- Bluetooth® Enabled: Attaches easily to existing torque tools, transforming them into smart devices.

- Seamless Data Capture: Instantly records torque measurements, ensuring accuracy and efficiency.

- Dedicated Reporting App: Facilitates compliance with industry standards and enhances traceability.

- Cloud Storage: Securely stores all data, providing easy access and robust data management.

Hydrajaws Expands Digital Excellence with Launch of Verify Torque

Hydrajaws, a leader in pull testing technology, has introduced the Verify Torque adaptor, a significant enhancement to its digital solutions portfolio.

This cutting-edge Bluetooth®-enabled torque wrench adaptor is set to revolutionise compliance and traceability in torque testing by integrating seamlessly with existing tools.

Since introducing the industry’s first reporting app in 2016, Hydrajaws has consistently led the way in bringing digital advancements to pull testing. The company’s latest innovation, the Verify Torque adaptor, now extends this digital excellence to torque testing, ensuring precise and reliable torque measurements that enhance the installation process of anchors.

The Verify Torque adaptor empowers users to effortlessly capture torque data effortlessly via a dedicated reporting app. This app not only ensures all measurements align with manufacturers’ recommendations but also provides comprehensive traceability.

The collected data is securely stored in the cloud, offering users easy access and peace of mind, knowing their data is protected and readily available whenever needed.

In a testament to its groundbreaking innovation, Hydrajaws’ Verify Torque has been awarded Product Innovation of the Year – Tools at the Torque Expo in May 2024. This prestigious accolade highlights Hydrajaws’ commitment to delivering advanced solutions that meet the evolving demands of the industry.

Key Features of Verify Torque:

NASC Launches Groundbreaking SG6 Manual Handling Training Video

The National Access & Scaffolding Confederation (NASC) has announced the launch of its revolutionary SG6 Manual Handling Training Video, aimed at transforming safety standards within the scaffolding and access industry.

This cutting-edge digital resource is set to redefine training methodologies and significantly reduce risks associated with manual handling, a critical area in scaffolding and access operations. Designed with precision and expertise, the SG6 Manual Handling Training Video offers a comprehensive approach to tackling the intricate challenges of manual handling in the industry. By leveraging advanced techniques and best practices, this video becomes an indispensable tool for scaffolding and access operatives, equipping them with the knowledge and skills necessary to handle this high-risk area with confidence and proficiency. The SG6 video stands out due to its innovative delivery format. It employs state-of-the-art digital avatars, tailored to suit diverse learning environments. Whether used in toolbox talks on handheld devices or in classroom and office settings, the video adapts seamlessly to various training scenarios, ensuring maximum accessibility and effectiveness.Exclusive First Look: Watch the 10-Second Preview Video

As a special feature, we are excited to offer an exclusive first look at the SG6 Manual Handling Training Video. Watch the 10-second preview below: An additional advantage of the SG6 Manual Handling Training Video is its inclusion in the NASC ePortal subscription at no extra cost to subscribers. This move underscores NASC’s commitment to advancing safety standards across the industry, making essential training more accessible than ever before. Key features of the SG6 Manual Handling Training Video include:- Comprehensive coverage of manual handling best practices and techniques specific to scaffolding and access operations.

- Engaging and interactive content designed to enhance retention and understanding.

- Seamless integration into toolbox talks on handheld devices for on-the-go learning.

- Flexibility for use in classroom and office settings for thorough training sessions.

- Inclusion as part of the NASC ePortal subscription, ensuring affordability and widespread accessibility.

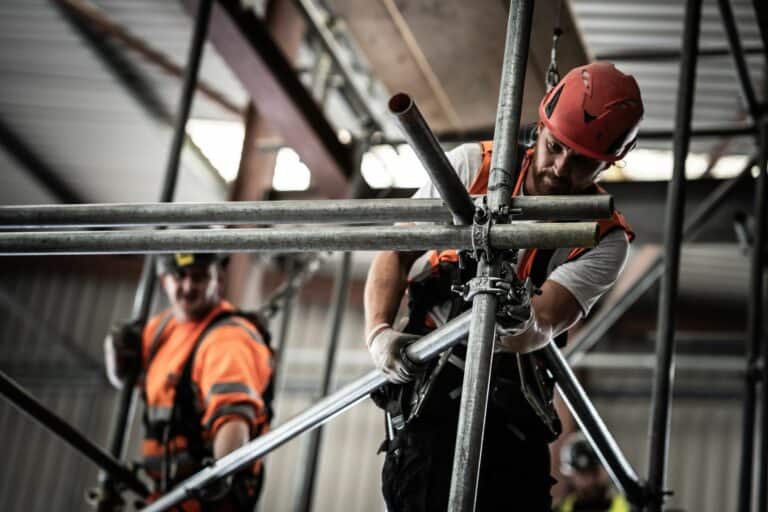

Hanger Time: H&H Contract Scaffolding Ltd & Layher UK’s Engineering Triumph at Oxford Uni

