A long-timetime advocate of the need for more detailed data, the Association says the latest figures, although clearly important, do little or nothing to help identify the cause of these fatalities. Such data, claims PASMA, is essential to help target information and initiatives at those areas needing it most.

Firmly committed to advancing safety and best practice in the work at height sector – a major cause of workplace injuries and deaths – the Association says the need for in depth information is paramount in order to help influence future outcomes and enable all organisations who champion safety to focus their attention where it matters most.

Comments Neil Tomlinson, PASMA’s head of marketing and communications: “Only in this way will we be able to prioritise, direct and take the action necessary to influence the figures and be able to demonstrably show progress on significantly reducing accident statistics. Not only in the UK, but ultimately internationally.”

A long-timetime advocate of the need for more detailed data, the Association says the latest figures, although clearly important, do little or nothing to help identify the cause of these fatalities. Such data, claims PASMA, is essential to help target information and initiatives at those areas needing it most.

Firmly committed to advancing safety and best practice in the work at height sector – a major cause of workplace injuries and deaths – the Association says the need for in depth information is paramount in order to help influence future outcomes and enable all organisations who champion safety to focus their attention where it matters most.

Comments Neil Tomlinson, PASMA’s head of marketing and communications: “Only in this way will we be able to prioritise, direct and take the action necessary to influence the figures and be able to demonstrably show progress on significantly reducing accident statistics. Not only in the UK, but ultimately internationally.” Fatality Figures need to be more forensic demands PASMA

A long-timetime advocate of the need for more detailed data, the Association says the latest figures, although clearly important, do little or nothing to help identify the cause of these fatalities. Such data, claims PASMA, is essential to help target information and initiatives at those areas needing it most.

Firmly committed to advancing safety and best practice in the work at height sector – a major cause of workplace injuries and deaths – the Association says the need for in depth information is paramount in order to help influence future outcomes and enable all organisations who champion safety to focus their attention where it matters most.

Comments Neil Tomlinson, PASMA’s head of marketing and communications: “Only in this way will we be able to prioritise, direct and take the action necessary to influence the figures and be able to demonstrably show progress on significantly reducing accident statistics. Not only in the UK, but ultimately internationally.”

A long-timetime advocate of the need for more detailed data, the Association says the latest figures, although clearly important, do little or nothing to help identify the cause of these fatalities. Such data, claims PASMA, is essential to help target information and initiatives at those areas needing it most.

Firmly committed to advancing safety and best practice in the work at height sector – a major cause of workplace injuries and deaths – the Association says the need for in depth information is paramount in order to help influence future outcomes and enable all organisations who champion safety to focus their attention where it matters most.

Comments Neil Tomlinson, PASMA’s head of marketing and communications: “Only in this way will we be able to prioritise, direct and take the action necessary to influence the figures and be able to demonstrably show progress on significantly reducing accident statistics. Not only in the UK, but ultimately internationally.” Kent scaffold firms set to pay more for pavement permits

Kent County Council discussed and agreed the new charges on Wednesday to the dismay of local businesses who say this is nothing more than a way of generating more cash.

The Managing director of a local scaffolding firm said:

“We could do without any cost increases at the moment. It’s really tough out there and really tough keeping people employed.”

While he welcomed the introduction of charges for site inspections in principle, he believed it would unfairly target companies that played by the rules, while the “fly by nights” would continue to flout them.

“Reputable companies are hauled over the coals and less legitimate organisations seem to be able to ride roughshod over the system,” he said.

“Rather than go after reputable companies I feel a bit more time driving out the others would make everybody’s life a lot safer.”

Managing director of the NASC (National Access and Scaffolding Federation), Robin James, said: “This looks like an attempt to recoup costs, possibly due to Government subsidy cutbacks.

“Are the price rises justifiable in the current climate? Obviously not, but whether it’s the principal contractor paying or the subcontractor, the cost will simply be passed down the line.”

