George Roberts’ Finance Director Wins Prestigious Award

Mark Roach, Finance Director at George Roberts (North West) Ltd., has been named Finance Director of the Year in the £50–£120 million turnover category at the North West Regional FD Awards.

The awards at Liverpool’s Crowne Plaza on 14 November recognise the region’s top financial directors for their contributions to business growth and economic development. Mark stood out as one of the winners from the eight different categories among 28 finalists selected from 285 nominees.

Judges praised Mark’s leadership and the strategic foresight of George Roberts, highlighting the company’s ongoing commitment to quality and reliability.

Speaking about the accolade, Mark said: “This award reflects the hard work of the entire team at George Roberts. Together, we’ve redefined the standard for delivering reliable scaffolding solutions, ensuring peace of mind for our customers.”

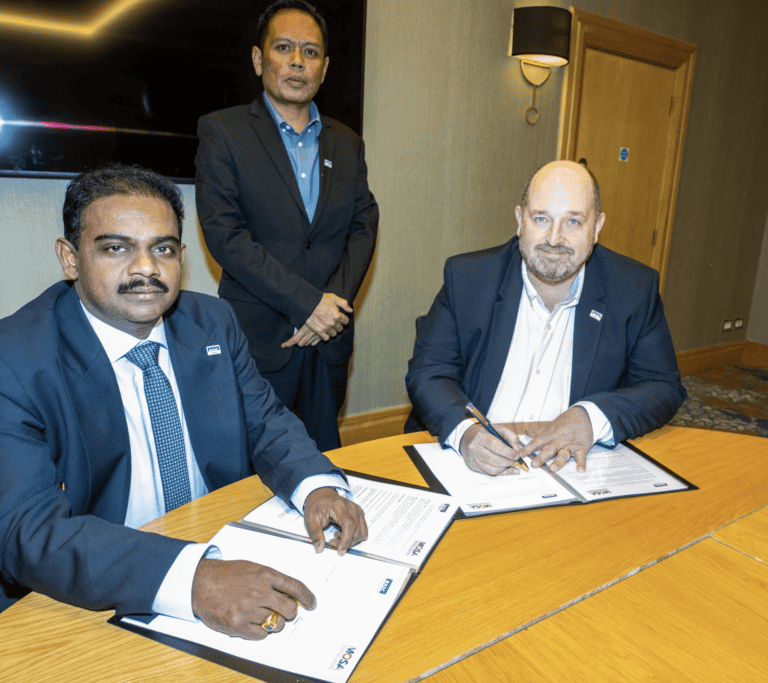

NASC Expands Global Reach with Agreement in Malaysia

The National Access & Scaffolding Confederation (NASC) has taken a significant step towards strengthening its global presence through a newly signed Memorandum of Understanding (MOU) with the Malaysian Occupational Scaffolding Association (MOSA).

The landmark agreement was formalised following the NASC’s Annual General Meeting in Belfast, marking a key milestone in international collaboration for the scaffolding industry.

The MOU reflects the close ties between the two organisations, both renowned for their leadership and commitment to advancing scaffolding standards.

The partnership aims to promote mutual expertise, share resources, and champion best practices in scaffolding, access, and rigging.

Speaking about the agreement, NASC CEO Clive Dickin highlighted its potential to drive innovation and elevate industry standards worldwide. “This partnership with MOSA, like our other MOUs, fosters a harmonious exchange of expertise and resources. It is a testament to both organisations’ shared vision of advancing the scaffolding industry to new heights.”

The agreement outlines plans for joint initiatives to improve safety, enhance training opportunities, and boost global recognition of industry standards. The collaboration aligns with NASC’s reputation as a pioneer in scaffolding standard-setting and MOSA’s respected position as a leader in Malaysia.

This is the latest in a series of international agreements signed by NASC over the past year, underscoring its commitment to global cooperation and the development of the scaffolding profession.

The signing marks the beginning of a new chapter for the scaffolding sector, as NASC and MOSA work together to shape a safer, more efficient, and innovative future.

Both organisations are inviting stakeholders and industry professionals to join their efforts in elevating the global scaffolding industry.

This agreement not only enhances the connection between two prominent scaffolding bodies but also highlights the importance of international partnerships in achieving progress and excellence in scaffolding.

Engineering History: The Scaffolding That’s Redefining Halifax’s Skyline

ScaffMag discovers the story behind one of the UK’s most ambitious scaffolding projects—a transformative refurbishment of the iconic former Halifax Building Society’s head office. Crossway Scaffolding has redefined what’s possible in the scaffolding industry with a blend of cutting-edge engineering, collaboration, and a deep respect for heritage.

The former Halifax Building Society’s head office, is a striking example of 1970s architectural ambition, which stands as a landmark in the cityscape. Initially built in 1974 and opened by the Queen, this listed building was one of the most advanced constructions of its time.

The building, whose design won a Royal Institute of British Architect’s Award, featured a futuristic, cantilevered structure supported by deep steel beams and concrete stair towers. The design gave the illusion of the building “hanging in mid-air,” a feature that still draws admiration today.

Beneath its bold exterior lies a fascinating history. With basements extending nearly 10 meters underground, the building originally housed a deed retrieval system that could deliver documents directly to desks at the press of a button—an innovation unheard of in its time.

Fast forward 50 years, and this architectural marvel required modernisation. It prompted a near to £100 million refurbishment to preserve its historical significance, while preparing it for a new chapter.

The building, whose design won a Royal Institute of British Architect’s Award, featured a futuristic, cantilevered structure supported by deep steel beams and concrete stair towers. The design gave the illusion of the building “hanging in mid-air,” a feature that still draws admiration today.

Beneath its bold exterior lies a fascinating history. With basements extending nearly 10 meters underground, the building originally housed a deed retrieval system that could deliver documents directly to desks at the press of a button—an innovation unheard of in its time.

Fast forward 50 years, and this architectural marvel required modernisation. It prompted a near to £100 million refurbishment to preserve its historical significance, while preparing it for a new chapter.

Taking on a project of this scale and complexity was no small feat. The head office needed a complete overhaul of its glazing system, with glass panels weighing up to half a tonne each. Each panel had to be removed and replaced delicately without compromising the building’s structural integrity or disrupting its iconic appearance.

“The building itself posed unique challenges,” explained Alan Slater, Head of Technical & Product Support at TRAD UK. “The scaffold couldn’t be tied into the structure until it reached circa the 20 metre high mark, meaning everything below had to be buttressed. With roads and public walkways adjacent, this required precise engineering and innovative solutions.”

