The UK’s most decorated Paralympian to feature at NASC AGM

Dame Sarah Storey, the most decorated British Paralympian of all time will deliver a keynote speech at this year’s NASC AGM later this month.

Following NASC’s first-ever virtual Annual General Meeting in 2020 where Harry Redknapp and Build UK Chief Executive Suzannah Nichol MBE featured as special guests the scaffolding trade body will this year be back in full swing with a live-in person event.

Hundreds of guests from some of the largest specialist scaffolding contractors in the country will be attending the meeting that will be held at the Celtic Manor Resort in Newport on Friday 19 November.

The NASC has announced that its keynote speech will this year be delivered by Dame Sarah Storey, the most decorated British Paralympian of all time, having amassed a collection of 28 medals, including 17 golds, across a range of swimming and cycling events.

The AGM will also feature short presentations from NASC’s MD Robin James and NASC’s President Lynn Way. The event will also feature Anne Pavey from the Department for Work and Pensions, who will speak about the NASC’s Kickstart Scheme Gateway.

An overview of entries shortlisted for the NASC’s Awards will also be delivered. The winners are set to be announced at the Annual Ball & Awards in the evening at the same venue.

Phoenix Brickwork continues its strong growth

The fast-growing national brickwork, scaffolding and drywall business, Phoenix Brickwork continues its strong growth with a £2.4m project, delivering services to create over 170 homes for another new client.

The firm has begun work on a 6-acre development at Throstle Recreation Ground, Leeds as part of a £40m project for new client, Wates Construction Ltd., on behalf of Leeds City Council.

The large contract will take 73 weeks to complete and involve a team of over 30 in delivering more than 100 new homes, as well as a specialised 60-bed Extra Care Facility, all enhanced by the provision of new green space and sports pitches.

The development at Throstle Recreation Ground in Middleton will feature 100 two, three and four-bedroom homes, 60 apartments – complete with communal areas – a hair salon and roof garden and 17, one-bedroom fully wheelchair accessible bungalows.

Operating nationally from its Derbyshire and Northamptonshire offices, Phoenix Brickwork is continuing its recent impressive growth, since taking on several key staff from the failed Irvine Whitlock earlier this year, and has recently celebrated a milestone, passing £20m in just its eleventh year of trading, as it expands further, both North and into the Southeast.

“It is a pleasure to be involved in this important project for Leeds City Council, developing our relationship with Wates Construction,” said Christian Watson, Managing Director at Phoenix Brickwork.

“We are excited to have added them to the long list of new projects and clients we have won since we extended our reach right across the country. This project has created opportunity for local bricklayers and apprentices to join Phoenix whilst tackling the social housing shortage within the ever-growing city of Leeds.”

Noel Ryan, Regional Contracts Manager at Phoenix Brickwork said: “This is an exciting but challenging project, and our team is already working well to stay on schedule. In addition, the project is creating dozens of new jobs locally, which is great news for both the local labour market and Phoenix Brickwork. I look forward to the development taking shape over the next few months.”

Operating nationally from its Derbyshire and Northamptonshire offices, Phoenix Brickwork is continuing its recent impressive growth, since taking on several key staff from the failed Irvine Whitlock earlier this year, and has recently celebrated a milestone, passing £20m in just its eleventh year of trading, as it expands further, both North and into the Southeast.

“It is a pleasure to be involved in this important project for Leeds City Council, developing our relationship with Wates Construction,” said Christian Watson, Managing Director at Phoenix Brickwork.

“We are excited to have added them to the long list of new projects and clients we have won since we extended our reach right across the country. This project has created opportunity for local bricklayers and apprentices to join Phoenix whilst tackling the social housing shortage within the ever-growing city of Leeds.”

Noel Ryan, Regional Contracts Manager at Phoenix Brickwork said: “This is an exciting but challenging project, and our team is already working well to stay on schedule. In addition, the project is creating dozens of new jobs locally, which is great news for both the local labour market and Phoenix Brickwork. I look forward to the development taking shape over the next few months.”

Operating nationally from its Derbyshire and Northamptonshire offices, Phoenix Brickwork is continuing its recent impressive growth, since taking on several key staff from the failed Irvine Whitlock earlier this year, and has recently celebrated a milestone, passing £20m in just its eleventh year of trading, as it expands further, both North and into the Southeast.

