Altrad expands with 2000 new employees after completing acquisition

Bilfinger UK priming for growth with recruitment drive

Construction impacted by cost of living crisis, inflation, and supply chain issues

UKSSH and Tamworth Scaffolding answer Wireless SOS

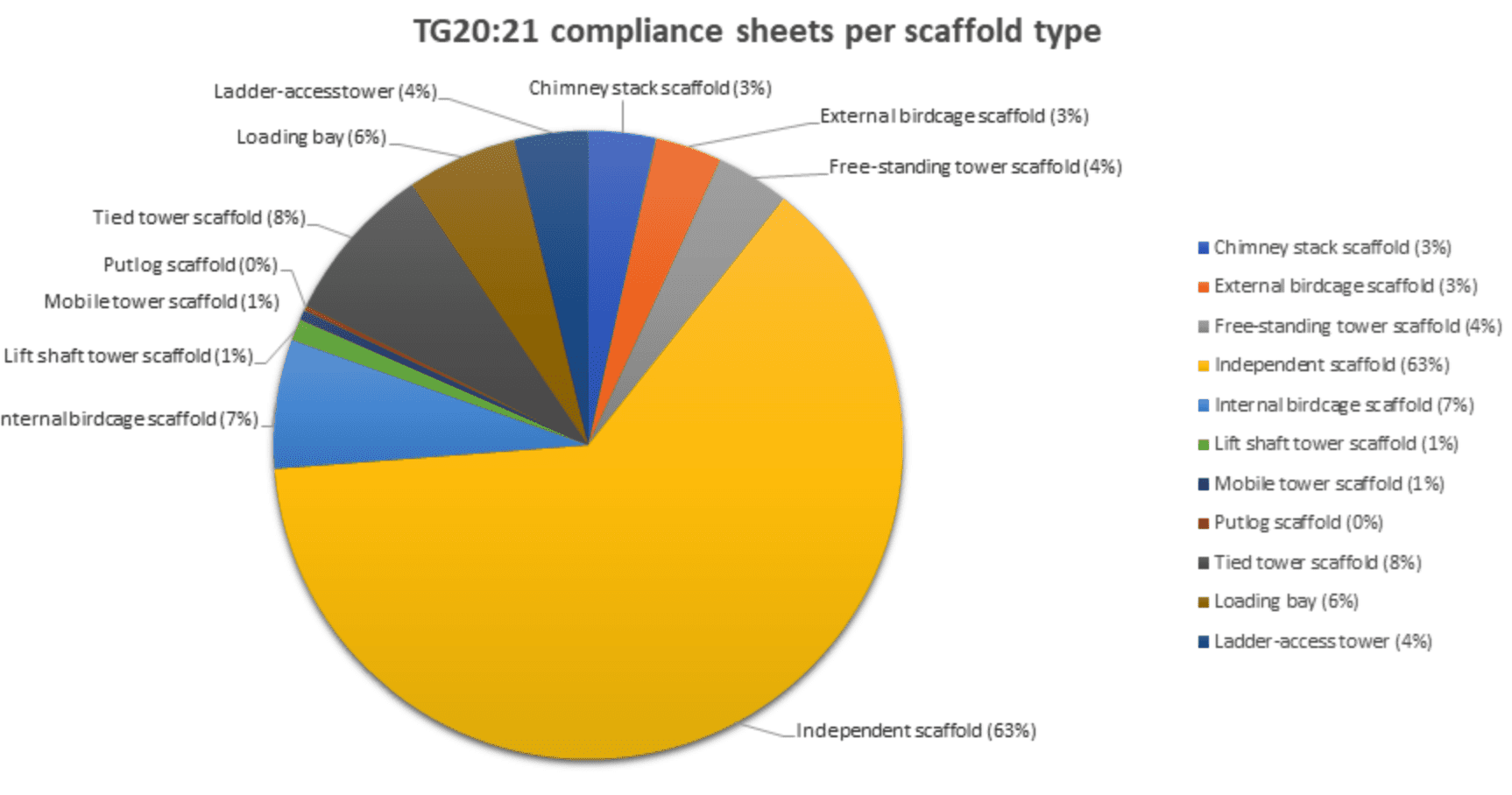

100,000 TG20:21 compliance sheets downloaded

Robin James, NASC Managing Director, said: “We’re delighted to see downloads pass the six-figure mark. Each of these downloads represents a scaffold that was erected in compliance with the necessary regulations, helping to keep construction workers and sites across the UK safe.