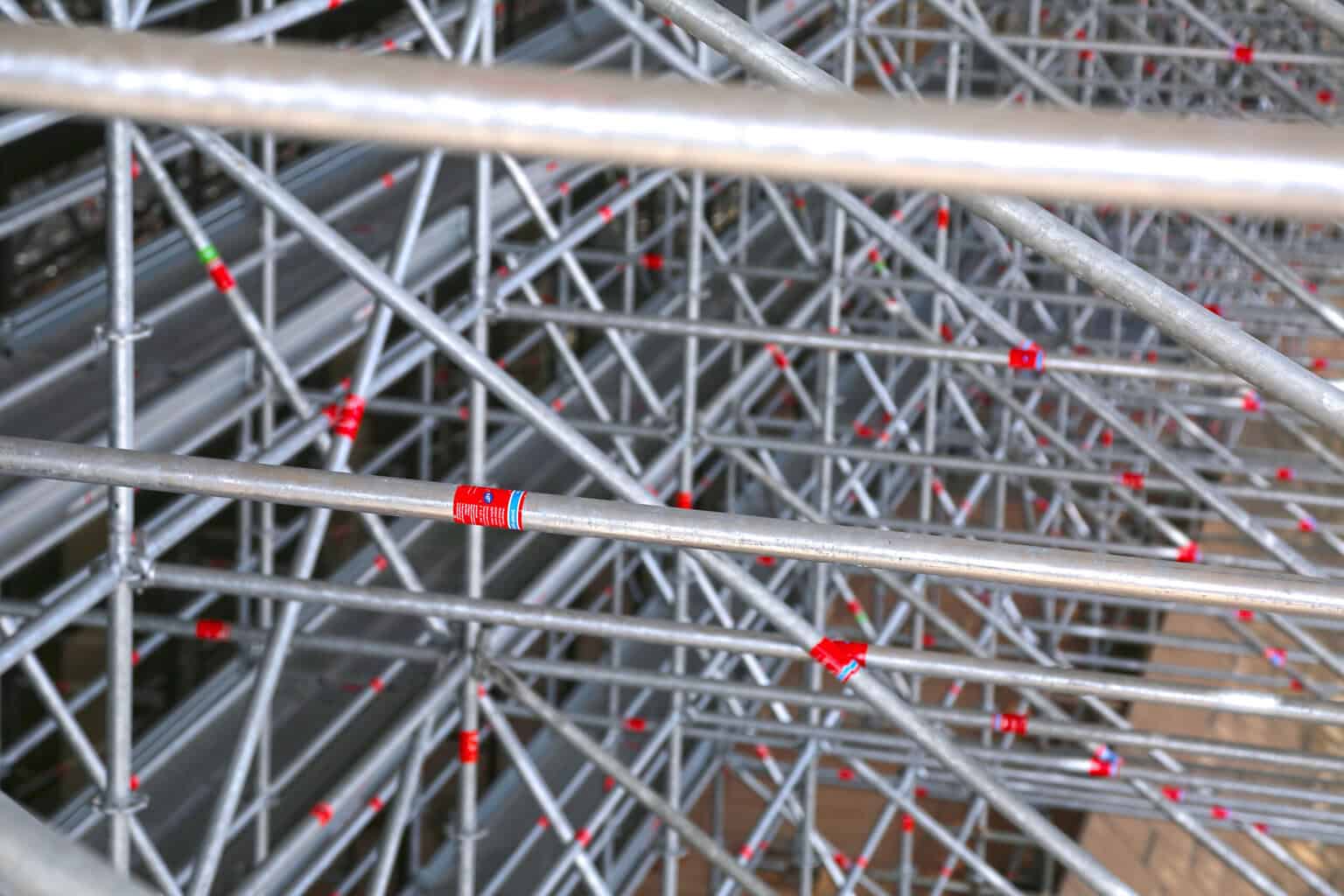

Crossway Scaffolding installed 20,000 square meters of Plettac Metrix System Scaffold, a cutting-edge system selected for its efficiency and adaptability.

In partnership with TRAD UK, the company invested over £1 million in scaffolding materials. This was Crossway’s largest project using the Plettac Metrix system, and its success left a lasting impression.

Crossway’s Contract Manager Luke Schofield highlighted the system’s advantages: “One of our most seasoned scaffolders, who had been using tube and fitting for 25 years, didn’t want to go back after working with this system. The precision and speed it offers are game-changers.”

Taking on a project of this scale and complexity was no small feat. The head office needed a complete overhaul of its glazing system, with glass panels weighing up to half a tonne each. Each panel had to be removed and replaced delicately without compromising the building’s structural integrity or disrupting its iconic appearance.

“The building itself posed unique challenges,” explained Alan Slater, Head of Technical & Product Support at TRAD UK. “The scaffold couldn’t be tied into the structure until it reached circa the 20 metre high mark, meaning everything below had to be buttressed. With roads and public walkways adjacent, this required precise engineering and innovative solutions.”

Crossway Scaffolding installed 20,000 square meters of Plettac Metrix System Scaffold, a cutting-edge system selected for its efficiency and adaptability.

In partnership with TRAD UK, the company invested over £1 million in scaffolding materials. This was Crossway’s largest project using the Plettac Metrix system, and its success left a lasting impression.

Crossway’s Contract Manager Luke Schofield highlighted the system’s advantages: “One of our most seasoned scaffolders, who had been using tube and fitting for 25 years, didn’t want to go back after working with this system. The precision and speed it offers are game-changers.”

The project demanded creativity and precision, starting with a reworking of the initial designs. Crossway was initially provided with 73 scaffold drawings but ultimately required 174 due to the complexity of the structure.

Working in partnership with Manchester-based Buckley Design Solutions to redesign key elements, utilising advanced bracing techniques, which saved both time and resources.

The installation of a 350-meter NIKO rail system around the building was another standout feature. This system supported the weight of the massive glass panels, which were transported along a 2.5-meter-wide scaffold walkway to hoist locations. The operation was seamless, aided by meticulous planning and the use of innovative equipment described as “sucker machines” for the glass.

The project demanded creativity and precision, starting with a reworking of the initial designs. Crossway was initially provided with 73 scaffold drawings but ultimately required 174 due to the complexity of the structure.

Working in partnership with Manchester-based Buckley Design Solutions to redesign key elements, utilising advanced bracing techniques, which saved both time and resources.

The installation of a 350-meter NIKO rail system around the building was another standout feature. This system supported the weight of the massive glass panels, which were transported along a 2.5-meter-wide scaffold walkway to hoist locations. The operation was seamless, aided by meticulous planning and the use of innovative equipment described as “sucker machines” for the glass.

The partnership between Crossway and TRAD UK was a cornerstone of the project’s success. With regular site visits and constant communication, both companies worked together to address challenges and ensure smooth progress.

“We’ve been working with Crossway for over 25 years,” said Alan Slater, Head of Technical & Product Support at TRAD UK. “The mutual trust and open dialogue between our teams made all the difference. This level of collaboration and partnership is what complex projects like this need.”

The partnership between Crossway and TRAD UK was a cornerstone of the project’s success. With regular site visits and constant communication, both companies worked together to address challenges and ensure smooth progress.

“We’ve been working with Crossway for over 25 years,” said Alan Slater, Head of Technical & Product Support at TRAD UK. “The mutual trust and open dialogue between our teams made all the difference. This level of collaboration and partnership is what complex projects like this need.”

The proximity of Crossway’s base and TRAD UK’s Leeds depot, just 5 miles and 20 miles from the site respectively, also played a vital role in minimising environmental impact. “Every delivery was carefully coordinated,” Stewart Quinn, TRAD UK’s Regional Director added. “This approach allowed us to collectively reduce our carbon footprint while keeping the project on schedule.”

The proximity of Crossway’s base and TRAD UK’s Leeds depot, just 5 miles and 20 miles from the site respectively, also played a vital role in minimising environmental impact. “Every delivery was carefully coordinated,” Stewart Quinn, TRAD UK’s Regional Director added. “This approach allowed us to collectively reduce our carbon footprint while keeping the project on schedule.”

As the former Halifax Building Society’s head office undergoes its transformation, the project stands as a testament to Crossway Scaffolding’s ingenuity and dedication. By blending advanced engineering, innovative design, and a commitment to people and the planet, Crossway has helped in the restoration of an architectural icon and set a new benchmark for scaffolding excellence.

