There is a new double on the block designed for tube on tube scaffolds and more. The new drop forged fitting from Klawz Ltd is named KLAWZ and it is fully tested to EN74-1:2005 Class B. Klawz Ltd’s director, Mark Parkin says, “The Klawz doesn’t actually stop at the basic 9.1kN safe working load Class B, with tested slip loadings exceeding 30kN on both steel and Aluminium tube.”

Mark added that KLAWZ was in development, testing and manufacturing for around 18 months before the company was happy to launch the product. “It’s been a long and expensive process with new machinery being bought and additional tooling costs an almost daily event, and all that that before the hours spent with patent solicitors.”

Mark said, “Initial feedback has been very positive with indications that there are huge benefits with this product from design, logistics materials and labour saving. It is the only double that works with a prefabricated transom unit full stop, and offers the benefits of working tube on tube either with transom units or standard tube and fitting scaffolds.”

The cost of a KLAWZ double is £4.95 and Mark said that because it is drop forged it is very robust. “The fitting has been designed, developed and tested in the UK and is manufactured by our partners in a dedicated section of their facility in China”, he said.

Going forward there are no plans to change the fitting. “However,” said Parkin, “we will be conducting additional testing and gathering further data and analysis to justify the capabilities of the fitting beyond the limitations imposed by the EN74 standard.”

In terms of sales Mark said that right now companies are taking batches of KLAWZ to try them out. “We have also in the last week entered into an agreement with one of the UK’s largest scaffolding hire and sale companies, who will be offering KLAWZ for sale through their depots as well as online,” he said.

Technical information provided by Klawz Ltd.

KLAWZ perfectly complements the ReadyLok transom unit, allowing seamless transfer between sections of scaffolding constructed with transom units and traditional tube and fitting, by aligning the tube and fitting ledgers with Transom ledger spacing.

- Patented KLAWZ ledger spacing arrangement, aligns tube and fitting with ReadyLok transom ledger offset.

- Double and triple standards, necessitated by extra leg loading requirements, can be added at any point of a build with single or multiple KLAWZ fittings.

- Adding a Deadman when using ReadyLok Transoms can be done with a single KLAWZ fitting directly from the ledger, removing the need to under sling with doubles and punch up, saving tube and fittings.

- Aluminium beams suspended from ReadyLok transoms, can be secured directly to the standard with a single KLAWZ fitting, while guaranteeing a perfect parallel attachment effortlessly, and removing the time to plumb it up.

KLAWZ also offers the first EN74 tested answer to designing a “Double on Double” Scaffold.

- Allows a tube and fitting scaffold to be designed with high load bearing for both ledgers and transoms.

- Patented KLAWZ spacing design results in the ledger and transom sitting together, allowing the scaffold to be boarded out on a single level while maximising node point strength.

- Patented Wide Angle adaptation allows the scaffold to be splayed by up to 60 degrees, while maintaining all of the benefits of the “Double on Double” design.

- Removes the requirement to use “Aberdeen Transoms” as the strength is provided by the regular transom.

- Patented KLAWZ “Wing Design” automatically sets the transom spacing so it sits at the ideal height minimising the need for constant adjustment to level in.

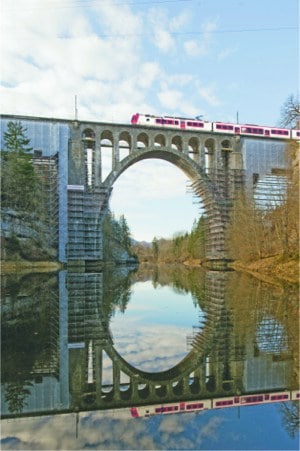

Roth Gerüste traces its roots back to 1932 and its present form to 1958. The name dates from 1987 and, over the past two decades, it has become the market leader in Switzerland, where it now has 17 locations and employs over 400 staff. In 2015, Keystone Constructions AG acquired a majority share in Roth Gerüste with a view to complementing its existing portfolio of real estate ventures.

Roth Gerüste traces its roots back to 1932 and its present form to 1958. The name dates from 1987 and, over the past two decades, it has become the market leader in Switzerland, where it now has 17 locations and employs over 400 staff. In 2015, Keystone Constructions AG acquired a majority share in Roth Gerüste with a view to complementing its existing portfolio of real estate ventures. The company tends to work on large projects and, is usually involved from the very start. “We will sometimes be working with the clients before the building permission is granted,” says Mr Laurenti. The scaffolding is very much an integral part of the construction process. “We present the projects with the architect and the engineers. We make our own recommendations and we’ve often changed the course of the construction.” This might mean anything from starting the building at a different point because it is not possible to scaffold into, say, a river, to explaining that actually, parts of the design may not be achievable because a supporting scaffold cannot be built.