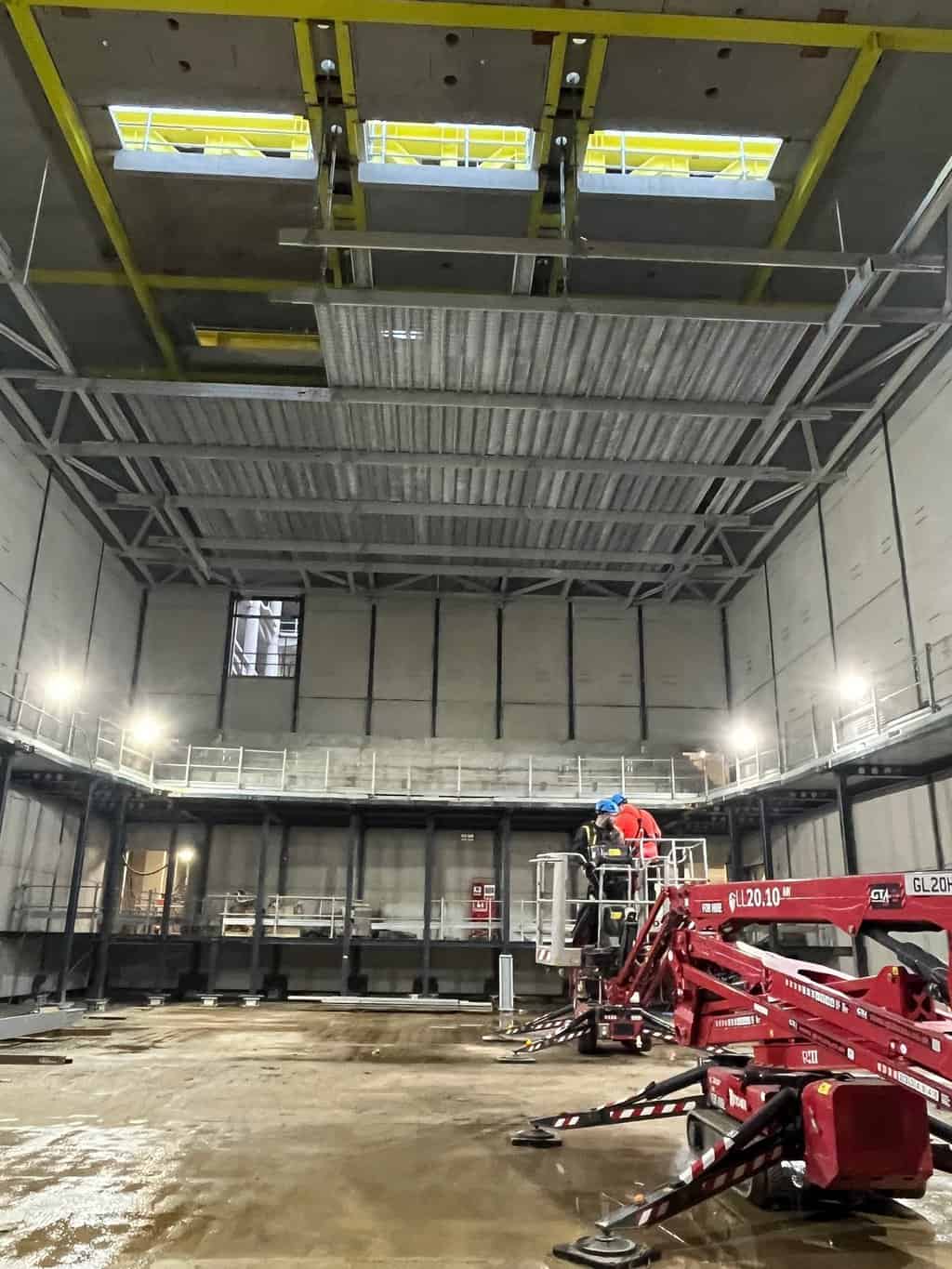

Oxford University, a bastion of academic excellence, is renowned for its architectural beauty. Now, led by Laing O’Rourke, a new state-of-the-art humanities building is taking shape, featuring a spectacular 500-seat concert hall, lecture rooms, and study spaces.

