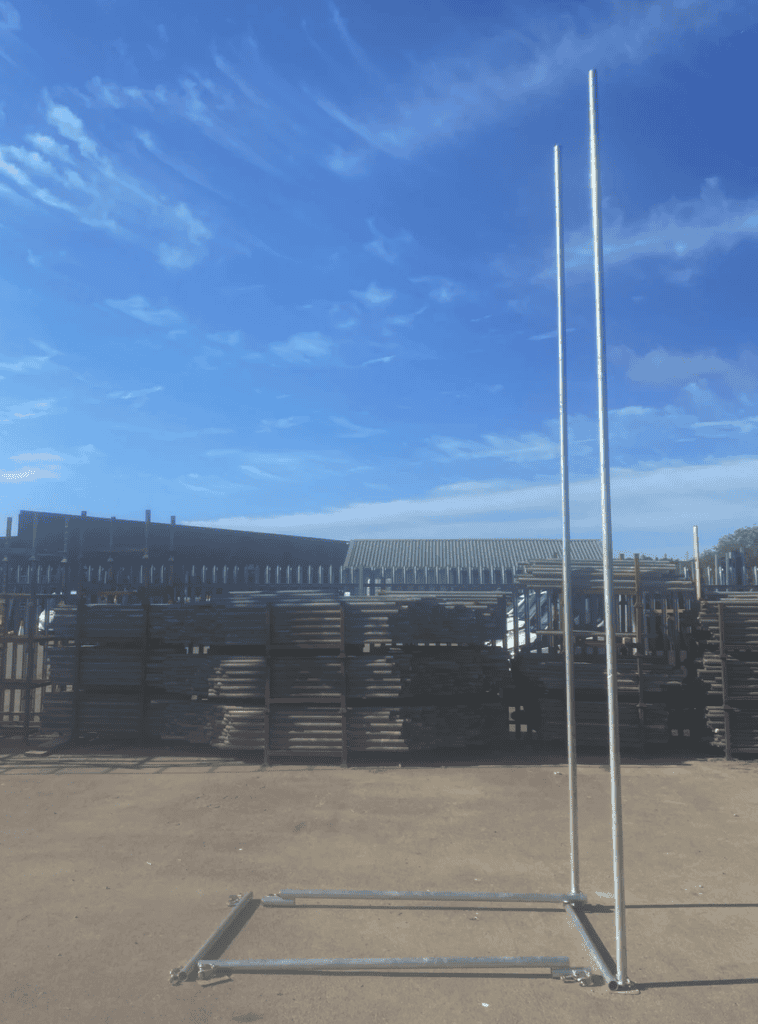

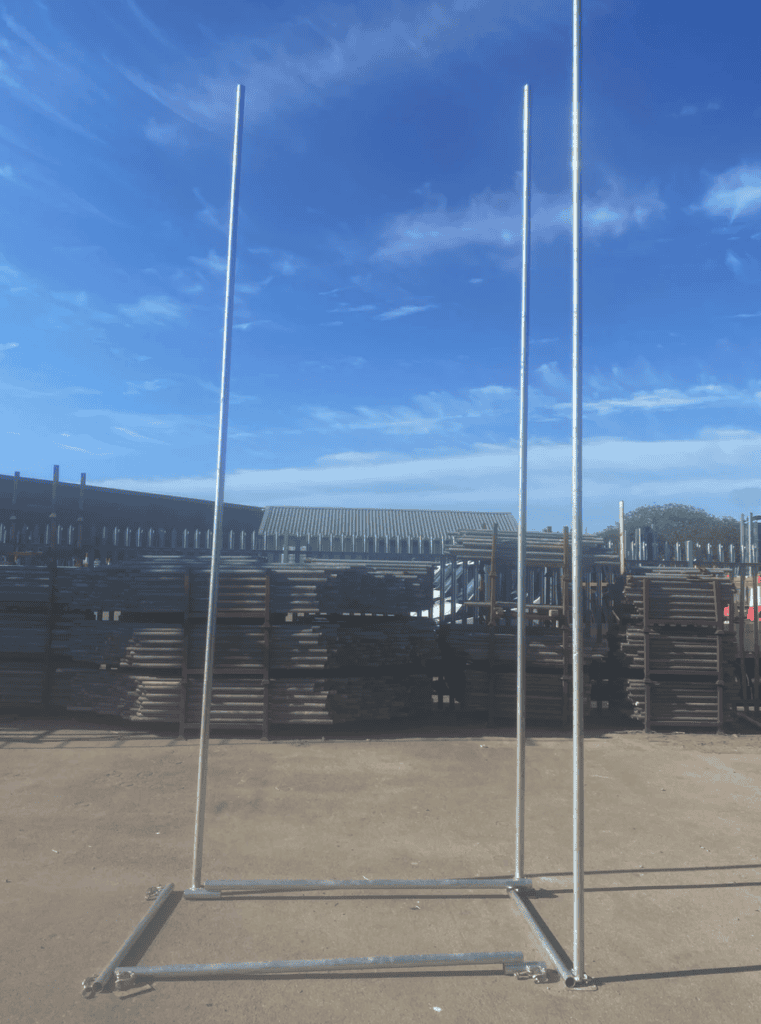

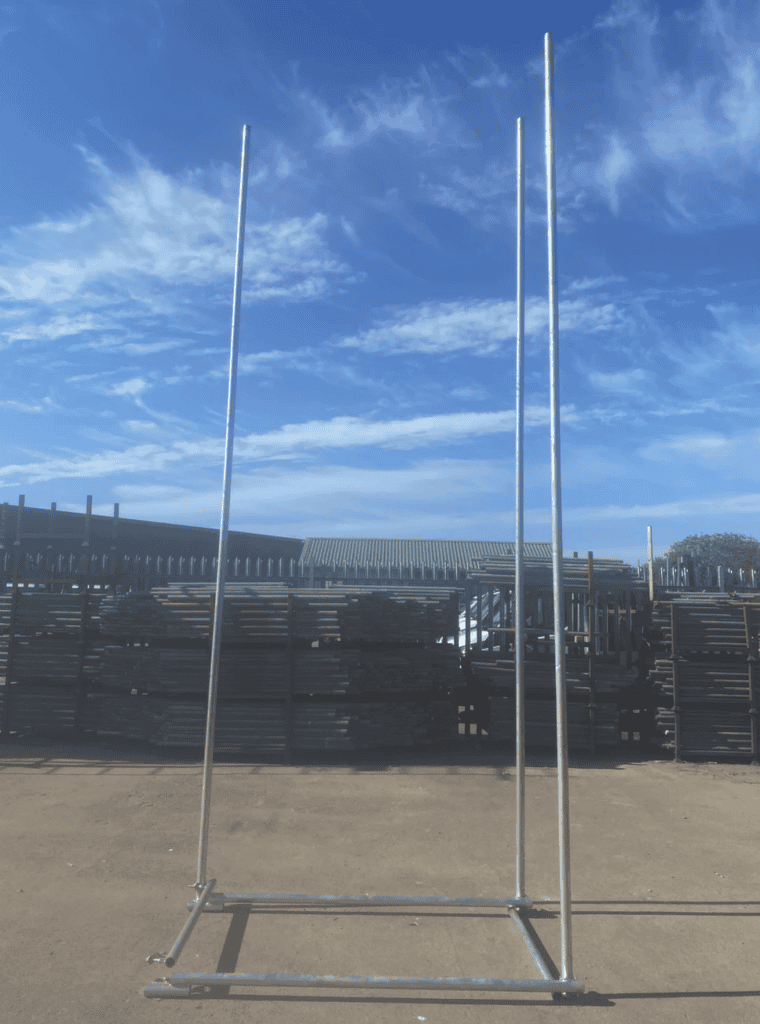

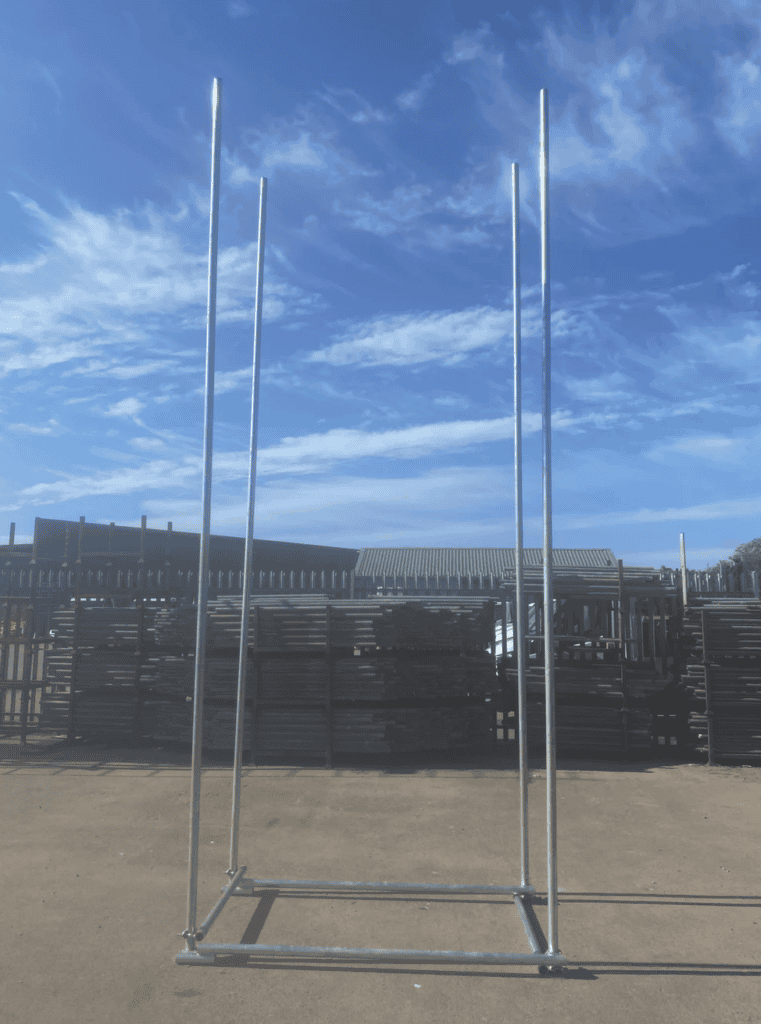

Paul Lynch of Lynch Developments, a serial innovator known for previous products such as his Advanced Double Handrail and the Lynch System Scaffold, has introduced another exciting product: the Tube & Fitting System Scaffold.

This new system aims to transform the UK scaffolding industry, seamlessly integrating existing scaffolding materials and eliminating the need for a complete restock of system scaffolding.

Approved by Lloyds British, the Tube & Fitting System Scaffold provides numerous advantages. Companies can gradually transition to this system, which significantly reduces costs and logistical challenges.

Paul Lynch, a serial innovator known for previous products such as the advanced double handrail and kicker board, and the Lynch System Scaffold, has developed this new system to eliminate the need for a complete restock of materials.

Lynch explains, “Tube & Fitting scaffold, also known in the industry as traditional scaffold, was the first type of steel scaffolding. Over the years, many other system types of scaffolds have been invented to reduce timescales and the intellectual knowledge required for erection or dismantling.

However, these systems all require a complete restock of materials, adjustable jack plates on the ground surface, and have restrictions on working platforms. They also rely on Tube & Fitting scaffolds for secure attachment.”

