Des Moore looks at how to manage the challenges of becoming part of a bigger group – and how to make sure your acquisition is a success.

A few months ago, I wrote an article for ScaffMag about

preparing your business for sale. But the challenges don’t stop once you’ve sold your business – in fact, they’ve

only just begun. There are a number of new things to consider as you become part of a big group of companies or just start working for a new owner.

So how do you manage, both commercially and culturally, to adapt to your new ownership and make the deal a success?

Read any article about acquisitions; you’ll see that around 50-90% of mergers and acquisitions fail. There are three common reasons for failure:

- Poor strategic focus

- Poor cultural integration

- Poor delivery of synergies

Let’s remind ourselves of your starting point. Most acquired businesses are either independent or family-owned. The sale of the business is either to allow the owners to exit, or to open up new opportunities for growth.

After sale, the business simply becomes another business in the group – and that position requires a completely different mindset and approach from what you might be used to. Essentially, all large commercial groups are the same – they have the same goals and outcomes. Think of them like a mannequin – all the same underneath, but just clothed in a different way.

As you get to this point, it’s worth reminding yourself why you sold the business. I think there are seven clear commercial reasons to take this step – and the top three of these are usually the most important:

- Access to exit capital for new ventures or retirement

- Access to capital for business growth

- Access to new clients

- Access to new horizontal or vertical markets

- Access to broader product range or innovation expertise

- Access to experienced leadership team with wider commercial knowledge and experience

- Access to other group companies for knowledge sharing

Any type of sale or acquisition exercise will create change. How you manage that change for yourself, your leadership team and your employees is critical to long-term success.

Preparing for the challenge

Although I have run several businesses, I have never been a majority shareholder. However, before the sale of TRAD to Altrad, I had complete autonomy to run the companies as I thought fit. This was, and still is, highly unusual in our industry. Hayden Smith operated on an arm’s length basis, so I ran the business the way I wanted to – making decisions on everything from staffing and salaries to equipment and markets without any restrictions or approval processes. Although clearly, as a majority shareholder, Hayden wouldn’t hesitate to tell me if I overstepped the mark!

Change doesn’t always suit the senior team. And this was certainly a challenge I faced, knowing that one of my management abilities was to be able to instantly implement new ideas, opportunities or ways of working. It’s easy to feel, in those circumstances, that your essential value and potential productivity is being eroded. In fact, in my own personal journey through acquisition, I certainly felt this way. But it is important to remember that you are now working from a group perspective and not on your own.

So, the first thing to be ready for after acquisition is that you are no longer in complete charge. In fact, you move from being an owner or MD to being an employee of the new group. You may be in the same named role as before – but this is an important change to manage nevertheless.

Also be prepared to lose your visibility over the ‘bigger picture’. As a business owner or MD, you are used to having complete visibility and control over your business. As part of a larger group, you often have limited access to the decisions being made or the reasons for those decisions. Come to terms with this, and be honest with your teams about it.

You and your senior leadership team will now have to work within strict financial rules and restrictions that you have not been used to, and you will have to adapt to these quickly and with a positive attitude.

Understanding the process

Your new group is likely to put a transition period in place to help everyone adjust to their new position. When I was involved in the acquisition of TRAD by Altrad, I found the new owners operated with honesty and acted with integrity, and this is reliant on mutual respect and trust, which is important. There were certainly times when messages may have been confusing, because I didn’t have the same visibility of the workings of the larger group as I was used to, but again, you have to adapt, and take a positive approach.

Don’t underestimate the challenge of replacing the spontaneous way you may have made decisions in the past with working under a new corporate framework – you will now be reporting to someone, and your decisions will require justification and approval before you can go ahead. This can, at times, be a long, laborious and frustrating process, which may lead to missed opportunities, so make sure you understand these processes and how best to use them to run your business smoothly and meet your targets.

There will also be changes to the way you handle financial planning and commitments, and you should be ready for these. Being part of a group comes with strict regulations and overviews – which are there for a reason. It may seem onerous, but they are essential for a larger group to run smoothly. They have to be commercially practical and clinical – and so do you.

You’re likely to see an immediate focus on EBITDA and free cash flow (FCF). Groups are all about maximising the value of their investment, satisfying shareholders and continuing growth. Everything is commercial first – and I know that if I were running a large group of companies, this is exactly the focus I would have to apply.

Open, honest communications

You and your employees are facing a journey into a new corporate culture, and your people will look to you to lead them through that journey.