“It is a pleasure to be involved in this important project for Leeds City Council, developing our relationship with Wates Construction,” said Christian Watson, Managing Director at Phoenix Brickwork.

“We are excited to have added them to the long list of new projects and clients we have won since we extended our reach right across the country. This project has created opportunity for local bricklayers and apprentices to join Phoenix whilst tackling the social housing shortage within the ever-growing city of Leeds.”

Noel Ryan, Regional Contracts Manager at Phoenix Brickwork said: “This is an exciting but challenging project, and our team is already working well to stay on schedule. In addition, the project is creating dozens of new jobs locally, which is great news for both the local labour market and Phoenix Brickwork. I look forward to the development taking shape over the next few months.”

Operating nationally from its Derbyshire and Northamptonshire offices, Phoenix Brickwork is continuing its recent impressive growth, since taking on several key staff from the failed Irvine Whitlock earlier this year, and has recently celebrated a milestone, passing £20m in just its eleventh year of trading, as it expands further, both North and into the Southeast.

“It is a pleasure to be involved in this important project for Leeds City Council, developing our relationship with Wates Construction,” said Christian Watson, Managing Director at Phoenix Brickwork.

“We are excited to have added them to the long list of new projects and clients we have won since we extended our reach right across the country. This project has created opportunity for local bricklayers and apprentices to join Phoenix whilst tackling the social housing shortage within the ever-growing city of Leeds.”

Noel Ryan, Regional Contracts Manager at Phoenix Brickwork said: “This is an exciting but challenging project, and our team is already working well to stay on schedule. In addition, the project is creating dozens of new jobs locally, which is great news for both the local labour market and Phoenix Brickwork. I look forward to the development taking shape over the next few months.” PERI set to host construction recruitment fair

Formwork and scaffolding specialist, PERI, will be hosting its recruitment fair on Tuesday 9th November 2021 from 10am – 3.30pm at its flagship office in Brentwood, Essex.

The one-day event is being held to give those either qualified or interested in construction an insight into the career opportunities available at PERI.

The fair will aid the business’s search for fresh talent, with it currently recruiting for a range of entry and senior-level positions across scaffolding, engineering, customer services and other areas.

Attendees will have the chance to speak to experts from across the business and find out more about the areas of construction that interest them, while experiencing the modern working environment at PERI UK’s newly built office.

“We welcome you to come along and see our state-of-the-art facilities in Brentwood and explore the current opportunities to join the PERI team. As a family-owned business, our employees are at the heart of everything we do, and we are excited to bring new talent on board to help the business grow further,” says Lauren Wilde – HR Officer at PERI.

Those interested can register to attend by emailing [email protected]. Attendees are encouraged to bring a copy of their CV with them. Further details can be found at: https://www.peri.ltd.uk/company/career.html

Construction College Midlands launches new NVQ qualifications

‘You’ve got the experience, now get qualified’ is the message from Construction College Midlands (CCM) to all operatives, supervisors and managers.

The Birmingham-based college which was formerly CITB Birmingham was acquired by Walsall College in December 2020.

They have launched a new suite of NVQ qualifications that workers can study remotely.

Each of these programmes utilises existing skills, knowledge and experience within a nationally recognised, industry accredited qualification.

CCM say it’s the best opportunity yet for people to fulfil their day to day roles and responsibilities while accessing meaningful professional development in key industry areas.

Training courses are available from Level 2 all the way up to Level 7. They include specialist concrete operations, construction supervision, operations and site management as well as health and safety practice.

All courses are suitable for the following:

- Employers/employees of any-sized construction business and income

- Learners aged 18 and over from across the West Midlands/UK

- Anyone working in the industry who needs a relevant CSCS card

- Individuals who do not want to be away from work and want to avoid downtime (all courses involve remote learning bar a one-day site visit)

- Individuals with years of experience but no qualifications

Scaffolding boss recieves suspended jail term after forklift death

The Managing Director of a scaffolding company has been slammed with a suspended prison sentence and fine after an employee died when he was struck from behind by a forklift truck.

Leicester Magistrate’s Court heard how in June 2016, Shaun Flynn had just finished loading a lorry in the yard of Boss Scaffolding (Northampton) Limited when he was struck from behind by the raised forks of a moving forklift truck.