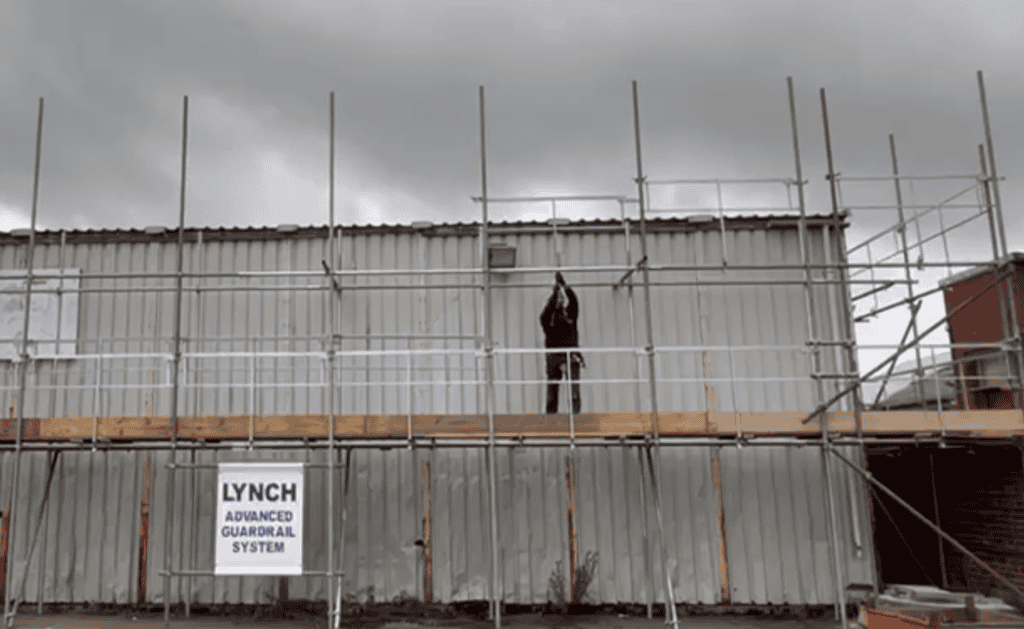

The new Tube & Fitting System Scaffold allows companies to gradually transition to a more efficient setup, reducing costs and logistical challenges. One of the system’s standout features is its advanced guardrail mechanism, which significantly enhances safety for scaffolding operatives.

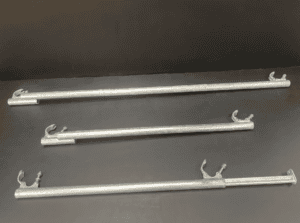

This guardrail can be installed from a lower, safer level, minimising risks during erection and dismantling. Additionally, the system’s ledger tubes, available in sizes of 1.815mm and 1.140mm, improve the stability of scaffolding structures through welded connections rather than traditional bolts, providing a more robust and secure setup.

