Westminster Magistrates’ Court heard today (23 January) he was part of a crew of labourers working for Swanley-based MJM Fitout Ltd to remove ventilation ducting from a two-storey gym in the basement.

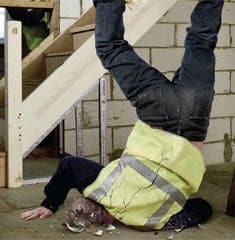

A scaffolding tower was erected to support the work and was being used by the worker to access ducting from a ceiling above a squash court. However, it was knocked over as he worked at height and both he and the tower crashed to the floor below, a distance of some 4.5 metres.

An investigation by the Health and Safety Executive (HSE) identified that none of the temporary labourers was competent to erect a scaffolding tower, and that it was constructed without adequate supervision.

A district judge was told the incident could have been prevented had the work been properly planned, managed and monitored by MJM Fitout.

The company, of Horizon House, Azalea Drive, Swanley, Kent, was fined £8,000 and ordered to pay £3,500 in costs after pleading guilty to a single breach of the Construction (Design and Management) Regulations 2007.

After the hearing HSE Inspector Keith Levart said:

“The worker suffered painful injuries that could have been avoided had the labour crew been properly managed, and had their work on site been adequately monitored by MJM Fitout Ltd.

“The temporary staff had effectively been left to their own devices and were working in an unplanned and unsafe manner. It illustrates the clear need for companies to have practical arrangements in place to ensure that all personnel involved in and undertaking construction work understand what is expected of them, and are able to co-operate and communicate with one another.

“Work at height from scaffolding poses clear risks, and should only ever be undertaken by competent personnel with the right equipment, knowledge and experience.”

Westminster Magistrates’ Court heard today (23 January) he was part of a crew of labourers working for Swanley-based MJM Fitout Ltd to remove ventilation ducting from a two-storey gym in the basement.

A scaffolding tower was erected to support the work and was being used by the worker to access ducting from a ceiling above a squash court. However, it was knocked over as he worked at height and both he and the tower crashed to the floor below, a distance of some 4.5 metres.

An investigation by the Health and Safety Executive (HSE) identified that none of the temporary labourers was competent to erect a scaffolding tower, and that it was constructed without adequate supervision.

A district judge was told the incident could have been prevented had the work been properly planned, managed and monitored by MJM Fitout.

The company, of Horizon House, Azalea Drive, Swanley, Kent, was fined £8,000 and ordered to pay £3,500 in costs after pleading guilty to a single breach of the Construction (Design and Management) Regulations 2007.

After the hearing HSE Inspector Keith Levart said:

“The worker suffered painful injuries that could have been avoided had the labour crew been properly managed, and had their work on site been adequately monitored by MJM Fitout Ltd.

“The temporary staff had effectively been left to their own devices and were working in an unplanned and unsafe manner. It illustrates the clear need for companies to have practical arrangements in place to ensure that all personnel involved in and undertaking construction work understand what is expected of them, and are able to co-operate and communicate with one another.

“Work at height from scaffolding poses clear risks, and should only ever be undertaken by competent personnel with the right equipment, knowledge and experience.” Company fined for labourers fall from scaffolding

Westminster Magistrates’ Court heard today (23 January) he was part of a crew of labourers working for Swanley-based MJM Fitout Ltd to remove ventilation ducting from a two-storey gym in the basement.

A scaffolding tower was erected to support the work and was being used by the worker to access ducting from a ceiling above a squash court. However, it was knocked over as he worked at height and both he and the tower crashed to the floor below, a distance of some 4.5 metres.

An investigation by the Health and Safety Executive (HSE) identified that none of the temporary labourers was competent to erect a scaffolding tower, and that it was constructed without adequate supervision.

A district judge was told the incident could have been prevented had the work been properly planned, managed and monitored by MJM Fitout.

The company, of Horizon House, Azalea Drive, Swanley, Kent, was fined £8,000 and ordered to pay £3,500 in costs after pleading guilty to a single breach of the Construction (Design and Management) Regulations 2007.

After the hearing HSE Inspector Keith Levart said:

“The worker suffered painful injuries that could have been avoided had the labour crew been properly managed, and had their work on site been adequately monitored by MJM Fitout Ltd.