As the former Halifax Building Society’s head office undergoes its transformation, the project stands as a testament to Crossway Scaffolding’s ingenuity and dedication. By blending advanced engineering, innovative design, and a commitment to people and the planet, Crossway has helped in the restoration of an architectural icon and set a new benchmark for scaffolding excellence.

This scaffolding excellence has also recently been recognised `by the National Access and Scaffolding Confederation (NASC), with the project being a finalist in the Project of the Year (Major) category at their recent annual awards ceremony in Belfast, which is a true testament to the dedication of all involved, in making such a complex and innovative scheme work.

“This was a monumental task, but our team rose to the occasion,” said Steve Fearnehough. “It’s a proud moment for us to see this project come together so beautifully.”

With the external refurbishment nearing completion, this isn’t just another scaffolding job—it’s a masterclass in innovation, collaboration, and community-focused construction, a legacy that will endure for years to come.

This scaffolding excellence has also recently been recognised `by the National Access and Scaffolding Confederation (NASC), with the project being a finalist in the Project of the Year (Major) category at their recent annual awards ceremony in Belfast, which is a true testament to the dedication of all involved, in making such a complex and innovative scheme work.

“This was a monumental task, but our team rose to the occasion,” said Steve Fearnehough. “It’s a proud moment for us to see this project come together so beautifully.”

With the external refurbishment nearing completion, this isn’t just another scaffolding job—it’s a masterclass in innovation, collaboration, and community-focused construction, a legacy that will endure for years to come.

The building, whose design won a Royal Institute of British Architect’s Award, featured a futuristic, cantilevered structure supported by deep steel beams and concrete stair towers. The design gave the illusion of the building “hanging in mid-air,” a feature that still draws admiration today.

Beneath its bold exterior lies a fascinating history. With basements extending nearly 10 meters underground, the building originally housed a deed retrieval system that could deliver documents directly to desks at the press of a button—an innovation unheard of in its time.

Fast forward 50 years, and this architectural marvel required modernisation. It prompted a near to £100 million refurbishment to preserve its historical significance, while preparing it for a new chapter.

The building, whose design won a Royal Institute of British Architect’s Award, featured a futuristic, cantilevered structure supported by deep steel beams and concrete stair towers. The design gave the illusion of the building “hanging in mid-air,” a feature that still draws admiration today.

Beneath its bold exterior lies a fascinating history. With basements extending nearly 10 meters underground, the building originally housed a deed retrieval system that could deliver documents directly to desks at the press of a button—an innovation unheard of in its time.

Fast forward 50 years, and this architectural marvel required modernisation. It prompted a near to £100 million refurbishment to preserve its historical significance, while preparing it for a new chapter.

The Challenge: Balancing History and Modernity

Taking on a project of this scale and complexity was no small feat. The head office needed a complete overhaul of its glazing system, with glass panels weighing up to half a tonne each. Each panel had to be removed and replaced delicately without compromising the building’s structural integrity or disrupting its iconic appearance.

“The building itself posed unique challenges,” explained Alan Slater, Head of Technical & Product Support at TRAD UK. “The scaffold couldn’t be tied into the structure until it reached circa the 20 metre high mark, meaning everything below had to be buttressed. With roads and public walkways adjacent, this required precise engineering and innovative solutions.”

Crossway Scaffolding installed 20,000 square meters of Plettac Metrix System Scaffold, a cutting-edge system selected for its efficiency and adaptability.

In partnership with TRAD UK, the company invested over £1 million in scaffolding materials. This was Crossway’s largest project using the Plettac Metrix system, and its success left a lasting impression.

Crossway’s Contract Manager Luke Schofield highlighted the system’s advantages: “One of our most seasoned scaffolders, who had been using tube and fitting for 25 years, didn’t want to go back after working with this system. The precision and speed it offers are game-changers.”

Taking on a project of this scale and complexity was no small feat. The head office needed a complete overhaul of its glazing system, with glass panels weighing up to half a tonne each. Each panel had to be removed and replaced delicately without compromising the building’s structural integrity or disrupting its iconic appearance.

“The building itself posed unique challenges,” explained Alan Slater, Head of Technical & Product Support at TRAD UK. “The scaffold couldn’t be tied into the structure until it reached circa the 20 metre high mark, meaning everything below had to be buttressed. With roads and public walkways adjacent, this required precise engineering and innovative solutions.”

Crossway Scaffolding installed 20,000 square meters of Plettac Metrix System Scaffold, a cutting-edge system selected for its efficiency and adaptability.

In partnership with TRAD UK, the company invested over £1 million in scaffolding materials. This was Crossway’s largest project using the Plettac Metrix system, and its success left a lasting impression.

Crossway’s Contract Manager Luke Schofield highlighted the system’s advantages: “One of our most seasoned scaffolders, who had been using tube and fitting for 25 years, didn’t want to go back after working with this system. The precision and speed it offers are game-changers.”

Innovative Redesigns

The project demanded creativity and precision, starting with a reworking of the initial designs. Crossway was initially provided with 73 scaffold drawings but ultimately required 174 due to the complexity of the structure.

Working in partnership with Manchester-based Buckley Design Solutions to redesign key elements, utilising advanced bracing techniques, which saved both time and resources.

The installation of a 350-meter NIKO rail system around the building was another standout feature. This system supported the weight of the massive glass panels, which were transported along a 2.5-meter-wide scaffold walkway to hoist locations. The operation was seamless, aided by meticulous planning and the use of innovative equipment described as “sucker machines” for the glass.

The project demanded creativity and precision, starting with a reworking of the initial designs. Crossway was initially provided with 73 scaffold drawings but ultimately required 174 due to the complexity of the structure.

Working in partnership with Manchester-based Buckley Design Solutions to redesign key elements, utilising advanced bracing techniques, which saved both time and resources.

The installation of a 350-meter NIKO rail system around the building was another standout feature. This system supported the weight of the massive glass panels, which were transported along a 2.5-meter-wide scaffold walkway to hoist locations. The operation was seamless, aided by meticulous planning and the use of innovative equipment described as “sucker machines” for the glass.

Supporting the Community

Crossway’s commitment to social value was evident throughout the project. Five apprentices worked on-site, three of whom lived within 15 minutes of the project. This not only fostered local employment but also provided invaluable hands-on experience. “This is the kind of project that shapes careers,” said Steve Fearnehough, Managing Director at Crossway. “Our apprentices gained exposure to some of the most advanced scaffolding techniques and learned to adapt to the unique challenges of a listed building.”Collaboration at the Core

The partnership between Crossway and TRAD UK was a cornerstone of the project’s success. With regular site visits and constant communication, both companies worked together to address challenges and ensure smooth progress.

“We’ve been working with Crossway for over 25 years,” said Alan Slater, Head of Technical & Product Support at TRAD UK. “The mutual trust and open dialogue between our teams made all the difference. This level of collaboration and partnership is what complex projects like this need.”

The partnership between Crossway and TRAD UK was a cornerstone of the project’s success. With regular site visits and constant communication, both companies worked together to address challenges and ensure smooth progress.

“We’ve been working with Crossway for over 25 years,” said Alan Slater, Head of Technical & Product Support at TRAD UK. “The mutual trust and open dialogue between our teams made all the difference. This level of collaboration and partnership is what complex projects like this need.”

The proximity of Crossway’s base and TRAD UK’s Leeds depot, just 5 miles and 20 miles from the site respectively, also played a vital role in minimising environmental impact. “Every delivery was carefully coordinated,” Stewart Quinn, TRAD UK’s Regional Director added. “This approach allowed us to collectively reduce our carbon footprint while keeping the project on schedule.”