He subsequently died from his injuries.

An HSE investigation found that Boss Scaffolding director Leon Gill and an employee of the firm failed to take reasonable care for the health and safety of others who might be affected by the poor management of risks arising from the use of a counterbalance forklift truck in a state of disrepair.

Company director Leon Gill pleaded guilty of breaching the Health and Safety at Work Act 1974. He was sentenced to 10 weeks imprisonment suspended for eighteen months and ordered to pay £7,000 fine and £45,000 costs.

Speaking after the hearing, HSE inspector Jenna McDade said: “This case highlights the importance of regular pro-active maintenance and inspection of work equipment, to ensure equipment does not deteriorate to the extent that it puts people at risk. Sadly the tragic death of Mr Flynn could have been prevented.

“Companies and individuals should be aware that HSE will not hesitate to take appropriate enforcement action against those that fall below the required standards.

‘Our Town Hall’ the UK’s largest commercial scaffolding project

Scaffolding industry titans Lyndon SGB are deploying and expertly installing a huge array of complex access solutions for one of the country’s most prestigious renovation projects. ‘Our Town Hall’ in Manchester is said to be UK’s largest commercial scaffolding project currently underway. Scaffmag’s Editor Daniel Norton was keen to visit and learn more.

Standing proudly at the very heart of the city in Albert Square, Manchester’s iconic Grade 1 listed Town Hall has been a much-loved landmark for more than 140 years. Opened in 1877, the neo-Gothic architectural masterpiece has taken centre stage for council business and important large-scale city events for decades, from Manchester International Festival through to location shoots for Peaky Blinders.

Hosting presidents, prime ministers and even monarchs, this significant building has a formidable past. Suffice to say, though, after 14 decades in use, with only a minimal refurbishment carried out in 1977, a restoration is well overdue to ensure it can enjoy an equally storied future.

To restore, protect and improve this magnificent historic building to its former civic glory – which involves extensive internal and external repair work – main contractors Lendlease have been entrusted with the renovation. The £330-million, six-year contract will see the building lovingly restored and updated for the people of Manchester and the nation.

In December 2019, Lendlease called upon Lyndon SGB’s unrivalled expertise in supplying, designing and planning for all the external and internal access requirements for this massive renovation project.

Lyndon SGB is no stranger to giant challenging projects. Since its birth in 1919, the nationwide firm has provided a full range of temporary access solutions to some of the UK’s biggest and most prestigious projects. Recent examples include resurrecting the Mackintosh Building at Glasgow School of Arts following 2018’s devastating fire, London’s Coal Drops Yard development and work on Edinburgh Castle.

Although the COVID pandemic and nesting peregrine falcons slowed the project slightly, work is now in full swing, with up to 300 workers onsite on any given day. More than 50 Lyndon SGB scaffolding operatives have already safely erected a 32 lift large tube and fitting perimeter scaffold with Class-B protection fans, a multitude of crash decks and birdcages, a bespoke and highly technical 90m high clock tower scaffold and provided designed access for 34 huge chimney stacks.

Although the COVID pandemic and nesting peregrine falcons slowed the project slightly, work is now in full swing, with up to 300 workers onsite on any given day. More than 50 Lyndon SGB scaffolding operatives have already safely erected a 32 lift large tube and fitting perimeter scaffold with Class-B protection fans, a multitude of crash decks and birdcages, a bespoke and highly technical 90m high clock tower scaffold and provided designed access for 34 huge chimney stacks.

Around 450m of staircases have also been erected, enough to reach the summit of the Empire State Building. And, to top it all off, in August Lyndon SGB are set to install 10,000m2 of the most complex temporary weather protection roofs the industry has ever seen, covering both the central Great Hall and the perimeter structure.

Lyndon SGB northwest regional manager, Jon Cooke, described the project as “massive” and said: “You just don’t get jobs like this. It’s such a rarity in our industry to have a commercial scaffolding project on this scale. It’s not just a once-in-a-lifetime opportunity. It’s a once-in-a-100-year-job-opportunity. The scaffolders love it and feel privileged working on the site.”

Lyndon SGB has already provided millions of pounds worth of In-house designed scaffolds for the eight-year Town Hall project. Over 200 separate scaffold designs have been produced so far. Utilising cutting edge scaffold design techniques, Lyndon SGB’s design team – including manager David Flaherty, and engineers Jamie Robertson, Maarten van Dijk and Bram Sanders – have used 3D models and clash detection systems to avoid the need for re-designs mid-project.

