HAKI provides a unique weather protection system in Sweden

HAKI’s designers have produced new, effective, safe solutions to bridge an unusually wide span in Sweden.

When the Municipality of Gotland commenced its second largest-ever construction project, the XERVON depot and assembly personnel from Örebro provided one of Sweden’s largest weather protection systems – a 4,000 square-metre weather protection system from HAKI, covering what will be the completely new Wisby high school building, the Sävehuset. The weather protection system, which will be 64 metres long, will be completed in August 2015. It is not only the size of the weather protection system being assembled over the Sävehuset that makes it unique. Instead of attaching the weather protection system and the scaffolding to the building in the usual way, the scaffolding is being attached around the building to specially cast concrete beams in the ground. This keeps the weather protection system and scaffolding stable, and quite separate from the building. The weather protection system spans 44.5 metres; about 64 metres of the length of the building will be under cover during the summer. Total height to the ridge is about 20 metres, and the structure is cantilevered with double adjacent queen-post trusses, i.e. without any support in the centre. The weather protection system is being built in sections, about 10 metres at a time, and the sections, which can be rolled along, are jointed together in a so-called cap solution, making them weatherproof. This allows efficient demolition and subsequent new building of the outer walls and roof, with protection from weather and wind. ”Together with XERVON we take on some of Sweden’s most challenging weather protection system projects. These need proficient design and construction personnel, the right material, expert assembly personnel and close cooperation. With our joint solutions we contribute to efficient, safe construction workplaces,” says Kjell Sundlin, Sales Manager at HAKI in Sweden. The Sävehuset is being rebuilt by NCC/Nybergs Entreprenad, and the total budget for the project is SEK 275 million. For XERVON’s eight assembly workers, the project started in May 2015, and it will continue to February 2016, when the walls and roof of the new building will be in place. The new high school will be finished in 2017. ”For XERVON this is yet another prestige project, together with HAKI, on behalf of NCC. Last winter we contributed all the scaffolding and a large weather protection system for the renovation of the Örebro Konserthus. In the Sävehuset project, a completely different design is used to provide weather protection and the required support. In both cases these are very large, quite unique assignments for XERVON’s expert assembly personnel,” said Jens Sjöberg, CEO of XERVON in Sweden.Scaffolder falls to his death at TV Studios

A scaffolder has been pronounced dead after falling from scaffolding at Maidstone TV studios.

Scaffolder Justin Newitt, was yesterday (23 september) working at height when an incident occurred resulting in a reported 15ft fall at the Maidstone TV Studios at around 8am. Police, ambulances and the Kent Air Ambulance were called, Mr Newitt was taken to hospital but died later. An investigation by the Health and Safety Executive is taking place. Speaking after the incident, a spokesman for the studios said: “It is with considerable sadness that Maidstone Studios can confirm that one of our employees, Justin Newitt, was tragically involved in a fatal accident whilst at work on September 23, 2015. “We would like to extend our sincerest condolences to Justin’s family, friends and colleagues at this time. “Maidstone Studios would also like to confirm that we are co-operating fully with the relevant authorities in their on-going investigation”MP backs apprentice scaffolders.

West Worcestershire MP Harriett Baldwin has urged youngsters to climb the ladder to success in the scaffolding industry.

As part of a national campaign to get more construction companies to take on apprentices, Mrs Baldwin met up with Jon Stone from Malvern Scaffolding to talk about the challenges this presents. Speaking to the Ledbury Reporter she said: “Malvern Scaffolding is a well-known local company with contracts all over the county and in Birmingham and recruits some of its staff through apprenticeships. As more and more construction projects get underway across the region, the company is eager to recruit and train more young people. “Scaffolders are in high demand and can command great salaries so it’s a high-flying and demanding job and these skills are very valuable. Vacancies are at an all-time high and there are plenty of opportunities for people who want more vocationally-based education. I have offered Jon my help to try and make sure that we spread the word that the sky’s the limit when it comes to a job in scaffolding.”VIDEO: HSE prosecutes Scaffolder caught on film.

A scaffolder has been prosecuted after he repeatedly allowed unsafe work at height to be carried out on a busy London street.