Although new owners often try to retain your existing culture for a while, your identity will, over time, naturally change so that you are aligned with the group culture. This must be carefully handled so that everyone has as much information and reasoning as possible – this helps you to retain key people and manage a smooth transition to new ways of working.

Be honest with your employees from the start of the acquisition process. Don’t say ‘nothing will change’ because you can’t go through a sale without things changing – many things do. So be open, communicate the potential for change and, as soon as you know what those changes are, make sure you support your people through them.

It is likely that employees will be managed or transferred into the group hierarchy and salary bandings. It’s important to be aware of these changes so that you can communicate them to your staff. You should also feel confident to challenge those decisions at times – particularly in regard to remuneration – with the new owner where appropriate.

You will probably have to accept that there is almost certainly going to be a focus on overhead reduction. This could be people, facilities or suppliers – or across the board. Think about Twitter, for example. As soon as Elon Musk took over, he dramatically reduced the workforce and refocused the business.

Your sale is unlikely to be so dramatic, but new owners see the potential for profitability, and often want to make visible changes and savings that demonstrate they can make the acquisition work. Be realistic about why the sale happened, and how your business can thrive with new ownership.

Meeting earn-out requirements

Part of the sale will rely on an earn-out phase, where the business has to meet agreed targets during the period after acquisition.

In this phase, the group needs the buy-in of the senior leadership team to help the business reach the earnings goals, and deliver the promised value to shareholders. You need to keep this end of the deal, and so as a leader, you need to make sure your senior team and all your staff have this focus in mind.

It’s usually better if as much of your original approach and culture is retained during the earn-out phase of the deal, to help your business to meet the agreed targets.

How can you manage the initial transition period?

After the sale has completed, you are committed to being a successful part of your new group. There are likely to be lots of initial communications, and it’s critical that you are able to be a reliable conduit between the new owner and your employees.

I found that the best way to do this was to absorb everything that our new owners told me, and then re-message it to our employees in the way I usually communicated with them.

Communicate the values of the new group to your team by relating them to the way you already work. Most values are similar – they are just called different things, or looked at from a different perspective, so refer to and reference your own values to show your team that you share these with the new group already.

In this way, you’re shielding them from what can be corporate ‘coldness’ and instructions coming from head office, or your own line manager, while maintaining the relationships and communications that have made your company a good acquisition target in the first place.

So, when given instructions by the group – always look to say yes, until such time as the answer has to be ‘no’. And where you have said yes, deliver on those instructions. It may be tempting to push back – because you are used to being in sole control, or because the new group does things differently – but the best thing to do is work with the group and deliver what it wants. Then, when there are issues or mandates where you really have to say no, the group is more likely to listen to you.

Three critical steps to acquisition success

At the top of this article, I listed the three reasons why acquisitions often fail. Understanding this can help you prepare yourself, your leadership team and your employees for success. My advice is to:

- Remember why you have sold the business in the first place, and take the time to understand the strategic focus of your new owners.

- Take time to adapt to the culture of your new owners, by being open and honest with your employees, and making sure your messages reflect the way you have always communicated with them.

- Support your team to adapt quickly to new processes and requirements, so you can take advantage of the opportunities available to your business.

Taking the time to get this right will put you in a positive and proactive position to make the most of this new chapter in your business life.

Is it worth selling your business to a new owner? You should certainly give due consideration to the alternatives – an Employee Ownership Trust, for example, or a Management Buyout. If you decide to sell, you need to do so with a clear understanding of what such a sale entails, and with a positive attitude towards making it a success.

Put simply, as long as you enter into the transaction and the new relationship with your eyes open, and you fully understand and accept that your business will change, a sale can transform your business prospects.

If you are thinking about selling your business and you’d like some advice on any of these sale or buyout options, you can contact me on

[email protected]

This article was originally published in Issue 21 of the ScaffMag magazine.

What is ‘Rent-to-Try’? They have a purpose-stocked depot of rental-only kits that is available for customers to rent at very competitive rates. Layher don’t mind if you rent a little or rent a lot, their experienced sales team will help you qualify what products best fit your requirements & provide you with a quotation specific for the number of weeks you would like to rent the kit for. You can either collect it from their depot in West Bromwich or have it delivered to your site.

Should a customer decide they love using Layher via their Rent-to-Try scheme, Layher can support with various options to purchase material with their Rent-to-Own scheme. This allows customers to purchase brand-new materials via monthly payments, effectively turning the initial monthly rental costs into an investment in their scaffolding equipment.

Layher have an experienced team that work across the UK providing support with sales, technical design & on-site specialist support & training.

