New Layher heavy duty scaffolding beam creates new opportunities

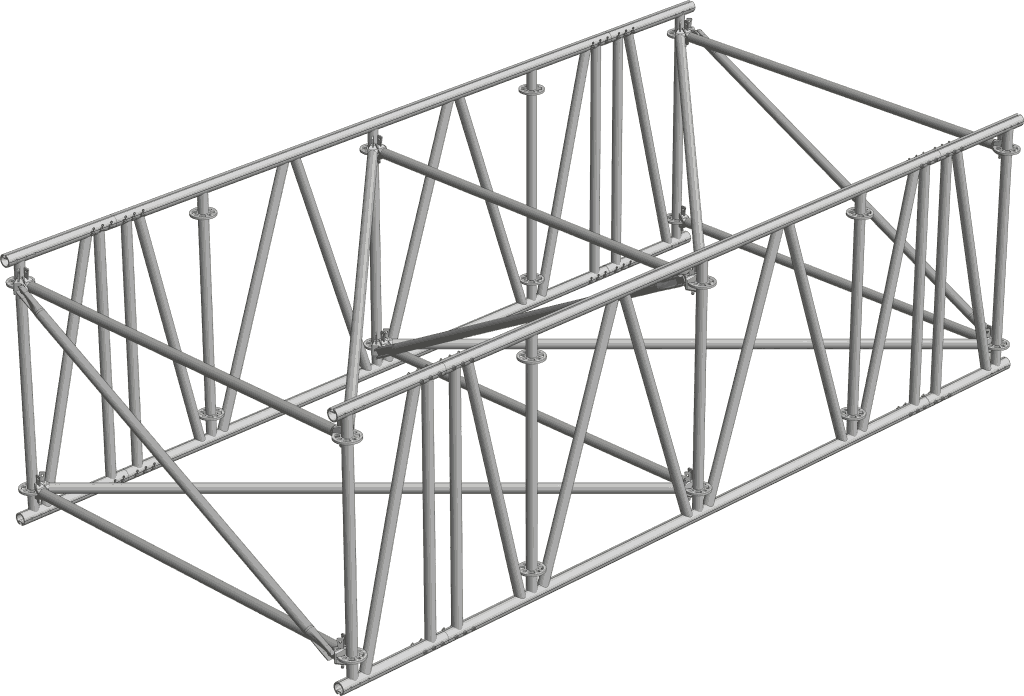

The latest innovation from Layher – the new heavy duty lightweight aluminium beam – is set to open up new opportunities in a wide range of scaffolding applications.

With a depth of 1.25 metres between top and bottom chords, the development, says the company, combines strength and versatility and can be utilised in conjunction with its modular Allround system or with tube and fit scaffolds.

“The HD beam benefits from our commitment to engineering design and testing which has resulted in strength that will be widely recognised by everybody in the industry,” says Sean Pike, Layher’s UK Managing Director.

“The top and bottom chords gain from a 60mm OD with the upright and diagonal chords having a 48.3mm OD. A maximum moment of 150 kNm at 1.036 top chord restraint and shear of 53.8 kN are the direct results.”

Layher has developed the system with installation versatility in mind, which has led directly to a choice of several beam lengths ranging between 1.036 metres and 5.18 metres. Each incorporates Layher’s rosette system and post spacing for ease of installation, and can be specified with an extensive range of accessories and fittings.

The result is a development which lends itself immediately to use in the full range of Layher’s marketplaces – these range from construction to event-based installations and with layouts from façade and birdcage scaffolds to domed installations.

“As with all of our equipment, the new beam comes complete with our extensive support capability which is centred on close working relationships with both scaffolding and main contractors alike,” adds Sean Pike.

“With our service input encompassing design, training and advice on safety, and with proven equipment performance arising from our approach to testing and high quality material selection, the HD beam is well placed to become a major part of our extensive choice of scaffolding and access systems.”

Layher Opens in Ireland

Layher has opened a new facility in Northern Ireland.

Established as a subsidiary, Layer Ireland, based in County Meath, operates in the Republic of Ireland and Northern Ireland. Managed by John Carolan who has a well established reputation as a successful scaffolding contractor, the depot provides extensive stock of the Layher scaffolding and weather protection ranges and will offer user training. Mr Carolan said although modular scaffolds are well-established in Ireland, he believes the subsidiary will make Layher products more readily available to the market. “We can demonstrate equipment that is faster, easier to handle and which has fewer components, resulting directly in reduced costs associated with labour, transportation and maintenance.” Layher Ltd, Ireland is not just providing extensive equipment stockholding, but also full technical and site support. “These are factors that have always been central to Layher’s reputation in the countries in which it operates and which are therefore at the heart of the new facility in Ireland,” adds John Carolan.Dutch scaffolders complete giant scaffolding staircase in Rotterdam city centre

Dutch firm erects an impressive scaffolding staircase in Rotterdam city centre.