“The temporary staff had effectively been left to their own devices and were working in an unplanned and unsafe manner. It illustrates the clear need for companies to have practical arrangements in place to ensure that all personnel involved in and undertaking construction work understand what is expected of them, and are able to co-operate and communicate with one another.

“Work at height from scaffolding poses clear risks, and should only ever be undertaken by competent personnel with the right equipment, knowledge and experience.”

Westminster Magistrates’ Court heard today (23 January) he was part of a crew of labourers working for Swanley-based MJM Fitout Ltd to remove ventilation ducting from a two-storey gym in the basement.

A scaffolding tower was erected to support the work and was being used by the worker to access ducting from a ceiling above a squash court. However, it was knocked over as he worked at height and both he and the tower crashed to the floor below, a distance of some 4.5 metres.

An investigation by the Health and Safety Executive (HSE) identified that none of the temporary labourers was competent to erect a scaffolding tower, and that it was constructed without adequate supervision.

A district judge was told the incident could have been prevented had the work been properly planned, managed and monitored by MJM Fitout.

The company, of Horizon House, Azalea Drive, Swanley, Kent, was fined £8,000 and ordered to pay £3,500 in costs after pleading guilty to a single breach of the Construction (Design and Management) Regulations 2007.

After the hearing HSE Inspector Keith Levart said:

“The worker suffered painful injuries that could have been avoided had the labour crew been properly managed, and had their work on site been adequately monitored by MJM Fitout Ltd.

“The temporary staff had effectively been left to their own devices and were working in an unplanned and unsafe manner. It illustrates the clear need for companies to have practical arrangements in place to ensure that all personnel involved in and undertaking construction work understand what is expected of them, and are able to co-operate and communicate with one another.

“Work at height from scaffolding poses clear risks, and should only ever be undertaken by competent personnel with the right equipment, knowledge and experience.” Q&A with the Director of Buckinghamshire Scaffolding Specialists.

We grabbed a quick Q&A with Matt Bowler, Director of Buckinghamshire Scaffolding Specialists.

BSS was established in 2007 in Milton Keynes, Buckinghamshire Scaffolding Specialists provide an extensive range of scaffolding services in the industrial, commercial, residential and event sectors.

- 2012 – How was it for you, Matt?

- With scaffolding firms folding left right and centre, how have you weathered the financial storm?

- Give us an overview of your year in headlines.

- Best moment?

- And the worst?

- What do you look forward to in 2013?

- Anything else?

Scaffolding van overturns in Weymouth

COOMBE Valley Road is now re-open after a scaffolding van overturned. The police closed the Weymouth road earlier following the incident at 7.25am.

Police were waiting for the van to be recovered before the road could be fully re-opened.

News Via: dorsetecho.co.uk

COOMBE Valley Road is now re-open after a scaffolding van overturned. The police closed the Weymouth road earlier following the incident at 7.25am.

Police were waiting for the van to be recovered before the road could be fully re-opened.