Around 450m of staircases have also been erected, enough to reach the summit of the Empire State Building. And, to top it all off, in August Lyndon SGB are set to install 10,000m2 of the most complex temporary weather protection roofs the industry has ever seen, covering both the central Great Hall and the perimeter structure.

Lyndon SGB northwest regional manager, Jon Cooke, described the project as “massive” and said: “You just don’t get jobs like this. It’s such a rarity in our industry to have a commercial scaffolding project on this scale. It’s not just a once-in-a-lifetime opportunity. It’s a once-in-a-100-year-job-opportunity. The scaffolders love it and feel privileged working on the site.”

Lyndon SGB has already provided millions of pounds worth of In-house designed scaffolds for the eight-year Town Hall project. Over 200 separate scaffold designs have been produced so far. Utilising cutting edge scaffold design techniques, Lyndon SGB’s design team – including manager David Flaherty, and engineers Jamie Robertson, Maarten van Dijk and Bram Sanders – have used 3D models and clash detection systems to avoid the need for re-designs mid-project.

“The building is totally unique. There is nothing mirrored on each of its elevations. We are using our Dutch engineers who have created complex 3D models of the whole building allowing us to detect clashes before the scaffolding was erected,” Cooke said.

“The building is totally unique. There is nothing mirrored on each of its elevations. We are using our Dutch engineers who have created complex 3D models of the whole building allowing us to detect clashes before the scaffolding was erected,” Cooke said.

As he guides us through the huge site, he’s quick to point out that “overseeing the work is the easy bit,” and the backroom staff are the ones that deserve all the credit due to the challenges presented each day at work on Our Town Hall. These include contracts manager Craig Parry and Nathan Maylett, alongside senior supervisor Shane Scoynes and commercial manager Paul Fishwick.

When quizzed about the defining project challenges, Parry said: “Other than the national shortage of materials the biggest challenge has been logistics and moving scaffolding materials around site. We are positioned in the very centre of Manchester, so strict early morning deliveries were essential.”

As he guides us through the huge site, he’s quick to point out that “overseeing the work is the easy bit,” and the backroom staff are the ones that deserve all the credit due to the challenges presented each day at work on Our Town Hall. These include contracts manager Craig Parry and Nathan Maylett, alongside senior supervisor Shane Scoynes and commercial manager Paul Fishwick.

When quizzed about the defining project challenges, Parry said: “Other than the national shortage of materials the biggest challenge has been logistics and moving scaffolding materials around site. We are positioned in the very centre of Manchester, so strict early morning deliveries were essential.”

He went on to explain how attention to detail involved in the project is also commendable, from the placement of protective sheeting hiding the work taking place within, through to the historical information presented on perimeter boards.

“You’ve got to put the extra work in,” said Parry. “Otherwise it just looks like a nightmare. They’re just the little things that nobody really appreciates.”

The nature of the building itself has also presented some issues. As a listed structure, individual bricks that needed drilling into had to be approved by architects to avoid damaging priceless structural fabric. Meanwhile, much of the installation on the upper levels had to be lifted in through windows and doors which were never designed for modern construction requirements.

He went on to explain how attention to detail involved in the project is also commendable, from the placement of protective sheeting hiding the work taking place within, through to the historical information presented on perimeter boards.

“You’ve got to put the extra work in,” said Parry. “Otherwise it just looks like a nightmare. They’re just the little things that nobody really appreciates.”

The nature of the building itself has also presented some issues. As a listed structure, individual bricks that needed drilling into had to be approved by architects to avoid damaging priceless structural fabric. Meanwhile, much of the installation on the upper levels had to be lifted in through windows and doors which were never designed for modern construction requirements.

“You need a certain ability of scaffolder to be doing the work on here,” Parry said of the team involved, explaining not all hard hats on-site could be filled by Manchester residents. “This means that not everyone could be found in the region, but certainly a very high percentage of those here are from the area.”

“You need a certain ability of scaffolder to be doing the work on here,” Parry said of the team involved, explaining not all hard hats on-site could be filled by Manchester residents. “This means that not everyone could be found in the region, but certainly a very high percentage of those here are from the area.”