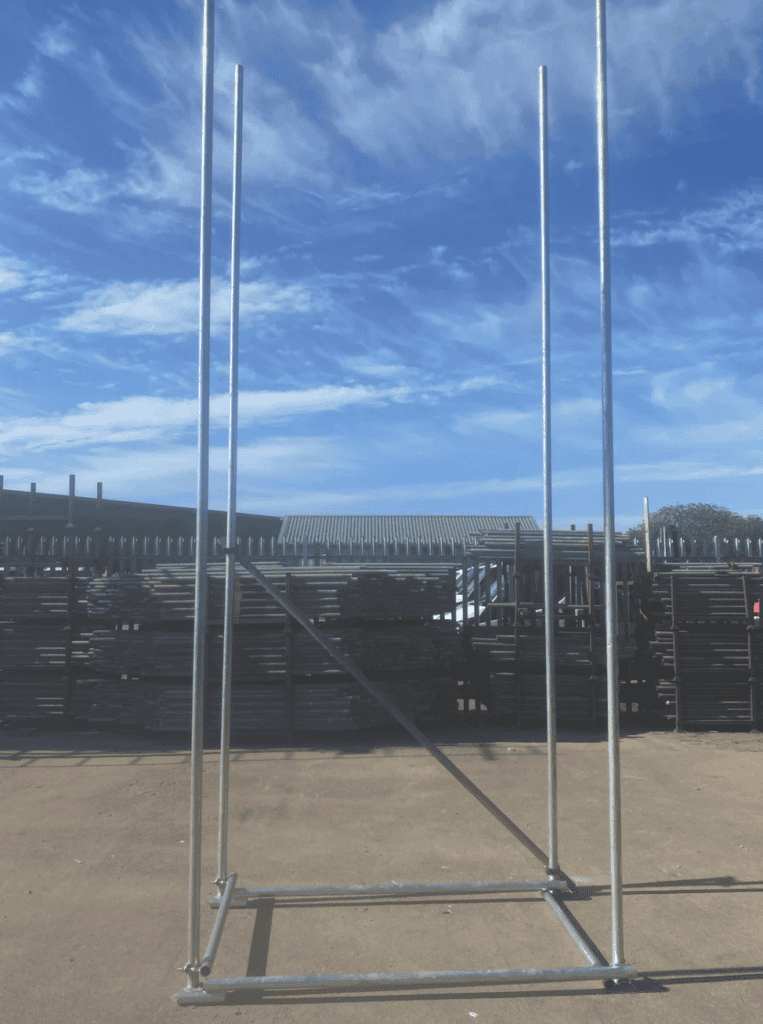

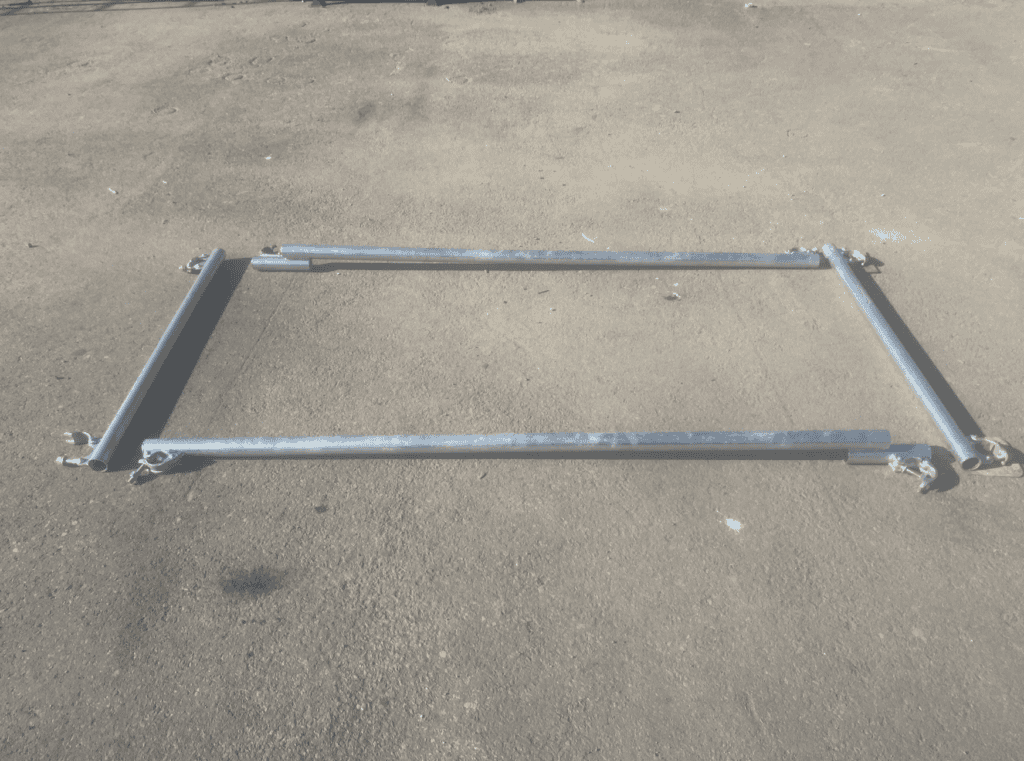

Another key advantage of the Tube & Fitting System Scaffold is its versatility. It can be used to set out the width and length of scaffolding bays, making it suitable for various project requirements. The transom tubes, with their double coupler fittings, increase the safe working load (SWL) in bay sections, enabling the scaffold to handle heavier loads with greater structural integrity.

Basing Out with The Tube & Fitting System Scaffold

Lynch adds, “The Tube & Fitting System Scaffold works with traditional scaffolds, reducing timescales and the need for extensive knowledge. It eliminates the need for a complete restock of materials, provides stability and rigidity, and performs all scaffolding access requirements whether used solo or mixed with traditional scaffolds.”

Furthermore, the system’s design simplifies the setup and dismantling processes, reducing labour costs and time, and making it particularly beneficial for scaffold training centres. “If the Tube & Fitting System Scaffold had been invented years ago, none of the other system scaffolds would exist today as this system stems from the origin of steel scaffolding.

Training schools need to accept innovative products like this to increase productivity, improve safety, and attract more people into the scaffolding industry by teaching the next generation of scaffolding apprentices how to use Tube & Fitting scaffolds,” says Lynch.

Open Day Announcement

Paul Lynch will hold an open day to allow potential customers to get up close and personal with the new Tube & Fitting System Scaffold. This event will provide an opportunity to see the system in action and discuss its benefits with the inventor himself.

The open day will be held at South Wales Brickwork & Scaffold Ltd, Queensway, Fforestfach, Swansea, SA5 4DJ, at 11 a.m. on July 30, 2024.

Those interested in attending should email [email protected] to register.

For more details, visit the Tube & Fitting System Scaffold website.