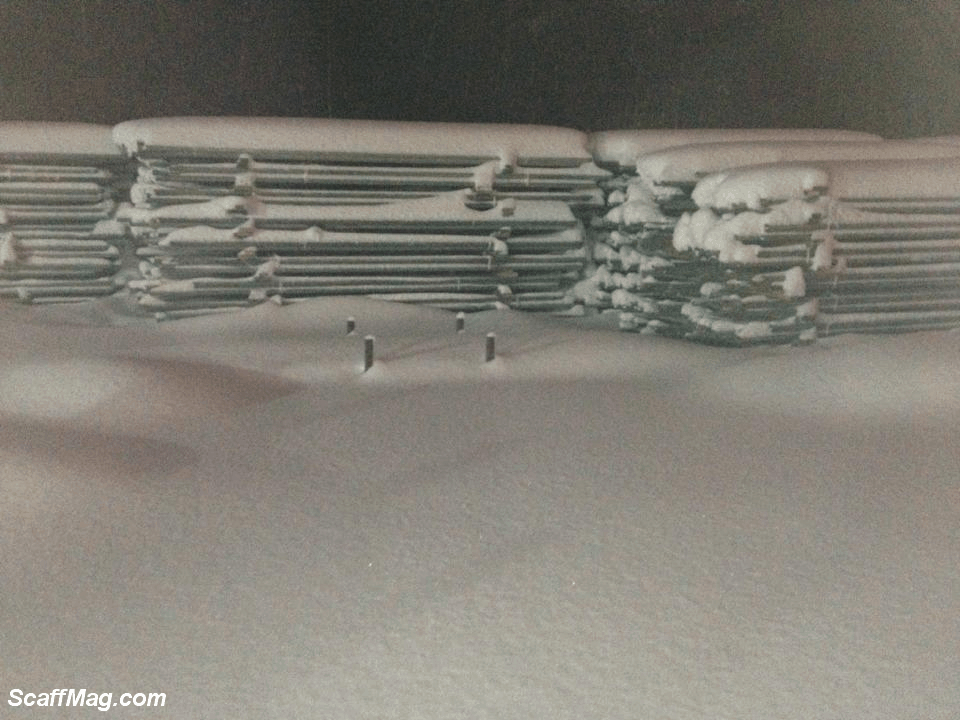

News Via: dorsetecho.co.uk LBG – London Bridge Train Station Scaffolding, London Bridge [Video]

httpv://youtu.be/O0URBInTWAg

LBG – London Bridge Train Station, London Bridge

A quick view of the Scaffold that i, and a good 20 other Scaffolders built during nights on London Bridge Train Station. Its MASSIVE! one of the longest scaffolds ive worked on, several hundred feet in.Builder impaled by scaffold tube after scaffolding collapses in London

Resident John Huxtable, who had taken the day off from his job as an animal warden for Tower Hamlets Council, said: “I was indoors when one of the men ran in wanting to know the door number because he’d dialled 999.

“I hadn’t actually heard the scaffolding collapse, but when I went into the back garden it was carnage. It’s not the normal thing you expect to see in your garden.

“One bloke had slipped off the roof as the scaffolding fell, but he was lucky because he just had a bruised ankle. It was actually his birthday, and some of the other men later joked he’d just had a big birthday bump.

“But a pole went in the shin of the man who’d been up on the scaffold – he had a round indent where the pole had been and he needed lots of stitches. When the ambulance came they were very concerned about his back too, but we later heard that was ok.”

The 54-yar-old rushed inside to grab dressings and bandaged the builder’s leg as best he could.

The worker, who is thought to be in his 50s, began shaking uncontrollably and John covered him with dust blankets to keep him warm before an ambulance arrived to take both builders to the Royal London Hospital in Whitechapel.

Fire crews and health and safety inspectors came to investigate the site, but the scaffolding was later re-erected and all the building work was finished by Friday.

June Morton, managing director of Old Ford Housing Association which is responsible for the property, said: “Thankfully, no-one was seriously hurt in this incident and no residents were affected.

“We take health and safety extremely seriously and have asked our contractor to carry out a full investigation which we will review carefully.”

News Via: eastlondonadvertiser.co.uk

Resident John Huxtable, who had taken the day off from his job as an animal warden for Tower Hamlets Council, said: “I was indoors when one of the men ran in wanting to know the door number because he’d dialled 999.

“I hadn’t actually heard the scaffolding collapse, but when I went into the back garden it was carnage. It’s not the normal thing you expect to see in your garden.

“One bloke had slipped off the roof as the scaffolding fell, but he was lucky because he just had a bruised ankle. It was actually his birthday, and some of the other men later joked he’d just had a big birthday bump.

“But a pole went in the shin of the man who’d been up on the scaffold – he had a round indent where the pole had been and he needed lots of stitches. When the ambulance came they were very concerned about his back too, but we later heard that was ok.”

The 54-yar-old rushed inside to grab dressings and bandaged the builder’s leg as best he could.

The worker, who is thought to be in his 50s, began shaking uncontrollably and John covered him with dust blankets to keep him warm before an ambulance arrived to take both builders to the Royal London Hospital in Whitechapel.

Fire crews and health and safety inspectors came to investigate the site, but the scaffolding was later re-erected and all the building work was finished by Friday.

June Morton, managing director of Old Ford Housing Association which is responsible for the property, said: “Thankfully, no-one was seriously hurt in this incident and no residents were affected.

“We take health and safety extremely seriously and have asked our contractor to carry out a full investigation which we will review carefully.”