Greg Pearson, from Enfield, trading as ‘Pearsons Scaffolding’, was prosecuted by the Health and Safety Executive (HSE) after a member of the public raised concerns about scaffolding work being carried out on Tavistock Street in central London. She was so concerned for the safety of passers-by and workers on the fifteen metre high scaffold that three separate complaints including photographs and videos were passed to HSE. HSE visited the site twice and found the incomplete scaffold to be poorly erected and unsafe work practices were putting workers at risk. No measures had been taken to prevent any falling scaffolding equipment hitting members of the public below. HSE served a Prohibition Notice ordering work to be stopped until the scaffold was made safe, but Westminster Magistrates’ Court heard that Pearson ignored this and other warnings, carrying on regardless. The court also heard Pearson failed to respond when required to produce documents for inspection during the investigation, hindering the HSE’s efforts to ensure future work was carried out safely at other sites. Pearsons Scaffolding’s involvement at the site only ended when a second Prohibition Notice was served and the project’s Principal Contractor decided to take on another scaffolder to complete the work. Greg Pearson, 33, of South Street, Enfield, pleaded guilty to two breaches of the Work at Height Regulations 2005 (6(3), 10(1)) and was given two suspended prison sentences of 10 weeks to run concurrently, suspended for 12 months. He was also ordered to pay costs of £200 and a victim surcharge of £80. Speaking after the hearing HSE Inspector Andrew Verrall-Withers said: “Greg Pearson repeatedly put the lives of other workers and members of the public at risk. He blatantly disregarded all warnings and enforcement action taken against him and it was just good fortune that no one was killed. It’s vital that law abiding scaffolders have confidence they will not lose work to others who underquote them because they take shortcuts at the expense of safety. This case should send a message to other scaffolders that Courts will sentence robustly even when the reckless working practices have thankfully not resulted in serious injuries or fatalities. “I applaud the member of the public who alerted us to this as thankfully we were able to avoid the workers or the public being injured or killed. We encourage people to report unsafe work to us so we can act to protect workers and the public.”SHS appoints new Regional Director of Transmission Business

SHS appoints Michael Griffiths as Regional Director to its Doncaster Office.

SHS Integrated Services, a specialist provider of high-specification industrial scaffolding to highly regulated environments, has appointed a new regional director to its Doncaster office in a bid to boost its presence in the north east. Michael Griffiths, 34, from Rotherham has been a prominent figure in the power and transmission sector for over eight years and will now be responsible for strengthening SHS’s relationships with existing clients and driving new business leads in the industrial, construction, civil and rail sectors across the north. Prior to joining SHS, Mr Griffiths spent seven years working at Balfour Beatty Utility Solutions, starting as a draughtsman and progressing to become a team leader, where he was responsible for the design, feasibility and planning of contracts ranging from £10,000 to £2.5 million. Mr Griffiths joined SHS in 2013 as part of the acquisition of Dixon Pentland Scaffolding, where he had worked since 2007, and has spent the 18 months working as a commercial manager with SHS, before being promoted into this newly created position. Commenting on his appointment, Mr Griffiths said: “I am delighted to have been given the opportunity to lead SHS’s UK transmission & distribution division and develop the company’s presence in north east England. We have ambitious growth plans for SHS in the north east and hope to double the current turnover within the next three years while ensuring the business model remains both sustainable and diverse. “Building on our strong presence in the area, we will be providing a wider range of services to our customers, while driving growth and increasing operations. SHS has a wide-ranging client base and we hope to secure and foster additional relationships, especially in the Yorkshire and Humber region, as we expand into the area. “With a team of highly-skilled, experienced and motivated staff at the core of the company’s operations, I have no doubt that SHS’s presence in the north east will develop as we continue delivering innovative and cost effective solutions while maintaining our high safety and quality standards. “All the stepping stones are in place to ensure the business achieves its ambitious growth plans and I am excited to be a part of this highly focussed and driven company going forward.” SHS has witnessed a number of high-profile contract wins in recent years and has successfully developed the transmission division, providing solutions to clients such as Balfour Beatty, Amec Foster Wheeler and Babcock International. In addition to the company’s recent expansion, SHS has diversified its market sector presence, incorporating the specialist power and transmission firm it acquired in 2013 into the business’ long term growth plans. SHS currently provides services principally to the utility, petrochemical, transmission and construction sectors but hopes to widen its operations into nuclear, rail, marine and pharmaceutical sectors as part of its growth strategy. Gavin Payne, chief executive officer of SHS, said: “Appointing Michael to the position of regional director is an important part of our long term strategy and strengthens our existing management team in the north east. “Michael is an exceptionally dedicated and technically gifted person and will bring invaluable skills to the company. I am certain that his extensive experience and industry knowledge will have a big impact in delivering growth while nurturing existing client relationships in the region. “Michael’s experience in a large contractor environment and knowledge of the transmission sector is invaluable to the wide range of complex projects SHS undertakes and will be of huge benefit in helping to meet our ambitious growth strategy in 2016 and beyond. “The company has gone from strength-to-strength in recent years and, as we continue to deliver exceptional quality to our customers, we are committed to holding a strong, competitive position in the market. “The company’s recent success is a reflection of our highly skilled workforce and exhibits our commitment to exceptional health and safety and focus on providing an efficient, sustainable, high quality and cost effective service.” Established in 1998, SHS Integrated Services offers scaffold access, industrial and HVAC insulation, and construction and demolition services. It currently employs more than 300 people across the UK.Dublin hotel firm in court after worker falls from scaffolding

The bosses of a Dublin hotel have pleaded not guilty to breaching Ireland’s health and safety laws after a worker was injured when he allegedly fell through a rotten board on a scaffolding tower.