For more information about Layher UK’s ‘Rent-to-Try’ and ‘Rent-to-Own’ initiatives, please visit their website or contact [email protected]

What is ‘Rent-to-Try’? They have a purpose-stocked depot of rental-only kits that is available for customers to rent at very competitive rates. Layher don’t mind if you rent a little or rent a lot, their experienced sales team will help you qualify what products best fit your requirements & provide you with a quotation specific for the number of weeks you would like to rent the kit for. You can either collect it from their depot in West Bromwich or have it delivered to your site.

Should a customer decide they love using Layher via their Rent-to-Try scheme, Layher can support with various options to purchase material with their Rent-to-Own scheme. This allows customers to purchase brand-new materials via monthly payments, effectively turning the initial monthly rental costs into an investment in their scaffolding equipment.

Layher have an experienced team that work across the UK providing support with sales, technical design & on-site specialist support & training.

For more information about Layher UK’s ‘Rent-to-Try’ and ‘Rent-to-Own’ initiatives, please visit their website or contact [email protected]

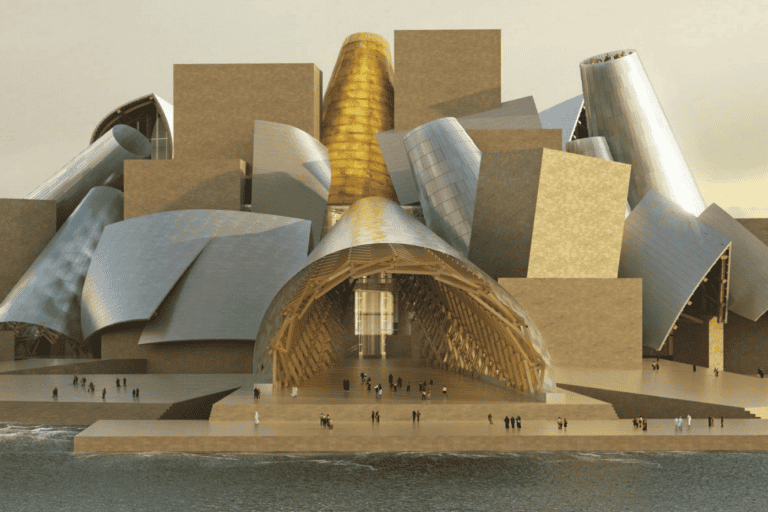

Founded in 2000 by Alan White, AWD has established itself within the industry, winning numerous accolades, including the Millennium Product Award and the Institution of Structural Engineers Structural Award; AWD’s reputation for delivering complex engineering solutions is unmatched. This leadership transition is set to further enhance the company’s ability to provide unparalleled service and innovative solutions to its clients.

Malachy Ryan had this to say about the changes: “We thrive on delivering products that satisfy and inspire our clients. Our dynamic team of engineers offer our clients cross fertilisation of engineering principles to produce bespoke, one-off designs. We take a holistic approach to engineering design which has become our trademark, associated with quality and professionalism, and this is what makes us unique and creates the foundation for our continued success.”

For more information about Alan White Design and its services, please visit

Founded in 2000 by Alan White, AWD has established itself within the industry, winning numerous accolades, including the Millennium Product Award and the Institution of Structural Engineers Structural Award; AWD’s reputation for delivering complex engineering solutions is unmatched. This leadership transition is set to further enhance the company’s ability to provide unparalleled service and innovative solutions to its clients.

Malachy Ryan had this to say about the changes: “We thrive on delivering products that satisfy and inspire our clients. Our dynamic team of engineers offer our clients cross fertilisation of engineering principles to produce bespoke, one-off designs. We take a holistic approach to engineering design which has become our trademark, associated with quality and professionalism, and this is what makes us unique and creates the foundation for our continued success.”

For more information about Alan White Design and its services, please visit

Following the Covid-19 pandemic, there has been a sharply increased demand for hybrid and flexible working in some sectors. I appreciate that times have changed post-pandemic, and we need to be considerate to employees’ needs, but while these working practices might work well in some office environments, they do not easily lend themselves to scaffolding. This could put some recruits off a career in our industry, so rather than present it as a rigid work environment, we need to promote the clear benefits: a rewarding and potentially lucrative career path, good pay and support, interesting work, fresh air and fitness from the job, camaraderie, to name but a few. We can still provide the positive workplace experience many people are looking for, but this does need to be face-to-face, either in the office or out on site.