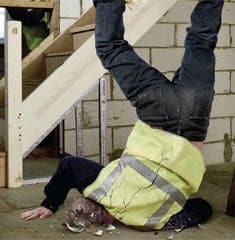

News Via: eastlondonadvertiser.co.uk The big freeze grips the scaffolding industry

Have you been affected by the snow ? let us know in the comments below.

This week in Scaffolding: Seven posts you may of missed

This Week In Scaffolding…

Cape secures 3 year extension to SABIC Contract at Teeside sites

Cape plc, the international provider of essential, non-mechanical support services to the energy and mineral resources sectors, announces the award of an extension to the existing multi-disciplinary site services contract for SABIC Petrochemicals at its Teesside sites.

This Week In Scaffolding…

Cape secures 3 year extension to SABIC Contract at Teeside sites

Cape plc, the international provider of essential, non-mechanical support services to the energy and mineral resources sectors, announces the award of an extension to the existing multi-disciplinary site services contract for SABIC Petrochemicals at its Teesside sites.

Social Reach- 0: Facebook Likes 3: Tweets

Billy Gavin the singing scaffolder: [Video] If you have been freezing your nuts off today maybe this little video will cheer you up. The video was uploaded to YouTube by a co-worker Matthew Oneill and shows Billy Gavin singing his own scaffolder song he wrote himself wrote this himselfSocial Reach- 80: Facebook Likes 5: Tweets

Safway Group Purchases Assets of Swing Staging, Inc. & Related Companies In a move to enhance its position in the New York metro area and expand its expertise and offerings in motorized access solutions, Safway Group is announcing the acquisition of the assets of Swing Staging, Inc.Social Reach- 22: Facebook Likes 5: Tweets

VIDEO: Horrific aftermath of helicopter clipping crane in London You probably have already heard or read about the horrific accident that happened this morning in London our thoughts are with the families of the people that were killed and the people injured. I thought I would post this video showing the scene just seconds after the helicopter crashed to ground.. A scary scene to say the least.Social Reach- 8: Facebook Likes 3: Tweets

BTS Group acquires OBO Scaffolding firm Suffolk-based overhead power line services contractor BTS Group has broadened its scope with the acquisition of OBO Scaffolding firm. BTS, which is based at Needham Market, provides engineering and tree management support to electricity distribution network operators, being responsible for about 24,000 miles of power lines around the country..Social Reach- 2: Facebook Likes 5: Tweets

Offshore Scaffolding Safety Alert Issued In Australia The NOPSEMA (National Offshore Petroleum Safety and Environmental Management Authority) issued a safety alert after the investigation found a list of failures after a major scaffolding incident on-board an offshore platform in Australia.Social Reach- Facebook likes: 90 Tweets: 6

48.3 Scaffold Design launch new “Scaffolding Insights” project 48.3 Scaffold Design company have launched an interesting project called “Scaffolding Insights” that aims to provide a ‘real-time’ review of the scaffolding industry today. 48.3 have compiled a short list of questions and asked industry professionals from all sectors to answer them – Scaffolders, Health & Safety Advisor’s, Design Engineers, Contracts Managers and Business Owners.Social Reach- Facebook likes: 12 Tweets: 13

Cape secures 3 year extension to SABIC Contract at Teeside sites

Let us know your thoughts in the comments below.

Billy Gavin the singing scaffolder: [Video]

httpv://youtu.be/UjZ7_5TSEMA

The singing scaffolder..

If you have been freezing your nuts off today maybe this little video will cheer you up. The video was uploaded to YouTube by a co-worker Matthew Oneill and shows Billy Gavin singing his own scaffolder song he wrote himself wrote this himself. As always let us know what you think in the comments below.

Safway Group Purchases Assets of Swing Staging, Inc. & Related Companies

companies – including Twin & Swing Scaffolding, Inc., Specialty Access Systems, LLC, Long Island City Trucking Corporation, and Scaffold King Inc. (collectively ‘Swing Staging’). The assets, including equipment, inventory and brand name of Swing Staging have been transferred to Swing Staging, LLC, a new Safway Group business entity.

“By acquiring the leading provider of suspended access solutions in the New York metro area, we will enhance our presence in this critical market,” explained Bill Hayes, Safway Group president and CEO. “Swing Staging has built a strong reputation in the area as the ‘go-to’ provider for a wide range of suspended access solutions. For more than 50 years, they have been known for offering the most extensive, high-quality rental fleet, and delivering the right equipment in pristine condition – whenever and wherever customers need it. Swing Staging is a strong addition to the Safway Group and will help grow our motorized access business.”