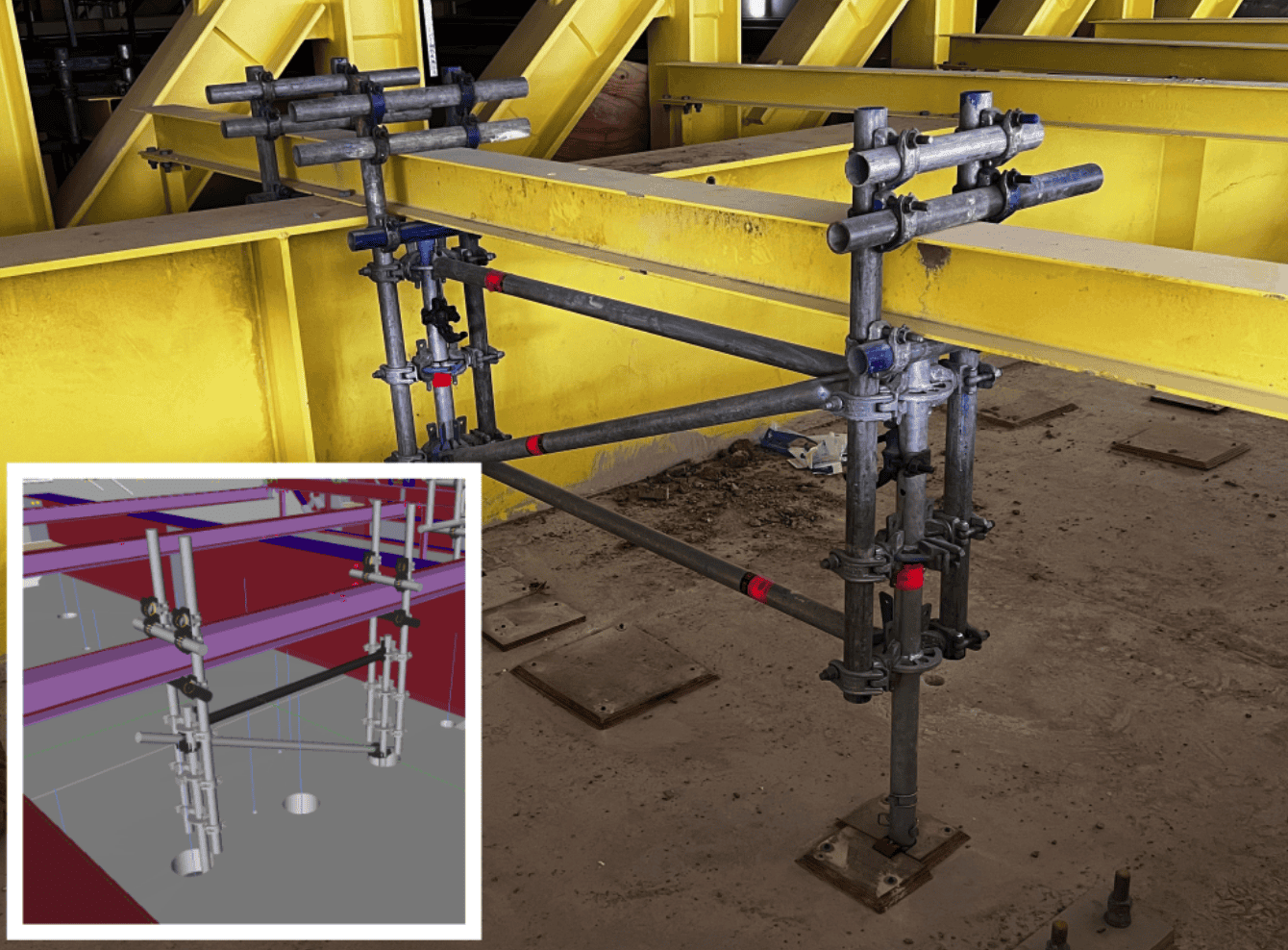

At the core of this ambitious project lies an extraordinary scaffolding access solution for the construction of the auditorium’s intricate ceiling, which is a testament to Layher UK’s ingenuity and the skilful execution by scaffolding experts H&H Contract Scaffolding Ltd.

Extensive use of Navisworks modelling ensured every element was seamlessly integrated for optimal stability and functionality.

Extensive use of Navisworks modelling ensured every element was seamlessly integrated for optimal stability and functionality.

The result is a visually striking scaffold that provides rock-solid support for the construction of the auditorium’s intricate ceiling, including its expensive wood panel feature.

The result is a visually striking scaffold that provides rock-solid support for the construction of the auditorium’s intricate ceiling, including its expensive wood panel feature.

Think Outside the Birdcage

The initial plan involved erecting a traditional 36m x 15m birdcage scaffold with eight 2m lifts, projected to take approximately two months for construction. This timescale conflicted with the project timeline, prompting the search for a more efficient solution. The objective shifted towards a ‘hanging scaffold’ design, suspended directly from the concrete roof slab via preformed lighting holes. This unprecedented approach aimed to free up valuable ground-level space, enabling construction work to continue unhindered. A conventional tube and fitting approach was deemed too complex to accommodate the required 2kNm2 loading. The solution arrived with Layher UK’s modular Allround system, which is world-renowned for its versatility and strength. Layher’s innovative new Twix and Flex beams, integrated with their standard steel decks, provided the backbone for the suspended working platform. To ensure safe and efficient assembly, the entire scaffold was designed to be erected from spider MEWPs, and materials were craned into the concert hall before the roof slab was completed. A Triple Win for Laing O’Rourke “The innovative scaffolding solution we’ve implemented at Oxford Humanities has been a game-changer, providing a triple win for our project,” said Jack Higgins, Construction Manager at Laing O’Rourke. “Compared to a traditional birdcage scaffold, this suspended platform allowed us to maximise productivity by working simultaneously above and below the structure. The rapid installation time significantly minimised disruption to our construction schedule, and the reduced material requirement simplified logistics and mitigated the risk of damage to finishes. Put simply, delivering this project on our tight timeline wouldn’t have been possible without this impressive scaffolding solution.”