The proximity of Crossway’s base and TRAD UK’s Leeds depot, just 5 miles and 20 miles from the site respectively, also played a vital role in minimising environmental impact. “Every delivery was carefully coordinated,” Stewart Quinn, TRAD UK’s Regional Director added. “This approach allowed us to collectively reduce our carbon footprint while keeping the project on schedule.”

Environmental Responsibility: A Greener Future

Crossway implemented Just-In-Time deliveries, reducing transport emissions and storage demands. Additionally, using steel decks instead of traditional timber further highlighted the company’s commitment to sustainability. As the former Halifax Building Society’s head office undergoes its transformation, the project stands as a testament to Crossway Scaffolding’s ingenuity and dedication. By blending advanced engineering, innovative design, and a commitment to people and the planet, Crossway has helped in the restoration of an architectural icon and set a new benchmark for scaffolding excellence.

As the former Halifax Building Society’s head office undergoes its transformation, the project stands as a testament to Crossway Scaffolding’s ingenuity and dedication. By blending advanced engineering, innovative design, and a commitment to people and the planet, Crossway has helped in the restoration of an architectural icon and set a new benchmark for scaffolding excellence.

This scaffolding excellence has also recently been recognised `by the National Access and Scaffolding Confederation (NASC), with the project being a finalist in the Project of the Year (Major) category at their recent annual awards ceremony in Belfast, which is a true testament to the dedication of all involved, in making such a complex and innovative scheme work.

“This was a monumental task, but our team rose to the occasion,” said Steve Fearnehough. “It’s a proud moment for us to see this project come together so beautifully.”

With the external refurbishment nearing completion, this isn’t just another scaffolding job—it’s a masterclass in innovation, collaboration, and community-focused construction, a legacy that will endure for years to come.

This scaffolding excellence has also recently been recognised `by the National Access and Scaffolding Confederation (NASC), with the project being a finalist in the Project of the Year (Major) category at their recent annual awards ceremony in Belfast, which is a true testament to the dedication of all involved, in making such a complex and innovative scheme work.

“This was a monumental task, but our team rose to the occasion,” said Steve Fearnehough. “It’s a proud moment for us to see this project come together so beautifully.”

With the external refurbishment nearing completion, this isn’t just another scaffolding job—it’s a masterclass in innovation, collaboration, and community-focused construction, a legacy that will endure for years to come. Scaffolding Christmas Cheer at Former Bristol Royal Infirmary

A dazzling Christmas light display at the Bristol Royal Infirmary (BRI) has brought festive cheer to central Bristol, raising vital funds for The Grand Appeal on behalf of Bristol Children’s Hospital.

Organised by scaffolding contractors Shield Services Group, the lights adorn the historic former BRI building and were illuminated during a special event.

Former Premier League player and manager Ian Holloway joined the celebrations, switching on the lights to the delight of onlookers, including children from the hospital directly opposite.

The event is part of the “Shine Bright for Bristol Children’s Hospital” campaign, which supports the hospital’s innovative Patient Hotel. This groundbreaking facility, the first of its kind in the UK, offers families a comforting “home away from home” just moments from the hospital.

With therapy spaces and practical support services, it provides vital emotional and logistical help to families navigating their children’s hospital care.

So far, the campaign has raised an impressive £1,950, just shy of its £2,000 target, thanks to the generosity of over 70 supporters.

Organisers hope the display will inspire further donations to help keep families together and ensure children receive the care they need.

Ian Holloway said: “It’s an honour to be part of something so meaningful. This is what Christmas is all about – bringing light and hope to families who need it most.”

Luke House Shield Services Group Chairman expressed gratitude to all involved: “We’re thrilled to contribute to such an amazing cause. The lights are not just a festive gesture; they’re a beacon of hope for the families and children in the hospital.”

To support the campaign and help transform the lives of families at Bristol Children’s Hospital, donations can be made via the JustGiving page: Shine Bright for Bristol Children’s Hospital.

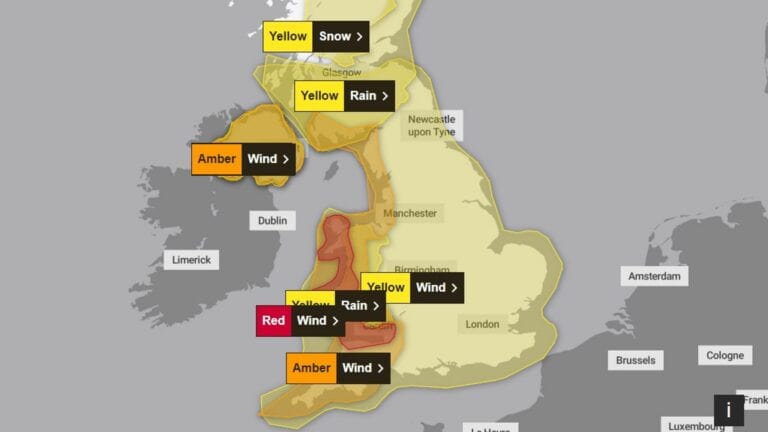

UK Braced for Storm Darragh as 90mph Winds Trigger Red Warning

The Met Office has issued a rare red weather warning as Storm Darragh prepares to batter parts of the UK with gusts of up to 90mph.

Coastal areas in Wales and the southwest of England are in the firing line, with the warning in place from 3 am to 11 am on Saturday.

The storm is expected to bring “damaging winds” that could cause major disruption to transport, power supplies, and construction sites. Scaffolding firms in the affected regions are being urged to take extra precautions to secure structures and prioritise safety.

Danger to Life and Property

According to the Met Office, the intense winds pose a “danger to life” due to flying debris, while large waves are expected to hammer exposed coastlines. Gusts could be particularly hazardous in areas like the Bristol Channel, where funnelling winds may intensify the storm’s impact. Irish forecasters at Met Éireann have also issued a red wind warning for parts of the west coast of Ireland, including Galway, Mayo, and Donegal, as the storm barrels across the Irish Sea overnight.Amber and Yellow Warnings Add to Chaos

Elsewhere, amber warnings remain in place for much of Wales, Northern Ireland, and parts of Scotland, with yellow alerts covering a wider area. Heavy rain is also forecast for some regions, compounding the risk of flooding and site disruptions. Storm Darragh arrives just weeks after Storm Bert, which caused chaos in several parts of the UK. For those in the scaffolding trade, this means another challenging period as sites brace for potentially severe weather conditions.How to Prepare

For scaffolding contractors, ensuring the safety of workers and the public is paramount. Check that all scaffolds are properly tied and braced, remove any loose materials or tools from structures. The Met Office advises that “extremely strong winds will ease from late morning, but it will remain very windy into the evening.” If work is planned on exposed sites, it may be worth considering a delay until conditions improve.Stay Safe and Stay Prepared