Swing Staging, Inc. was owned and operated by John Pantanelli, who had taken over the business from his father who founded it. Pantanelli will join Safway as vice president of Sales for Swing Staging, LLC.

“Being a part of a larger company that is a major national player, like the Safway Group, is an opportunity for us to move Swing Staging to the next level of development,” said Pantanelli. “We are looking forward to leveraging our operational and management expertise in the suspended access business to a much broader market.”

“We are excited about acquiring Swing Staging and having John join the team,” concluded Hayes. “This is a natural expansion of Safway’s motorized expertise and capabilities.”

About Safway Group

With more than 90 locations in the U.S. and Canada and a system of distributors across South America, Safway Group companies deliver efficient, high-performance multiservice solutions – The Smart Way™ – by collaborating, communicating and sharing resources. Offering experience and expertise in access, scaffolding, insulation, fireproofing, surface preparation and coatings, Safway Group companies include Redi Insulation; CL Coatings; Industrial Coatings & Fireproofing; Safway Atlantic; Safway Services; and Safway Services Canada. With the largest engineering staff, an exclusive project management system, award-winning safety excellence and a full line of products and services, Safway Group companies design and implement innovative, quality solutions at the lowest installed cost for projects of any size and scope. Safway has been an industry leader since 1936. Safway Group companies serve the petrochemical, oil and gas, power, refining, marine, manufacturing, transportation and commercial construction industries worldwide. For more information, visit www.safway.com.

companies – including Twin & Swing Scaffolding, Inc., Specialty Access Systems, LLC, Long Island City Trucking Corporation, and Scaffold King Inc. (collectively ‘Swing Staging’). The assets, including equipment, inventory and brand name of Swing Staging have been transferred to Swing Staging, LLC, a new Safway Group business entity.

“By acquiring the leading provider of suspended access solutions in the New York metro area, we will enhance our presence in this critical market,” explained Bill Hayes, Safway Group president and CEO. “Swing Staging has built a strong reputation in the area as the ‘go-to’ provider for a wide range of suspended access solutions. For more than 50 years, they have been known for offering the most extensive, high-quality rental fleet, and delivering the right equipment in pristine condition – whenever and wherever customers need it. Swing Staging is a strong addition to the Safway Group and will help grow our motorized access business.”

Swing Staging, Inc. was owned and operated by John Pantanelli, who had taken over the business from his father who founded it. Pantanelli will join Safway as vice president of Sales for Swing Staging, LLC.

“Being a part of a larger company that is a major national player, like the Safway Group, is an opportunity for us to move Swing Staging to the next level of development,” said Pantanelli. “We are looking forward to leveraging our operational and management expertise in the suspended access business to a much broader market.”

“We are excited about acquiring Swing Staging and having John join the team,” concluded Hayes. “This is a natural expansion of Safway’s motorized expertise and capabilities.”

About Safway Group

With more than 90 locations in the U.S. and Canada and a system of distributors across South America, Safway Group companies deliver efficient, high-performance multiservice solutions – The Smart Way™ – by collaborating, communicating and sharing resources. Offering experience and expertise in access, scaffolding, insulation, fireproofing, surface preparation and coatings, Safway Group companies include Redi Insulation; CL Coatings; Industrial Coatings & Fireproofing; Safway Atlantic; Safway Services; and Safway Services Canada. With the largest engineering staff, an exclusive project management system, award-winning safety excellence and a full line of products and services, Safway Group companies design and implement innovative, quality solutions at the lowest installed cost for projects of any size and scope. Safway has been an industry leader since 1936. Safway Group companies serve the petrochemical, oil and gas, power, refining, marine, manufacturing, transportation and commercial construction industries worldwide. For more information, visit www.safway.com.

![LBG – London Bridge Train Station Scaffolding, London Bridge [Video] LBG – London Bridge Train Station Scaffolding, London Bridge [Video]](https://scaffmag.com/wp-content/uploads/2013/01/vid1.png)

![Billy Gavin the singing scaffolder: [Video] Billy Gavin the singing scaffolder: [Video]](https://scaffmag.com/wp-content/uploads/2013/01/singingscaffolder.png)