Due to complete in 2024, the Alfred Waterhouse-designed Manchester Town Hall reflects both the complexity and grandeur of British neo-Gothic architecture, and represents the apex of modern scaffolding technology. With this in mind, the restoration itself is just as impressive as the end results will be, with the efforts to refurbish and future proof a work of art in itself.

Due to complete in 2024, the Alfred Waterhouse-designed Manchester Town Hall reflects both the complexity and grandeur of British neo-Gothic architecture, and represents the apex of modern scaffolding technology. With this in mind, the restoration itself is just as impressive as the end results will be, with the efforts to refurbish and future proof a work of art in itself.

Out Onsite

Although the COVID pandemic and nesting peregrine falcons slowed the project slightly, work is now in full swing, with up to 300 workers onsite on any given day. More than 50 Lyndon SGB scaffolding operatives have already safely erected a 32 lift large tube and fitting perimeter scaffold with Class-B protection fans, a multitude of crash decks and birdcages, a bespoke and highly technical 90m high clock tower scaffold and provided designed access for 34 huge chimney stacks.

Although the COVID pandemic and nesting peregrine falcons slowed the project slightly, work is now in full swing, with up to 300 workers onsite on any given day. More than 50 Lyndon SGB scaffolding operatives have already safely erected a 32 lift large tube and fitting perimeter scaffold with Class-B protection fans, a multitude of crash decks and birdcages, a bespoke and highly technical 90m high clock tower scaffold and provided designed access for 34 huge chimney stacks.

Around 450m of staircases have also been erected, enough to reach the summit of the Empire State Building. And, to top it all off, in August Lyndon SGB are set to install 10,000m2 of the most complex temporary weather protection roofs the industry has ever seen, covering both the central Great Hall and the perimeter structure.

Lyndon SGB northwest regional manager, Jon Cooke, described the project as “massive” and said: “You just don’t get jobs like this. It’s such a rarity in our industry to have a commercial scaffolding project on this scale. It’s not just a once-in-a-lifetime opportunity. It’s a once-in-a-100-year-job-opportunity. The scaffolders love it and feel privileged working on the site.”

Lyndon SGB has already provided millions of pounds worth of In-house designed scaffolds for the eight-year Town Hall project. Over 200 separate scaffold designs have been produced so far. Utilising cutting edge scaffold design techniques, Lyndon SGB’s design team – including manager David Flaherty, and engineers Jamie Robertson, Maarten van Dijk and Bram Sanders – have used 3D models and clash detection systems to avoid the need for re-designs mid-project.

Around 450m of staircases have also been erected, enough to reach the summit of the Empire State Building. And, to top it all off, in August Lyndon SGB are set to install 10,000m2 of the most complex temporary weather protection roofs the industry has ever seen, covering both the central Great Hall and the perimeter structure.

Lyndon SGB northwest regional manager, Jon Cooke, described the project as “massive” and said: “You just don’t get jobs like this. It’s such a rarity in our industry to have a commercial scaffolding project on this scale. It’s not just a once-in-a-lifetime opportunity. It’s a once-in-a-100-year-job-opportunity. The scaffolders love it and feel privileged working on the site.”

Lyndon SGB has already provided millions of pounds worth of In-house designed scaffolds for the eight-year Town Hall project. Over 200 separate scaffold designs have been produced so far. Utilising cutting edge scaffold design techniques, Lyndon SGB’s design team – including manager David Flaherty, and engineers Jamie Robertson, Maarten van Dijk and Bram Sanders – have used 3D models and clash detection systems to avoid the need for re-designs mid-project.

“The building is totally unique. There is nothing mirrored on each of its elevations. We are using our Dutch engineers who have created complex 3D models of the whole building allowing us to detect clashes before the scaffolding was erected,” Cooke said.

“The building is totally unique. There is nothing mirrored on each of its elevations. We are using our Dutch engineers who have created complex 3D models of the whole building allowing us to detect clashes before the scaffolding was erected,” Cooke said.

As he guides us through the huge site, he’s quick to point out that “overseeing the work is the easy bit,” and the backroom staff are the ones that deserve all the credit due to the challenges presented each day at work on Our Town Hall. These include contracts manager Craig Parry and Nathan Maylett, alongside senior supervisor Shane Scoynes and commercial manager Paul Fishwick.