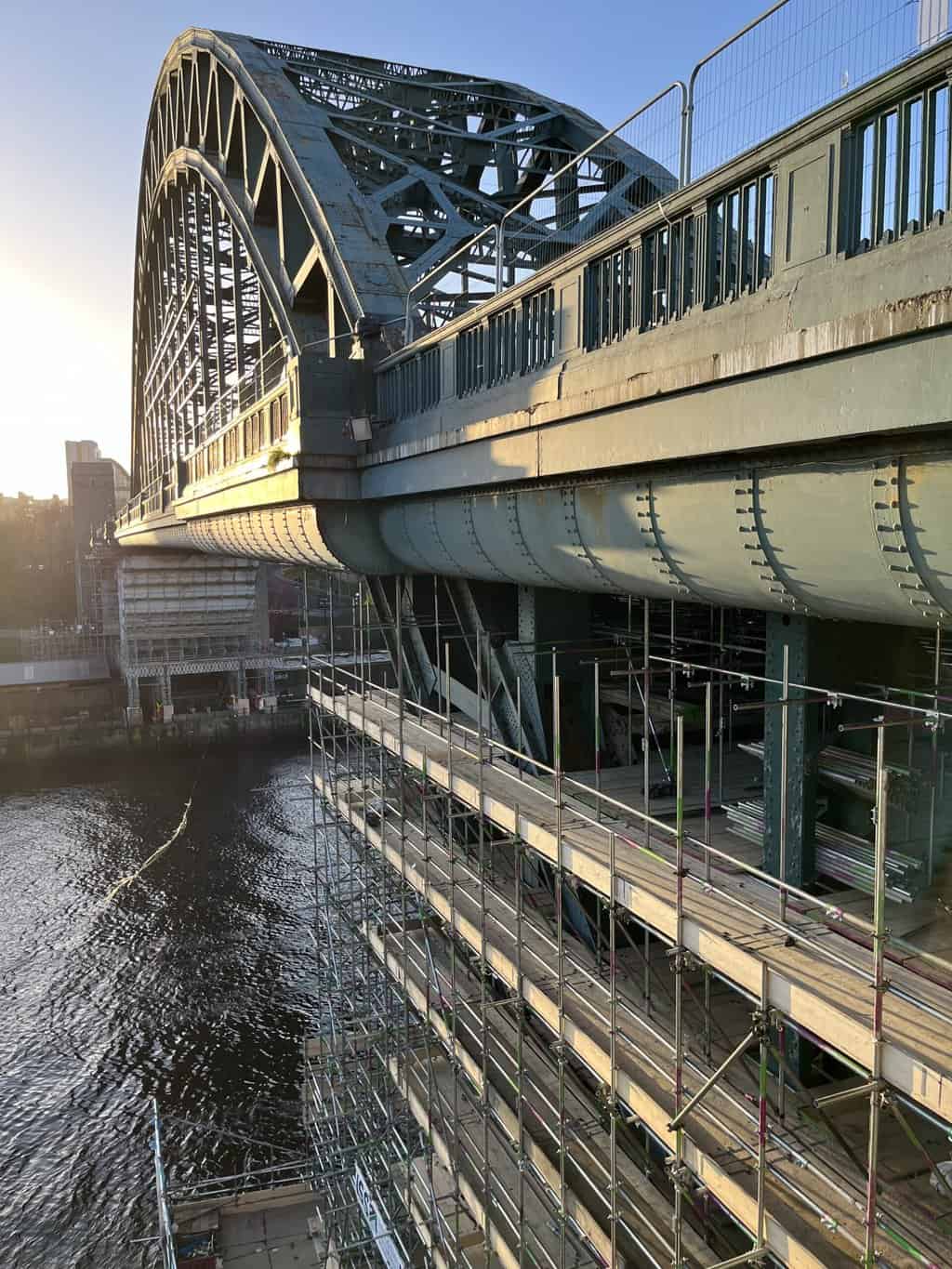

Storm Darragh serves as a stark reminder of the power of nature and the importance of thorough preparation. For those in the scaffolding industry, it’s critical to double down on safety measures to prevent accidents and damage during these challenging conditions. Keep an eye on the latest forecasts, follow safety guidance, and, above all, stay safe.Tyne Bridge Restoration Enters Next Phase with Scaffolding Across River

Work on the iconic Tyne Bridge has taken a significant step forward as scaffolding is set to span the River Tyne in the next phase of its comprehensive restoration project.

The ambitious operation follows the successful installation of scaffolding adjacent to the Newcastle tower. Now, Esh Construction, in collaboration with specialist contractor Infrastructure Site Solutions (ISS), is moving ahead with an underdeck scaffold structure that will stretch from the Newcastle tower to its counterpart on the Gateshead side, 84 feet above the river.

This latest phase will see operatives working underneath the bridge, securely fastened with safety harnesses and supported by a safety boat stationed below for emergency rescues.

The 100-metre-long by 11-metre-wide scaffold will allow for detailed inspections beneath the bridge, paving the way for subsequent cleaning, grit blasting, and repainting. To ensure safety and minimise environmental impact, the structure will be enclosed in protective sheeting throughout the work.

Gareth Dawson, Project Manager for Esh Construction, highlighted the progress made:

“A programme resequencing exercise has allowed the underdeck scaffolding to be actioned earlier than originally planned. The change in programme will provide efficiencies throughout the project given the scale of the repair and restoration work to be delivered – this scheme is far more than ‘just a lick of paint.’”

The restoration, commissioned by Newcastle and Gateshead councils, is a monumental undertaking. Over four years, it will use more than 180 miles of scaffolding tubes—enough to stretch from Newcastle to Dundee—and over 13,000 tonnes of scaffolding components, equivalent to the weight of six London Eyes.

The work is divided into 20 phases due to the bridge’s weight restrictions.

Cllr Dr Juna Staithan, Newcastle City Council’s cabinet member for Climate Change and Transport, expressed her enthusiasm for the project:

“I am really delighted with the progress on site as we restore this icon to its former glory. Everyone involved is hugely proud and passionate to be part of this major project to preserve this much-loved icon for future generations.”

The restoration, commissioned by Newcastle and Gateshead councils, is a monumental undertaking. Over four years, it will use more than 180 miles of scaffolding tubes—enough to stretch from Newcastle to Dundee—and over 13,000 tonnes of scaffolding components, equivalent to the weight of six London Eyes.

The work is divided into 20 phases due to the bridge’s weight restrictions.

Cllr Dr Juna Staithan, Newcastle City Council’s cabinet member for Climate Change and Transport, expressed her enthusiasm for the project:

“I am really delighted with the progress on site as we restore this icon to its former glory. Everyone involved is hugely proud and passionate to be part of this major project to preserve this much-loved icon for future generations.”

The restoration hit a major milestone in October when scaffolding around the Gateshead tower was dismantled, revealing the first section of blasted, repaired, and repainted steel.

With over 1,000 repairs planned, the Tyne Bridge restoration is as much about preserving history as it is about modernising infrastructure. As one of the North East’s most recognisable landmarks, the bridge will continue to be a symbol of regional pride for generations to come.

The restoration hit a major milestone in October when scaffolding around the Gateshead tower was dismantled, revealing the first section of blasted, repaired, and repainted steel.

With over 1,000 repairs planned, the Tyne Bridge restoration is as much about preserving history as it is about modernising infrastructure. As one of the North East’s most recognisable landmarks, the bridge will continue to be a symbol of regional pride for generations to come.

The restoration, commissioned by Newcastle and Gateshead councils, is a monumental undertaking. Over four years, it will use more than 180 miles of scaffolding tubes—enough to stretch from Newcastle to Dundee—and over 13,000 tonnes of scaffolding components, equivalent to the weight of six London Eyes.

The work is divided into 20 phases due to the bridge’s weight restrictions.

Cllr Dr Juna Staithan, Newcastle City Council’s cabinet member for Climate Change and Transport, expressed her enthusiasm for the project:

“I am really delighted with the progress on site as we restore this icon to its former glory. Everyone involved is hugely proud and passionate to be part of this major project to preserve this much-loved icon for future generations.”

