Guest Technical Article By IDH, The Independent Design House

IDH was incorporated in July 2011 and established to provide specialist Scaffold Design, Formwork Design & general Temporary Works Design consultancy serving Sub-Contractors, Main Contractors and Client developers.

What is Effective Length?

Effective length is a critical concept in Structural Design for all structural members such as Steel UC and UB sections, reinforced concrete columns and scaffold tubes. Its technical definition is ‘the length of a component which is effectively restrained’. When designing structural members they can be subject to a number of forces such as Shear, Tension, Compression, Torsion and combinations of these to name but a few. Generally speaking, when we look at structural members, be it beams or struts, the Compressive force element is predominant in determining the structural capacity and the failure mechanism.Example 1:

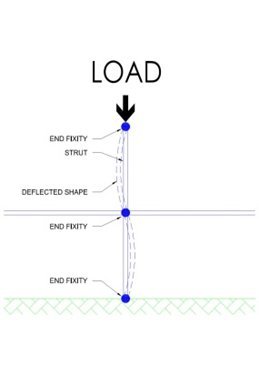

In this example, if the ends of the strut are held in place in all directions then the effective length Le is equal to the length of strut.

In this example, if the ends of the strut are held in place in all directions then the effective length Le is equal to the length of strut.

Example 2:

Now if we introduce a support in the middle and prevent it from moving in all directions, the Le becomes half the strut length. This is critical, if we started for example with a scaffold tube of 2m it would have a strut capacity of 29.1 kN (TG20:08 Table 20). By reducing the effective length to 1.0m the strut capacity increases to 58.6 kN.

Now if we introduce a support in the middle and prevent it from moving in all directions, the Le becomes half the strut length. This is critical, if we started for example with a scaffold tube of 2m it would have a strut capacity of 29.1 kN (TG20:08 Table 20). By reducing the effective length to 1.0m the strut capacity increases to 58.6 kN.

Example 3:

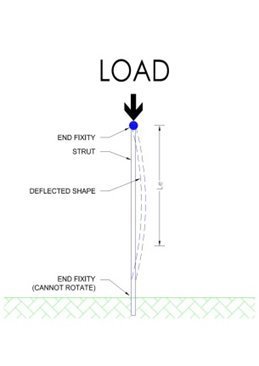

If we now fix one end of the tube in to concrete say so that it cannot pivot or rotate, although the length of the tube is still 2m, it now has an Le of 1.4m. So our 2m tube in the last example can carry 45.3 kN – much more than a tube of the same length restrained as the first example.

In scaffolds, the same principles apply. If we have a 2m lift ledger braced pair of standards, with each end of each pair prevented from moving left and right, the effective length would be 2.0m. However we seldom have this scenario in scaffolds – we have every other pair of standards ledger braced, we have ties on varying lifts and we typically only sway brace the outside face. Meaning, on closer review, we have lots of different standards with lots of different end fixity conditions resulting in lots of different effective lengths throughout the scaffold arrangement. This results in different standards having different load capacities and the global capacity of the scaffold limited to the single standard with the worst leg load / effective length ratio.

For more explanation on this and other technical scaffold design subjects visit the IDH blog: http://www.idh-design.co.uk/blog/

Author: Tim Burt

If we now fix one end of the tube in to concrete say so that it cannot pivot or rotate, although the length of the tube is still 2m, it now has an Le of 1.4m. So our 2m tube in the last example can carry 45.3 kN – much more than a tube of the same length restrained as the first example.

In scaffolds, the same principles apply. If we have a 2m lift ledger braced pair of standards, with each end of each pair prevented from moving left and right, the effective length would be 2.0m. However we seldom have this scenario in scaffolds – we have every other pair of standards ledger braced, we have ties on varying lifts and we typically only sway brace the outside face. Meaning, on closer review, we have lots of different standards with lots of different end fixity conditions resulting in lots of different effective lengths throughout the scaffold arrangement. This results in different standards having different load capacities and the global capacity of the scaffold limited to the single standard with the worst leg load / effective length ratio.