When quizzed about the defining project challenges, Parry said: “Other than the national shortage of materials the biggest challenge has been logistics and moving scaffolding materials around site. We are positioned in the very centre of Manchester, so strict early morning deliveries were essential.”

As he guides us through the huge site, he’s quick to point out that “overseeing the work is the easy bit,” and the backroom staff are the ones that deserve all the credit due to the challenges presented each day at work on Our Town Hall. These include contracts manager Craig Parry and Nathan Maylett, alongside senior supervisor Shane Scoynes and commercial manager Paul Fishwick.

When quizzed about the defining project challenges, Parry said: “Other than the national shortage of materials the biggest challenge has been logistics and moving scaffolding materials around site. We are positioned in the very centre of Manchester, so strict early morning deliveries were essential.”

He went on to explain how attention to detail involved in the project is also commendable, from the placement of protective sheeting hiding the work taking place within, through to the historical information presented on perimeter boards.

“You’ve got to put the extra work in,” said Parry. “Otherwise it just looks like a nightmare. They’re just the little things that nobody really appreciates.”

The nature of the building itself has also presented some issues. As a listed structure, individual bricks that needed drilling into had to be approved by architects to avoid damaging priceless structural fabric. Meanwhile, much of the installation on the upper levels had to be lifted in through windows and doors which were never designed for modern construction requirements.

He went on to explain how attention to detail involved in the project is also commendable, from the placement of protective sheeting hiding the work taking place within, through to the historical information presented on perimeter boards.

“You’ve got to put the extra work in,” said Parry. “Otherwise it just looks like a nightmare. They’re just the little things that nobody really appreciates.”

The nature of the building itself has also presented some issues. As a listed structure, individual bricks that needed drilling into had to be approved by architects to avoid damaging priceless structural fabric. Meanwhile, much of the installation on the upper levels had to be lifted in through windows and doors which were never designed for modern construction requirements.

“You’ve got to put the extra work in, Otherwise it just looks like a nightmare. They’re just the little things that nobody really appreciates.”

Building for the Future

Our Town Hall isn’t just about safeguarding one of the UK’s most treasured civic buildings for the coming decades. The project also involves a large number of apprentices, not least given the advanced technical demands of the work, while the majority of the labouring crew are based locally. That means this undertaking is directly impacting the city region’s economy and up-skilling its workforce. “You need a certain ability of scaffolder to be doing the work on here,” Parry said of the team involved, explaining not all hard hats on-site could be filled by Manchester residents. “This means that not everyone could be found in the region, but certainly a very high percentage of those here are from the area.”

“You need a certain ability of scaffolder to be doing the work on here,” Parry said of the team involved, explaining not all hard hats on-site could be filled by Manchester residents. “This means that not everyone could be found in the region, but certainly a very high percentage of those here are from the area.”

Due to complete in 2024, the Alfred Waterhouse-designed Manchester Town Hall reflects both the complexity and grandeur of British neo-Gothic architecture, and represents the apex of modern scaffolding technology. With this in mind, the restoration itself is just as impressive as the end results will be, with the efforts to refurbish and future proof a work of art in itself.

Due to complete in 2024, the Alfred Waterhouse-designed Manchester Town Hall reflects both the complexity and grandeur of British neo-Gothic architecture, and represents the apex of modern scaffolding technology. With this in mind, the restoration itself is just as impressive as the end results will be, with the efforts to refurbish and future proof a work of art in itself. Avontus Software launches BeatMyScaffold Contest 2021

Scaffolding software company Avontus is bringing the popular scaffold design contest back for 2021.

Avontus Software is launching #BeatMyScaffold 2021, an industry-wide contest that showcases the best of 3D designs using Avontus Designer. The competition was last held in 2019, and they are bringing it back this year with more exciting prizes. This year, participants will have a four-week period to gain votes. Avontus will share the leaderboard via its social media channels and email. Participants with the top five most votes will move on to the judging round, where a panel of judges will decide the top three winners. The first-place winner will walk away with a DJI FPV Combo – First-Person View Drone UAV Quadcopter with 4K Camera, while the second prize is a Samsung Gear 360 (2017 Edition) Real 360° 4K VR Camera, followed by the third-place prize of a Portable Weather Devices Kit (Lightning Detector & Anemometer). The contest officially launches on October 25, 2021 and will run until November 28, 2021. Participants are encouraged to submit their entries via the official website within this time frame. Winners will be announced and notified via email on December 3, 2021. To enter the contest, simply visit the website and enter the relevant information, including your 3D scaffold design, company and project name. As a bonus Avontus say, you can also submit a 3D video walkthrough or YouTube exported video, on-site AR video, and completed project photo.Altrad secure North Sea contract for Serica Energy

Altrad has signed a three-year critical support services contract for Serica Energy, in support of the Bruce offshore oil & gas platform located in the North Sea, Scotland.