“This latest milestone shows that use of TG20:21 is growing steadily and that the software is serving a multitude of required scaffold types.

“Making TG20:21 available via the NASC ePortal – including the associated Operational and Design guides – was a huge undertaking but has been extremely well received by both NASC Contractor members and non-members alike.”

Robin James, NASC Managing Director, said: “We’re delighted to see downloads pass the six-figure mark. Each of these downloads represents a scaffold that was erected in compliance with the necessary regulations, helping to keep construction workers and sites across the UK safe.

“This latest milestone shows that use of TG20:21 is growing steadily and that the software is serving a multitude of required scaffold types.

“Making TG20:21 available via the NASC ePortal – including the associated Operational and Design guides – was a huge undertaking but has been extremely well received by both NASC Contractor members and non-members alike.” Doka acquires majority stake in AT-PAC scaffolding business

New growth opportunities

The majority shareholding enables Doka via AT-PAC to address entirely new customer segments in the industrial sector, where AT-PAC is already widely experienced. AT-PAC, on the other hand, gains a robust partner as Doka has an extensive global sales network and is active in over 60 countries with 160 locations. “Together we can perfectly serve the requirements and the needs of customers in the hydropower plant, chemical and mining industries, among others,” says Hauser. “By leveraging Doka’s global network and AT-PAC’s experience, we can unlock further growth potential in industrial scaffolding and be part of the entire project lifecycle.” Jeff Davis CEO of AT-PAC commented on the majority stake; “Today marks a prominent landmark in our already illustrious 25-year history. We have been providing innovative scaffold access products and solutions that drive positive impact on large industrial projects all over the world with great success. Doka has seen our dedication to provide the best level of service to our clients as well as proving our inhouse capabilities to develop and deploy a world-renowned DIBt-certified scaffolding system Ringlock, designed and developed from our Global HQ in Atlanta, USA. The majority shareholding only strengthens our ability to service our clients, and we are very excited about our future opportunities to prosper and continue to grow our amazing company”.Scaffolding solutions at bauma

During the world’s largest construction trade fair bauma 2022, which will be held in Munich from October 24 to 30, Doka will be debuting its DIBt-certified scaffolding system Ringlock under the AT-PAC Doka brand. As a result of the strategic progression, Doka will also be showing applications for industrial customers as well as for the construction industry. The combination of the formwork portfolio, the scaffolding management software Hi-Vis® and other additional services, positions Doka as a one-stop-shop for the global construction industry.123 Workers Killed Last Year

NASC Bosses Meet With Incoming President

Scaffolding Association to hold UK’s first dedicated scaffolding and access conference event

Scaffolding firm extends transport capabilities with Mercedes

Acquired with funding support from Mercedes-Benz Finance, the Atego is now being inspected and maintained under a Mercedes-Benz Complete Service Contract at BLS Truck & Van’s workshop on the Altens Industrial Estate, Aberdeen.

Northern Platforms & Stagings was established in 1984 by John Johnston, who remains at the helm as Managing Director.

The company offers a comprehensive range of scaffolding services at competitive prices but without compromising on safety. It has extensive experience of serving customers from the petrochemical and marine engineering sectors in the Grampian region, as well as local builders and construction firms.

The Atego range from 7.5 to 16 tonnes GVW is purpose-designed for light- and medium-duty distribution work, and construction applications.