Kent County Council discussed and agreed the new charges on Wednesday to the dismay of local businesses who say this is nothing more than a way of generating more cash.

The Managing director of a local scaffolding firm said:

“We could do without any cost increases at the moment. It’s really tough out there and really tough keeping people employed.”

While he welcomed the introduction of charges for site inspections in principle, he believed it would unfairly target companies that played by the rules, while the “fly by nights” would continue to flout them.

“Reputable companies are hauled over the coals and less legitimate organisations seem to be able to ride roughshod over the system,” he said.

“Rather than go after reputable companies I feel a bit more time driving out the others would make everybody’s life a lot safer.”

Managing director of the NASC (National Access and Scaffolding Federation), Robin James, said: “This looks like an attempt to recoup costs, possibly due to Government subsidy cutbacks.

“Are the price rises justifiable in the current climate? Obviously not, but whether it’s the principal contractor paying or the subcontractor, the cost will simply be passed down the line.”

Have you noticed an increase in charges for pavement permits in your area ? Let us know in the comments below.

Ex-scaffolder in a ‘battle for justice’ on asbestos

Michael Brown believes he developed mesothelioma after breathing in asbestos while working in and around Plymouth in the early 1960s.

The devastating disease can take decades to develop but is usually fatal within 18 months to two years of diagnosis.

The 68-year-old grandfather told his story before tomorrow’s Action Mesothelioma Day, which is being marked by special events in Plymouth.

The city is one of the UK’s worst hotspots for the disease, mainly due to the heavy use of asbestos at Devonport dockyard and on ships. The condition also affects many former labourers.

Mr Brown is looking to take legal action against his former employer Scaffolding (GB) Ltd, which has ceased trading.

He is appealing to former workmates for help with his battle for justice.

When a firm no longer exists, compensation is sought through their insurers.

Mr Brown said: “When I was told I had mesothelioma, my family and I were completely devastated.

“I worked in several different places for different companies and can’t say exactly where I picked it up, but I was definitely exposed to it while working for Scaffolding (GB) Ltd.

“I was always working next to people removing asbestos and I would end up covered in dust but I had no idea how serious this would end up being.

“I have had six rounds of chemotherapy treatment, which I am recovering from.

“I want to enjoy some quality time with my family, but I’m very aware this will now be cut short.”

He said Action Mesothelioma Day is a chance to raise awareness about the “terrible illness” and the dangers of asbestos.

“I hope that what happened to me serves as a warning to other workers and, in particular employers,” he said.

Mr Brown is the main carer for two disabled relatives and has six children and nine grandchildren.

He described coming into contact with deadly asbestos dust at building sites in Plymouth and the South West.

“I was sent to work in the Penzance Gas Works to erect scaffolding where I worked next to men who were removing asbestos lagging from extensive pipework using hand chisels,” he said.

“The air in the gas works was also filled with huge white asbestos dust clouds that I couldn’t avoid inhaling.”

Mr Brown, who has moved to Bristol, said he completed a contract at the Ramington typewriter factory in Plymouth and worked next to roofers who were cutting asbestos corrugated sheets using a grinder.

He also worked at the Plymouth Gas Works with another company.

“I can recall being constantly in close proximity to laggers who were mixing the asbestos powder in large drums and then applying the asbestos paste onto the pipework,” he said.

Helen Grady, from Irwin Mitchell Solicitors, is representing Mr Brown in his legal battle.

MESOTHELIOMA: the facts.

Mesothelioma is an asbestos-related cancer of the lungs or abdomen.

Although exposure to asbestos has been strictly regulated since the late 1970s, mesothelioma is still arising in people who were exposed beforehand.

Health and Safety Executive figures show 373 Plymouth men died from mesothelioma between 1981 and 2005.

Victims may be entitled to compensation but the battle for justice can be complex.

There are different rules for civilians and servicemen.