The contract commenced in October 2021 and includes the provision of scaffolding access, insulation, painting, deck crew services, heat exchanger maintenance and environmental services to support the platform’s critical asset integrity, maintenance and project activities.

Altrad’s Director of Upstream Operations – Chris Garland said, “The award of this contract builds upon our successful, long-term relationship with Serica Energy, and we look forward to using the ingenuity of our people to support the safe and efficient operation of these assets.”

Serica Energy and Altrad are both strong supporters of the SEQal initiative and which facilitates efficiency and transparency in the supply chain. This resonates with Altrad’s continued investment in the development of the 40 people who work on the platform, a number that is expected to reach around 60 during peak activity periods.

The contract was awarded to Altrad on the basis of its proven ability to enhance safety performance and improve operational efficiency whilst aligning with Serica Energy’s strategic objectives and goals during the past three years.

“We are delighted to have been awarded this contract from our long-standing client Serica Energy, which marks another exciting milestone in the repositioning of our upstream business – aligning with the objectives of the Altrad 2026 strategy – which will see Altrad transform into a business that is 75% larger than it is today, by 2026” added Peter Hughes – Altrad’s Director of Business Development & Strategy.

JR Group introduces new scaffold inspection service

The JR Group has launched a new scaffold inspection service as part of its new training services division.

The service will provide a thorough seven-day scaffolding inspection in accordance with the Working at Height Regulations, 2005.

The launch from the Paisley based firm, which has more than 25 years of expertise in the field, meets massive demand from the sector, offering a fully compliant service to comply with SG4.

As well as mandatory weekly scaffold inspections, the team will also provide one-off inspections, independent scaffold inspections, Anchor Tie Pull Out Testing, PASMA aluminium tower inspections, advanced design structure inspections and incident and accident investigations.

The firm will also offer expert advice on access solutions.

All audits and inspection reports will provide detailed information regarding remedial works required within an appropriate timescale, complete with photographs.

Ronnie Charters, HSEQ Manager for JR Scaffold will be leading with the new inspection service. He has more 30 years’ experience within the scaffold industry and is the current regional chair for Scotland / Northern Ireland for NASC.

As the NCC / CITB access instructor/safety advisor for all National Construction colleges throughout the UK, Ronnie has been carrying out safety site audits and scaffolding weekly inspections for various clients throughout the UK and abroad for more than 20 years.

Ronnie Charters, HSEQ Manager, said: “We are very excited to be able to offer this invaluable service to the industry considering the current high demand, and at the same time satisfying the shortage of accredited, competent personnel available to carry out this type of work.

“The demand for this type of service is massive as there is a conflict of interest once a company erects a structure and carries out its own scaffold inspections. Introducing an impartial company to carry out audits and inspections provides peace of mind for all involved.

“By using a service like this, it will ensure that all scaffold structures meet appropriate safety standards before first use, and they will be inspected at intervals of no more than seven days until it is dismantled. It will inspect structures after extreme weather conditions, high winds or any other events likely to affect its strength or stability, as well as after any substantial additions or alterations or after any unauthorised or third-party interference.

“We look forward to rolling this service out, providing much-needed support to the sector.”

The JR Group employs around 200 staff and was founded in Govan in 1995. It started as a scaffolding business and is now one of the largest building and construction firms in Scotland.

The business operates throughout Scotland and Northern England working on behalf of a number of the UK’s leading housebuilders, registered social landlords and private clients.