Starting a new job is daunting, and the workplace can be an unfamiliar environment for many of the younger generation. Suddenly, they must learn different policies, working practices and how to interact with people other than their friends or family. Working in person, whether in an office or on site, helps them to develop their interpersonal skills, create collaborative relationships with colleagues and managers, socialise, and generally feel like an integral part of the company. It builds confidence and enables a person to learn ‘on the job’ and through mentoring by other experienced team members. If working remotely, young people can feel disconnected, less committed and are more likely to miss out on career development opportunities.

Following the Covid-19 pandemic, there has been a sharply increased demand for hybrid and flexible working in some sectors. I appreciate that times have changed post-pandemic, and we need to be considerate to employees’ needs, but while these working practices might work well in some office environments, they do not easily lend themselves to scaffolding. This could put some recruits off a career in our industry, so rather than present it as a rigid work environment, we need to promote the clear benefits: a rewarding and potentially lucrative career path, good pay and support, interesting work, fresh air and fitness from the job, camaraderie, to name but a few. We can still provide the positive workplace experience many people are looking for, but this does need to be face-to-face, either in the office or out on site.

Starting a new job is daunting, and the workplace can be an unfamiliar environment for many of the younger generation. Suddenly, they must learn different policies, working practices and how to interact with people other than their friends or family. Working in person, whether in an office or on site, helps them to develop their interpersonal skills, create collaborative relationships with colleagues and managers, socialise, and generally feel like an integral part of the company. It builds confidence and enables a person to learn ‘on the job’ and through mentoring by other experienced team members. If working remotely, young people can feel disconnected, less committed and are more likely to miss out on career development opportunities.

Scaffolding is an excellent career choice, but those entering the sector today must be under no illusion. On the labouring side, it is manual work and can be tough; you need to put in a solid day’s effort, which can mean early starts and working in unpleasant weather. But the rewards are great: stability, variety and pride in what you do are just a few.

Our senior contracts manager, Darren Hayward, likens the qualities needed for a role in scaffolding to those he learned during his time in the Royal Marines. “The Marines is a high-intensity environment, but scaffolding can be too. Resilience is a key skill to have. Scaffolding is a tough job and is easily underestimated, but it is also extremely rewarding and can provide a very good living. A strong work ethic, good moral values, and a humbleness to learn from others will always give you a positive return.”

Scaffolding is an excellent career choice, but those entering the sector today must be under no illusion. On the labouring side, it is manual work and can be tough; you need to put in a solid day’s effort, which can mean early starts and working in unpleasant weather. But the rewards are great: stability, variety and pride in what you do are just a few.

Our senior contracts manager, Darren Hayward, likens the qualities needed for a role in scaffolding to those he learned during his time in the Royal Marines. “The Marines is a high-intensity environment, but scaffolding can be too. Resilience is a key skill to have. Scaffolding is a tough job and is easily underestimated, but it is also extremely rewarding and can provide a very good living. A strong work ethic, good moral values, and a humbleness to learn from others will always give you a positive return.”

M R Scaffolding is a well-established family-run business that has been providing access solutions to the construction industry since 1974. This year, it is celebrating 50 years in the industry.

Leach’s has recently celebrated 100 years, so together, they form a powerhouse of knowledge. Earlier this year, Leach’s released their BIGGUY Safety range, as they found that the weight testing for the majority of height safety PPE wasn’t fit for purpose when tested against the average user in full kit. This was the first range in the world that supported a weight of up to 160kg!

“At Leach’s, height safety is core to our mission of keeping workers safe, this is why we have chosen to expand the BIGBEN Harness range again, this time stepping into the digital world. We spoke with M R Scaffolding and heard their feedback on productivity for their apprentices and we even had great feedback from their clients on being able to track the productivity of gangs on sites.” Russell Tennent, Managing Director at Leach’s.

M R Scaffolding is a well-established family-run business that has been providing access solutions to the construction industry since 1974. This year, it is celebrating 50 years in the industry.

Leach’s has recently celebrated 100 years, so together, they form a powerhouse of knowledge. Earlier this year, Leach’s released their BIGGUY Safety range, as they found that the weight testing for the majority of height safety PPE wasn’t fit for purpose when tested against the average user in full kit. This was the first range in the world that supported a weight of up to 160kg!

“At Leach’s, height safety is core to our mission of keeping workers safe, this is why we have chosen to expand the BIGBEN Harness range again, this time stepping into the digital world. We spoke with M R Scaffolding and heard their feedback on productivity for their apprentices and we even had great feedback from their clients on being able to track the productivity of gangs on sites.” Russell Tennent, Managing Director at Leach’s.