The restoration, commissioned by Newcastle and Gateshead councils, is a monumental undertaking. Over four years, it will use more than 180 miles of scaffolding tubes—enough to stretch from Newcastle to Dundee—and over 13,000 tonnes of scaffolding components, equivalent to the weight of six London Eyes.

The work is divided into 20 phases due to the bridge’s weight restrictions.

Cllr Dr Juna Staithan, Newcastle City Council’s cabinet member for Climate Change and Transport, expressed her enthusiasm for the project:

“I am really delighted with the progress on site as we restore this icon to its former glory. Everyone involved is hugely proud and passionate to be part of this major project to preserve this much-loved icon for future generations.”

Major Repairs and a Historic Paint Job

Beyond the scaffolding, restoration work is advancing inside the bridge’s deck void, where three of the 36 steel hangers supporting the carriageway are set to undergo strengthening. Repairs also include steel, concrete, stonework, and masonry restoration, along with drainage improvements, deck waterproofing, and parapet protection. One of the restoration’s crowning achievements will be the bridge’s new coat of paint in the historic ‘Hollybush’ shade, chosen for its resemblance to the original colour. The new paint system is designed for durability and will protect the bridge for up to 30 years against the harsh conditions of the Tyne Valley gorge. The restoration hit a major milestone in October when scaffolding around the Gateshead tower was dismantled, revealing the first section of blasted, repaired, and repainted steel.

With over 1,000 repairs planned, the Tyne Bridge restoration is as much about preserving history as it is about modernising infrastructure. As one of the North East’s most recognisable landmarks, the bridge will continue to be a symbol of regional pride for generations to come.

The restoration hit a major milestone in October when scaffolding around the Gateshead tower was dismantled, revealing the first section of blasted, repaired, and repainted steel.

With over 1,000 repairs planned, the Tyne Bridge restoration is as much about preserving history as it is about modernising infrastructure. As one of the North East’s most recognisable landmarks, the bridge will continue to be a symbol of regional pride for generations to come. PERI Wins NASC Product of the Year Award

PERI has been named winner of the Product of the Year award at the Scaffolding Excellence Awards, hosted by the NASC in Belfast.

The company received the accolade for its PERI UP Cladding system, which has been recognised for its innovation and versatility since its launch in the UK earlier this year.

PERI competed against two other finalists in the category, with judges praising the cladding system’s design and its potential to transform scaffolding practices.

The PERI UP Cladding system has been widely adopted for its flexibility, serving as a protective enclosure, temporary roofing system, and hoarding for building sites.

Its lightweight panels, fast assembly process, and adaptability have made it popular among contractors, while its safety features, including dust and noise containment, have been welcomed by those working in public-facing projects.

The Product of the Year award highlights PERI’s commitment to innovation in the scaffolding sector.

“Our system provides scaffolding contractors with more choices, increased efficiency, and unparalleled adaptability. It’s an honour to be recognised for these contributions,” Stratford added.

The Product of the Year award highlights PERI’s commitment to innovation in the scaffolding sector.

“Our system provides scaffolding contractors with more choices, increased efficiency, and unparalleled adaptability. It’s an honour to be recognised for these contributions,” Stratford added.

A Standout Exhibit at ScaffEx24

PERI’s success at the awards coincided with a strong showing at ScaffEx24, the NASC’s first-ever conference and exhibition. The company’s 24-square-metre stand, which was one of the largest at the event, showcased a range of products, including the award-winning PERI UP Cladding system. The display featured a custom-built viewing deck, allowing attendees to experience the system up close. Charles Stratford, Business Development Manager for PERI UP, described the event as a major success. “ScaffEx24 was a fantastic opportunity to reconnect with colleagues and showcase the capabilities of our scaffolding systems. Winning Product of the Year was a highlight and reinforces the benefits our cladding system offers to the industry.”Enhancing Safety and Efficiency

The PERI UP Cladding system is designed to improve safety for scaffolders, contractors, and the public. It helps reduce the risks associated with falling debris and dust pollution while containing noise from construction sites. Its seamless integration with PERI scaffolding systems has made it a valuable addition to construction and public event projects across the UK. The Product of the Year award highlights PERI’s commitment to innovation in the scaffolding sector.

“Our system provides scaffolding contractors with more choices, increased efficiency, and unparalleled adaptability. It’s an honour to be recognised for these contributions,” Stratford added.

The Product of the Year award highlights PERI’s commitment to innovation in the scaffolding sector.

“Our system provides scaffolding contractors with more choices, increased efficiency, and unparalleled adaptability. It’s an honour to be recognised for these contributions,” Stratford added. IE Access Tackles Bridge Repairs with PERI UP

North East Lincolnshire sees innovative scaffolding solutions for essential maintenance work.

Maintenance work is in full swing on the A180 Gilbey Road Bridge in North East Lincolnshire, with proactive repairs aiming to prevent future closures and extensive repair needs.

The project, focused on refurbishing steel beams and replacing bridge bearings, is critical to ensuring the structure can continue to handle the load of heavy traffic for years to come.

Worksop-based IE Access was appointed to deliver a full temporary access solution beneath the bridge to enable these essential repairs. The scaffolding contractor opted for the PERI UP Flex system, a modular scaffolding solution praised for its adaptability and efficiency.

Speed and safety were key priorities. By using the PERI UP Flex system, IE Access was able to create a tailored scaffolding solution that simplified alignment with the river’s course. The system’s modular design allowed scaffolders to step the scaffolding in and out with ease, using fewer components to reduce installation time and material handling.

Speed and safety were key priorities. By using the PERI UP Flex system, IE Access was able to create a tailored scaffolding solution that simplified alignment with the river’s course. The system’s modular design allowed scaffolders to step the scaffolding in and out with ease, using fewer components to reduce installation time and material handling.

Charlie Wheeler, Managing Director of IE Access, praised the PERI UP system for its practicality. “Minimal standard components from the PERI UP range made work easier for our scaffolders. We didn’t have to manage numerous small parts and fittings or worry about safety while working above the public walkway. It also minimised material handling during construction,” he said.

Charlie Wheeler, Managing Director of IE Access, praised the PERI UP system for its practicality. “Minimal standard components from the PERI UP range made work easier for our scaffolders. We didn’t have to manage numerous small parts and fittings or worry about safety while working above the public walkway. It also minimised material handling during construction,” he said.

Innovative Solutions for Complex Challenges

Spanning five sections of the bridge, the project presented several logistical challenges, including a river, a public walkway, and a complex site layout with structures running in different directions. Careful pre-planning and close collaboration between VSL’s temporary works team, IE Access, and PERI’s project team ensured an efficient scaffolding solution that integrated seamlessly with the site’s requirements. Speed and safety were key priorities. By using the PERI UP Flex system, IE Access was able to create a tailored scaffolding solution that simplified alignment with the river’s course. The system’s modular design allowed scaffolders to step the scaffolding in and out with ease, using fewer components to reduce installation time and material handling.

Speed and safety were key priorities. By using the PERI UP Flex system, IE Access was able to create a tailored scaffolding solution that simplified alignment with the river’s course. The system’s modular design allowed scaffolders to step the scaffolding in and out with ease, using fewer components to reduce installation time and material handling.

