Scaffs Sit Com Set To Take Centre Stage

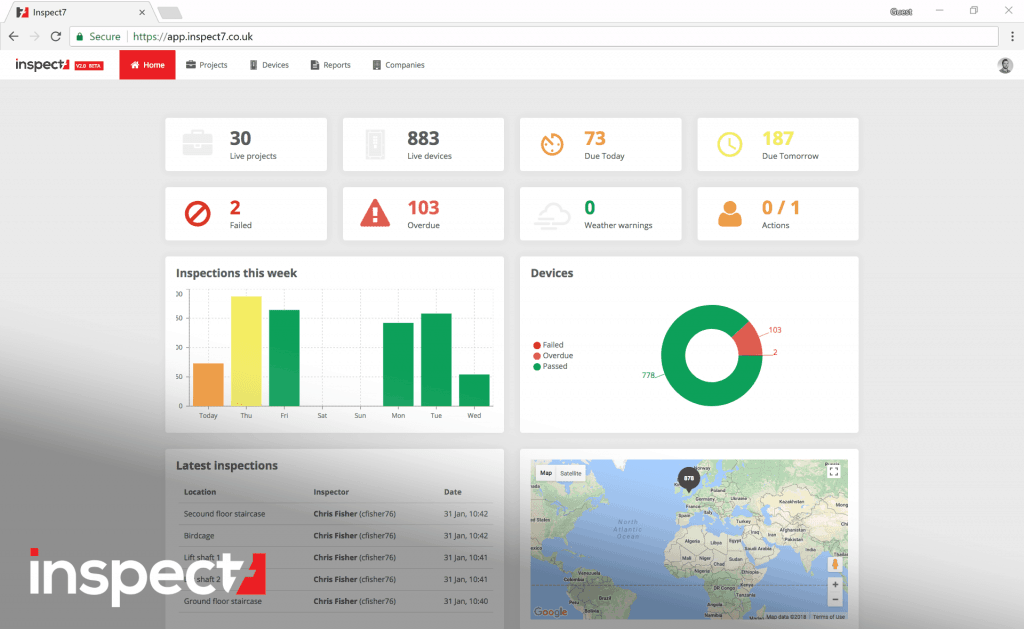

SafeTime launches new scaffolding inspection portal Inspect7

The award-winning London based digital scaffolding inspections company SafeTime® has been hard at work redesigning their scaffolding inspection portal.

The new portal which is now called Inspect7 aims to vastly improve usability, add beneficial features and demonstrate a fresh new look, says SafeTime®. The revamp comes shortly after their website redesign and product rebrand. With the company branching out into new sectors, SafeTime® has now become the overall brand name, with Inspect7 (digital scaffolding inspections) now becoming one of the multiple products the company aims to provide. SafeTime® have put in a lot of effort into making the new portal easy to move over to. Despite the revamp, everything will still appear and work in the same way as before. The portal has been carefully designed so that it matches the new look, without making any fundamental changes that affect usability. A full list of changes is available on the companies website blog here

Commenting on the update Carl Sharley, Co-Founder at SafeTime® said: “We are always looking to innovate and very proud of our latest release. We are very excited for the year to come and looking forward to releasing the next stages of our planned roadmap.”

SafeTime® also say they have been working on various new projects for 2018, that they plan to announce in the coming months.

A full list of changes is available on the companies website blog here

Commenting on the update Carl Sharley, Co-Founder at SafeTime® said: “We are always looking to innovate and very proud of our latest release. We are very excited for the year to come and looking forward to releasing the next stages of our planned roadmap.”

SafeTime® also say they have been working on various new projects for 2018, that they plan to announce in the coming months. CPD scaffolder training to be funded by employer

All NASC members are set to pay for the scaffolder CPD course according to a new statement of clarification within the Working Rule Agreement (WRA).

The requirement for Scaffolders and Advanced Scaffolders to complete the mandatory CISRS 2-day CPD course has been in place since 1st July 2017. The hotly debated issue of who pays for the CPD training has been on everybody’s lips across the industry since the mandatory course went live. According to NASC, The issue was raised with the confederation via the Construction Industry Joint Council who wish to include a statement within the WRA giving clarification. Additionally, a statement of clarification as appropriate to the National Agreement for the Engineering Construction Industry (NAECI) has recently been added to that Agreement. Towards the end of 2017, further to consideration by NASC Council, the basic premise that employers should pay for CPD training courses was agreed by consensus, says NASC. A proposed form of words was circulated to Council members in respect to the issue and the following statement has since been agreed:‘The NASC Council has confirmed that Members will fund the CPD course fee and reasonable associated costs of attendance for scaffolders in their direct employment as at the date of CISRS Scaffolder and CISRS Advanced Scaffolder card renewal. As with other employer-funded training, such funding may be linked to Training Agreements.’The NASC added, A very similar statement has been offered by the CIJC Employers to the CIJC Trade Unions for inclusion within the Working Rule Agreement and if adopted will then apply to all scaffolding companies who operate under that WRA agreement. CISRS Manager and NASC Director of Training, Dave Mosley said: ”I see this as a very welcome and positive move. One of the most frequently asked questions following the introduction of CPD was the issue of who will pay for the course. It is clear with this statement that NASC members are looking to do the right thing by their directly employed labour force.”