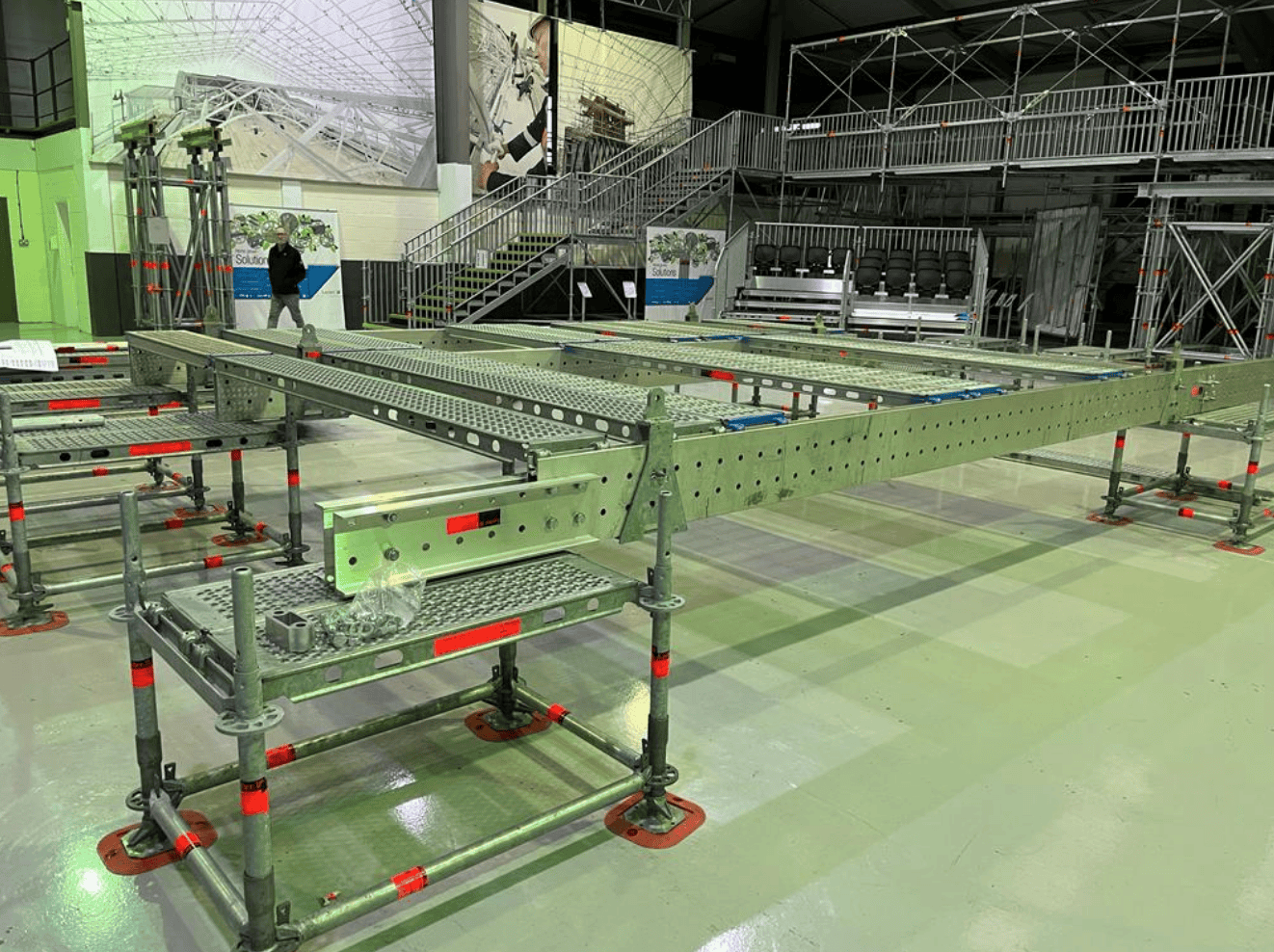

More Possibilities with Layher

Underscoring the collaborative spirit of this project, during the planning phase, H&H Contract Scaffolding Ltd. was invited to Layher UK headquarters in Letchworth for a pre-build test of the scaffold design with, Layher’s After Sales Specialist Support provider. This proactive approach ensured a seamless and efficient real-world installation, which Layher further supported during the actual build too. However, this wasn’t just a courtesy visit; it was a chance for H&H Scaffolding’s team to work through the plans and assemble the structure on the ground under controlled conditions, ironing out any unforeseen complications before the actual installation began at the Oxford University site. This minimised risks ensured a flawless assembly process and saved valuable time on the project.

Powered by Layher’s Expertise

At the heart of this impressive structure are Layher’s renowned Allround system scaffolding and the integration of their versatile Flex and Twix beams. This combination represents the pinnacle of Layher’s engineering expertise. The Allround system is a modular scaffolding solution renowned for its versatility, strength, and ease of use. Its components can be swiftly configured into a wide range of structures, making it ideal for complex projects like this one. Layher’s Flex and Twix beams add another adaptability dimension to the equation. These new innovative beams offer exceptional load-bearing capacities. They can be seamlessly integrated with the Allround system, creating expansive working platforms that can handle significant weight, whilst providing additional flexibility and solutions to difficult aspects of any site requirementsOxford Expertise: H&H Contract Scaffolding

