The scaffolding world is buzzing with anticipation as ScaffChamp 2024 is just over two weeks away!

This prestigious competition will see some of the world’s finest system scaffolding teams battle for supremacy, showcasing their unmatched skill, speed, and commitment to safety. And for the first time ever, teams from the United Kingdom are making their mark on the competition and doing so in force! Three UK teams are gearing up to prove their mettle on the international stage. The championship is due to kick off on May 24-25 in Vilnius, Lithuania. Get ready, scaffolding fans! The stage is set for a thrilling ScaffChamp 2024. This year’s competition boasts an impressive roster of over 20 teams representing countries across Europe, Asia, and beyond. From seasoned veterans to ambitious newcomers, ScaffChamp24 promises electrifying displays of skill, speed, and teamwork as scaffolders worldwide battle for the coveted title. Let’s take a closer look at the championship contenders:

XPRTS (Bulgaria):

XPRTS (Bulgaria):

XPRTS is a unique player in the scaffolding world—a recruitment firm focused on matching skilled workers with the right jobs. Their participation in ScaffChamp, with a solid 9th place finish in 2023, shows that their commitment to the field extends beyond the business side.

Danish Scaffolders Club (Denmark):

Danish Scaffolders Club (Denmark):

More than just a scaffolding team, the Danish Scaffolders Club represents the workers themselves! A union-backed team, they champion fair wages, better working conditions, and safety throughout the Danish scaffolding industry. Their impressive 5th place finish at ScaffChamp 2023 shows they can compete and advocate for workers at the same time.

Starteline Oy (Finland):

Starteline Oy (Finland):

Starteline Oy focuses on safety and efficiency in the Finnish scaffolding industry. Its in-house technical team ensures every project receives a customized and meticulously planned solution. Devoted to continuous improvement, its ScaffChamp debut showcases an ambition to compete at the highest level.

Telinetiimi Oy (Finland):

Telinetiimi Oy is a small but mighty Finnish team known for its reliability under pressure. Its strong ScaffChamp finishes in 2022 (4th) and 2023 (8th) suggest it’s a team to watch in Vilnius.

Stabil Építo Kft (Hungary):

Stabil Építo Kft (Hungary):

Stabil Építo brings flexibility to the competition with its expertise in both Blitz and Layher Allround systems. Its recent victory at the Hungarian ScaffChamp qualifiers underscores its skill and determination, making it a serious contender in Vilnius.

Látvány-Állvány Kft (Hungary):

Látvány-Állvány Kft (Hungary):

One of two teams to qualify from the Hungarian national championships, Látvány-Állvány Kft brings proven skill to the competition. Their expertise with Layher Keder XL roof structures could be a major advantage.

Cumiskey Scaffolding Ltd (Ireland):

Cumiskey Scaffolding Ltd (Ireland):

Focusing on safety certifications and a family-run work ethic, Cumiskey Scaffolding tackles projects big and small across Ireland. Their ScaffChamp debut represents an exciting chance to showcase their skills to a global audience.

Globalita (Lithuania):

Globalita (Lithuania):

Lithuanian powerhouse Globalita is a force to be reckoned with. Their dedication to quality and customer service is evident in their comprehensive insulation and scaffolding services. A consistent ScaffChamp competitor, Globalita has seen impressive results, including a 5th-place debut in 2019 and back-to-back second-place victories in 2022 and 2023. They’re determined to claim the champion’s title on their home turf this year!

HOTREMA (Lithuania):

HOTREMA (Lithuania):

HOTREMA is a European industry titan, boasting a 500-strong workforce and huge scaffolding resources. Their focus on timely project completion and cost-effectiveness solidifies their reputation. A two-time ScaffChamp champion (2019 and 2022) with a 3rd place finish in 2023, HOTREMA is a constant podium contender.

UAB RNDV Industries (Lithuania):

UAB RNDV Industries (Lithuania):

Part of the larger RNDV group, the RNDV Scaffolding Installation team is growing fast! Their experience across Europe and ambition to be winners makes them a team to watch at ScaffChamp.

NBIK LLC (Mongolia):

NBIK LLC (Mongolia):

NBIKLLC brings experience from large-scale mining and construction projects in Mongolia. Their impressive 6th place finish at ScaffChamp 2023 shows they can translate that experience into competitive success.

N-Projects (Poland):

N-Projects (Poland):

N-Projects is a company deeply invested in safety and professionalism. This commitment and their commitment to employee development have led to rapid growth in the Swedish and Polish markets. Their striking 4th place finish at ScaffChamp 2023 hints at their enormous potential in this competition!

