched after a scaffolder working at Fawley refinery fell 30ft through the roof of a disused building.

It has been reported that the 33-year-old casualty landed on a concrete floor and was airlifted to Southampton General Hospital, where he is being treated for serious injuries.

Police were called to the 3,250-acre refinery following the incident and an investigation has been launched by the Health and Safety Executive (HSE).

Reports suggest the injured man is an employee of Cape plc – one of the contractors that support the operation of the huge petro-chemical complex.

A refinery spokesman told the Daily Echo the accident occurred last Saturday at about 8am.

She added: “He was treated at the scene and transferred to hospital by the Hampshire and Isle of Wight Air Ambulance.

“The Health and Safety Executive has been informed and an investigation has been launched”

First female Scottish CISRS Scaffolder named Runner up in Apprenticeship Awards

Broughty Ferry, near Dundee, scaffolding specialists A&J Maintenance Support Ltd. (A&J) revealed recently that one of their employees and management family member, Lisa Duncan was named as a runner up of the NASC apprenticeship awards 2016, which were announced at the NASC’s AGM in Amsterdam.

“We are led to believe Lisa is the first female Scottish fully Qualified CITB, CISRS scaffolder and contracting NASC member to date but third female Scottish CITB scaffolder. What she has achieved so far is incredible and we as her employer are immensely proud,” said A&J spokesperson Jaclyn Duncan.

NASC Apprentice of the Year Scheme Judge Paul Gaze of CITB said in a statement, “This year’s awards were very tough to judge, with a record number of quality entries from NASC members across the UK. Whilst it was a difficult process, two candidates in particular stood out – demonstrating their commitment to the scaffolding and access industry. They are a credit to themselves and their employers.”

Dave Mosley, NASC director of training and CISRS scheme manager said, “Congratulations to both winner Kier Phur and runner-up Lisa Duncan. This NASC Apprentice of the Year award is a great way of promoting the many apprenticeships NASC member companies create year on year – providing a backbone and lifeblood to their firms.”

A&J told Project Scotland magazine Lisa holds a degree in accountancy and law but wanted to qualify as a scaffolder after being asked to join the family business (A&J) where Lisa’s mother, June Duncan is a company director and sister, Jaclyn Duncan is the company secretary.

Project Scotland reported that Lisa is now one of only three female NASC, CITB qualified CISRS scaffolders in Scotland. Lisa told the magazine that she wants to spend more time on site and also intends to obtain her CISRS Scaffold Supervisor and Scaffold Inspection Training Scheme qualifications.

“Lisa is herself very proud of her recent collaboration with local schools off the back of her achievements and is fronting a “Girls in Construction” workshop through Go Construct (CITB) as an Ambassador later this month and is already in discussions with more Dundee & Angus schools regarding more construction (not just scaffolding) workshops for pupils considering a career in construction,” said Jaclyn Duncan.

Generation earns Advanced Training Centre approval & appoints new Lead Scaffolding Instructor

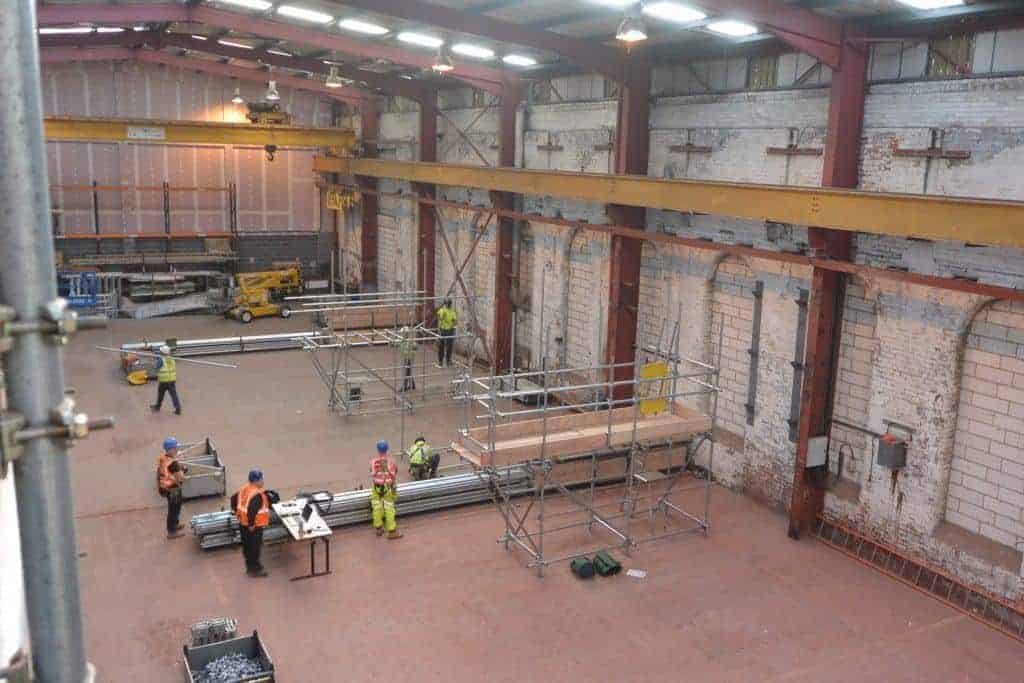

Generation Training Services has announced their CISRS Advanced Centre approval status and the appointment of a new lead scaffolding instructor.