Amsterdam based scaffolding firm Dutch Steigers have completed a huge Layher system staircase in the heart of Rotterdam city centre. The staircase forms one part of several new exciting projects within the city by contemporary architects MVRDV. MVRDV co-founder Winy Maas believes the project is the first step in creating a new network of rooftop spaces around the city. Measuring 29 meters high and 57 meters long, the installation allows visitors to climb 180 steps leading to a rooftop observation deck on the Groot Handelsgebouw building – one of the first buildings constructed in the city after the end of the second world war. Winy Maas added; “The stairs are a symbolic first step towards a better use of our city’s second layer, and ideally would be replaced with a set of escalators in the next step,”. “It is, in this way, a second reconstruction, a ‘Tweederopbouw’, that gives access to, activates and connects the rooftops of Rotterdam.” An exhibition is being held alongside the installation, reimagining how other buildings in the city can accommodate rooftop activities.

“With this installation and in our exhibition we show what this city could look like if we do that in many places, engaging a series of our existing buildings and giving access to their roofs, to create a new, much more interactive, three dimensional and denser urban topography for the next city generation,” added Maas.

An exhibition is being held alongside the installation, reimagining how other buildings in the city can accommodate rooftop activities.

“With this installation and in our exhibition we show what this city could look like if we do that in many places, engaging a series of our existing buildings and giving access to their roofs, to create a new, much more interactive, three dimensional and denser urban topography for the next city generation,” added Maas. SG4 YOU Pocket Guide Launches

The NASC has launched the user-friendly SG4 You (2015) pocket guide further to publication of its core scaffolding fall prevention guidance note, SG4:15 ‘Preventing Falls in Scaffolding Operations’ – with support from BuildUK.

Copies of the SG4 You pocket guide will retail via the NASC website’s online shop, priced at:

- NASC Member 1-99 units: £3.00

- NASC Member 100+ units: £2.10

- NASC Information Members: £3.00

- Non Members 1-99 units: £6.00

- Non Members 100+ units: £4.20

The widely-recognised industry standard for safe scaffolding, SG4:15 was launched in its 2015 revised and updated format to the NASC’s membership at the 2015 AGM in November and has been widely praised by industry experts. The SG4 You guide completes the SG4:15 suite, offering both detail and convenience to scaffolding operatives, contractors, managers and those involved in scaffolding on construction sites.

Whilst many of the principles of SG4 remain unchanged, the fine-tuning “evolution not revolution” updates to the 2015 guidance (part of the NASC’s commitment to review guidance every five years) reflects the broader scope introduced by TG20 compliant scaffolds, changes to good practice and industry innovation in the scaffolding sector. These include:

- Erecting floor height lifts

- Bridging with beams

- Loading bay gate installation

- Cantilever scaffolding

- Chimney stack scaffolding

- Personal fall protection equipment

NASC Past President and member of the SG4:15 working party, Mr Kevin Ward said: “SG4 works! The NASC accident statistics speak for themselves and in light of these, this revision has been more of a fine-tuning exercise rather than trying to reinvent the wheel.”

And NASC MD Robin James added: “The updated SG4:15 safety guidance has been very well received as a free download, and we’re very happy to be launching the SG4 You pocket guidance note, as a condensed hard copy version. Since its inception 20 years ago, SG4 has stood the test of time and developed to become the established performance standard for the protection of scaffolders working at height. The A6 pocket guide only serves to strengthen its use and reference out on site.

“SG4 is a core NASC publication – supported by the the construction industry’s overarching trade association, BuildUK and used by principal contractors across the UK and beyond, internationally. It continues to focus on prevention and protection philosophy, like the ‘Scaffolders’ Safe Zone.’ But it now also includes a range of updates to reflect changes within the industry, such as the introduction of TG20:13 ‘Good Practice Guidance for Tube and Fitting Scaffolding.’

“Work at height is by far the biggest risk faced by scaffolders and adhering to the principles in SG4:15 will not only serve to offer continual improvement in accident prevention, but will assist users to meet work at height legal obligations. And the affordable SG4 You pocket guide will only serve to assist in this process.”

To order copies of the SG4 You pocket guide, please visit www.nasc.org.uk or email: [email protected].