Claimants may also face difficulties proving a company’s liability, or gaining compensation where a company is no longer operating.

Via: thisisplymouth.co.uk

Michael Brown believes he developed mesothelioma after breathing in asbestos while working in and around Plymouth in the early 1960s.

The devastating disease can take decades to develop but is usually fatal within 18 months to two years of diagnosis.

The 68-year-old grandfather told his story before tomorrow’s Action Mesothelioma Day, which is being marked by special events in Plymouth.

The city is one of the UK’s worst hotspots for the disease, mainly due to the heavy use of asbestos at Devonport dockyard and on ships. The condition also affects many former labourers.

Mr Brown is looking to take legal action against his former employer Scaffolding (GB) Ltd, which has ceased trading.

He is appealing to former workmates for help with his battle for justice.

When a firm no longer exists, compensation is sought through their insurers.

Mr Brown said: “When I was told I had mesothelioma, my family and I were completely devastated.

“I worked in several different places for different companies and can’t say exactly where I picked it up, but I was definitely exposed to it while working for Scaffolding (GB) Ltd.

“I was always working next to people removing asbestos and I would end up covered in dust but I had no idea how serious this would end up being.

“I have had six rounds of chemotherapy treatment, which I am recovering from.

“I want to enjoy some quality time with my family, but I’m very aware this will now be cut short.”

He said Action Mesothelioma Day is a chance to raise awareness about the “terrible illness” and the dangers of asbestos.

“I hope that what happened to me serves as a warning to other workers and, in particular employers,” he said.

Mr Brown is the main carer for two disabled relatives and has six children and nine grandchildren.

He described coming into contact with deadly asbestos dust at building sites in Plymouth and the South West.

“I was sent to work in the Penzance Gas Works to erect scaffolding where I worked next to men who were removing asbestos lagging from extensive pipework using hand chisels,” he said.

“The air in the gas works was also filled with huge white asbestos dust clouds that I couldn’t avoid inhaling.”

Mr Brown, who has moved to Bristol, said he completed a contract at the Ramington typewriter factory in Plymouth and worked next to roofers who were cutting asbestos corrugated sheets using a grinder.

He also worked at the Plymouth Gas Works with another company.

“I can recall being constantly in close proximity to laggers who were mixing the asbestos powder in large drums and then applying the asbestos paste onto the pipework,” he said.

Helen Grady, from Irwin Mitchell Solicitors, is representing Mr Brown in his legal battle.

MESOTHELIOMA: the facts.

Mesothelioma is an asbestos-related cancer of the lungs or abdomen.

Although exposure to asbestos has been strictly regulated since the late 1970s, mesothelioma is still arising in people who were exposed beforehand.

Health and Safety Executive figures show 373 Plymouth men died from mesothelioma between 1981 and 2005.

Victims may be entitled to compensation but the battle for justice can be complex.

There are different rules for civilians and servicemen.

Claimants may also face difficulties proving a company’s liability, or gaining compensation where a company is no longer operating.

Via: thisisplymouth.co.uk Jobs: Calling all graduate engineers

Review: Which gloves are best ?

We have all seen them and worn them and by far the best gloves for all scaffolding tasks. i got at least 3 to 4 days work out of the gloves before holes started appearing.

Overall very comfortable to wear and retained grip even when wet.

Price: £1.10 each

ScaffMag Rating:

We have all seen them and worn them and by far the best gloves for all scaffolding tasks. i got at least 3 to 4 days work out of the gloves before holes started appearing.

Overall very comfortable to wear and retained grip even when wet.

Price: £1.10 each

ScaffMag Rating:  The Snickers craftsman boasts unbeatable grip and uncompromising protection perfect for really tough jobs. The palm and fingers are reinforced with Grip TechT which is a durable rubber with an advanced textured surface.

When I first wore the gloves they provided great grip and felt like a second skin although scaffolding for a full shift took its toll on these high priced gloves. Overall A great pair of gloves to look at but just didn’t cut the mustard when worn for scaffolding.