For more explanation on this and other technical scaffold design subjects visit the IDH blog: http://www.idh-design.co.uk/blog/

Author: Tim Burt

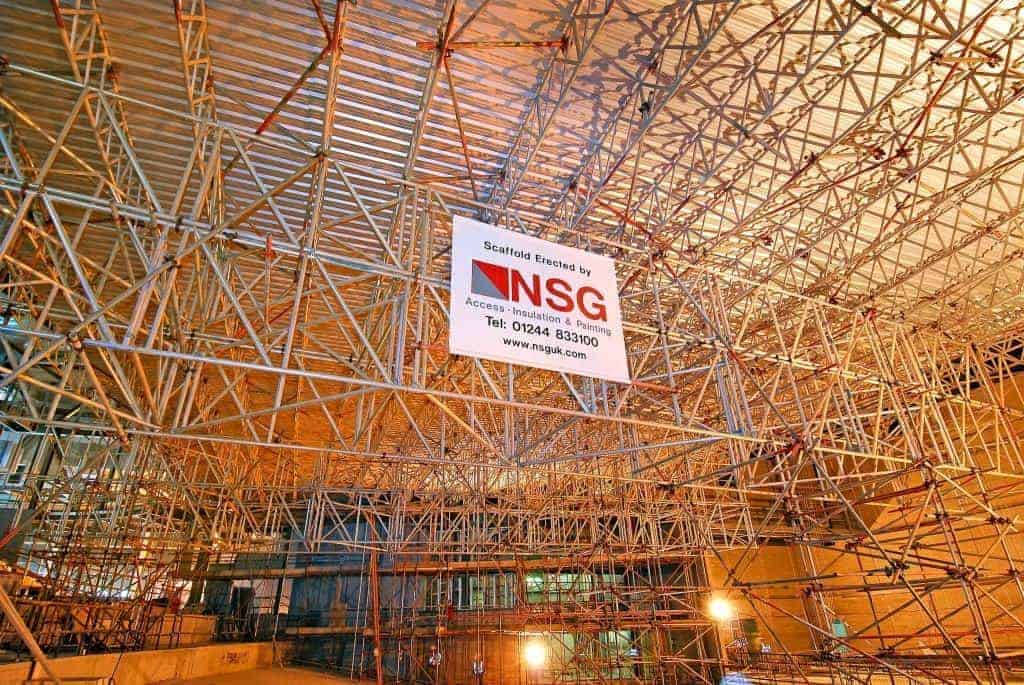

Scaffolding and industrial services firm Altrad NSG has achieved its eighth consecutive Gold Standard for excellence in health and safety.

The Deeside based firm, which operates at sites across the UK, was awarded a Gold Medal for Occupational Health & Safety, by the Royal Society for the Prevention of Accidents (RoSPA).

The award was presented by RoSPA to recognise the company’s achievement and commitment to raising the standards of health and safety management at its Ineos Chlor site in Runcorn. Altrad NSG is now setting its sights on two more years of continuous health and safety success to achieve a RoSPA President’s Award – presented to organisations who achieve 10 or more years of consecutive Gold standard.

Paul Hemingway, Health and Safety Advisor at Altrad NSG, said: “Safety is paramount to the business so we are delighted to be recognised with our eighth consecutive RoSPA Gold Award. Alongside our British Safety Council Five Star Award and Sword of Honour, it demonstrates to our clients and potential customers that we are a responsible and conscientious business that places health and safety as top priority.

“We have 140 staff at our Ineos Chlor site, providing multi-discipline maintenance works including scaffolding, rope access, painting and industrial cleaning, as well as thermal insulation and sheet metal work, together with road gritting, rigging and slinging and high pressure water jetting. We had to provide RoSPA with strong evidence of best practice health and safety management, highlighting our excellent track record over the past year. This continuing success has only been achievable because of the commitment to health and safety from all site operatives and the Site Management Team.”