The Oxford-based firm H&H Contract Scaffolding Ltd has a proven track record, having collaborated with the main contractor on numerous projects. This auditorium marks their 18th project at Oxford University, showcasing their in-depth understanding of the university’s unique requirements. “My guys have done an incredible job on this project,” remarked Andy Thomas, Managing Director of H&H Contract Scaffolding Ltd. “The Layher system and both the Flex beam and Twix beam are fantastic bits of kit, and Layher UK have supported us every step of the way. From the incredible engineering of the scaffold design to the support we received in understanding what can be achieved with the Flex and Twix beams with creating a test rig at Letchworth.” “We intend on entering this project for the forthcoming NASC awards for Project of The Year,” Thomas added proudly.Designed to Perfection

The intricate design, expertly crafted by the Design Engineering team at Layher UK’s Eggborough Depot, is a sight to behold. A massive hanging scaffold platform measuring 15m x 24m is suspended with remarkably minimal support, a testament to engineering brilliance at Layher UK. Extensive use of Navisworks modelling ensured every element was seamlessly integrated for optimal stability and functionality.

Extensive use of Navisworks modelling ensured every element was seamlessly integrated for optimal stability and functionality.

The result is a visually striking scaffold that provides rock-solid support for the construction of the auditorium’s intricate ceiling, including its expensive wood panel feature.

The result is a visually striking scaffold that provides rock-solid support for the construction of the auditorium’s intricate ceiling, including its expensive wood panel feature.

Beyond Boundaries

As the university’s construction project progresses, the scaffolding stands as a shining example of how forward-thinking design and cross-industry collaboration can transform the construction landscape. And as the auditorium nears completion, it stands as a testament to the power of innovation and the boundless possibilities that arise when leaders in the field push conventional boundaries and work in cross collaboration to create the right result.Exclusive: New Online HSE Test for Scaffolders Set to Launch

The Construction Industry Scaffolders Record Scheme (CISRS) is set to introduce an alternative innovative online Health, Safety, and Environment (HSE) test for scaffolding operatives in collaboration with the National Open College Network (NOCN).

Scaffmag can exclusively reveal that this new test will launch next month, marking a significant shift in how scaffolding professionals can achieve industry-recognised health and safety qualifications.

The upcoming test, designed in line with other recognised exemptions, will cover essential aspects of health, safety, and environmental practices required for obtaining a CISRS card. This card is a crucial credential for operatives in the scaffolding sector, ensuring they meet industry standards.

One of the standout features of this new test is its high-quality, neurodiverse eLearning content, which comes with an accompanying voice-over. This allows operatives to study and prepare for the test entirely online, eliminating the need for separate revision materials.

The comprehensive package of eLearning modules and the test itself will be available for a combined cost of £22.

David Brown, President of the National Access and Scaffolding Confederation (NASC) and IBN Scaffold Access Ltd, praised the new initiative. “I think this is a real win for the scaffolding sector,” Brown said.

“The operatives can now achieve an industry-recognised H&S test on their own terms. The flexibility it offers by being online means people can learn at their own pace, whenever and wherever is convenient. It obviously removes the need to travel to a test centre. This is a very positive move; the sooner it goes live, the better.”

Dave Mosley, Managing Director of CISRS, also expressed optimism about the forthcoming test. “NOCN administers the CISRS card scheme on our behalf, so we have a very close working relationship with them. They previously introduced a very similar H&S test for the Plant sector, which has proven to be very popular.

We are confident that this can be equally successful for our sector and is something we look forward to exploring further in future.”

In preparation for the launch, CISRS and NOCN will conduct webinars and meet with CISRS-approved training providers and the wider scaffolding industry in the coming weeks.

The test is scheduled to go live on Monday, 18th June 2024. Further information on how to book the test will soon be available on the CISRS and NOCN websites.

This new development is expected to significantly enhance accessibility and convenience for scaffolding operatives, aligning with broader trends towards digital and flexible learning solutions in the construction industry.

Pilosio’s Flydeck lightweight, System Takes Bridge Refurbishment to New Heights

The Flydeck system’s lightweight, easily stowable components, combined with faster and safer elastic pin joints, resulted in significant time and cost savings while improving overall safety

A groundbreaking scaffolding project on a major national highway recently concluded, showcasing innovative engineering solutions to tackle a complex refurbishment challenge. However, the project was not without its hurdles. The bridge’s location made traditional scaffolding methods impractical, and its exposure to harsh weather and heavy traffic posed significant challenges. The arch bridge, a majestic structure carrying traffic across a hydroelectric basin, required significant refurbishment after decades of service. The bridge’s impressive span of 406 meters and its exposure to harsh weather and heavy traffic had taken their toll, necessitating a comprehensive restoration project. Pilosio, a leading scaffolding manufacturer, stepped in with their revolutionary Flydeck system. This system, unlike traditional scaffolding, offers a suspended working platform solution by anchoring decks to the viaduct’s concrete structure using chains allowing workers safe access to all areas of the bridge. The Pilosio Solution setup was crucial to service the viaduct’s piles, beams, spandrels, and carriageway slabs:

The Pilosio Solution setup was crucial to service the viaduct’s piles, beams, spandrels, and carriageway slabs:

- Approx. 11,000 sqm of Flydeck with 25 cm beams, longitudinal setup: under the entire width of the underdeck intrados ( beams, spandrels, and carriageway slabs). The system was installed in 4 phases, approximately 3000 sqm for each phase.