Price: £22.90 each

ScaffMag Rating:

The Snickers craftsman boasts unbeatable grip and uncompromising protection perfect for really tough jobs. The palm and fingers are reinforced with Grip TechT which is a durable rubber with an advanced textured surface.

When I first wore the gloves they provided great grip and felt like a second skin although scaffolding for a full shift took its toll on these high priced gloves. Overall A great pair of gloves to look at but just didn’t cut the mustard when worn for scaffolding.

Price: £22.90 each

ScaffMag Rating:  The Swedish firm Blaklader have created a comfortable pair of gloves that provide a decent amount of protection. The gloves are made from synthetic leather and are a slip on design.

But like the Snickers gloves they fell short when used for erecting and dismantling scaffolding.

Price: £13.68 each

ScaffMag Rating:

The Swedish firm Blaklader have created a comfortable pair of gloves that provide a decent amount of protection. The gloves are made from synthetic leather and are a slip on design.

But like the Snickers gloves they fell short when used for erecting and dismantling scaffolding.

Price: £13.68 each

ScaffMag Rating:  Another well known brand giant Dewalt provides a well rounded protective glove but comes with a huge price tag. The glove provides a gel palm with Toughgrip Reinforced palm and fingers and comes with Velcro straps around the wrists.

When i first wore the gloves they felt like what i call “riggers gloves” but performed well during everyday scaffolding tasks and lasted well over the review period. Saying this I can not ignore the fact that these gloves cost a small fortune and why I can only give them a 4 star rating.

Price: £25.38 each

ScaffMag Rating:

Another well known brand giant Dewalt provides a well rounded protective glove but comes with a huge price tag. The glove provides a gel palm with Toughgrip Reinforced palm and fingers and comes with Velcro straps around the wrists.

When i first wore the gloves they felt like what i call “riggers gloves” but performed well during everyday scaffolding tasks and lasted well over the review period. Saying this I can not ignore the fact that these gloves cost a small fortune and why I can only give them a 4 star rating.

Price: £25.38 each

ScaffMag Rating: Free working at height safety videos

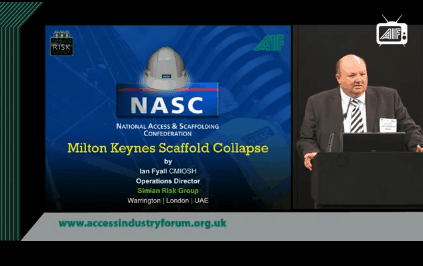

The Access Industry Forum (AIF) have released free working at height videos that was filmed in May at the latest Safety & Health Expo in Birmingham UK.

httpv://youtu.be/P6TSBphnmyc

The Milton Keynes scaffolding collapse What lessons can we learn?

The event was arguably the largest event ever to focus on working at height. The organisations involved in the event included the Department of Work and Pensions, the Health and Safety Executive, the Association of British Insurers, RIBA, IOSH, RoSPA, IIRSM, British Safety Council, RICS, Association for Project Safety, and all 11 trade association members of the Access Industry Forum.

A large number of these presentations and discussions were videoed and are now available free to view online in full here

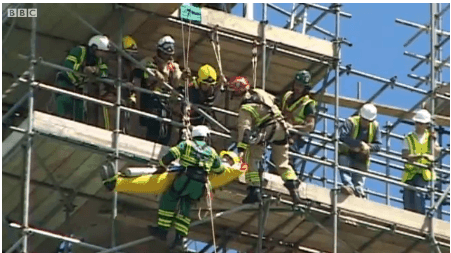

Scaffolder hurt in fall from Great Yarmouth church tower

A scaffolder had to be brought down a Norfolk church tower on a stretcher after he suffered three broken ribs in a fall.

Michael Sheldrake, 26, was working at St Nicholas Minster in Great Yarmouth when he lost his footing.