The Wakefield based scaffolding training facility successfully obtained the CISRS Advanced Centre approval earlier this year, after continuous high standards and extensive audits by CISRS and the CITB.

In addition to the various CISRS training on offer, the advanced status now enables the centre to also offer delegates the 10 day Advanced Scaffolding Training, Advanced Inspection courses and Level 3 Skills tests.

Generation say their Wakefield Centre is the largest commercial CISRS training facility in the UK, the 9,500sqft practical area allows for 4 CISRS courses at any one time along with PASMA & IPAF courses. The centre also benefits from five spacious classrooms and a canteen area with further expansion plans in the pipeline.

Generation Training Manager, Jonathan Gaunt said: “We are very pleased that CISRS and CITB have recognised our work to take the centre and our training services to the next level. The Advanced Training Centre approval now means that Generation Training offers our customers a one-stop shop for their scaffolding training needs.”

“The ease and convenience of everything under one roof has greatly benefited our customers which we have seen in our training bookings for 2017.”

“Our goal is to work with and support Generation customers to recruit, train and retain the skilled scaffolders they need to grow and sustain their business. We ensure every course delivers the best possible training irrespective of their level of competence. We provide the platform for the learner to start their careers in the scaffolding industry and have a place to call on for ongoing support as they progress to the top.”

New Lead Scaffolding Instructor

The newly appointed lead instructor John Hall will head up the team of four fully qualified and approved CISRS instructors. John has over 30 years’ hands-on industry experience, working in a majority of industry environments that vary from Street-work, Power-stations, Petrochemical Plants to working in Quarries and Offshore facilities.

Prior to joining Generation Training, John spent the last three and half years at the Nottingham and Humberside based Safety & Access Ltd.

“I feel that Generation Training are passionate about delivering really top quality training within the scaffolding industry” said John.

“With my background within the Industry, I can help Generation become an even more outstanding Training Centre. My aim is to develop the centre further to enable Generation to deliver the CISRS Supervisors Course as well as bespoke portfolio workshops and to train new instructors to be recognised as the best in the Industry.”

Generation Training Manager, Jonathan Gaunt said: “The addition of John Hall to our team further demonstrates Generation’s commitment to providing our customers with the ultimate one stop solution. With his many years of experience in the industry as an advanced scaffolder, supervisor and project manager and more latterly, scaffolding instructor/assessor, John will head up our team of four fully qualified and approved CISRS instructors.

Coming in as an advanced instructor, John is a great fit for our training division as 2016 is also a landmark year for us, gaining our CISRS advanced centre approval. In addition to supporting the team, John will also assist with the development of our future courses and oversee the training of our apprenticeship learners which currently stands at over 90 delegates.”

Looking towards the future, Gaunt added: “Our next step is to add the CISRS Supervisor course to our product range, which will complete the full suite of CISRS approved training at the centre.”

“We will also be continuing to look for new ways to improve the training experience for our learners, ever adapting to the advancement of technologies and teaching techniques to ensure that we also offer services that are able to cater to all learning styles for delegates of all levels of ability” said Gaunt.

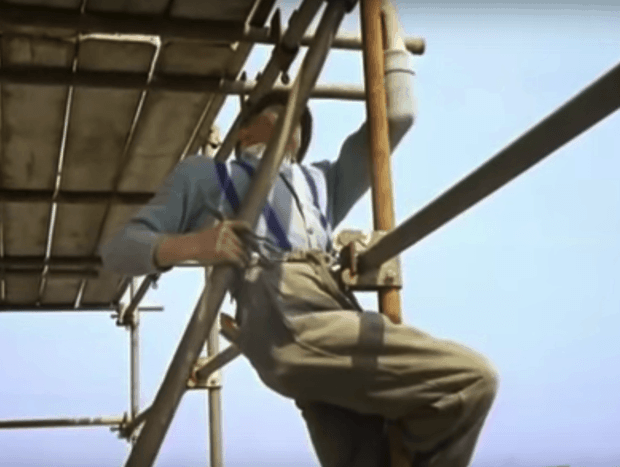

Video: Scaffolders life in the 1950s and 1960s

Well before the Health and Safety at Work Act this excellent historical video depicts the life of London construction in the early 1960’s.