- Approx. 3000 sqm of Flydeck with 25 cm beams, transversal stepped setup. The system was installed in 2 phases, approximately 1500 sqm for each phase.

- An approximately 150m flydeck catwalk was created in a longitudinal setup connecting one span and the next. The catwalk makes material handling quick.

- Electric single-column scaffolds and connecting walkways were deployed to ensure comprehensive access and efficient intervention.

However, the viaduct refurbishment project is not just a successful case study but a testament to the ingenuity of modern engineering solutions. By embracing innovative approaches like the Flydeck system, construction companies can overcome complex challenges and deliver successful projects.

This not only prioritises worker safety and efficiency but also sets a new standard for the industry, encouraging the adoption of similar innovative solutions.

However, the viaduct refurbishment project is not just a successful case study but a testament to the ingenuity of modern engineering solutions. By embracing innovative approaches like the Flydeck system, construction companies can overcome complex challenges and deliver successful projects.

This not only prioritises worker safety and efficiency but also sets a new standard for the industry, encouraging the adoption of similar innovative solutions. Fourth Annual ‘Scaffolding’s Golfer of the Year’ Event Announced

The scaffolding industry’s premier golfing event returns for its fourth year as SCP Forgeco announces the much-anticipated ‘Scaffolding’s Golfer of the Year’ tournament.

Scheduled for the 19th of July, 2024, the tournament will be held at The Astbury Golf and Lodge Resort in Bridgnorth, renowned as one of England’s finest 18-hole championship courses. This immaculate venue, built to the highest USGA standards, promises a spectacular setting for this esteemed event. The SCP annual golf tournament, complimentary for individuals working within the scaffolding industry, offers participants a unique opportunity to showcase their golfing prowess. Coinciding with the same week as the British Open, the event highlights the growing popularity and competitive spirit of golf within the industry. Since its inception, SCP Forgeco’s tournament has provided a remarkable platform for industry professionals to network and engage in a friendly yet competitive environment. This year’s participants will vie for the prestigious’ Scaffolders Golfer of the Year’ trophy, alongside various other prizes that will be awarded throughout the event. “Are you the best golfer in the scaffolding industry? Time to prove it!” reads the challenge from SCP Forgeco, encouraging scaffolding professionals to seize this opportunity. Interested participants are urged to register soon, as the company anticipates a high demand for spots. Registration is free but limited, and will close on the 21st of June. More details and registration can be found at https://golf.scpgroup.uk The SCP Group looks forward to welcoming all participants to the Astbury Golf and Lodge Resort on the 19th of July for a day filled with fun, camaraderie, and competitive golf. Don’t miss your chance to compete for your very own Claret Jug and enjoy a day of top-tier golfing at this esteemed industry event.CISRS Scaffolding Supervisor Skills Bootcamp Comes to North Yorkshire

A new CISRS Scaffolding Supervisor Skills Bootcamp is set to launch in York and North Yorkshire, thanks to funding from the York and North Yorkshire Combined Authority.

The bootcamp aims to address a shortage of scaffolding supervisors in the region by providing fully funded training opportunities for both self-employed individuals and employees of local businesses. The first courses, which will cover CISRS and CITB supervisor training, are scheduled to begin in June at the Construction Skills Village in Eastfield. The bootcamp is a collaborative effort between Working at Heights Safety Solutions and Northern Regeneration, with support from CISRS. Michael Mitchell, Scaffolding Trainer at Working at Heights Safety Solutions and Northern Regeneration, expressed his enthusiasm for the project, stating, “This is a brilliant opportunity for people in York and North Yorkshire to train to become scaffolding supervisors. Being a scaffolding supervisor is a superb career with great opportunities to be involved in the thriving local construction sector.”

Dave Mosley, CISRS MD, also voiced his support, adding, “Good supervision is essential in the scaffolding industry. I really hope those in the area take advantage of this offer, we are sure it will yield excellent results.”

The Skills Bootcamps are open to both self-employed and employed individuals residing or working in North Yorkshire who wish to develop supervisory skills in scaffolding.

For more information or to register for the courses, individuals and businesses are encouraged to contact the Construction Skills Village by email at [email protected] or by phone at 01723 585009.

Michael Mitchell, Scaffolding Trainer at Working at Heights Safety Solutions and Northern Regeneration, expressed his enthusiasm for the project, stating, “This is a brilliant opportunity for people in York and North Yorkshire to train to become scaffolding supervisors. Being a scaffolding supervisor is a superb career with great opportunities to be involved in the thriving local construction sector.”

Dave Mosley, CISRS MD, also voiced his support, adding, “Good supervision is essential in the scaffolding industry. I really hope those in the area take advantage of this offer, we are sure it will yield excellent results.”

The Skills Bootcamps are open to both self-employed and employed individuals residing or working in North Yorkshire who wish to develop supervisory skills in scaffolding.