David Dawlins, RoSPA Award Manager, said: “RoSPA firmly believes that organisations that demonstrate commitment to continuous improvement in accident and ill health prevention deserve recognition. Altrad NSG Limited – Ineos Site Runcorn has shown that it is committed to striving for such continuous improvement and we are delighted to honour it through the presentation of an award.”

Ineos Chlor is a leading global manufacturer of chlorine and PVC – its Runcorn site is the company’s biggest in the UK.

Will Gretton, Altrad NSG Health and Safety Manager, added: “We have also had our Asbestos Ancillary Licence for scaffolding renewed until 2016 – few other scaffolders hold this license and we have had to undergo rigorous assessment by the HSE. This means we are able to continue to provide access to asbestos removal sites and is another endorsement of our quality and robust health and safety procedures.

“We are continuing to invest in training across the workforce and have just completed Asbestos Awareness, Risk Assessment and Manual Handling training courses for the whole of the Altrad NSG workforce.”

Altrad NSG works with a range of blue chip construction clients, providing scaffolding and rope access systems, insulation, painting, coatings, blasting and industrial cleaning. Core sectors include on and offshore oil and gas, petrochemical, pharmaceutical, power generation (including nuclear), steel production, shipbuilding, rail and civil infrastructure.

In 2011 the business was purchased by French based multinational Altrad SA.

Scaffolding and industrial services firm Altrad NSG has achieved its eighth consecutive Gold Standard for excellence in health and safety.

The Deeside based firm, which operates at sites across the UK, was awarded a Gold Medal for Occupational Health & Safety, by the Royal Society for the Prevention of Accidents (RoSPA).

The award was presented by RoSPA to recognise the company’s achievement and commitment to raising the standards of health and safety management at its Ineos Chlor site in Runcorn. Altrad NSG is now setting its sights on two more years of continuous health and safety success to achieve a RoSPA President’s Award – presented to organisations who achieve 10 or more years of consecutive Gold standard.

Paul Hemingway, Health and Safety Advisor at Altrad NSG, said: “Safety is paramount to the business so we are delighted to be recognised with our eighth consecutive RoSPA Gold Award. Alongside our British Safety Council Five Star Award and Sword of Honour, it demonstrates to our clients and potential customers that we are a responsible and conscientious business that places health and safety as top priority.

“We have 140 staff at our Ineos Chlor site, providing multi-discipline maintenance works including scaffolding, rope access, painting and industrial cleaning, as well as thermal insulation and sheet metal work, together with road gritting, rigging and slinging and high pressure water jetting. We had to provide RoSPA with strong evidence of best practice health and safety management, highlighting our excellent track record over the past year. This continuing success has only been achievable because of the commitment to health and safety from all site operatives and the Site Management Team.”

David Dawlins, RoSPA Award Manager, said: “RoSPA firmly believes that organisations that demonstrate commitment to continuous improvement in accident and ill health prevention deserve recognition. Altrad NSG Limited – Ineos Site Runcorn has shown that it is committed to striving for such continuous improvement and we are delighted to honour it through the presentation of an award.”

Ineos Chlor is a leading global manufacturer of chlorine and PVC – its Runcorn site is the company’s biggest in the UK.

Will Gretton, Altrad NSG Health and Safety Manager, added: “We have also had our Asbestos Ancillary Licence for scaffolding renewed until 2016 – few other scaffolders hold this license and we have had to undergo rigorous assessment by the HSE. This means we are able to continue to provide access to asbestos removal sites and is another endorsement of our quality and robust health and safety procedures.

“We are continuing to invest in training across the workforce and have just completed Asbestos Awareness, Risk Assessment and Manual Handling training courses for the whole of the Altrad NSG workforce.”

Altrad NSG works with a range of blue chip construction clients, providing scaffolding and rope access systems, insulation, painting, coatings, blasting and industrial cleaning. Core sectors include on and offshore oil and gas, petrochemical, pharmaceutical, power generation (including nuclear), steel production, shipbuilding, rail and civil infrastructure.

In 2011 the business was purchased by French based multinational Altrad SA.