GLT Spó?ka Akcyjna (Poland):

GLT Spó?ka Akcyjna (Poland):

With over a decade of experience, hundreds of projects completed, and a large workforce, GLT brings significant scaffolding expertise to their ScaffChamp debut.

ALPACCESS SRL (Romania):

ALPACCESS SRL (Romania):

AlpAccess has a fascinating trajectory, transitioning from rope access specialists to a multi-faceted provider of scaffolding, corrosion protection, and more. This year marks a milestone as the first Romanian team to compete at ScaffChamp!

PDV INŽENJERING (Serbia):

PDV INŽENJERING (Serbia):

PDV INŽENJERING has made a rapid ascent within the Serbian industry. Founded in 2015, they quickly gained recognition for their expertise in industrial thermal insulation and scaffolding. Their capabilities are extensive, with a large Layher scaffolding inventory and a skilled workforce. This ScaffChamp debut marks the first time Serbia is represented in the competition, and PDV INŽENJERING is determined to make a strong impression!

Kukla Scaffolding (Slovakia):

Kukla Scaffolding (Slovakia):

What started as a small team in 2011 has blossomed into an international scaffolding powerhouse. Kukla Scaffolding boasts a large workforce, massive equipment inventory, and even its own scaffolding academy! Its ScaffChamp debut signals its intent to compete with the world’s best.

KAEFER (Sweden):

KAEFER (Sweden):

With nearly four decades of experience, KAEFER Sweden is a dominant force in the industry. Their team of 200+ professionals and massive scaffolding inventory ensure unmatched efficiency across major projects. KAEFER Sweden’s expertise extends to insulation, surface protection, and more. Their impressive victory at ScaffChamp 2023 with a record-breaking time of 0:59:01 highlights their relentless pursuit of excellence.

Björli Bygg (Sweden):

Björli Bygg (Sweden):

Björli Bygg has seen impressive growth since 2017, becoming a major scaffolding provider in Sweden. Their use of advanced systems like Layher’s TwixBeam demonstrates a commitment to innovation. As a consistent ScaffChamp competitor with a bronze medal in 2022, Björli Bygg aims to climb the podium once again.

XPRTS (Bulgaria):

XPRTS (Bulgaria):

Starteline Oy (Finland):

Starteline Oy (Finland): Stabil Építo Kft (Hungary):

Stabil Építo Kft (Hungary): Látvány-Állvány Kft (Hungary):

Látvány-Állvány Kft (Hungary): Cumiskey Scaffolding Ltd

Cumiskey Scaffolding Ltd  Globalita (Lithuania):

Globalita (Lithuania): HOTREMA (Lithuania):

HOTREMA (Lithuania):  UAB RNDV Industries (Lithuania):

UAB RNDV Industries (Lithuania): NBIK LLC (Mongolia):

NBIK LLC (Mongolia): N-Projects (Poland):

N-Projects (Poland): GLT Spó?ka Akcyjna (Poland):

GLT Spó?ka Akcyjna (Poland): ALPACCESS SRL (Romania):

ALPACCESS SRL (Romania): PDV INŽENJERING (Serbia):

PDV INŽENJERING (Serbia): Kukla Scaffolding (Slovakia):

Kukla Scaffolding (Slovakia): KAEFER (Sweden):

KAEFER (Sweden): Björli Bygg (Sweden):

Björli Bygg (Sweden): Connect Scaffolding Ltd (United Kingdom):

Connect Scaffolding Ltd (United Kingdom): Star Scaffolding Ltd (United Kingdom):

Star Scaffolding Ltd (United Kingdom): Rose System Scaffolding Ltd (United Kingdom):

Rose System Scaffolding Ltd (United Kingdom):

“While the initial investment may be higher compared to traditional tube and fitting scaffolding, the longevity and durability of system scaffolding far outweigh the costs over a 10-year period,” Des explains.

“When factoring in the savings on labour and the ability of system scaffolding to facilitate entry into new markets, its superiority becomes evident, leading to tangible turnover and margin benefits.”