For more information or to register for the courses, individuals and businesses are encouraged to contact the Construction Skills Village by email at [email protected] or by phone at 01723 585009. No Falls Week Kicks Off to Combat Rising Workplace Fatalities

Today marks the start of the inaugural No Falls Week, a campaign spearheaded by the No Falls Foundation to raise awareness and promote safety measures for work at height.

This initiative comes at a crucial time, as falls from height have become the leading cause of workplace fatalities in the UK. In 2022-2023, 40 individuals tragically lost their lives due to falls at work, accounting for a third of all workplace deaths. The alarming figures from the Health and Safety Executive (HSE) show an increase from the previous year, highlighting the urgent need for action. Beyond fatalities, the impact of non-fatal falls is significant, with over 5,000 reported injuries in the same period. However, experts believe this number is vastly underreported, particularly among self-employed individuals. The HSE estimates the actual number of workplace falls over the past decade could be as high as 425,000. The consequences of these accidents extend beyond the injured individuals, affecting families, businesses, and the wider economy. In 2022/23 alone, an estimated 992,000 working days were lost due to non-fatal falls, costing over £847 million. Hannah Williams, Charity Manager at the No Falls Foundation, emphasises the importance of prioritising safety for all workers at height. “Everyone who needs to work at height should be able to work safely and return home unharmed at the end of every shift,” she states. “No Falls Week is an opportunity for everyone to shine a spotlight onto the mental, physical, and societal consequences of working at height accidents.” Throughout this week, employers and organisations across various sectors are encouraged to participate in No Falls Week. The campaign offers toolkits and resources to help plan activities such as toolbox talks, workshops, and safety demonstrations. By fostering awareness and implementing preventive measures, the No Falls Foundation aims to create a safer working environment for millions across the UK. https://nofallsweek.org/Ofsted Praises SIMIAN’s Scaffolding Apprenticeship Program for Quality and Safety

SIMIAN, a renowned name in the scaffolding and broader construction industry, has once again demonstrated its unwavering commitment to excellence by achieving a ‘Good’ grading from Ofsted for its apprenticeship programs.

This prestigious recognition follows a rigorous four-day inspection conducted in early April across SIMIAN’s Warrington and London centres. Ofsted, the Office for Standards in Education, Children’s Services and Skills plays a crucial role in upholding educational standards in the United Kingdom. Their assessment of SIMIAN’s scaffolding and roofing apprenticeships underscores the organisation’s dedication to nurturing the next generation of skilled construction professionals. The ‘Good’ grading is a testament to the tireless efforts of the entire SIMIAN team, who have worked diligently to implement improvements since the previous Ofsted inspection in 2022. Simon Hughes, SIMIAN’s Managing Director, expressed his pride in the team’s accomplishment, stating, “The fact that we have been recognised as a ‘good’ apprenticeship provider bears testimony to the efforts and professionalism of the team, and it is an achievement of which they should all be proud.” The Ofsted report highlights several key strengths of SIMIAN’s apprenticeship programs. Inspectors noted that apprentices “quickly learn and practice new skills safely and competently” and tutors ” skillfully support apprentices.” The report also praised the “highly effective” planning and coordination of on-and-off-the-job training. Jackie Thomason, SIMIAN’s Commercial Director, attributed this success to years of hard work, determination, and a willingness to learn and develop. She emphasised the strong relationships SIMIAN has fostered with employers and other industry stakeholders, stating that the feedback received from these groups was “in many cases, simply breathtaking, and a source of enormous pride for everyone at SIMIAN.” This latest achievement solidifies SIMIAN’s position as a leading provider of scaffolding apprenticeships in the UK. The organisation is already implementing further improvements as it continues to address the challenges independent training providers face. With this ‘Good’ grading from Ofsted, SIMIAN is poised to continue making a significant contribution to the construction industry by equipping apprentices with the skills and knowledge needed to thrive in their scaffolding careers.Layher Magic on the Hogwarts Express Bridge

Goathland Station, nestled in the windswept beauty of the North Yorkshire Moors, is a place where magic and engineering collide. This historic station, beloved by Harry Potter fans worldwide as a backdrop for the Hogwarts Express, recently underwent a remarkable structural renovation.

BS Scaffolding Ltd faced the extraordinary challenge of providing a work platform for the bridge restoration while ensuring public safety and access within this bustling tourist hub. Their solution? The innovative Layher Scaffolding System.

The project aimed to install steel beams to support both pedestrian and future vehicular traffic. Given the bridge’s structural fragility and its crucial role as an access point to Goathland train station, it was vital to maintain uninterrupted pedestrian traffic.

The Layher scaffolding system was chosen for its robust yet lightweight structure, ideal for the sensitive environment of the bridge.

The project aimed to install steel beams to support both pedestrian and future vehicular traffic. Given the bridge’s structural fragility and its crucial role as an access point to Goathland train station, it was vital to maintain uninterrupted pedestrian traffic.

The Layher scaffolding system was chosen for its robust yet lightweight structure, ideal for the sensitive environment of the bridge.

The innovative ‘Twix and Flex beam’ used in combination to create an underdeck access platform were central to this project. This allowed the team to span significant distances while creating a suspended platform with ample headroom for pedestrians, ensuring minimal disruption during the installation—crucial given the unpredictable British weather.