Safety warning issued after scaffolder falls from dropper

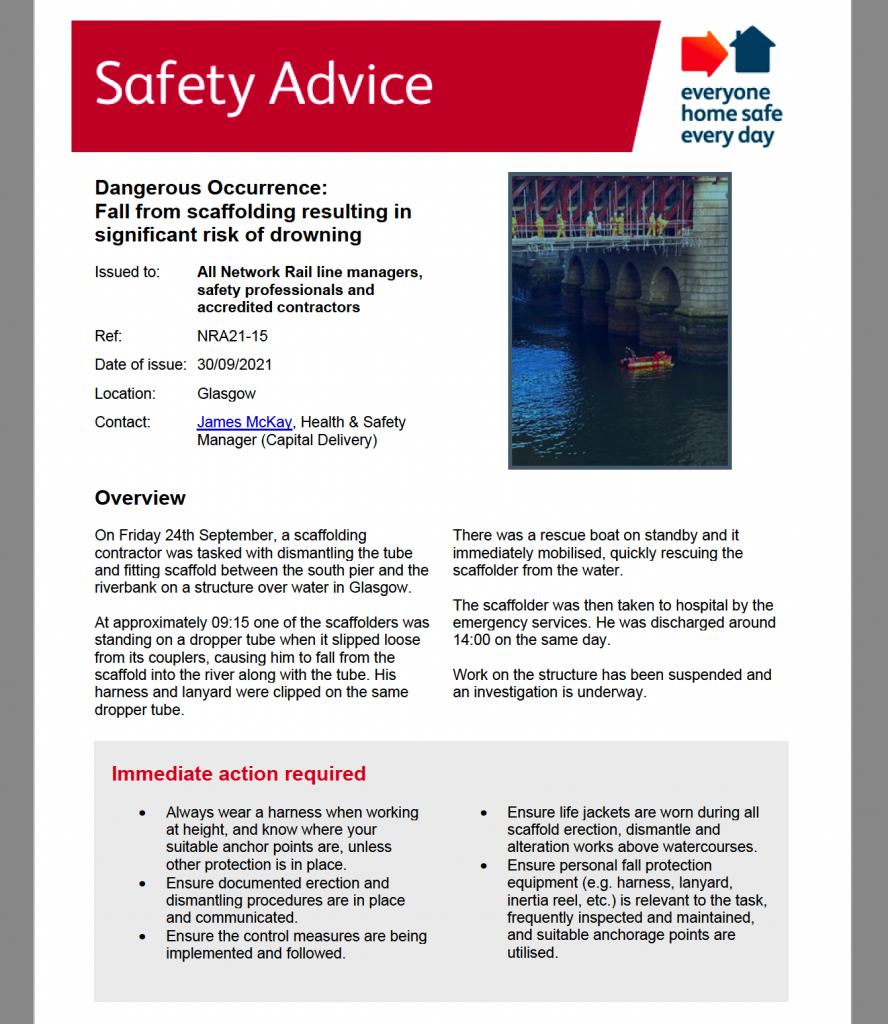

A warning has been issued by Network Rail after a scaffolder plunged into a river in Glasgow while dismantling a scaffold over water.

A safety advice bulletin published by Network Rail revealed that on Friday 24th September the scaffolder fell from a dropper tube that became loose from its coupler. The unnamed scaffolding contractor was tasked with dismantling a traditional tube and fitting scaffold between the south pier and the riverbank on a structure over a river in Glasgow, Scotland. According to the bulletin the scaffolder was standing on a dropper tube when it ‘slipped loose from its couplers’, causing the man and the tube to fall from the scaffold into the river. His harness and lanyard were clipped onto the same dropper tube. A nearby rescue boat on standby immediately mobilised and rescued the man by pulling him out of the water. The scaffolder was rushed to the hospital by emergency services but was discharged the same day. The safety warning issued to Network Rail line managers, safety professionals and its accredited contractors called for immediate safety action after the incident. These included:

The safety warning issued to Network Rail line managers, safety professionals and its accredited contractors called for immediate safety action after the incident. These included:

- Always ensure you are wearing a harness when working at height and know where suitable anchor points are.

- Make sure documented erection and dismantling procedures are in place on-site and communicated.

- Wearing life jackets during all scaffold erection, dismantling and alteration works above watercourses.

- Make sure that personal fall protection equipment (such as your harness, lanyard, inertia reel, etc.) is relevant to the task being carried out, as well as being frequently inspected and maintained, and that suitable anchorage points are used.

- Guarantee all control measures are correctly implemented and followed.