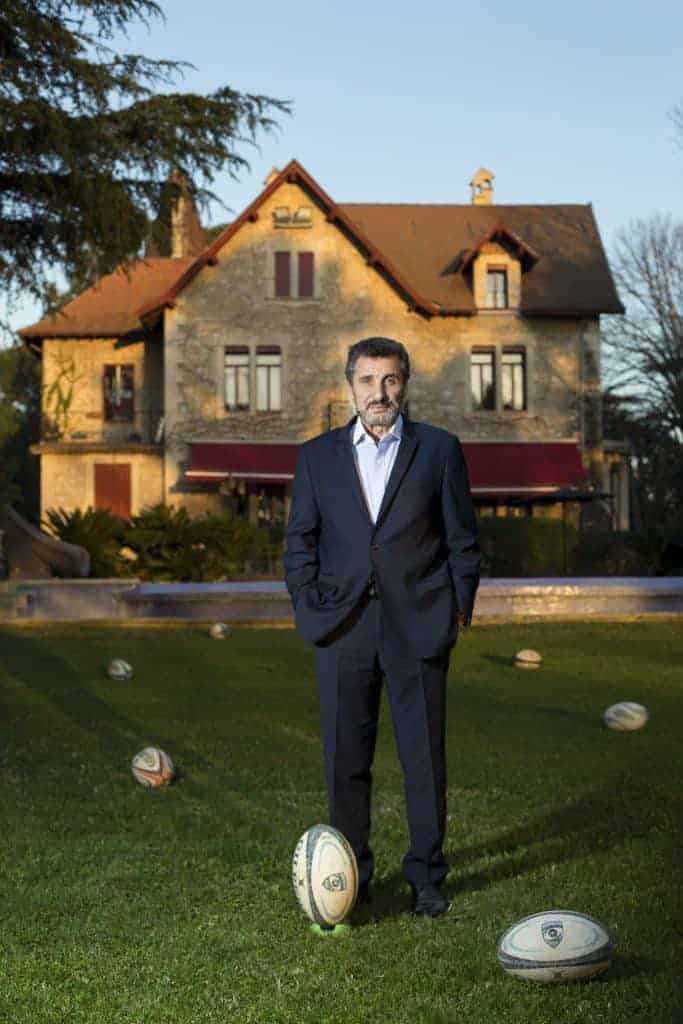

Mohed Altrad: The Interview

ScaffMag was given an interview with one of the world’s biggest movers and shakers, In order to find out more about this most enigmatic of business leaders. Grahame Anderson takes up the story.

If ever there was proof people can succeed whatever their background in life, Mohed Altrad is the perfect example. Born into a Syrian tribe he moved to France as a 17-year-old with little money and studied hard to secure a phD in Computer Sciences. He took the plunge with a partner in 1985 to buy a scaffolding maker close to bankruptcy.

The rest, as they say, is now history with the Altrad Group now a global leader in the industry with more than 39,000 employees in 130 worldwide subsidiaries. Given their recent acquisition of Cape, I wondered how big a step forward this was in real terms.

He told me: “The acquisition of Cape is another very important milestone for the Altrad Group. We truly respect and admire their achievements. Our ambition for our Industrial Services division is to become a global industrial solutions provider, offering a range of complimentary services to our customers. Cape complements our existing geographies, customers, and services, also including our respect for Safety. Our shareholders are long-term investors. The Altrad Group is just over 30 years old but is made up of businesses with histories exceeding 100 years. So, just as the businesses existed before I came along, they will survive long after I leave.”

“My longer term view is to provide a stable and sustainable business, for the benefit of our employees, customers, shareholders and all other stakeholders.”

Moving forward

It’s clear looking at the achievements of both Mohed and the group, meticulous planning is part of everyday working life. So what’s the strategic rationale for the company going forward? He added: “Altrad will continue to grow, both organically and through acquisitions. We see this growth as essential to our survival. It will enable us to penetrate new markets, attract a diverse and talented workforce, expand our service offering and, better meet our customers’ needs and expectations.”

Monopolizing the market

So what would be the answer to those who’d say your business is beginning to monopolize the market?

“Our ambition is to become best in class and we think this can be achieved through growth, consolidation, and sharing of resources, people, and knowledge. However, we do not believe we are monopolizing any market. There are a number of markets in which we have a stronger presence, but this has no adverse impact on competition. These markets have healthy competition with large and smaller operators able to compete, and sophisticated customers who select their suppliers based on many factors including safety, performance, productivity, quality and, of course, price. We have been through competition authority reviews in a number of jurisdictions and never been subject to any conditionality, which reinforces our view of the strong competition in the market.”

Brexit

This is, of course, a growing period of uncertainty given the ongoing Brexit negotiations. As a large company, I wondered what effect this might be having on the business, and what its legacy could be. Mohed told me:

“The impact of Brexit is still very difficult to judge. Unfortunately, the European and British politicians seem to be playing a very fragile game of cat and mouse. I sincerely hope common sense will prevail. Whilst our UK operations are relatively contained, the supply chain is international, and Brexit may impact this.”