Public Safety a Priority

Public access under the bridge was maintained throughout the project, with a pedestrian tunnel constructed using the PERI UP system. This provided a safe route for pedestrians while shielding them from overhead repair work. The modular scaffolding’s wide bay sizes and minimal components significantly reduced safety risks associated with traditional scaffolding, such as falling fixings and smaller parts during installation. These features also accelerated the build, as fewer components meant less time spent on fastening and handling operations.Flexible Adjustments Mid-Project

Even after the scaffolding was in place, the PERI UP system demonstrated versatility. IE Access adapted the structure to meet revised leg load requirements on the pavement without dismantling or delaying the project, showcasing the system’s modular flexibility. Charlie Wheeler, Managing Director of IE Access, praised the PERI UP system for its practicality. “Minimal standard components from the PERI UP range made work easier for our scaffolders. We didn’t have to manage numerous small parts and fittings or worry about safety while working above the public walkway. It also minimised material handling during construction,” he said.

Charlie Wheeler, Managing Director of IE Access, praised the PERI UP system for its practicality. “Minimal standard components from the PERI UP range made work easier for our scaffolders. We didn’t have to manage numerous small parts and fittings or worry about safety while working above the public walkway. It also minimised material handling during construction,” he said.

A Collaborative Success

The A180 Gilbey Road Bridge maintenance project highlights the importance of innovative scaffolding solutions in tackling complex infrastructure challenges. By using the PERI UP Flex system and fostering close collaboration between teams, the project is progressing efficiently, safeguarding the bridge’s long-term integrity while prioritising public safety and access. This project is a testament to the power of modern scaffolding systems in delivering safe, adaptable, and efficient solutions for critical infrastructure repairs.Winners Unveiled at Scaffolding Excellence Awards 2024

The scaffolding and access community came together in spectacular fashion at the NASC Annual Ball & Scaffolding Excellence Awards 2024, held at the ICC Belfast on Friday night.

The event celebrated the outstanding achievements and innovation within the industry, showcasing the best of scaffolding expertise and dedication.

The glittering evening followed the successful ScaffEx24, featuring a glamorous gala organised by the National Access & Scaffolding Confederation (NASC).

Over 700 distinguished guests, including international industry leaders from Japan, New Zealand, Malaysia, and Switzerland, joined the festivities, which included a luxurious drinks reception, a three-course dinner, and live entertainment.

The NASC Scaffolding Excellence Awards, a highlight in the industry’s calendar, honoured exceptional contributions across a range of categories.

Winners and runners-up were announced during a dazzling ceremony hosted by special guests, including TV stars James Nesbitt, Mike Tindall, and Denise van Outen, who paid tribute to the dedication and innovation of the industry’s finest.

Winner: Albie Cooper, Benchmark Scaffolding Ltd

Driven by a desire to support his young family, Albie Cooper was described by his Site Manager, Jack Murphy, as having one of the best attitudes he’s encountered in all his years in scaffolding. Judges praised Albie’s proactive and positive outlook, noting his ability to overcome challenges and seek additional opportunities. The award includes a £1,000 prize courtesy of CISRS.

Highly Commended: Harrison Mapley

Winner: Albie Cooper, Benchmark Scaffolding Ltd

Driven by a desire to support his young family, Albie Cooper was described by his Site Manager, Jack Murphy, as having one of the best attitudes he’s encountered in all his years in scaffolding. Judges praised Albie’s proactive and positive outlook, noting his ability to overcome challenges and seek additional opportunities. The award includes a £1,000 prize courtesy of CISRS.

Highly Commended: Harrison Mapley

Winner: SRK Scaffolding – Industrial Storage Tank

SRK Scaffolding’s design for accessing a 33-metre-high industrial storage tank required exceptional creativity and problem-solving to complete the project within a short timeframe. Judges were impressed by the out-of-the-box thinking and technical expertise demonstrated.

Winner: SRK Scaffolding – Industrial Storage Tank

SRK Scaffolding’s design for accessing a 33-metre-high industrial storage tank required exceptional creativity and problem-solving to complete the project within a short timeframe. Judges were impressed by the out-of-the-box thinking and technical expertise demonstrated.

Winner: PERI Ltd – PERI UP Cladding

PERI’s innovative cladding system protects scaffolders, contractors, and the public while offering unparalleled flexibility through removable individual panels. Judges commended the system’s unique design and wide-ranging practical applications.

Winner: PERI Ltd – PERI UP Cladding

PERI’s innovative cladding system protects scaffolders, contractors, and the public while offering unparalleled flexibility through removable individual panels. Judges commended the system’s unique design and wide-ranging practical applications.

Winner: Lee Rowswell

Recognised for over 30 years of service, Lee Rowswell has transformed GKR Scaffolding, taking it from a turnover of £800,000 to £36 million. His leadership has driven innovation, sustainability, and diversity within the industry, and he has played a pivotal role in NASC initiatives. Judges highlighted his collaborative spirit and his ability to inspire others while delivering landmark projects across London.

Winner: Lee Rowswell

Recognised for over 30 years of service, Lee Rowswell has transformed GKR Scaffolding, taking it from a turnover of £800,000 to £36 million. His leadership has driven innovation, sustainability, and diversity within the industry, and he has played a pivotal role in NASC initiatives. Judges highlighted his collaborative spirit and his ability to inspire others while delivering landmark projects across London.

Winner: Shield Services Group – Cathedral Park, Bristol

Shield Services Group delivered a 50-metre temporary roof structure and a 15-metre birdcage inside a converted cathedral, excelling in technical execution, environmental consideration, safety, and social value. Judges praised the project for its thoughtful approach and its exemplary representation of the scaffolding industry.

Highly Commended: Ingleford Scaffolding

Winner: Shield Services Group – Cathedral Park, Bristol

Shield Services Group delivered a 50-metre temporary roof structure and a 15-metre birdcage inside a converted cathedral, excelling in technical execution, environmental consideration, safety, and social value. Judges praised the project for its thoughtful approach and its exemplary representation of the scaffolding industry.

Highly Commended: Ingleford Scaffolding

Winner: Inner City Scaffolding Ltd – Parkside Court, Chelmsford

Inner City Scaffolding developed an innovative solution to safely access a live building for a recladding project. Judges described the work as a “fantastic piece of engineering” and called it the “scaffolder’s scaffold” for its precision and complexity.

Winner: Inner City Scaffolding Ltd – Parkside Court, Chelmsford

Inner City Scaffolding developed an innovative solution to safely access a live building for a recladding project. Judges described the work as a “fantastic piece of engineering” and called it the “scaffolder’s scaffold” for its precision and complexity.

Winner: Lyndon SGB – New Register House, Edinburgh

This project, valued between £1m and £2m, required Lyndon SGB to deliver a scaffold for the Grade-A listed New Register House while managing the challenges of Scottish winter weather, an open building, and stringent heritage restrictions. Judges praised the team’s coordination, collaboration, and expert management.

Winner: Lyndon SGB – New Register House, Edinburgh

This project, valued between £1m and £2m, required Lyndon SGB to deliver a scaffold for the Grade-A listed New Register House while managing the challenges of Scottish winter weather, an open building, and stringent heritage restrictions. Judges praised the team’s coordination, collaboration, and expert management.

Winner: GKR Scaffolding Ltd – 25 Canada Square, Canary Wharf

GKR Scaffolding’s work at 25 Canada Square, valued at over £2m, stood out for its complexity and scale. The project involved a bespoke cantilevered scaffold system constructed within a skyscraper and required meticulous planning and collaboration. Judges commended its innovative design, social value, and execution in a high-profile location.