Safety and Access open CISRS Accredited Training Facility in Nepal

Safety and Access have announced the opening of their new overseas CISRS Accredited Training facility in Nepal.

Nottingham and Humberside based Safety and Access Ltd have today announced a strategic partnership with Aecor in Kathmandu and the opening of a highly commended CISRS Accredited Training facility in the capital. The training facility is already open for business and is offering scaffolder skills training along with scaffolding supervisor and inspection training. There are also plans to further enhance and expand the support services in the future. The accredited training centre is located in the capital Kathmandu and is equipped with a large high level practical area for scaffolder training along with excellent classrooms. Its facilities include accommodation and catering along with high quality welfare facilities. Following an independent audit by CISRS represented by Dave Mosley (Scheme Manager) the centre was certified to be compliant with the high standards required by CISRS.

Dave Mosley commented; “The centre here in Nepal represents a world class international training facility and Safety & Access and partners Aecor should be commended for this. The added value for candidates such as the accommodation and excellent welfare facilities make this a prime example of how we can continue to promote and enhance safety and quality using best practice techniques”

Rick Statham, Joint Managing Director of Safety & Access added; “We are absolutely delighted to be able to offer CISRS international training here in Kathmandu. Nepal is widely regarding as an epicentre for scaffolders that work across the Middle East and beyond and we believe there is huge potential here. It is vitally important for Nepalese citizens to have recognised qualifications to enhance employability and to be able to support their dependants and the CISRS qualifications will enable this.

Following the tragic consequences of the major earthquake that occurred here just over one year ago that claimed almost 10’000 lives we are committed to supporting the Nepalese people and the international opportunities linked to the country”

Sandeep Lama Managing Director of Aecor Nepal commented;

“Nepalese scaffolders being considered one of the hardest working and best scaffolder’s across the Middle East for over 3 decades, it was only a matter of time that Nepal had its own international recognised scaffolding training.

With CISRS approved training centre we can be proud to provide international standard training to experienced scaffolders and aspiring scaffolders to have a safe and long career.”

Ricki Morgan, Area Scaffolding Manager for CCC Qatar has been involved from the early stages of the venture as technical adviser is also pleased with the outcome of the audit;

“This is the best thing to happen in the scaffolding industry relative to the gulf region in many years. I’m approaching 47 years in scaffolding and I fully understand the need for accredited, quality recognised training and certification. This will enhance the safety of the operatives and end user. The availability of CISRS training in GCC represents a huge step forward from current standards. In turn, this offers a career path for all participating”

For more details on the training in Nepal and course availability, please contact [email protected] or view the website at www.safetyaccess.co.uk for more details.

Following an independent audit by CISRS represented by Dave Mosley (Scheme Manager) the centre was certified to be compliant with the high standards required by CISRS.

Dave Mosley commented; “The centre here in Nepal represents a world class international training facility and Safety & Access and partners Aecor should be commended for this. The added value for candidates such as the accommodation and excellent welfare facilities make this a prime example of how we can continue to promote and enhance safety and quality using best practice techniques”

Rick Statham, Joint Managing Director of Safety & Access added; “We are absolutely delighted to be able to offer CISRS international training here in Kathmandu. Nepal is widely regarding as an epicentre for scaffolders that work across the Middle East and beyond and we believe there is huge potential here. It is vitally important for Nepalese citizens to have recognised qualifications to enhance employability and to be able to support their dependants and the CISRS qualifications will enable this.

Following the tragic consequences of the major earthquake that occurred here just over one year ago that claimed almost 10’000 lives we are committed to supporting the Nepalese people and the international opportunities linked to the country”

Sandeep Lama Managing Director of Aecor Nepal commented;

“Nepalese scaffolders being considered one of the hardest working and best scaffolder’s across the Middle East for over 3 decades, it was only a matter of time that Nepal had its own international recognised scaffolding training.

With CISRS approved training centre we can be proud to provide international standard training to experienced scaffolders and aspiring scaffolders to have a safe and long career.”

Ricki Morgan, Area Scaffolding Manager for CCC Qatar has been involved from the early stages of the venture as technical adviser is also pleased with the outcome of the audit;

“This is the best thing to happen in the scaffolding industry relative to the gulf region in many years. I’m approaching 47 years in scaffolding and I fully understand the need for accredited, quality recognised training and certification. This will enhance the safety of the operatives and end user. The availability of CISRS training in GCC represents a huge step forward from current standards. In turn, this offers a career path for all participating”

For more details on the training in Nepal and course availability, please contact [email protected] or view the website at www.safetyaccess.co.uk for more details.