“Likewise, the impact on exchange rates is impossible to predict. Given our very significant activity in the UK, with a turnover of approximately €950m and EBITDA of €115m, exchange rate fluctuations could have a material impact.”

The United States President

Looking at his Syrian background, I was particularly interested on his thoughts toward the United States President.

“His protectionist agenda in today’s modern world is not constructive. So far, I am not convinced that many of his ideologies will be implemented, as there seem to be divisions within his own ranks about their economic roadmap. Only time will tell. In terms of foreign policy, I think there is potential for these to create very significant repercussions to business worldwide. Having said this, I do agree in principle action is required – the global community has for too long been reluctant to move beyond diplomacy to resolve conflicts. Take Syria or Yemen, for example, where we see humanitarian disasters with little prospect for resolution. The consequences of a new nuclear arms race also concern me, and it will be terrible for business if we were to go beyond the tipping point.”

Oversupply of oil

Several commentators have made the claim, but is there really an oversupply of oil, and how would this affect the markets? He added: “It is not for me to say whether there is an oversupply of oil in the market. There is a complex relationship between oil supply, alternative energy sources, markets, growth, inflation, sovereign debt, etc all of which impact business and our economy. The Altrad Group has survived various economic peaks and troughs and retains a structure, with built-in agility.”

The Drive

This is clearly a highly driven man, so what spurs him on having already recorded significant achievements in his career?

“I am very optimistic for what more we can still achieve and am driven by a desire to create, to innovate and to challenge both myself and my colleagues to dig deeper. We all have the capacity to learn and develop. It gives me great pleasure to see people exceed their own expectations. I also feel a deep sense of responsibility towards stakeholders, who rely on our success and sustainability for their own security.”

“The Altrad Group now turns over in excess of €3bn. Some €2.7bn of this is paid to our employees and suppliers. It is hard to put a number on it, but I imagine our Group contributes to the livelihood of 500,000 people or more, once families are factored in. I have seen the Group grow over 32 years to what it is today – this is an exciting human adventure, in which we are creating a business built by its people, for its people. We each have our unique strengths and weaknesses. If sharing my past and providing insights into my work and life philosophy inspires other people to achieve their full potential, then I am delighted and truly humbled. My ambition was never to succeed in business. It has been to succeed in whatever I do, to the best of my abilities – whether in business, with Montpellier Hérault Rugby club, my literary projects… There is always more to achieve.”

Helping humanity

Mohed had previously said the object of life is to help humanity – what role can entrepreneurs play in this sense? “Helping humanity comes in so many different shapes and sizes,” he explained;

“From the dedicated and selfless work of charitable organizations to the impact of sport and the influence of community, political and business leaders. Somewhere within this spectrum is the entrepreneur. As I have mentioned above, building successful organizations provides financial security to countless families and communities. I hope my legacy will be to inspire humanity – to demonstrate anyone can achieve their ambition by pursuing their goals, facing and overcoming difficulties and challenging themselves. The biggest thing is to remain true to yourself, your beliefs and your values – and take pleasure in what you do, or aspire to do.”

This article was first published in the Winter 2017 issue of the ScaffMag magazine. View Issue40K Fine for spilling scaffolding tubes and injuring scaffolder

BAM Construction has been fined £40,000 after spilling scaffolding tubes and injuring a scaffolder.

The large well-known construction company was fined after Westminster Magistrates’ Court heard about the incident. On 9th December 2015 a pack of scaffolding tubes was being lifted by a crane onto a platform that was two stories above the gantry below. The crane driver could not see the load, and was being assisted by a slinger-signaller working from the platform. The load clipped the edge of the platform and tipped, spilling scaffolding tubes onto the gantry and injuring a scaffolder who was working there. Existing measures to control access to nearby areas during lifting operations were enhanced following the incident BAM Construction Ltd pleaded guilty to breaching Section 8(1) of the Lifting Operations and Lifting Equipment Regulations 1998. It was fined £40,000 and ordered to pay costs of £8,700. HSE inspector Stephron Baker Holmes said after the hearing: “Construction companies should think carefully about how best to prevent loads being lifted over people who may be working in areas nearby. In some cases it may be possible to restrict access to a particular area while lifting operations are being carried out above.”Brogan Group awarded Royal Winchester House scaffolding contract

Scaffolder faces jail for not being clipped on

A scaffolder faces jail after being caught erecting scaffolding 60ft in the air without clipping on.

Manchester and Salford Magistrates’ Court yesterday heard how on the 30 June 2017 Terrance Murray was erecting scaffolding at the rear of a Grade II-listed building on Quay Street in Manchester as part of works to renovate the windows. The court was told Terrance was spotted and photographed by a retired Health & Safety inspector wearing a harness but wasn’t clipped on, he was at least 60ft up on the top lift of the scaffolding. In the image below, the experienced scaffolder can be seen standing on the top lift without first erecting a SG4 guardrail.