Norfolk Fire Service said he fell 15ft (5m) from scaffolding on to a flat roof on the tower while working about 100ft (30m) up.

A specialist rescue team abseiled Mr Sheldrake down on a stretcher.

The area was cordoned off for several hours as paramedics climbed up scaffolding to treat him before the specialist team arrived.

His father, Dave Sheldrake, who owns the scaffolding business, claimed his son fell a much shorter distance and his injuries were not as serious as initially feared.

‘Amazing job’

“He fell 6ft (1.8m) and landed face-down on beams,” said Mr Sheldrake, who did not wish to give the name of his business.

“He’s got three broken ribs, he’s fine and should be coming home today or tomorrow.

“I’d like to thank the emergency services, they did an amazing job.”

He added his son, a qualified scaffolder, had been wearing a safety harness but the equipment only deploys at 15ft (5m).

Phil Berry, from Norfolk Fire and Rescue Service, said: “The man was injured in the fall and we worked with police and ambulance colleagues to bring him down safely.”

Mr Sheldrake was treated by paramedics who climbed scaffolding around the tower after a safety assessment was made.

‘Chest injuries’

The Reverend Andrew Avery, from the minster, said the accident happened as they were finishing morning prayer.

“When we came out the fire service were already here,” he said.

“I believe the man fell from the scaffolding around the spire into the tower which has a flat roof.

“He suffered chest injuries which are significant.

“We have prayed that he will make a swift recovery.”

The East of England Ambulance Service said it was called to Yarmouth Minster at 09:25 BST and the patient taken to James Paget Hospital in Gorleston.

A spokeswoman said: “This was a very complicated operation due to the difficult location.”

Via: bbc.co.uk

A scaffolder had to be brought down a Norfolk church tower on a stretcher after he suffered three broken ribs in a fall.

Michael Sheldrake, 26, was working at St Nicholas Minster in Great Yarmouth when he lost his footing.

Norfolk Fire Service said he fell 15ft (5m) from scaffolding on to a flat roof on the tower while working about 100ft (30m) up.

A specialist rescue team abseiled Mr Sheldrake down on a stretcher.

The area was cordoned off for several hours as paramedics climbed up scaffolding to treat him before the specialist team arrived.

His father, Dave Sheldrake, who owns the scaffolding business, claimed his son fell a much shorter distance and his injuries were not as serious as initially feared.

‘Amazing job’

“He fell 6ft (1.8m) and landed face-down on beams,” said Mr Sheldrake, who did not wish to give the name of his business.

“He’s got three broken ribs, he’s fine and should be coming home today or tomorrow.

“I’d like to thank the emergency services, they did an amazing job.”

He added his son, a qualified scaffolder, had been wearing a safety harness but the equipment only deploys at 15ft (5m).

Phil Berry, from Norfolk Fire and Rescue Service, said: “The man was injured in the fall and we worked with police and ambulance colleagues to bring him down safely.”

Mr Sheldrake was treated by paramedics who climbed scaffolding around the tower after a safety assessment was made.

‘Chest injuries’

The Reverend Andrew Avery, from the minster, said the accident happened as they were finishing morning prayer.

“When we came out the fire service were already here,” he said.

“I believe the man fell from the scaffolding around the spire into the tower which has a flat roof.

“He suffered chest injuries which are significant.

“We have prayed that he will make a swift recovery.”

The East of England Ambulance Service said it was called to Yarmouth Minster at 09:25 BST and the patient taken to James Paget Hospital in Gorleston.

A spokeswoman said: “This was a very complicated operation due to the difficult location.”

Via: bbc.co.uk Harsco secures renewal refinery contract worth $30 million

The five-year contract renewal from Zeeland Refinery N.V. expands Harsco’s exclusive onsite role for providing 24/7 access support and repairs to the plant’s mechanical insulation, a critical component of refinery operations that mitigates heat loss and reduced crude oil production due to thermal inefficiencies. A typical refinery plant can have more than 350 miles of insulated piping (1.85 million linear feet), operating at temperatures in excess of 600 degrees.