The company tends to work on large projects and, is usually involved from the very start. “We will sometimes be working with the clients before the building permission is granted,” says Mr Laurenti. The scaffolding is very much an integral part of the construction process. “We present the projects with the architect and the engineers. We make our own recommendations and we’ve often changed the course of the construction.” This might mean anything from starting the building at a different point because it is not possible to scaffold into, say, a river, to explaining that actually, parts of the design may not be achievable because a supporting scaffold cannot be built. Once building has started, the company remains flexible and reactive. “You partner with the site managers,” explains Mr Laurenti. “They will sometimes call in an emergency and say ‘We have to change this or the architects have decided to do something different or the roof has changed to save money.’” This can mean altering the design of the scaffolding – and often very quickly so as to minimise delays and extra costs.

Once building has started, the company remains flexible and reactive. “You partner with the site managers,” explains Mr Laurenti. “They will sometimes call in an emergency and say ‘We have to change this or the architects have decided to do something different or the roof has changed to save money.’” This can mean altering the design of the scaffolding – and often very quickly so as to minimise delays and extra costs.

Like many other scaffolding firms, Alltask used spreadsheets to track materials as they travelled between the yard and work sites. In 2002, the company also hired a software developer to build an internal system for tracking basic stock movements. But the program didn’t provide a global view of stock holdings, and Alltask lost track of the developer and couldn’t keep the software updated.

Like many other scaffolding firms, Alltask used spreadsheets to track materials as they travelled between the yard and work sites. In 2002, the company also hired a software developer to build an internal system for tracking basic stock movements. But the program didn’t provide a global view of stock holdings, and Alltask lost track of the developer and couldn’t keep the software updated.

“Scaffmark is a handheld marking machine that engraves company identification into scaffolding materials we are currently using it to provide security to ready-lock transoms, aluminium beams, stair treads, loading bay gate arms, hop up brackets and rubbish chute fixing frames, this item could also be used for marking system scaffolds,” said Montana’s director, Alan Clark.

Clark explained that Montana spends upwards of £10,000 a year on buying paint alone to identify the company’s scaffolding equipment, let alone the labour of applying it. “And we still have materials stolen as companies just paint over the top of our paint,” said Clark. “With Scaffmark even if you apply paint over the top company details are still visible as names are imprinted into scaffold products so you can categorically identify your product immediately without sending off a paint sample to confirm if it is your equipment.”

Scaffmark has 40 characters on its ramping wheel and although it is a new product costing £1,250 plus vat, Clark estimates that with normal use and regular greasing the engraver should last for up to 10 years. “The names could possibly be written over and if so it would identify that the product was possibly stolen but certainly not as easy as just painting over someone else’s security paint colour,” said Clark.

“I have spoken with technical at the NASC (National Access and Scaffolding Confederation) and they have said Scaffmark will be raised at their coming meetings,” he said. Clark is awaiting feedback from the meeting but was encouraged at the initial response.

“Scaffmark is a handheld marking machine that engraves company identification into scaffolding materials we are currently using it to provide security to ready-lock transoms, aluminium beams, stair treads, loading bay gate arms, hop up brackets and rubbish chute fixing frames, this item could also be used for marking system scaffolds,” said Montana’s director, Alan Clark.

Clark explained that Montana spends upwards of £10,000 a year on buying paint alone to identify the company’s scaffolding equipment, let alone the labour of applying it. “And we still have materials stolen as companies just paint over the top of our paint,” said Clark. “With Scaffmark even if you apply paint over the top company details are still visible as names are imprinted into scaffold products so you can categorically identify your product immediately without sending off a paint sample to confirm if it is your equipment.”

Scaffmark has 40 characters on its ramping wheel and although it is a new product costing £1,250 plus vat, Clark estimates that with normal use and regular greasing the engraver should last for up to 10 years. “The names could possibly be written over and if so it would identify that the product was possibly stolen but certainly not as easy as just painting over someone else’s security paint colour,” said Clark.

“I have spoken with technical at the NASC (National Access and Scaffolding Confederation) and they have said Scaffmark will be raised at their coming meetings,” he said. Clark is awaiting feedback from the meeting but was encouraged at the initial response.