The hotel company is accused of failing ensure the safety of the worker in that a scaffolding tower on site was not safe for use and that this resulted in the worker suffering personal injuries when he fell from a height.

Other charges allege that boards on the scaffolding were defective and failed to prevent the fall, that the scaffolding was inadequately planned and maintained, that there was inadequate training and supervision and that they did not have a required constructions skills registration card.

The trial continues in March 2016.

Christian Brash from John Brash & Co Ltd – which manufactures more than two million scaffold boards each year said – cases such as this are, thankfully, few and far between but they do serve as a sobering reminder of the importance of safety in the scaffolding industry. “Working at height is a challenging working environment and safety should always be the number one priority for every scaffolding contractor.” said Christian. “Cases such as this do send ripples through the industry and it is an opportune time for roofing contractors to review all their processes and equipment to ensure that everything is fully compliant with the current standards.” Christian signposted the British Standards Institution’s (BSI) BS2482 and National Access and Scaffolding Confederation’s (NASC) TG6:10.Broker Power: Scaffolders Insurance

Broker Power is a new idea for people looking for insurance to cover their small business.

It combines a powerful but easy-to-use web site with proven insurance products and the ability to buy through a local insurance broker – meaning you can configure the cover you need, compare prices from established insurers and call on the experience of a local insurance expert when you need it, before or after your purchase.

With Broker Power you can buy online and download your documents straight away or just get a quote and then speak to your chosen broker – either way your broker is there to help throughout the term of your policy.

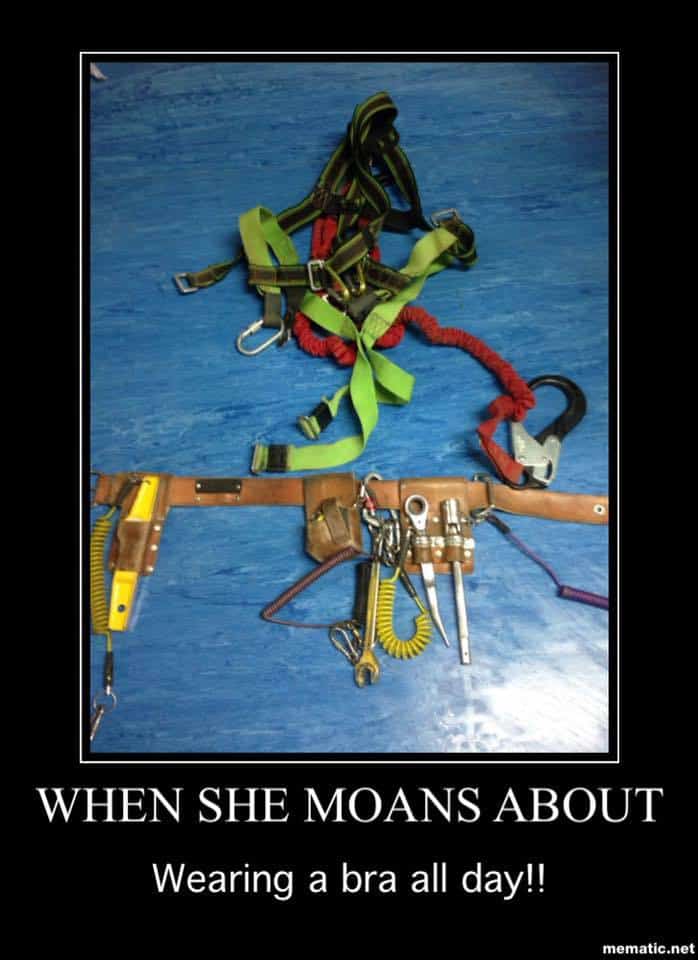

We believe that this is an unbeatable combination but don’t take our word for it – visit www.brokerpower.co.uk to find out more, get a quote today or leave us your expiry date so we can remind you nearer the time. Never moan to a scaffolder

This little beauty has been doing the rounds on social media lately, it had us in stitches.. so true, I had to share.