The innovative ‘Twix and Flex beam’ used in combination to create an underdeck access platform were central to this project. This allowed the team to span significant distances while creating a suspended platform with ample headroom for pedestrians, ensuring minimal disruption during the installation—crucial given the unpredictable British weather.

The project’s completion within a four-day deadline showcases the effectiveness of the Layher system and the expertise of the BS Scaffolding team. This endeavour not only ensured the structural enhancement of the Goathland Bridge but also preserved its role as a vital link in the community and a beloved landmark in the cinematic world.

As Goathland continues to attract visitors, the bridge and the scaffolding project stand as testaments to the harmonious blend of historical preservation and modern engineering—a celebration of innovation, safety, and collaborative spirit in overcoming logistical and environmental challenges.

The project’s completion within a four-day deadline showcases the effectiveness of the Layher system and the expertise of the BS Scaffolding team. This endeavour not only ensured the structural enhancement of the Goathland Bridge but also preserved its role as a vital link in the community and a beloved landmark in the cinematic world.

As Goathland continues to attract visitors, the bridge and the scaffolding project stand as testaments to the harmonious blend of historical preservation and modern engineering—a celebration of innovation, safety, and collaborative spirit in overcoming logistical and environmental challenges.

Introduction: The Stage is Set

In the quaint village of Goathland, the Goathland Bridge, widely known as the “Harry Potter Bridge,” recently saw a transformative scaffolding project led by Middlesbrough-based BS Scaffolding Ltd under the guidance of Vertex Construction. This four-day venture was a technical challenge, balancing the need to preserve public access and ensure safety amid the constant flow of tourists drawn by the bridge’s cinematic fame.Project Scope and Planning

The project aimed to install steel beams to support both pedestrian and future vehicular traffic. Given the bridge’s structural fragility and its crucial role as an access point to Goathland train station, it was vital to maintain uninterrupted pedestrian traffic.

The Layher scaffolding system was chosen for its robust yet lightweight structure, ideal for the sensitive environment of the bridge.

The project aimed to install steel beams to support both pedestrian and future vehicular traffic. Given the bridge’s structural fragility and its crucial role as an access point to Goathland train station, it was vital to maintain uninterrupted pedestrian traffic.

The Layher scaffolding system was chosen for its robust yet lightweight structure, ideal for the sensitive environment of the bridge.

Why Layher Was the Key

Craig Smith, Managing Director of BS Scaffolding Ltd, emphasised the unique demands of the project: “The bridge’s weak structure required a scaffolding solution that could reduce the overall load without compromising stability. Layher’s system was perfect due to its large bay sizes and high load-bearing capacity, which significantly minimised the material needed onsite.” The innovative ‘Twix and Flex beam’ used in combination to create an underdeck access platform were central to this project. This allowed the team to span significant distances while creating a suspended platform with ample headroom for pedestrians, ensuring minimal disruption during the installation—crucial given the unpredictable British weather.

The innovative ‘Twix and Flex beam’ used in combination to create an underdeck access platform were central to this project. This allowed the team to span significant distances while creating a suspended platform with ample headroom for pedestrians, ensuring minimal disruption during the installation—crucial given the unpredictable British weather.

Safety and Adaptations

Safety measures were meticulously planned, including integrating life jackets for water work and tethering tools and updating rescue plans specific to the Layher system. “Safety is non-negotiable, even when under tight schedules. Our strict adherence to the SG4:22 safety guideline and the bespoke Layher design to accommodate the bridge’s safe working load was fundamental,” Smith added.Collaboration and Technical Support

The project greatly benefited from the collaborative efforts between BS Scaffolding Ltd, Vertex Construction, Layher UK’s Technical Team, and local railway authorities. The technical and expert support from Layher UK’s Perry Todd [Specialist After Sales Support] and Jamie Alderson [Area Sales Manager] was crucial during the final stages of the scaffold erection, helping the team in adverse weather conditions.A Triumph of Innovation

Gareth Barnes, Contracts Manager at BS Scaffolding Ltd, reflected on the project’s execution and outcome, stating, “This project tested our technical capabilities and our ability to innovate under pressure. The success of the Goathland Bridge project has set a new benchmark for us in terms of efficiency and safety.” The project’s completion within a four-day deadline showcases the effectiveness of the Layher system and the expertise of the BS Scaffolding team. This endeavour not only ensured the structural enhancement of the Goathland Bridge but also preserved its role as a vital link in the community and a beloved landmark in the cinematic world.

As Goathland continues to attract visitors, the bridge and the scaffolding project stand as testaments to the harmonious blend of historical preservation and modern engineering—a celebration of innovation, safety, and collaborative spirit in overcoming logistical and environmental challenges.

The project’s completion within a four-day deadline showcases the effectiveness of the Layher system and the expertise of the BS Scaffolding team. This endeavour not only ensured the structural enhancement of the Goathland Bridge but also preserved its role as a vital link in the community and a beloved landmark in the cinematic world.

As Goathland continues to attract visitors, the bridge and the scaffolding project stand as testaments to the harmonious blend of historical preservation and modern engineering—a celebration of innovation, safety, and collaborative spirit in overcoming logistical and environmental challenges.