Winner: GKR Scaffolding Ltd – 25 Canada Square, Canary Wharf

GKR Scaffolding’s work at 25 Canada Square, valued at over £2m, stood out for its complexity and scale. The project involved a bespoke cantilevered scaffold system constructed within a skyscraper and required meticulous planning and collaboration. Judges commended its innovative design, social value, and execution in a high-profile location.

The NASC Annual Ball & Scaffolding Excellence Awards 2024 celebrated the talent and innovation driving the scaffolding and access industry forward. With a global audience and record-breaking attendance, it highlighted the sector’s continued growth and commitment to excellence.

Scaffolding Excellence Award Winners

Apprentice of the Year

Winner: Albie Cooper, Benchmark Scaffolding Ltd

Driven by a desire to support his young family, Albie Cooper was described by his Site Manager, Jack Murphy, as having one of the best attitudes he’s encountered in all his years in scaffolding. Judges praised Albie’s proactive and positive outlook, noting his ability to overcome challenges and seek additional opportunities. The award includes a £1,000 prize courtesy of CISRS.

Highly Commended: Harrison Mapley

Winner: Albie Cooper, Benchmark Scaffolding Ltd

Driven by a desire to support his young family, Albie Cooper was described by his Site Manager, Jack Murphy, as having one of the best attitudes he’s encountered in all his years in scaffolding. Judges praised Albie’s proactive and positive outlook, noting his ability to overcome challenges and seek additional opportunities. The award includes a £1,000 prize courtesy of CISRS.

Highly Commended: Harrison Mapley

Scaffold Design of the Year

Winner: SRK Scaffolding – Industrial Storage Tank

SRK Scaffolding’s design for accessing a 33-metre-high industrial storage tank required exceptional creativity and problem-solving to complete the project within a short timeframe. Judges were impressed by the out-of-the-box thinking and technical expertise demonstrated.

Winner: SRK Scaffolding – Industrial Storage Tank

SRK Scaffolding’s design for accessing a 33-metre-high industrial storage tank required exceptional creativity and problem-solving to complete the project within a short timeframe. Judges were impressed by the out-of-the-box thinking and technical expertise demonstrated.

Product of the Year

Winner: PERI Ltd – PERI UP Cladding

PERI’s innovative cladding system protects scaffolders, contractors, and the public while offering unparalleled flexibility through removable individual panels. Judges commended the system’s unique design and wide-ranging practical applications.

Winner: PERI Ltd – PERI UP Cladding

PERI’s innovative cladding system protects scaffolders, contractors, and the public while offering unparalleled flexibility through removable individual panels. Judges commended the system’s unique design and wide-ranging practical applications.

Service of the Year

Winner: Costain/Skanska (SCS Railways) – Scaffold Request App This innovative app streamlined scaffold requests for the HS2 JV project, saving time and money while maintaining safety standards. Judges highlighted its tangible improvements in productivity and on-site results.Lifetime Achievement Award

Winner: Lee Rowswell

Recognised for over 30 years of service, Lee Rowswell has transformed GKR Scaffolding, taking it from a turnover of £800,000 to £36 million. His leadership has driven innovation, sustainability, and diversity within the industry, and he has played a pivotal role in NASC initiatives. Judges highlighted his collaborative spirit and his ability to inspire others while delivering landmark projects across London.

Winner: Lee Rowswell

Recognised for over 30 years of service, Lee Rowswell has transformed GKR Scaffolding, taking it from a turnover of £800,000 to £36 million. His leadership has driven innovation, sustainability, and diversity within the industry, and he has played a pivotal role in NASC initiatives. Judges highlighted his collaborative spirit and his ability to inspire others while delivering landmark projects across London.

Project of the Year – Small

Winner: Shield Services Group – Cathedral Park, Bristol

Shield Services Group delivered a 50-metre temporary roof structure and a 15-metre birdcage inside a converted cathedral, excelling in technical execution, environmental consideration, safety, and social value. Judges praised the project for its thoughtful approach and its exemplary representation of the scaffolding industry.

Highly Commended: Ingleford Scaffolding

Winner: Shield Services Group – Cathedral Park, Bristol

Shield Services Group delivered a 50-metre temporary roof structure and a 15-metre birdcage inside a converted cathedral, excelling in technical execution, environmental consideration, safety, and social value. Judges praised the project for its thoughtful approach and its exemplary representation of the scaffolding industry.

Highly Commended: Ingleford Scaffolding

Project of the Year – Medium

Winner: Inner City Scaffolding Ltd – Parkside Court, Chelmsford

Inner City Scaffolding developed an innovative solution to safely access a live building for a recladding project. Judges described the work as a “fantastic piece of engineering” and called it the “scaffolder’s scaffold” for its precision and complexity.

Winner: Inner City Scaffolding Ltd – Parkside Court, Chelmsford

Inner City Scaffolding developed an innovative solution to safely access a live building for a recladding project. Judges described the work as a “fantastic piece of engineering” and called it the “scaffolder’s scaffold” for its precision and complexity.

Project of the Year – Large

Winner: Lyndon SGB – New Register House, Edinburgh

This project, valued between £1m and £2m, required Lyndon SGB to deliver a scaffold for the Grade-A listed New Register House while managing the challenges of Scottish winter weather, an open building, and stringent heritage restrictions. Judges praised the team’s coordination, collaboration, and expert management.

Winner: Lyndon SGB – New Register House, Edinburgh

This project, valued between £1m and £2m, required Lyndon SGB to deliver a scaffold for the Grade-A listed New Register House while managing the challenges of Scottish winter weather, an open building, and stringent heritage restrictions. Judges praised the team’s coordination, collaboration, and expert management.

Project of the Year – Major

Winner: GKR Scaffolding Ltd – 25 Canada Square, Canary Wharf

GKR Scaffolding’s work at 25 Canada Square, valued at over £2m, stood out for its complexity and scale. The project involved a bespoke cantilevered scaffold system constructed within a skyscraper and required meticulous planning and collaboration. Judges commended its innovative design, social value, and execution in a high-profile location.

Winner: GKR Scaffolding Ltd – 25 Canada Square, Canary Wharf

GKR Scaffolding’s work at 25 Canada Square, valued at over £2m, stood out for its complexity and scale. The project involved a bespoke cantilevered scaffold system constructed within a skyscraper and required meticulous planning and collaboration. Judges commended its innovative design, social value, and execution in a high-profile location.

The NASC Annual Ball & Scaffolding Excellence Awards 2024 celebrated the talent and innovation driving the scaffolding and access industry forward. With a global audience and record-breaking attendance, it highlighted the sector’s continued growth and commitment to excellence.

ScaffEx25 Set to Break Records with Expanded Venue and Attendance

The National Access and Scaffolding Confederation (NASC) has announced its plans for ScaffEx25, set to take place on 11 and 12 September 2025 at Manchester Central (formerly GMEX).

Following the success of this year’s ScaffEx24, which drew over 600 attendees, next year’s event is poised to be significantly larger, with organisers expecting more than 3,000 industry professionals to attend.

The event will feature an impressive 10,000 m² of exhibition space, making it 17 times larger than ScaffEx24, which was held at a more modest venue, the ICC in Belfast, as a trail.

The expanded size reflects significant interest in the UK’s scaffolding and access industries and provides ample room for exhibitors to display the latest innovations in scaffolding and access equipment. At ScaffEx25, over 30% of the exhibition space has already been secured, with 25% secured before the event, its set to be a global first, giving access and scaffolding the presence it deserves.