Harsco supports Zeeland Refinery with dedicated scaffolding support and services for the maintenance and repair of both its thermal and cold insulation, and under the expanded framework agreement, will also now provide mobile elevated work platforms and other access services. The refinery, a joint venture of France-based Total S.A. and Russia’s OAO Lukoil, processes approximately 7,500 kt of crude oil and 2,500 kt of heavy fuel oil annually.

The award reflects Harsco’s growing role in providing large-scale, recurring industrial plant maintenance services on a global basis, including specialized services for mechanical insulation at leading petrochemical and refinery operations. These latter services have continued to play an increasing role since the Company’s two specialty acquisitions in this sector: its 2006 acquisition of the Cleton industrial maintenance service operations in the Netherlands, Belgium and Germany and its 2009 acquisition of the UK-based Nicol businesses, which also include industrial site cleaning and painting services.

Harsco Corporation is a diversified industrial company that is helping build the world by providing essential services and products to fundamental global industries, including steel and metals production, construction, railways and energy. Harsco’s common stock is a component of the S&P MidCap 400 Index and the Russell 1000 Index. Additional information can be found at www.harsco.com.

The five-year contract renewal from Zeeland Refinery N.V. expands Harsco’s exclusive onsite role for providing 24/7 access support and repairs to the plant’s mechanical insulation, a critical component of refinery operations that mitigates heat loss and reduced crude oil production due to thermal inefficiencies. A typical refinery plant can have more than 350 miles of insulated piping (1.85 million linear feet), operating at temperatures in excess of 600 degrees.

Harsco supports Zeeland Refinery with dedicated scaffolding support and services for the maintenance and repair of both its thermal and cold insulation, and under the expanded framework agreement, will also now provide mobile elevated work platforms and other access services. The refinery, a joint venture of France-based Total S.A. and Russia’s OAO Lukoil, processes approximately 7,500 kt of crude oil and 2,500 kt of heavy fuel oil annually.

The award reflects Harsco’s growing role in providing large-scale, recurring industrial plant maintenance services on a global basis, including specialized services for mechanical insulation at leading petrochemical and refinery operations. These latter services have continued to play an increasing role since the Company’s two specialty acquisitions in this sector: its 2006 acquisition of the Cleton industrial maintenance service operations in the Netherlands, Belgium and Germany and its 2009 acquisition of the UK-based Nicol businesses, which also include industrial site cleaning and painting services.

Harsco Corporation is a diversified industrial company that is helping build the world by providing essential services and products to fundamental global industries, including steel and metals production, construction, railways and energy. Harsco’s common stock is a component of the S&P MidCap 400 Index and the Russell 1000 Index. Additional information can be found at www.harsco.com. John Brash take the lead in fire safety scaffold boards

- Reduced lead time due to a shorter supply chain

- Streamlined logistics and costs

- Treatment to Euroclass ‘B’ or ‘C’ (equivalent to BS476 Class 0 or 1)

HSE investigates after rail workers fall from scaffolding

The air ambulance landed at Sandown Park racecourse on Thursday, June 14, after a call that Network Rail workers had fallen about 15ft from scaffolding on a bridge they were working on.

The men, aged 49 and 52, were taken to St George’s Hospital in Tooting.

One had minor head injuries and the other sustained serious chest injuries, according to a spokesman for Kent, Surrey and Sussex Air Ambulance.

The air ambulance landed at Sandown Park racecourse on Thursday, June 14, after a call that Network Rail workers had fallen about 15ft from scaffolding on a bridge they were working on.

The men, aged 49 and 52, were taken to St George’s Hospital in Tooting.

One had minor head injuries and the other sustained serious chest injuries, according to a spokesman for Kent, Surrey and Sussex Air Ambulance.