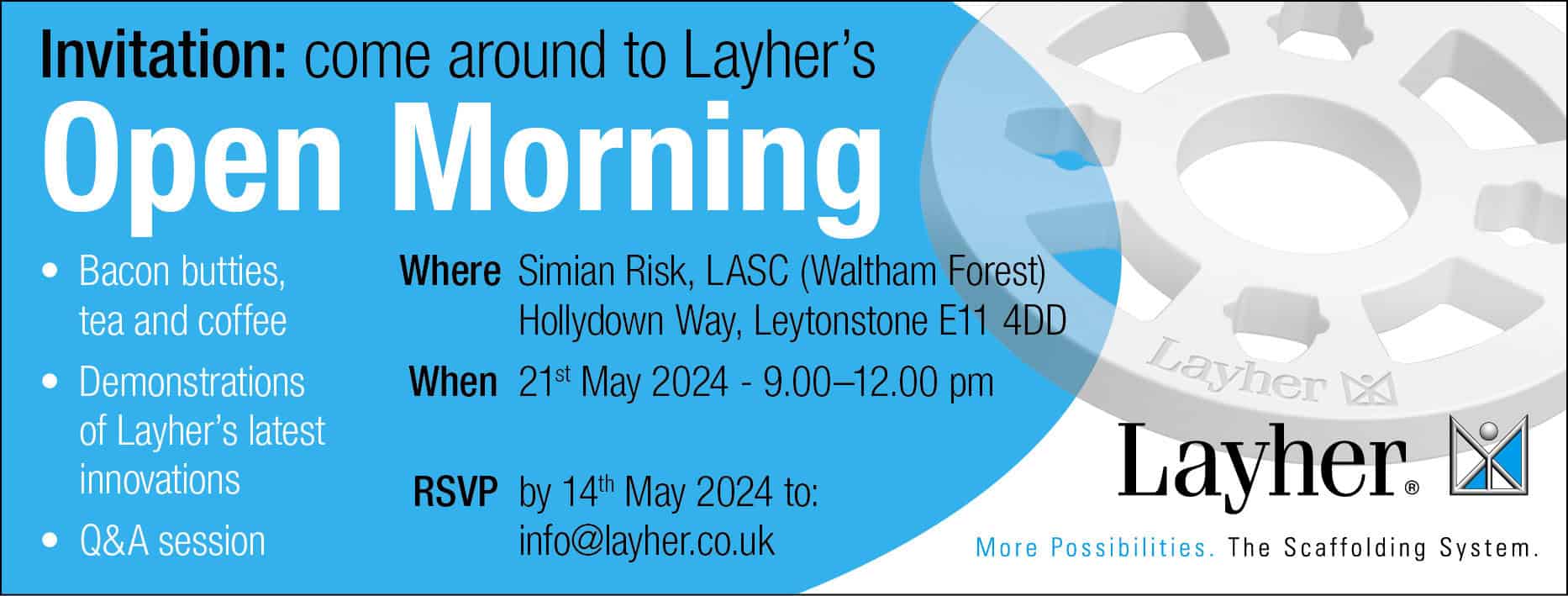

The Layher Open Day will run from 9 am to 12 pm, with limited places available to ensure attendees have ample opportunity to explore the products and engage with the Layher UK team.

Sean Pike, Managing Director at Layher UK, highlights the importance of these events in fostering meaningful interactions. “We’re committed to providing attendees with a comprehensive understanding of our products and fostering quality conversations,” Sean remarks. “That’s why we’re hosting multiple events throughout the year, with future dates to be announced soon.”

For those unable to attend the Open Day but interested in exploring the commercial advantages of system scaffolding, Des Moore offers the possibility of arranging presentations directly at individual business premises.

This event marks the first of four Open Mornings planned across the UK. It presents a unique opportunity for industry professionals to delve into the practical and financial benefits of Layher’s innovative scaffolding solutions, setting the stage for enhanced efficiency and profitability within the construction sector.

“While the initial investment may be higher compared to traditional tube and fitting scaffolding, the longevity and durability of system scaffolding far outweigh the costs over a 10-year period,” Des explains.

“When factoring in the savings on labour and the ability of system scaffolding to facilitate entry into new markets, its superiority becomes evident, leading to tangible turnover and margin benefits.”

The Layher Open Day will run from 9 am to 12 pm, with limited places available to ensure attendees have ample opportunity to explore the products and engage with the Layher UK team.

Sean Pike, Managing Director at Layher UK, highlights the importance of these events in fostering meaningful interactions. “We’re committed to providing attendees with a comprehensive understanding of our products and fostering quality conversations,” Sean remarks. “That’s why we’re hosting multiple events throughout the year, with future dates to be announced soon.”

For those unable to attend the Open Day but interested in exploring the commercial advantages of system scaffolding, Des Moore offers the possibility of arranging presentations directly at individual business premises.

This event marks the first of four Open Mornings planned across the UK. It presents a unique opportunity for industry professionals to delve into the practical and financial benefits of Layher’s innovative scaffolding solutions, setting the stage for enhanced efficiency and profitability within the construction sector.