Interestingly the two minute clip gives us a great insight into the life of the scaffolder back in the day. When Band and Plate was king with heavy gauge 3″ tubes and 1/2″ spanners was the norm, and not a pair of gloves in sight.

With just the wearing of a pair of brogues and a flat cap for PPE, the video shows these men were literally putting their life (and others) on the line above the busy London streets below.

Video’s like these just goes to show how far our industry has progressed with hugely increased safety and technical guidance, that hopefully ensures we go home alive everyday.

Video Credit: Lead Generator 365 with thanks to Paul Corfield for finding.

Long service scaffolding veteran Fran Michna retires

Veteran scaffolder and scaffolding instructor, Fran Michna retired on November 21, 2016 receiving an award from Dave Mosley Director of Training NASC (National Access & Scaffolding Confederation). Fran has accumulated over 40 years of experience and for anyone that has worked with or been taught by Fran he will not be forgotten.

Fran spent the latter 15 years of his career with NETA Training (NETA) as an CISRS (Construction Industry Scaffolders Record Scheme) instructor after having to give up working on the tools following a serious motorcycle accident in the mid 1990s.

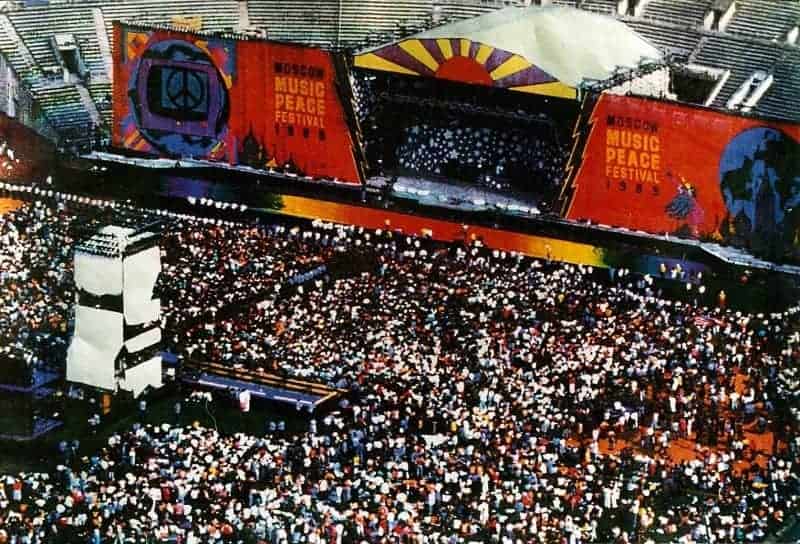

NETA interviewed Fran. He told NETA that one of his most notable career paths was working as a roadie with the likes of Madonna, Bruce Springsteen, REM, the Rolling Stones, including him delivering an off stage pep talk to Ozzy Osbourne at the Moscow Music Peace Festival in the former Soviet Union.

After being told by a doctor that he would never work as a scaffolder again after his accident Fran retrained and began another career in instructing. “The thing with scaffolding is you get your cowboys that just throw it up and think that will do, but it has to be right,” Fran told NETA.

“You have to be strict because what you are teaching is dangerous. When you are 300 foot in the air, you have to know what you are doing and you have to have your wits about you.”

Fran described tube and fitting as, “The best system in the world. You can build anything with it.”

Michael Allan, scaffolding training co-ordinator at NETA where Fran spent in total 15 years of his career, said, “Fran Michna has been a figure head in scaffolding for a number of years and he has always been heard of. Wherever you go people know Fran.

He has been an absolute pleasure to work with and I have learnt a lot from him that hopefully I can pass down in the training area. Fran leaves a legacy of tales behind him and no doubt will still be heard of for years to come.”

We asked Fran some questions too. And, typically he provided some insightful answers.

Q: What got you into scaffolding and why did you stay? Fran: “I was working in a boring job at the Vauxhall car factory in Luton when my friend Stefan saw an ad for scaffolders’ labourers at the Arndale Centre. I stayed in scaffolding because I liked the physical graft, the camaraderie and the money.” Q: What was the high point in your scaffolding career? Fran: “Too many to mention but some of the best were: Working at the Moscow Music Peace Festival, the first outdoor rock and roll festival in the Soviet Union. Working with the Rolling Stones. Designing and building the set for Doctor Marigold at the Arc theatre in Stockton. The set was inspired by a picture by M C Escher.”

Q: What do you wish could have worked out better in your scaffolding career? Fran: “Physical injuries from a motorbike accident prevented my continuing ‘on the spanners’. Although it led to a new career as a scaffolding instructor/assessor, it meant I missed out on the Oasis tour in 1996.” Q: What is, in your opinion, the biggest change in the industry? Fran: “The volume of academic components in scaffolding training.”

Q: What changes would you like to see in the scaffolding industry? Fran: “Get rid of the NVQ and go back to BS5973.”

Thank you for your service Fran. We wish you a long a happy retirement.